Stripping device for detecting filling rate of flux-cored wire and detection method

A technology of flux-cored welding wire and filling rate, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of not an order of magnitude, metal peeling, accurate positioning of wire peeling machines, and the accuracy of peeling can not meet the requirements, etc. Simple structure, easy to produce and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

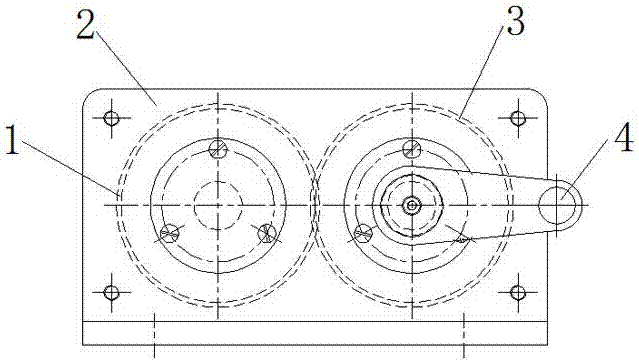

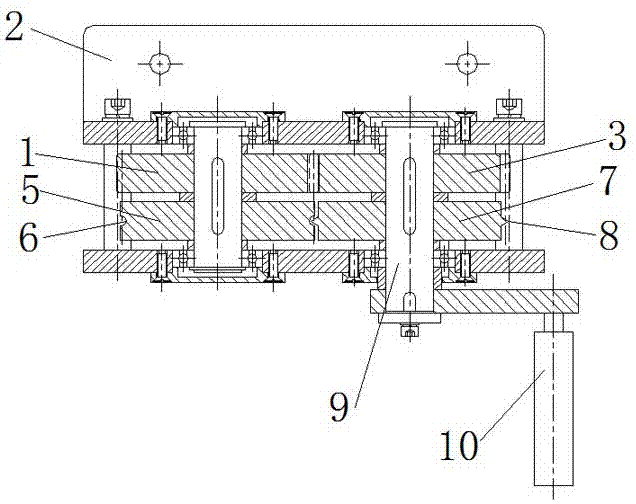

[0018] Such as figure 1 with figure 2 The shown debarking device for detecting the filling rate of flux-cored welding wire includes gear A1 and gear B3 that mesh with each other. Gear A1 and gear B3 have the same number of teeth and modulus. Gear A1 and gear B3 are respectively fixed on the bracket 2 through a mandrel 9. A disc A5 is fixed on the gear A1, a circular arc groove 6 is provided on the circumference of the disc A5, a disc B7 is fixed on the gear B3, and a circular arc groove 6 is provided on the circumference of the disc B7. A handle 10 is provided on the shaft 9 of the gear B3 with the matched convex sharp corner 8, and the gear A1 and the gear B3 are driven to rotate by rotating the handle 10, thereby driving the two discs to rotate with each other.

[0019] When in use, the gap of the head of the weighed metal wire is facing the sharp ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com