Throttling device for air conditioner check valve

A throttling device and one-way valve technology, applied in the direction of valve devices, control valves, functional valves, etc., can solve the problems of reducing the heating effect of air conditioners and reducing the heating capacity, so as to reduce power consumption and improve heating capacity , the effect of increasing the cooling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

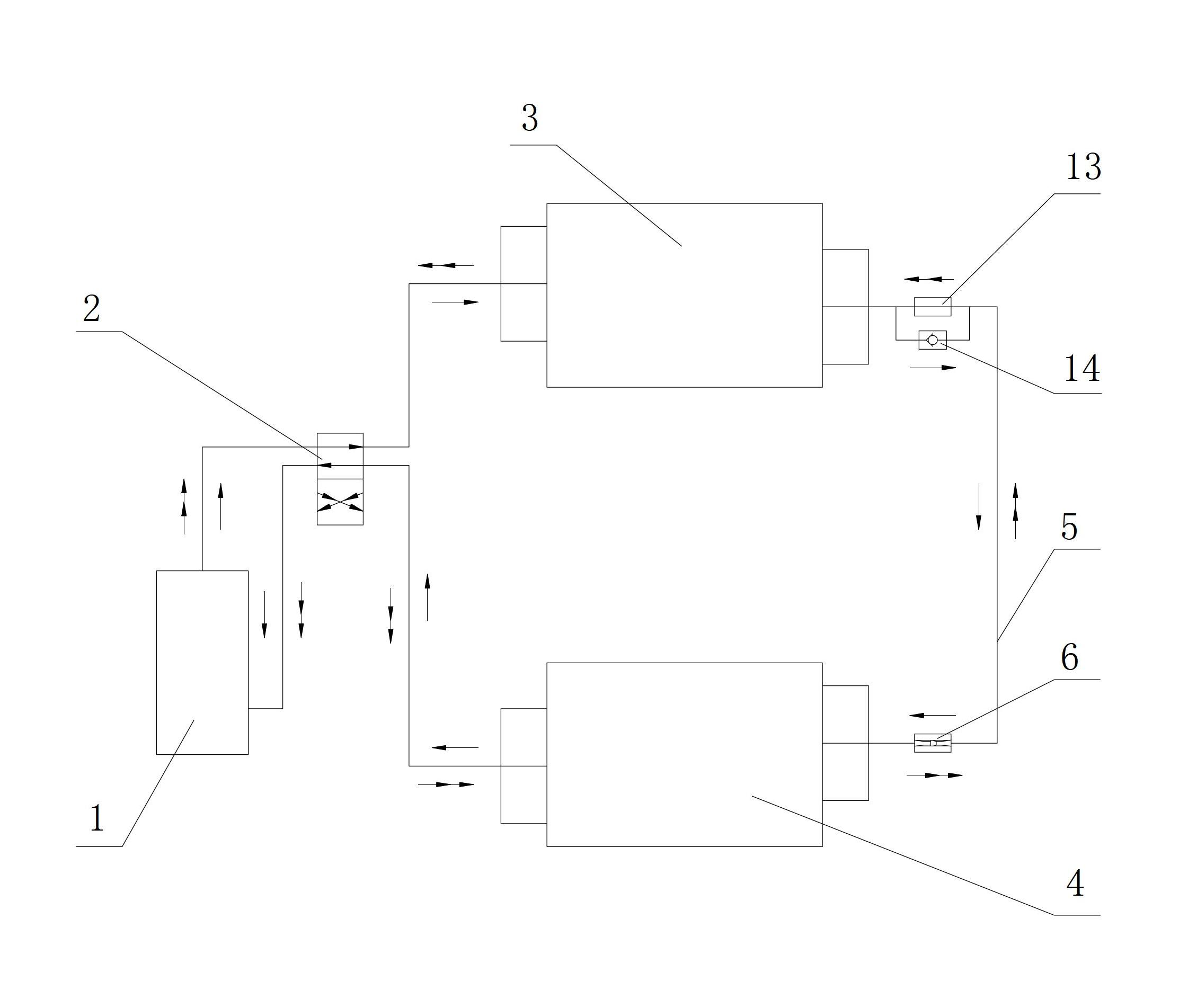

[0026] Embodiment 1: as figure 1 Shown is a structural schematic diagram of a specific embodiment of the one-way valve throttling device of the air conditioner provided by the present invention. Like a conventional air conditioner, it has a compressor 1, a four-way valve 2, The condenser 3 and the evaporator 4, and on the delivery pipe 5 connecting the condenser 3 and the evaporator 4, a heating throttling device is provided near the end of the condenser 3. In this embodiment, the heating throttling device is a capillary tube joint A flow device 13, and a check valve 14 is connected in parallel on the capillary restrictor 13; and a cooling throttling device is provided near the end of the evaporator 4, and the cooling throttling device is a check valve device 6 with a throttling function, and The conduction direction of this non-return valve device 6 with throttling function points to the condenser 3 .

