Patents

Literature

39results about How to "Reduce reaction volume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

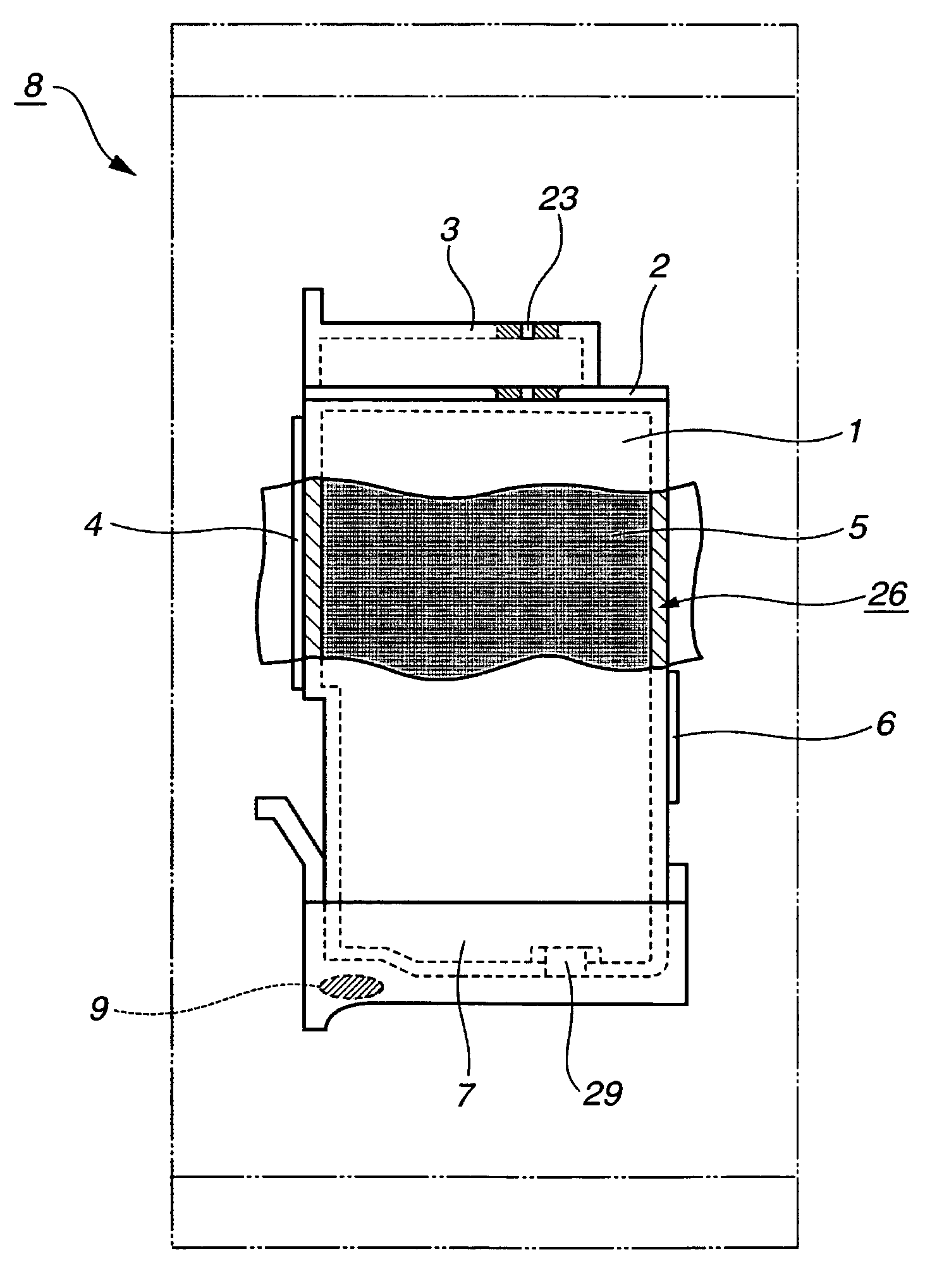

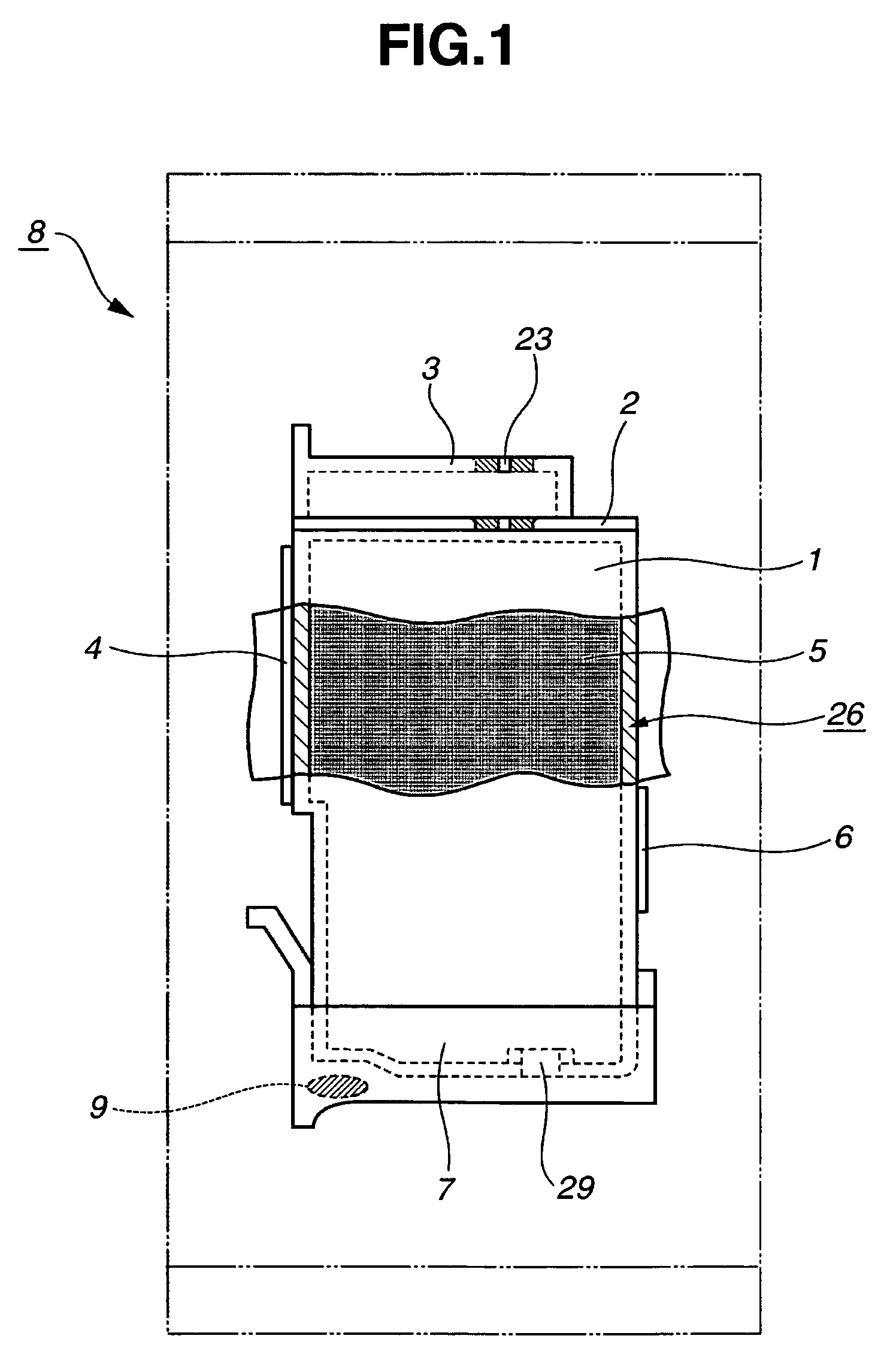

Continous flow thermal device

ActiveUS20050282206A1Avoid vaporizationMinimizing turbulent flowBioreactor/fermenter combinationsBiological substance pretreatmentsThermal contactThermal cycle

