Waste heat recovery system for cement production grate cooler employing square equipment

A technology of waste heat recovery system and waste heat recovery equipment, which is applied in F28D heat exchanger and F27D waste heat utilization field, to achieve the effect of saving energy, improving utilization and realizing intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

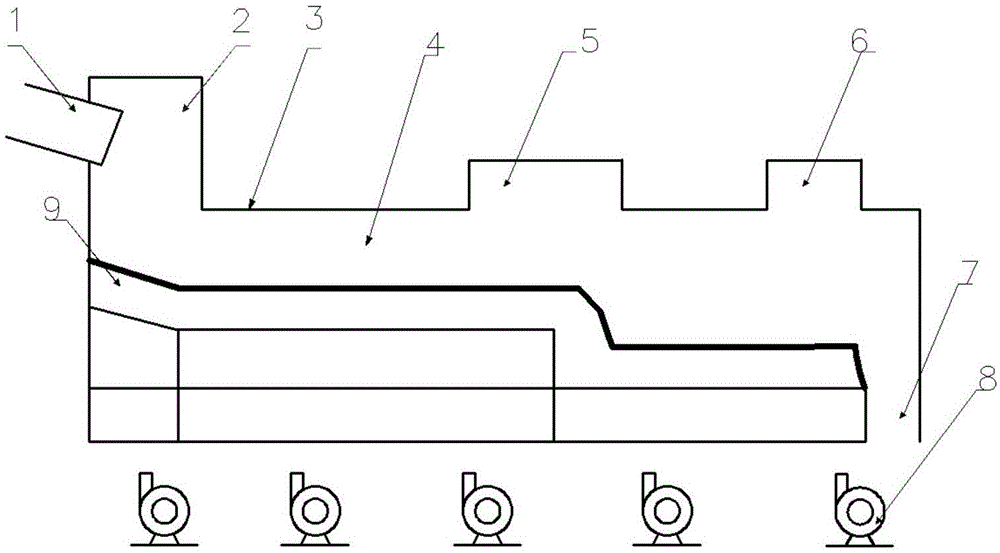

[0051] A grate cooler waste heat recovery system for cement production, including a grate cooler, figure 1A grate cooler 4 for cement production is shown. The grate cooler 4 includes a kiln head cover 2, a grate cooler shell 3, a high-temperature air outlet 5, a low-temperature air outlet 6, a clinker outlet 7 and a fan 8, wherein the clinker is rotated from The kiln 1 enters the grate cooler 4, and then transports in the clinker channel 9 in the grate cooler 4, and the fan 8 sends air to the grate cooler 4, and the temperature of the clinker is reduced by the wind, so that The clinker is cooled in the middle, and the cooled clinker is output through the clinker outlet 7.

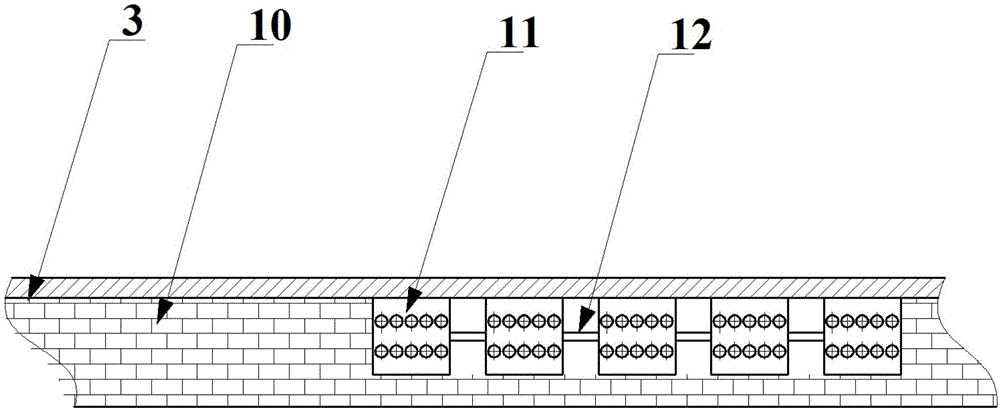

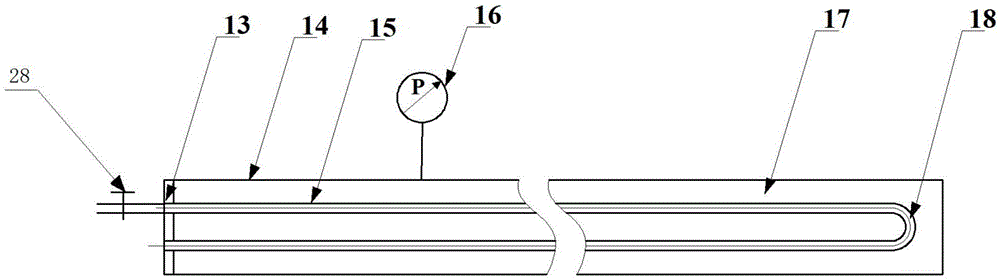

[0052] The clinker from the rotary kiln 1 is transported in the clinker channel 9 of the grate cooler, and is cooled by the wind delivered by the fan. An insulating ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com