A multi-purpose agricultural tool fiberglass handle and its production process

A glass fiber and agricultural tool technology, applied in the manufacture of tools, hand-held tools, coatings, etc., can solve the problems of poor toughness and elasticity of the handle, increase the weight of agricultural tools, and sweat and slippery hands, so as to prolong the service life, The effect of saving wood and steel and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

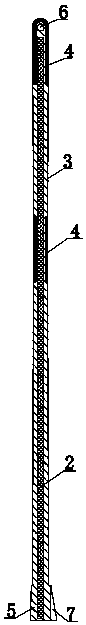

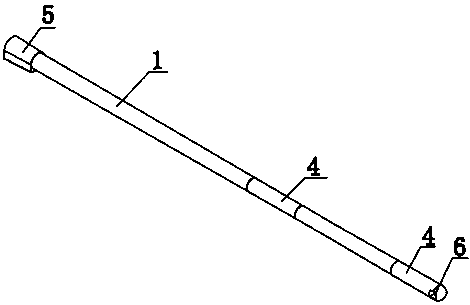

[0025] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

[0026] The production process of a kind of multi-purpose agricultural tool glass fiber handle provided by the invention comprises the following steps: A. making glass fiber core: glass is first made into glass fiber strands, and then several glass fiber strands are chemically bonded Carry out multiple bonding moldings, and finally cut and make glass fiber cores; B. One-time injection molding: put the glass fiber cores in a one-shot injection mold, and inject PP material on its outer surface, wherein the glass can be glass balls or waste glass , save production cost, and recycle waste. Glass fiber filaments are made by high-temperature melting, wire drawing, winding, cooling, and forming of waste glass. The diameter of glass fiber filaments is 0.2mm-0.3mm.

[0027] After one-time injection molding in step B, the han...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com