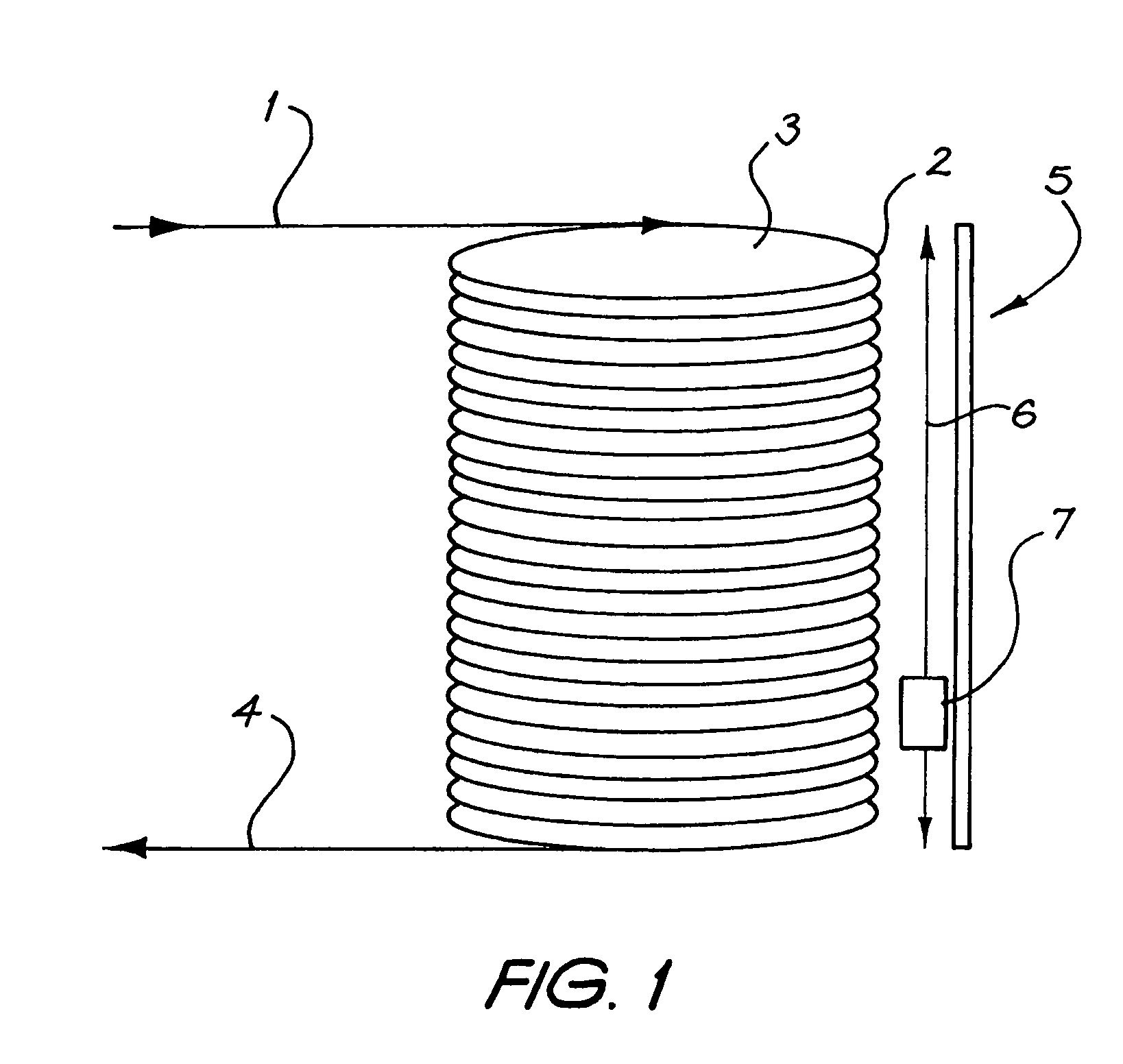

