Screwdrivers for use with impact drivers

A driving device and driver technology, applied in the direction of power tools, manufacturing tools, etc., can solve problems such as damage to the edge of the handle and can no longer be held

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

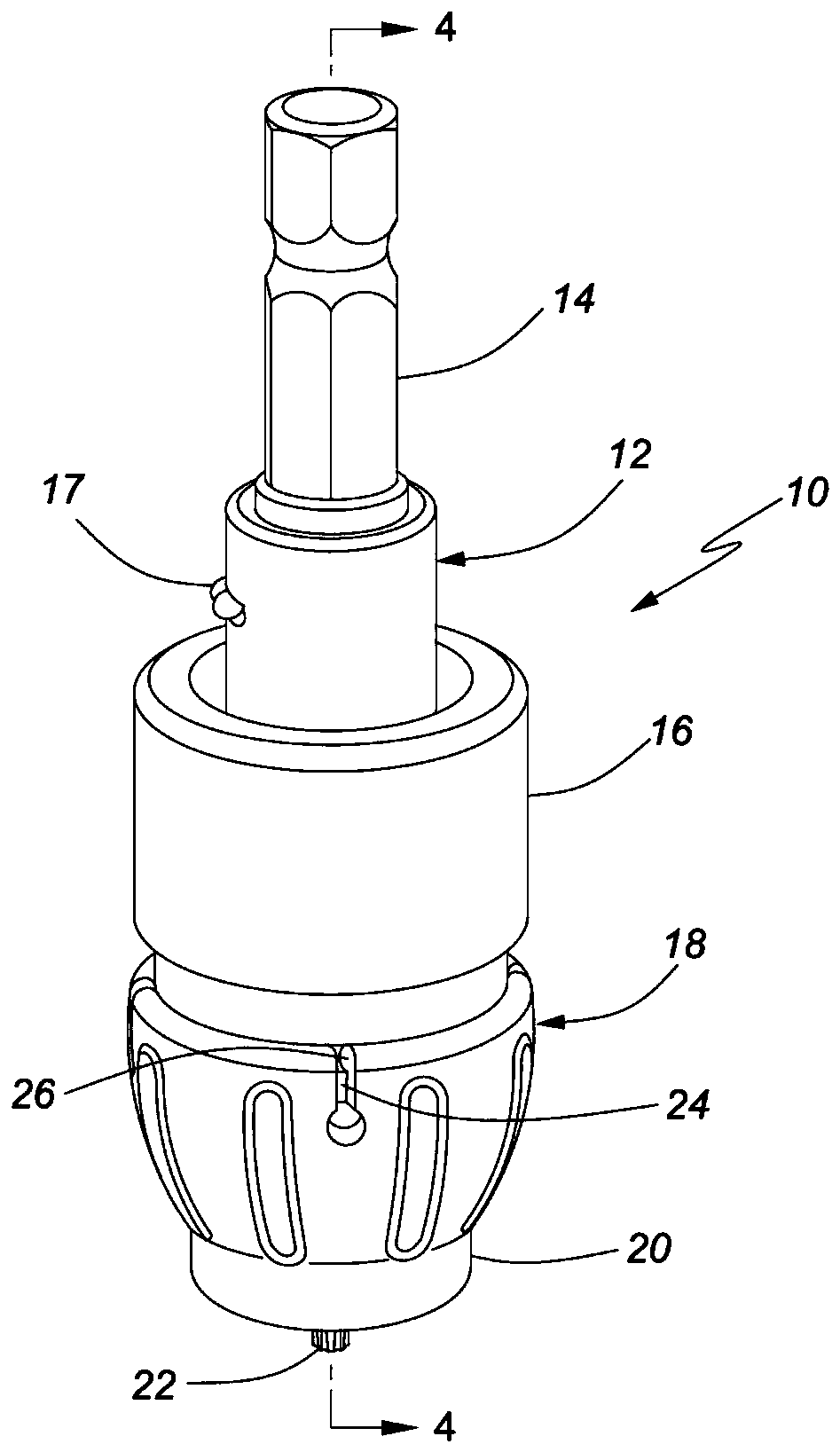

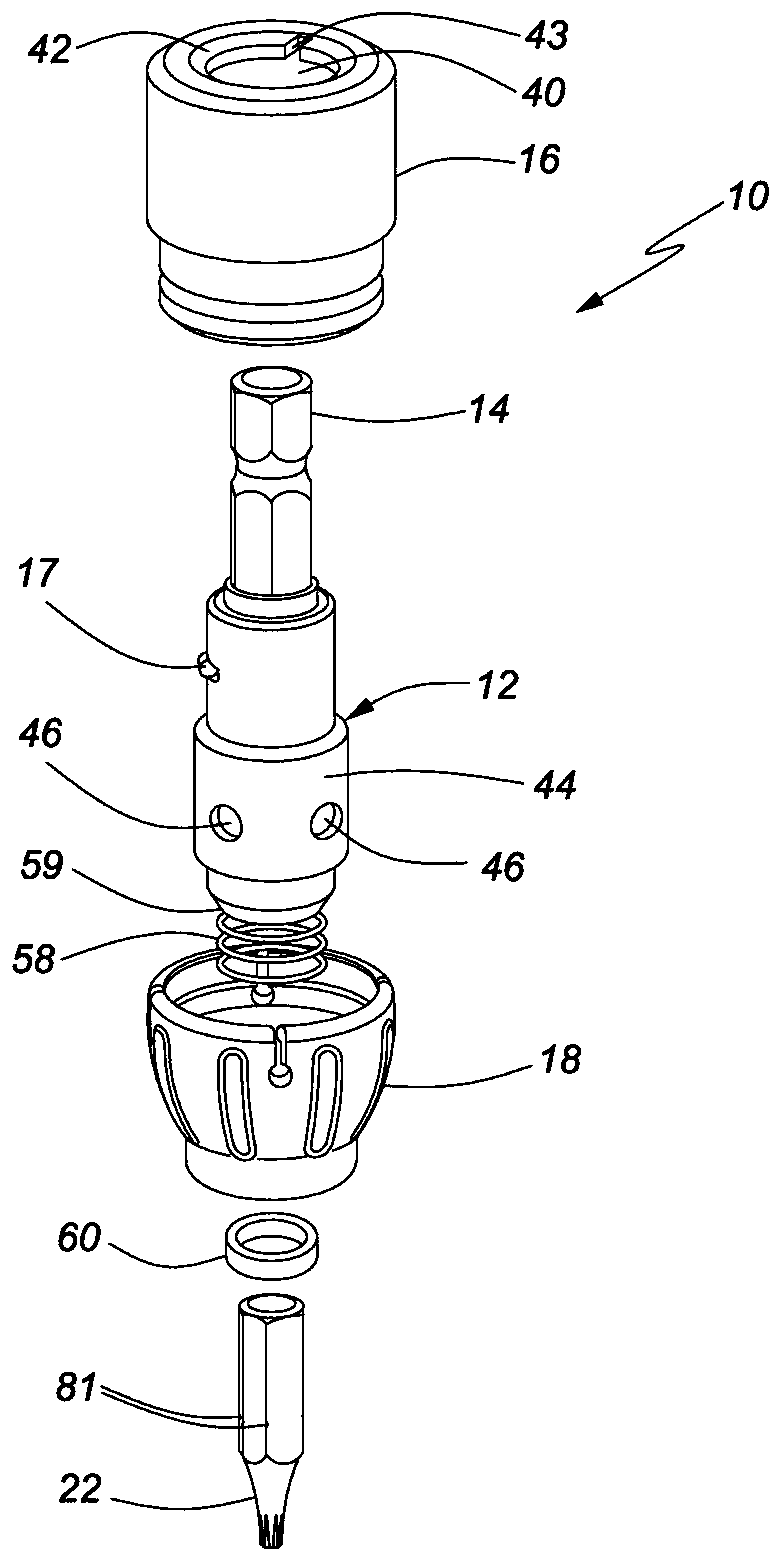

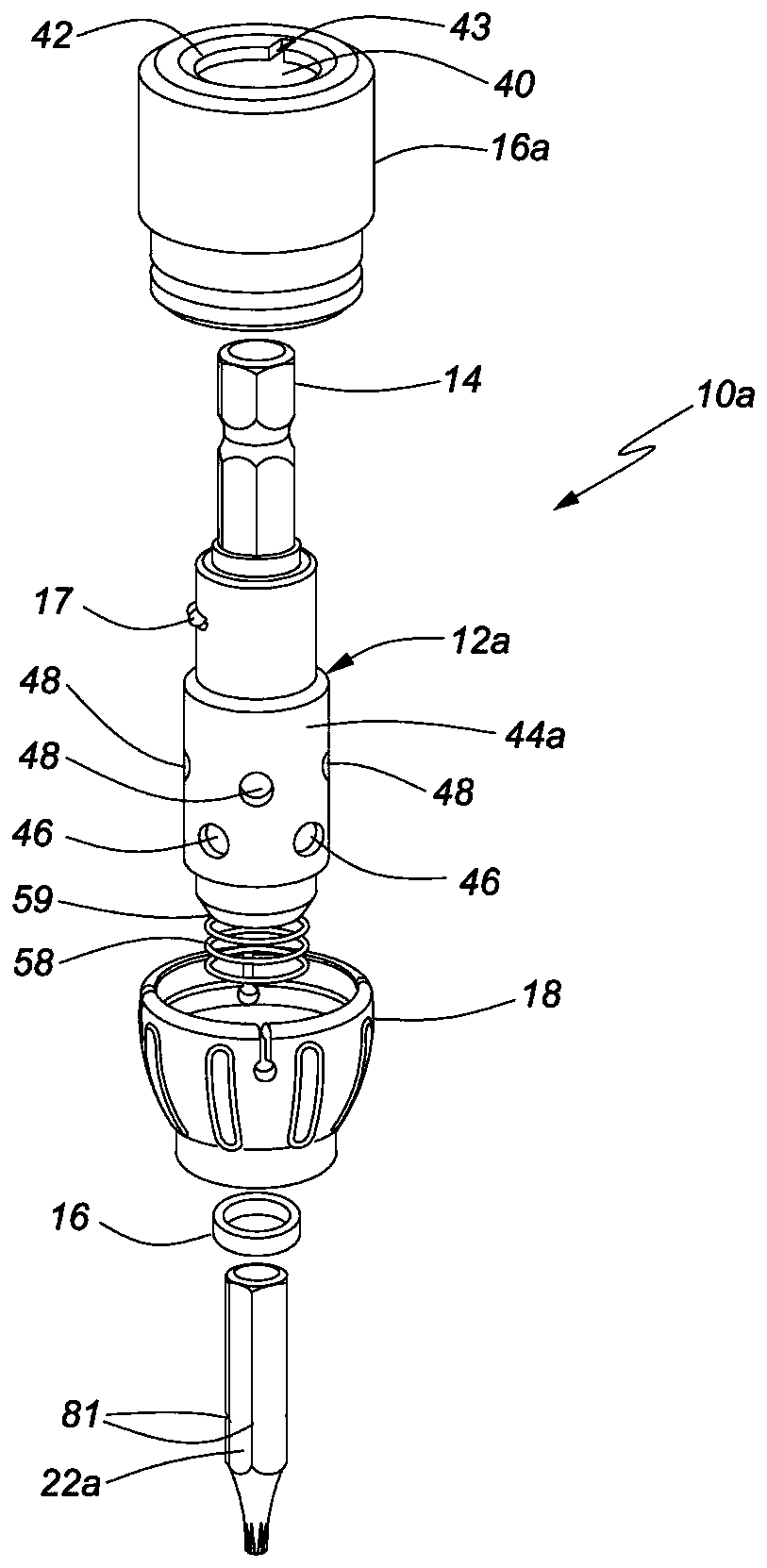

[0017] figure 1 is a perspective view of a screw driving device 10 according to the present invention.

[0018] The screw driver 10 has a drive shaft 12 having a drive end 14 adapted to be engaged and driven by a hand-held electric impact driver (not shown); such hand-held power tools are well known in the art.

[0019] A hollow clutch sleeve 16 accommodates the drive shaft 12; a locking protrusion 17 is formed on the side of the drive shaft 12 to lock the screw driver 10 in a locked position for removing the driven screw.

[0020] The following reference Figure 9 Illustrated, a depth control sleeve (nose cone) 18 grips the bottom end of the hollow clutch sleeve 16, the depth control sleeve 18 having a bottom 20 through which a bit 22 is received at the bottom end of the drive shaft 12 .

[0021] The following reference Figure 4 to Figure 8 Illustrating, the bit 22 rotates with the drive shaft 12 when the screw driver 10 is in the drive position, and the bit 22 is releas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com