Laminated plate, and terminal treating method for laminated material

A technology of end treatment and laminate, applied in chemical instruments and methods, layered products, transportation and packaging, etc., can solve problems such as large wrinkles, laminated blank constraints, and inaccessibility, and achieve the effect of improving rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

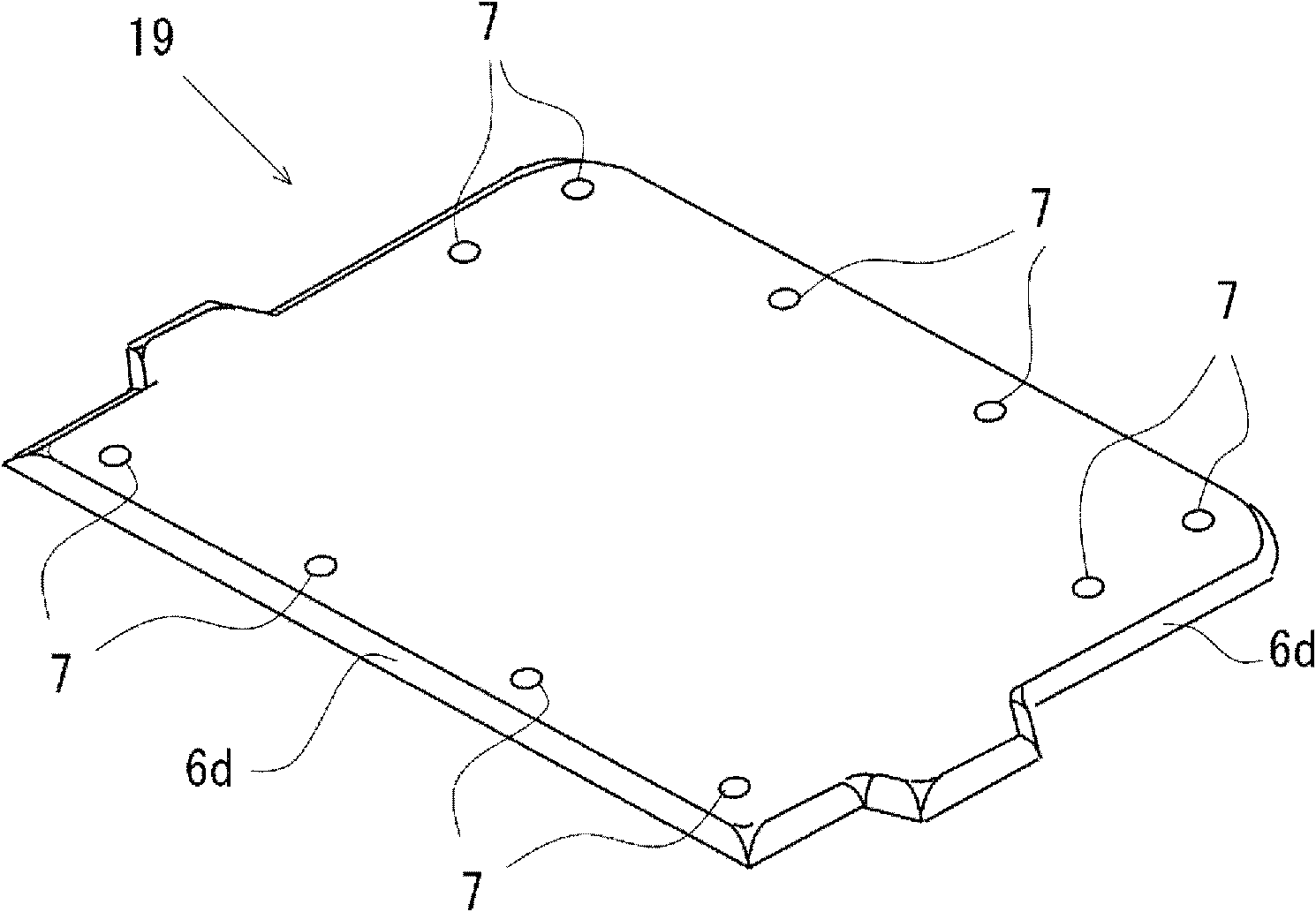

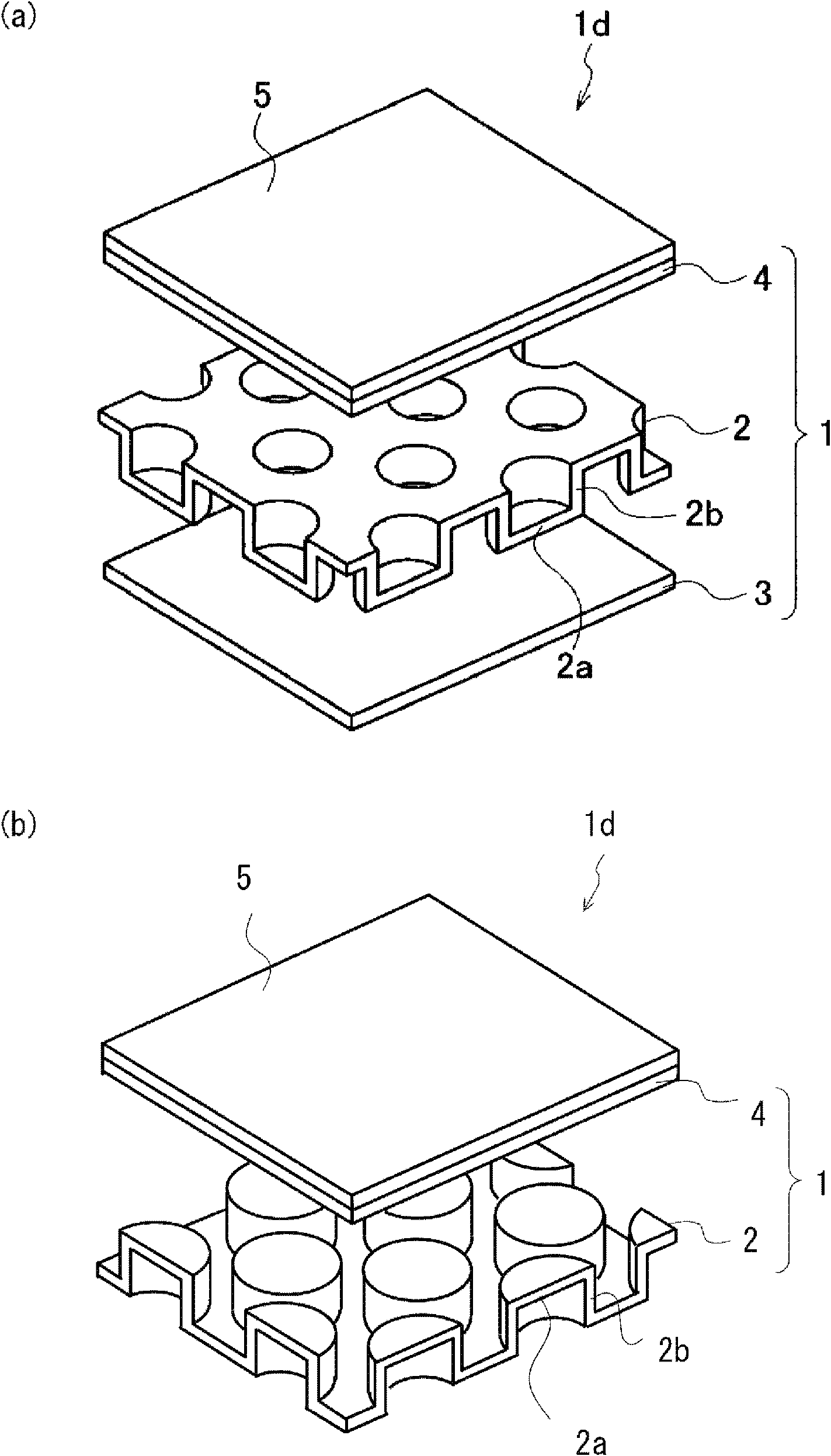

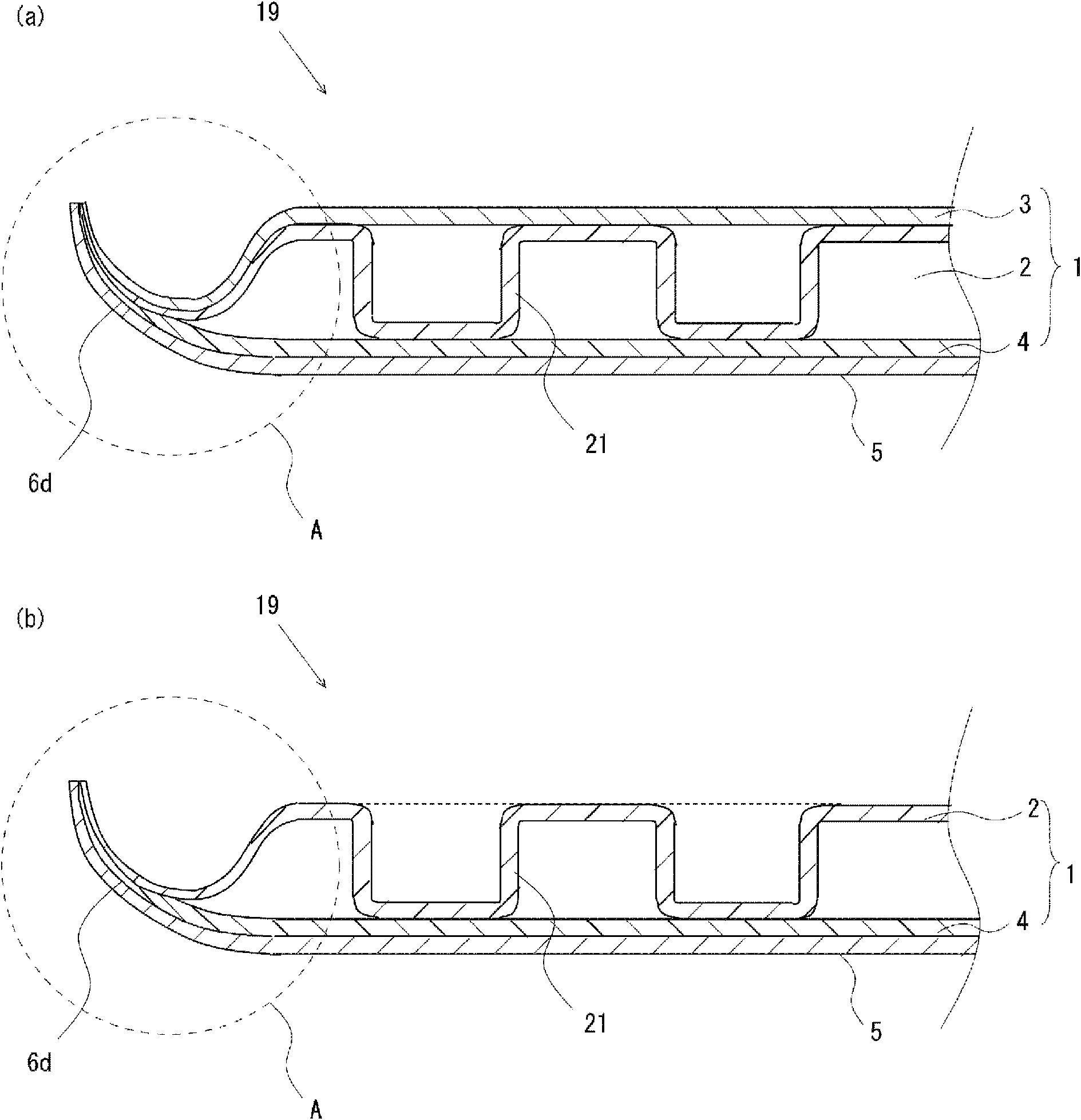

[0026] Next, the best mode for carrying out the present invention (hereinafter simply referred to as "embodiment") will be specifically described with reference to the drawings. In the embodiments described below, a resin molded product (laminated sheet) used as an interior part of an automobile, specifically, a rear door trim attached to a rear door of an automobile will be described. figure 1 is a perspective view showing a rear door trim (laminate) 19 according to this embodiment, figure 2 is an exploded perspective view showing the structure of the laminated material 1d with skin material constituting the rear door trim 19, image 3 It is a sectional view of the laminated material 1 constituting the rear door trim 19 . in addition, figure 2 with image 3 Reversely up and down. and, figure 2 (a) and image 3 (a) shows the structure of the laminated material 1d with skin material which consists of the laminated material 1 of a 3-layer structure, and the back door tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com