High-power lithium ion battery system with laminated battery structure

A technology for lithium-ion batteries and stacked batteries, applied in battery electrodes, secondary batteries, structural parts, etc., can solve the problems of battery internal pressure rise, lithium battery explosion, and aggravated electrolyte corrosion of electrode materials, etc., to prevent Explosion, improved safety, beneficial to the effect of system integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: Air-cooled battery system.

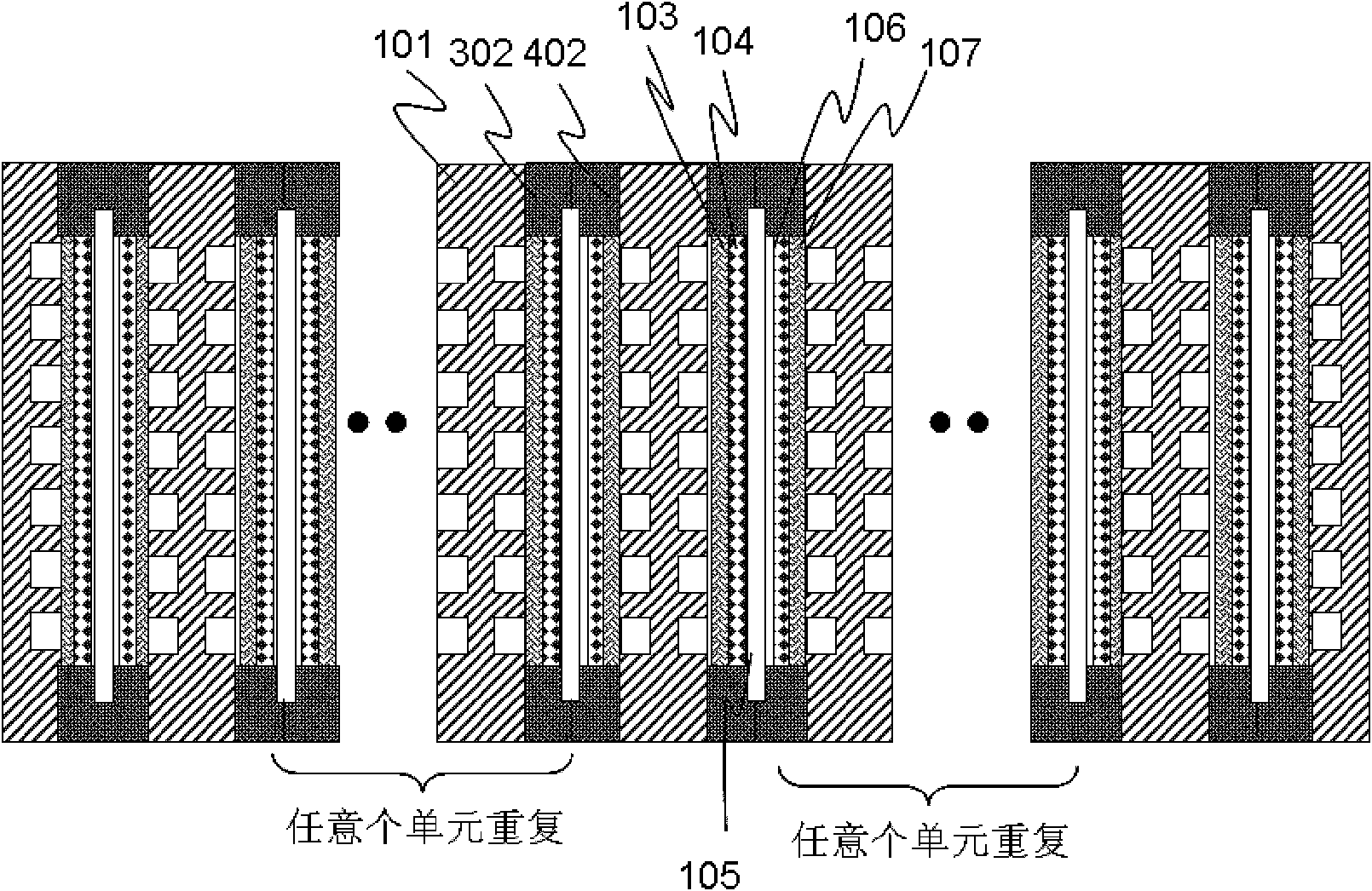

[0032] Take lithium-ion battery cathode material (104) LiCoO 2 Mix it mechanically with acetylene black and polyacrylic acid (5wt%) at a mass ratio of 95:5:5 for 10 minutes to prepare a paste, apply it to carbon paper (103), and dry in the shade. at 20 Kg cm -2 Press-molded under pressure as the positive electrode.

[0033] Take lithium-ion battery negative electrode material (106) acetylene black and polyacrylic acid solution (5wt%) at a mass ratio of 1:1, mix mechanically for 10 minutes, make a paste, apply it on carbon paper (107), and dry in the shade. at 20 Kg cm -2 Press-molded under high pressure as the negative electrode.

