LED panel light structure

A technology of LED panel lights and LED light strips, applied in lighting and heating equipment, semiconductor devices of light-emitting elements, lighting devices, etc., can solve problems such as desoldering of LED lights, loose position of light strips, and displacement of light panels, and achieve The market prospect is broad, the structure is simple and compact, and the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific examples are given in conjunction with the accompanying drawings to describe in detail as follows, but the present invention is not limited thereto.

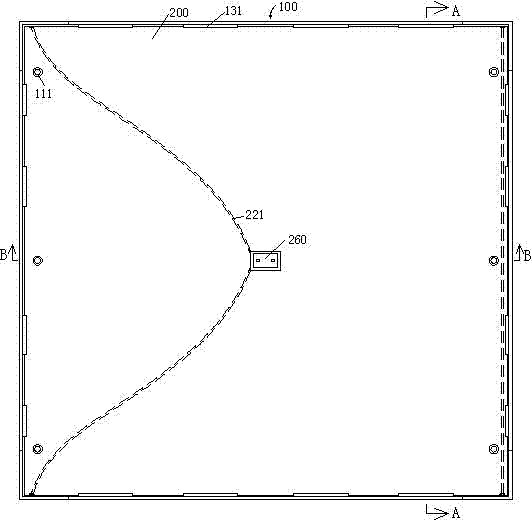

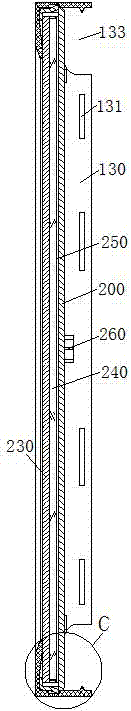

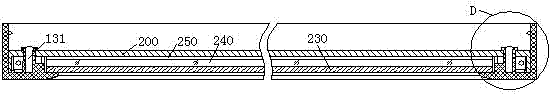

[0024] reference Figure 1 to Figure 8

[0025] An LED flat panel lamp structure, comprising a rectangular frame 100, the frame side 110 of the rectangular frame has an upwardly convex convex edge 130 outside, and the rectangular frame is buckled with a side plate 210 that has a downwardly convex side plate. The suspended ceiling 200 is provided with LED light bars 220 on the inner side of the side panels on both sides of the suspended ceiling. A number of lamp beads 222 are arranged on the LED light bars at intervals, and a lower side is arranged from bottom to top between the two LED light bars. The diffuser plate 230, the light guide plate 240 and the reflective paper 250 that are in contact wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com