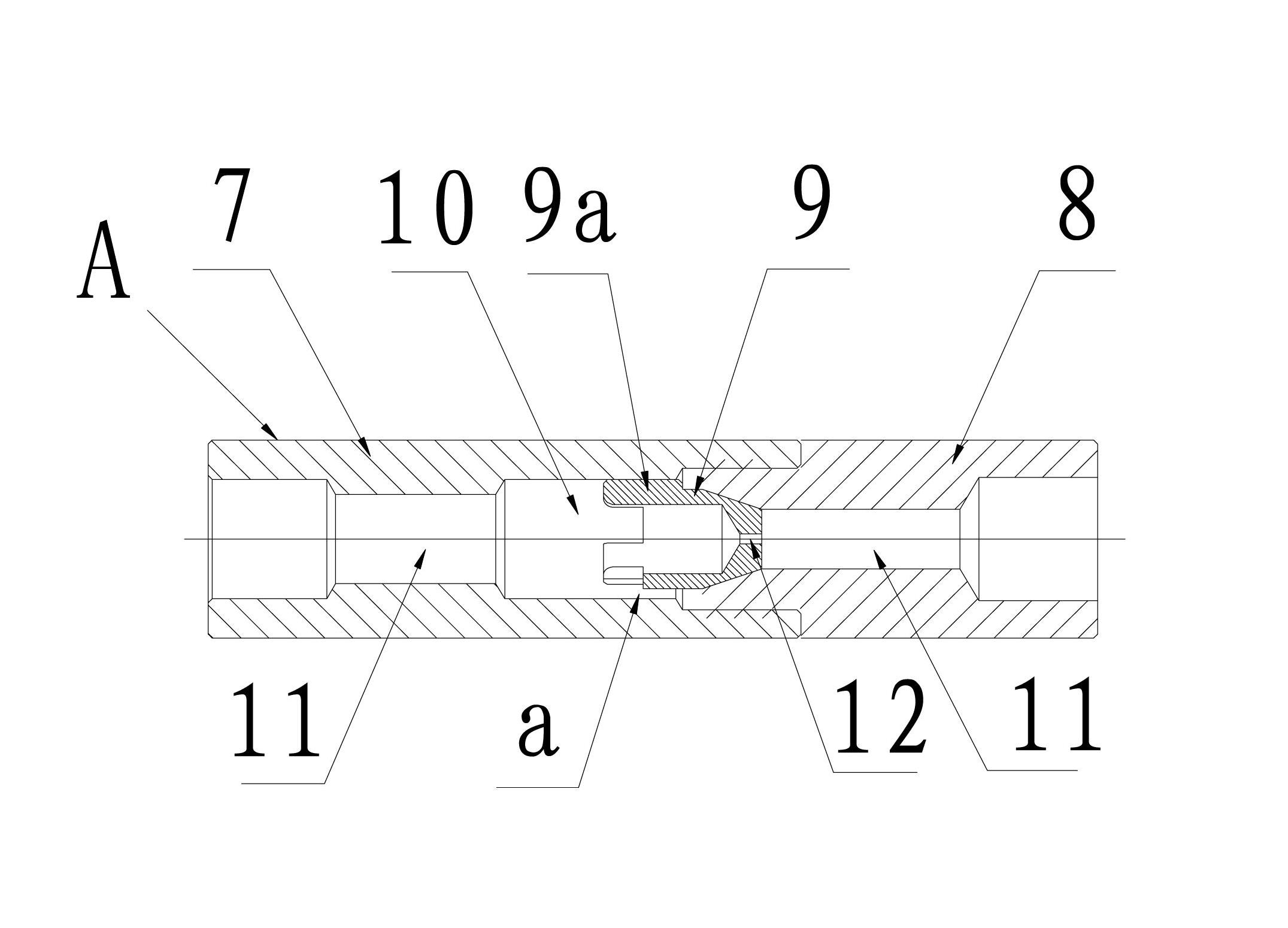

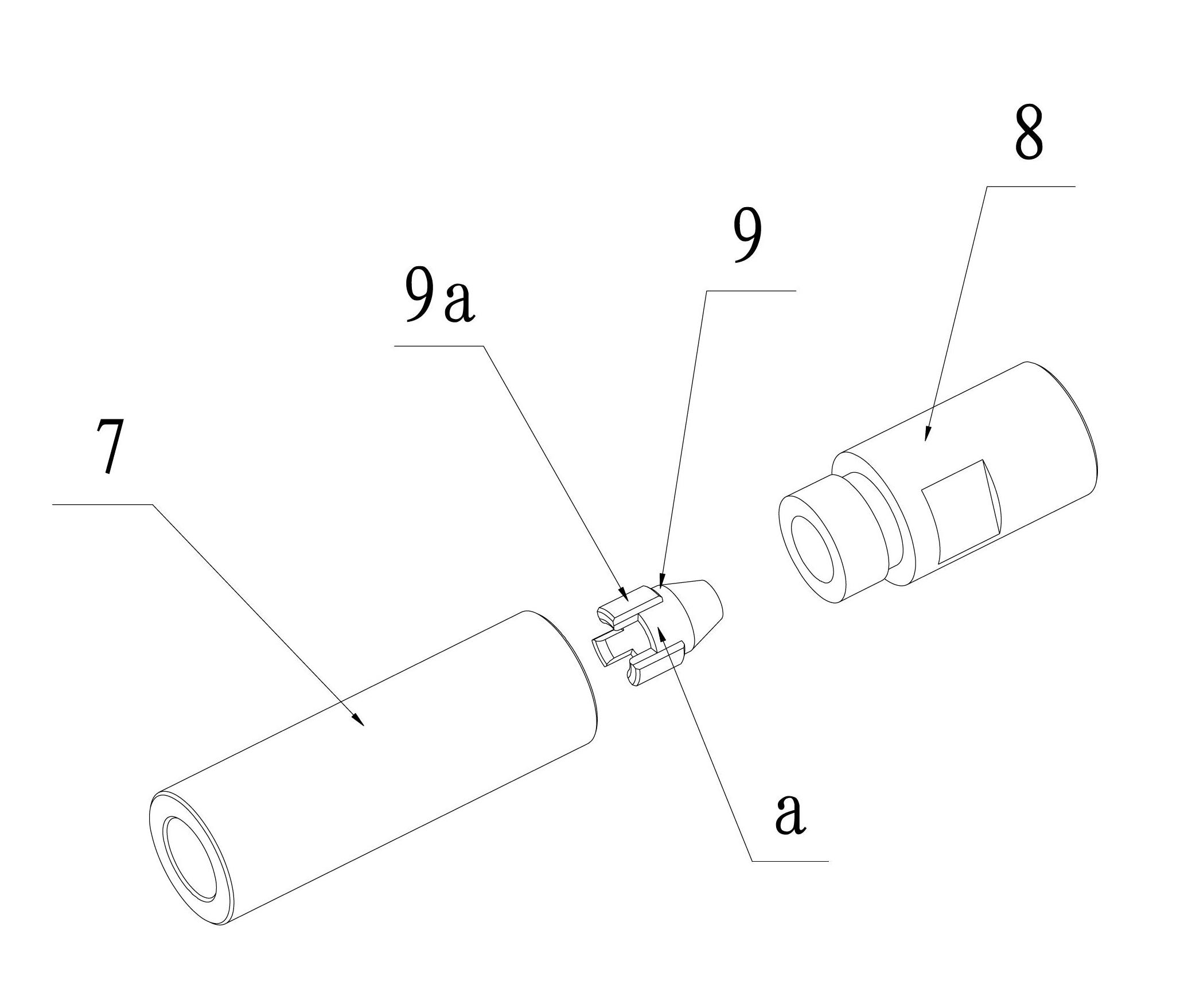

[0027] Concrete combination figure 2 , image 3 As shown, the one-way...

Embodiment 2

[0043] Embodiment 2: as Figure 4 Shown is another specific embodiment of the air conditioner check valve throttling device of the present invention, its structure is basically the same as that of embodiment 1, the difference is that the cooling throttling device near the end of the evaporator 4 is three parallel connections The one-way valve device 6 with throttling function, the aperture parameters of the capillary orifice 12 in the three one-way valve devices 6 with throttling function are respectively selected as 0.59mm, 0.61mm, 0.65mm, and the throttle length is also That is, the hole lengths of the fine detail orifices 12 are all 4mm. The working principle and method of this embodiment can be referred to Embodiment 1, so it will not be described in detail.

[0044] Further illustrate the remarkable effect of the present invention with actual test data comparison below:

[0045] 1. Test model: a split-type air conditioner with a cooling capacity of 3500 W.

[0046] 2. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com