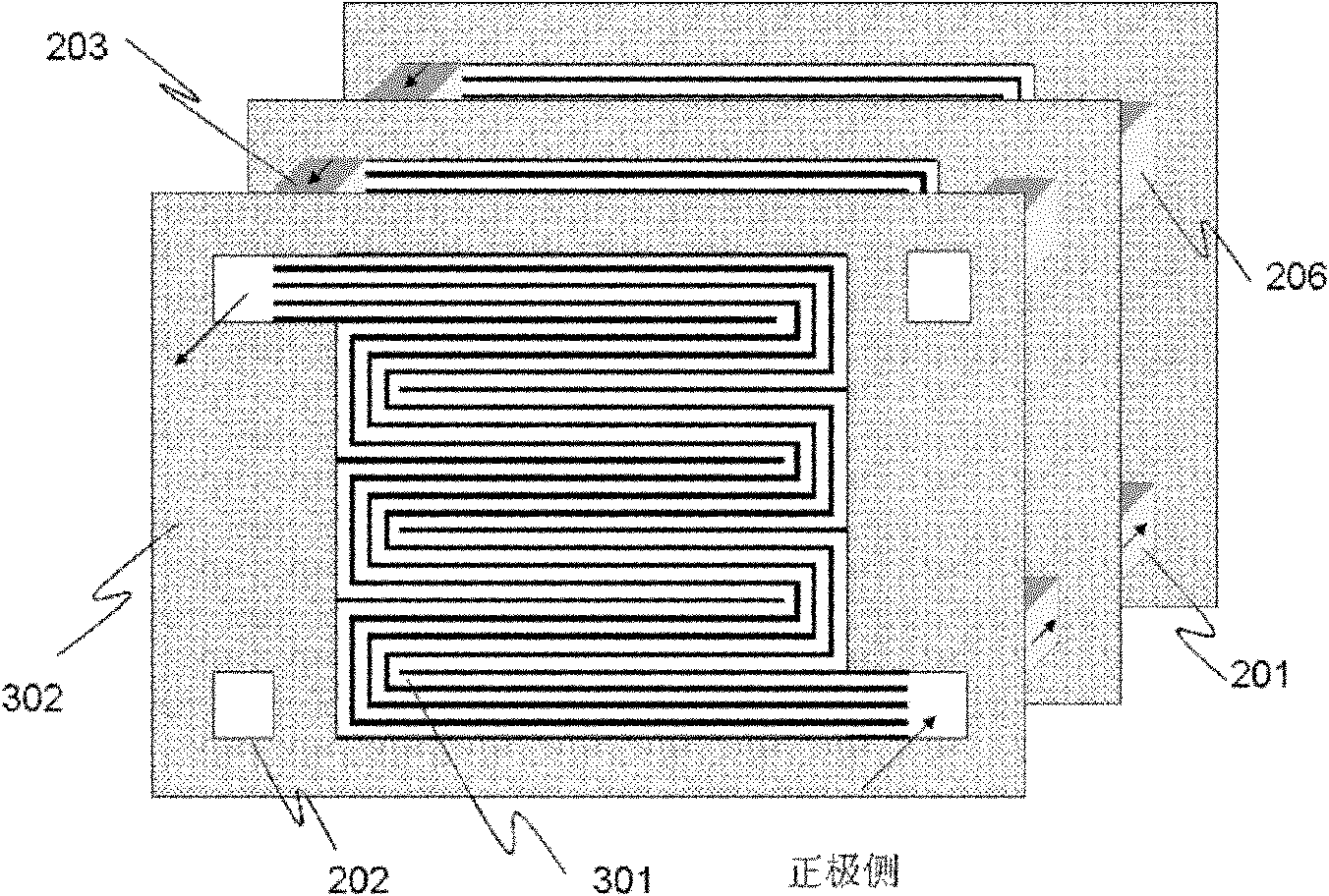

[0034] The electrode material sides of the positive and negative electrodes face each other to form a sandwich structure with the diaphragm (105), and the diaphragm is a microporous polypropylene film. The carbon paper sides of the positive and negative electrodes are respectively separated by s...

