Cooker

A pot body and ceramic layer technology, which is applied to special materials for cooking utensils, cooking utensils, household utensils, etc., can solve the problem that the aluminum pot body and the ceramic layer cannot be melted and connected, and the adhesion between the aluminum pot body and the ceramic layer is not strong. The non-stick performance of the pot is not ideal, and the effect of preventing vaporization and volatilization, strong adhesion and good non-stick performance can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

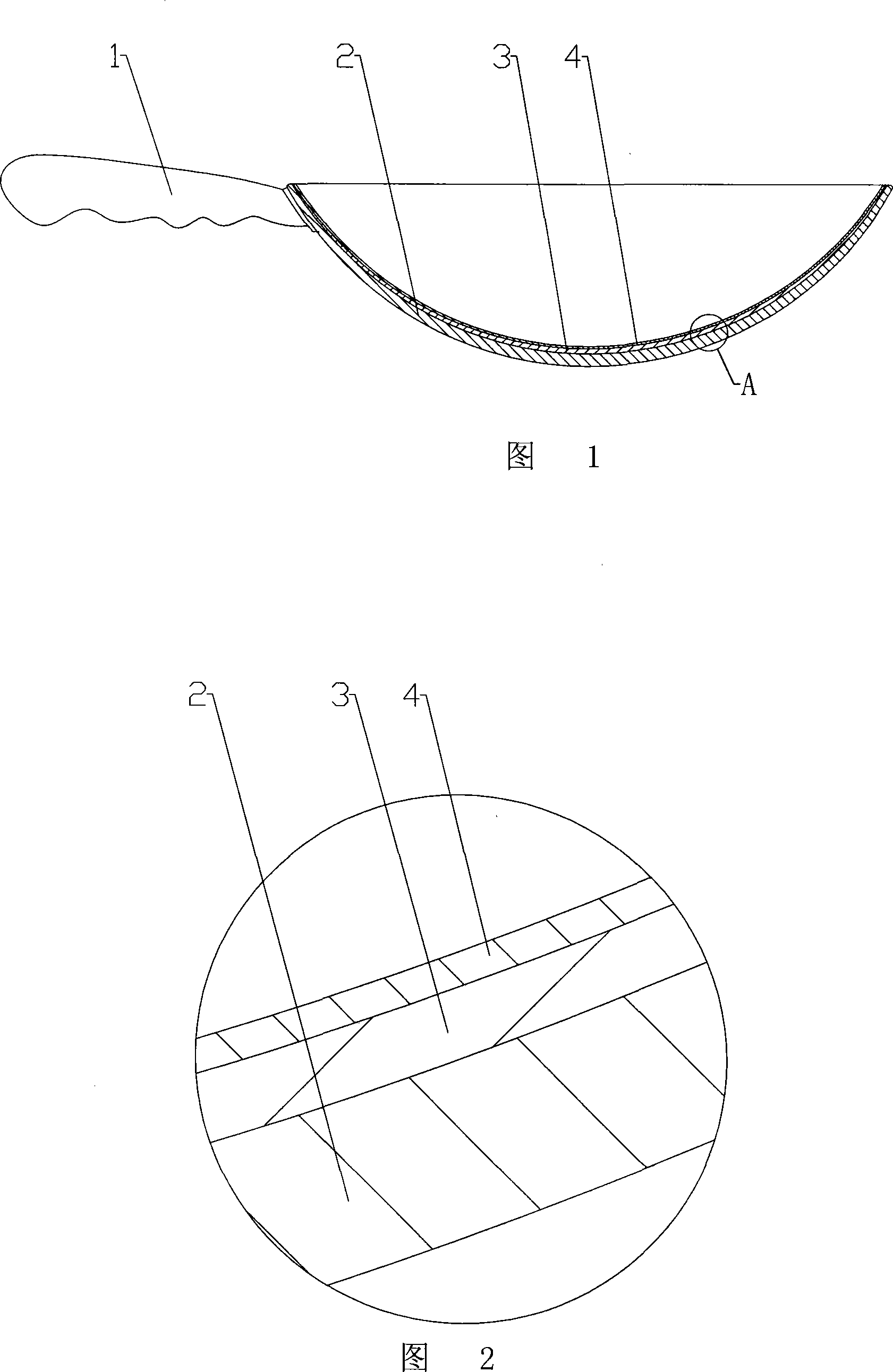

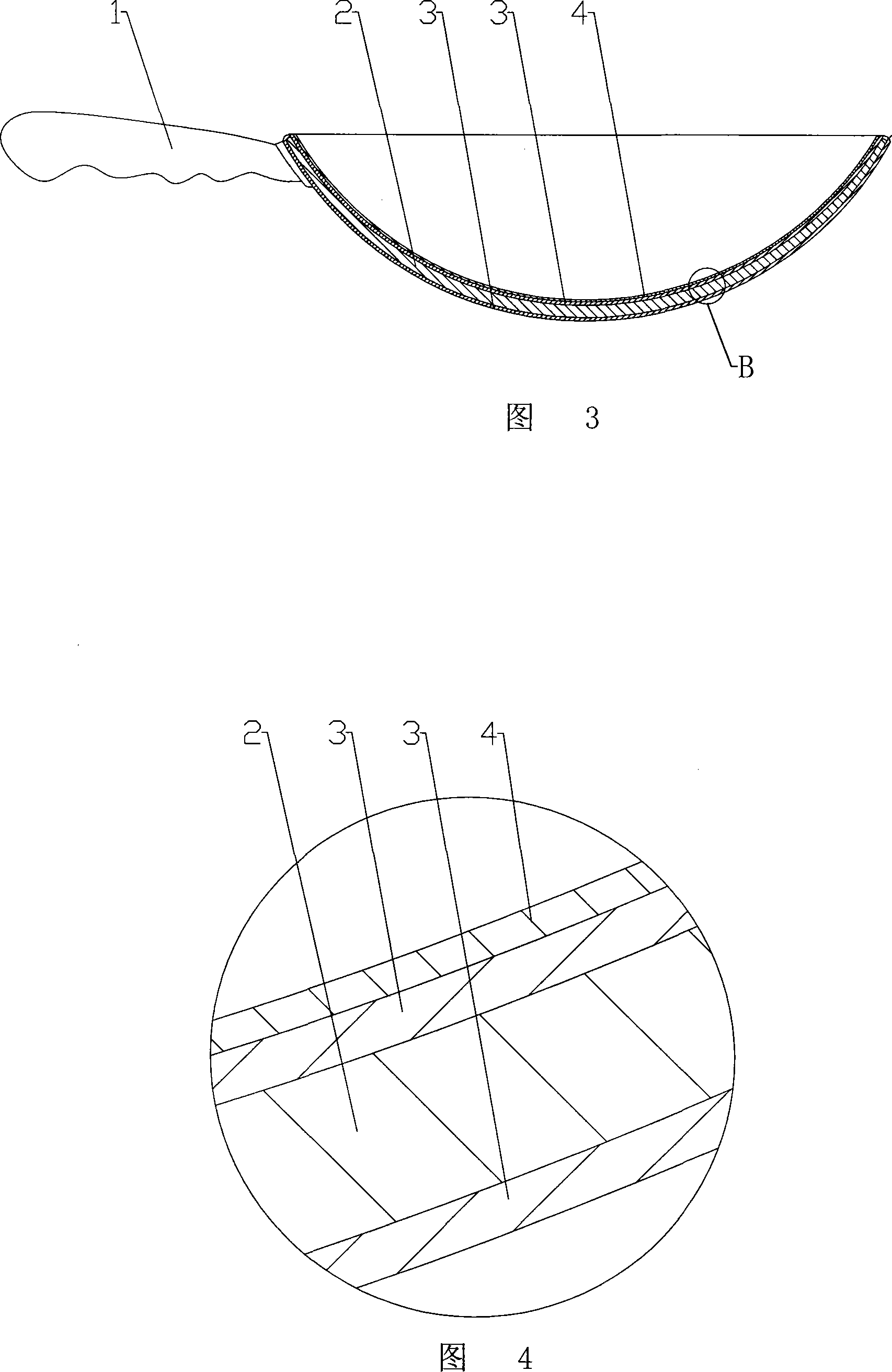

[0020] As shown in Fig. 1 and Fig. 2: the pot body of this embodiment is provided with a handle 1, and the pot body includes a metal layer and a ceramic layer, and the metal layer and the ceramic layer are composited into one. The metal layer and the ceramic layer are closely combined into one body through local melting. The metal layer in this embodiment is an aluminum alloy layer 2 , and the inner surface of the aluminum alloy layer is thermally sprayed with a ceramic layer 3 . The ceramic layer on the inner surface of the pot is covered with a non-stick layer 4 containing ceramic components. The non-stick layer is bonded to the ceramic layer by baking at 200-420°C.

[0021] The pot of this embodiment is manufactured by the following method:

[0022] A. Made of aluminum alloy pan blank, the aluminum alloy pan blank is preferably treated with hard anodic oxidation to form a dense surface.

[0023] B. Melt the ceramic powder with thermal spraying equipment, and spray the me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com