Embodiment 2

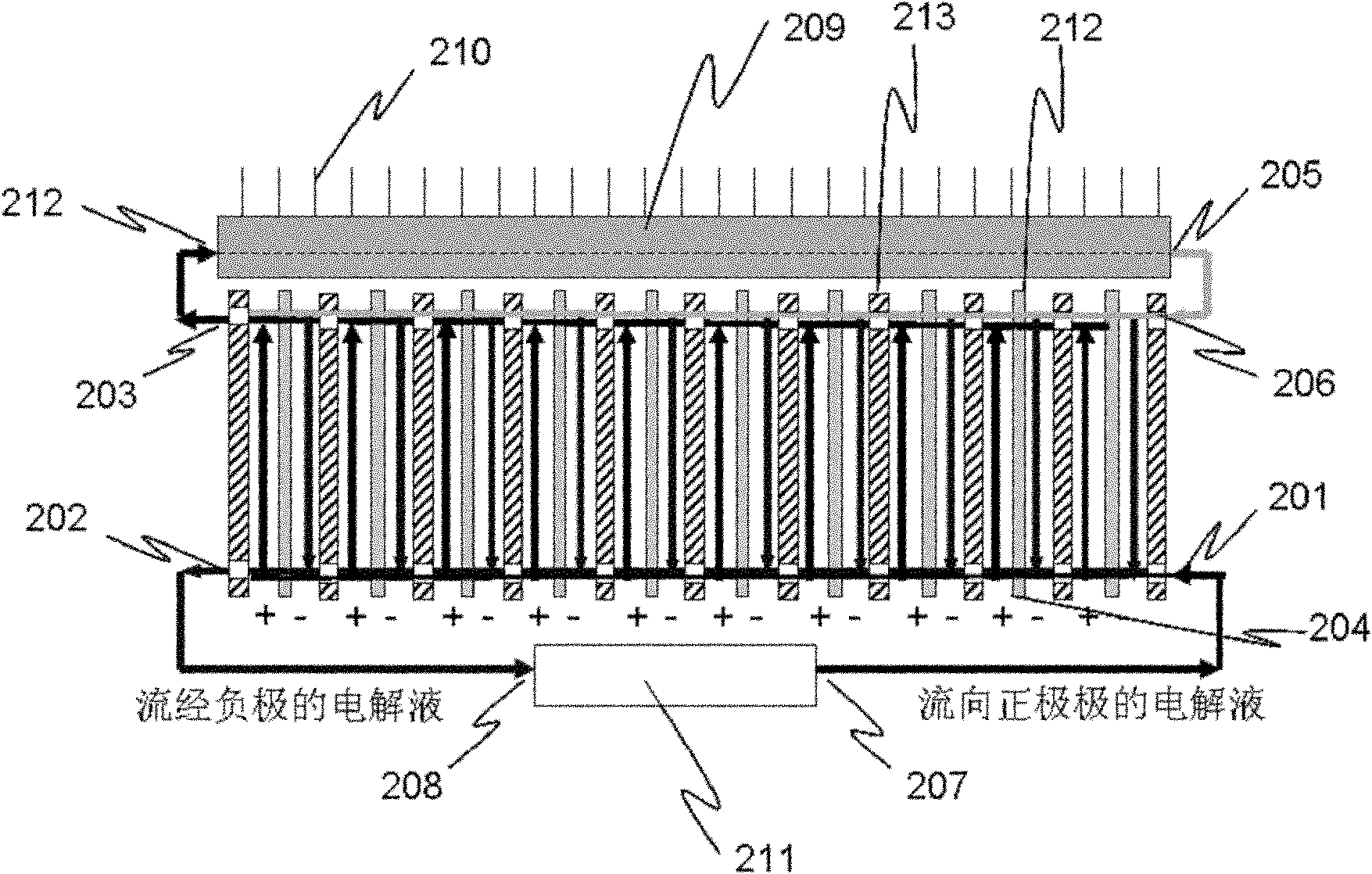

[0038] Embodiment 2: water-cooled battery system.

[0039] Take lithium-ion battery cathode material (104) LiFePO 4 Mix it mechanically with acetylene black and Nafion solution (5wt%) at a mass ratio of 95:5:20 for 30 minutes to make a paste, apply it to carbon paper (103), and dry in the shade. at 100 Kg cm -2 Press-molded under pressure as the positive electrode.

[0040] Take lithium-ion battery negative electrode material (106) acetylene black and Nafion solution (5wt%) at a mass ratio of 1:4, mechanically mix for 30 minutes, prepare a paste, apply it on carbon paper (107), and dry in the shade. at 50 Kg cm -2 Press-molded under high pressure as the negative electrode.

[0041] The positive and negative electrodes were respectively immersed in the lithium-ion battery electrolyte for 60 o C is heated for 30 minutes to carry out lithium ionization treatment, so that the binder Nafion resin exists in the form of lithium ion Nafion resin. Electrolyte with LiPF 6 As the ...

Embodiment 3

[0046] Embodiment 3: Air-cooled battery system.

[0047] Take lithium-ion battery cathode material (104) LiMnO 2 Mix it mechanically with acetylene black and polyacrylic acid (5wt%) at a mass ratio of 95:5:10 for 20 minutes to make a paste, apply it to carbon paper (103), and dry in the shade. at 50 Kg cm -2 Press-molded under pressure as the positive electrode.

[0048] Take lithium-ion battery negative electrode material (106) acetylene black and polyacrylic acid solution (5wt%) at a mass ratio of 1:2, mechanically mix for 20 minutes, make a paste, apply it on carbon paper (107), and dry in the shade. at 50 Kg cm -2 Press-molded under high pressure as the negative electrode.

[0049] The electrode material sides of the positive and negative electrodes face each other to form a sandwich structure with the diaphragm (105), and the diaphragm is a microporous polypropylene film. The carbon paper sides of the positive and negative electrodes are respectively separated by sep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com