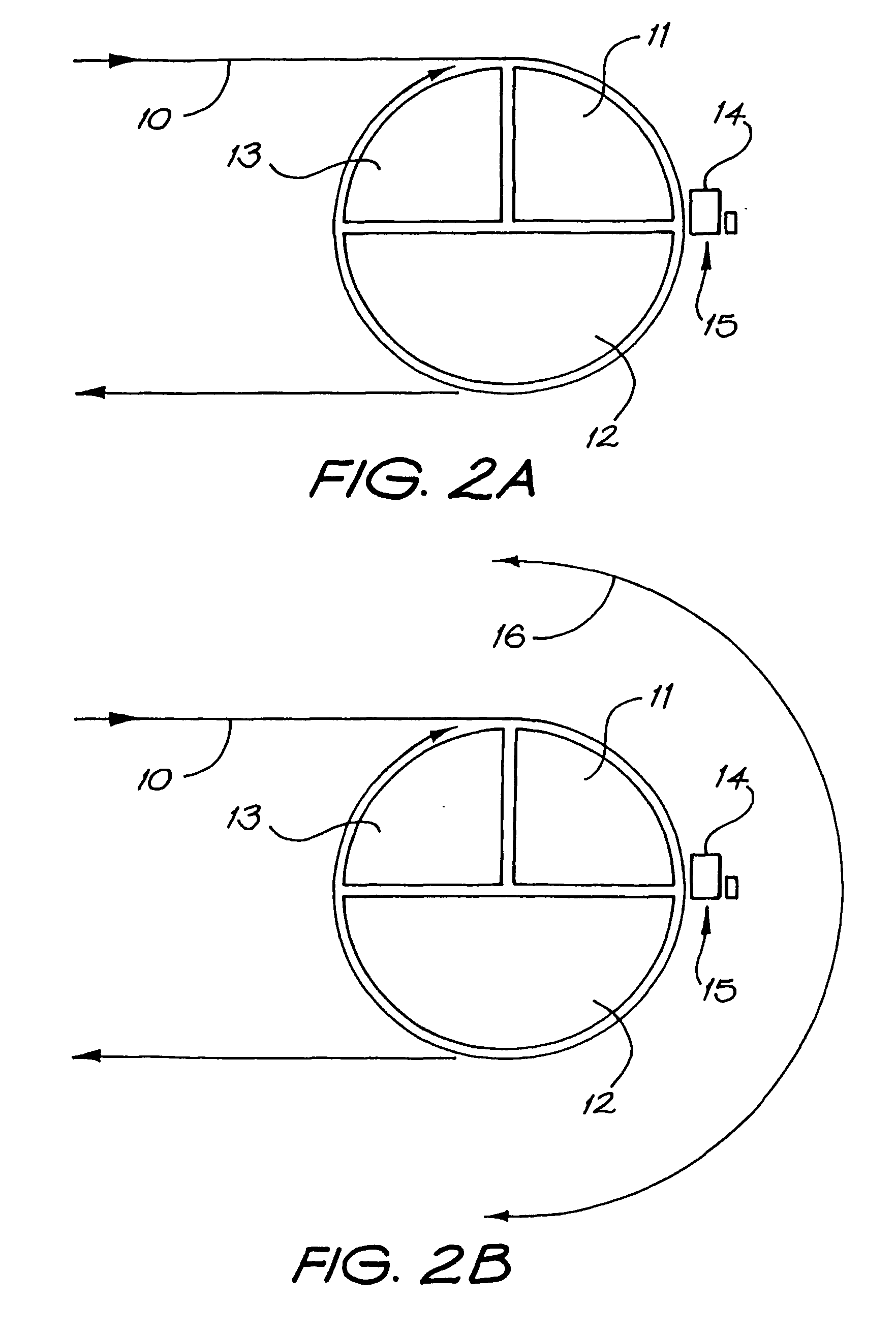

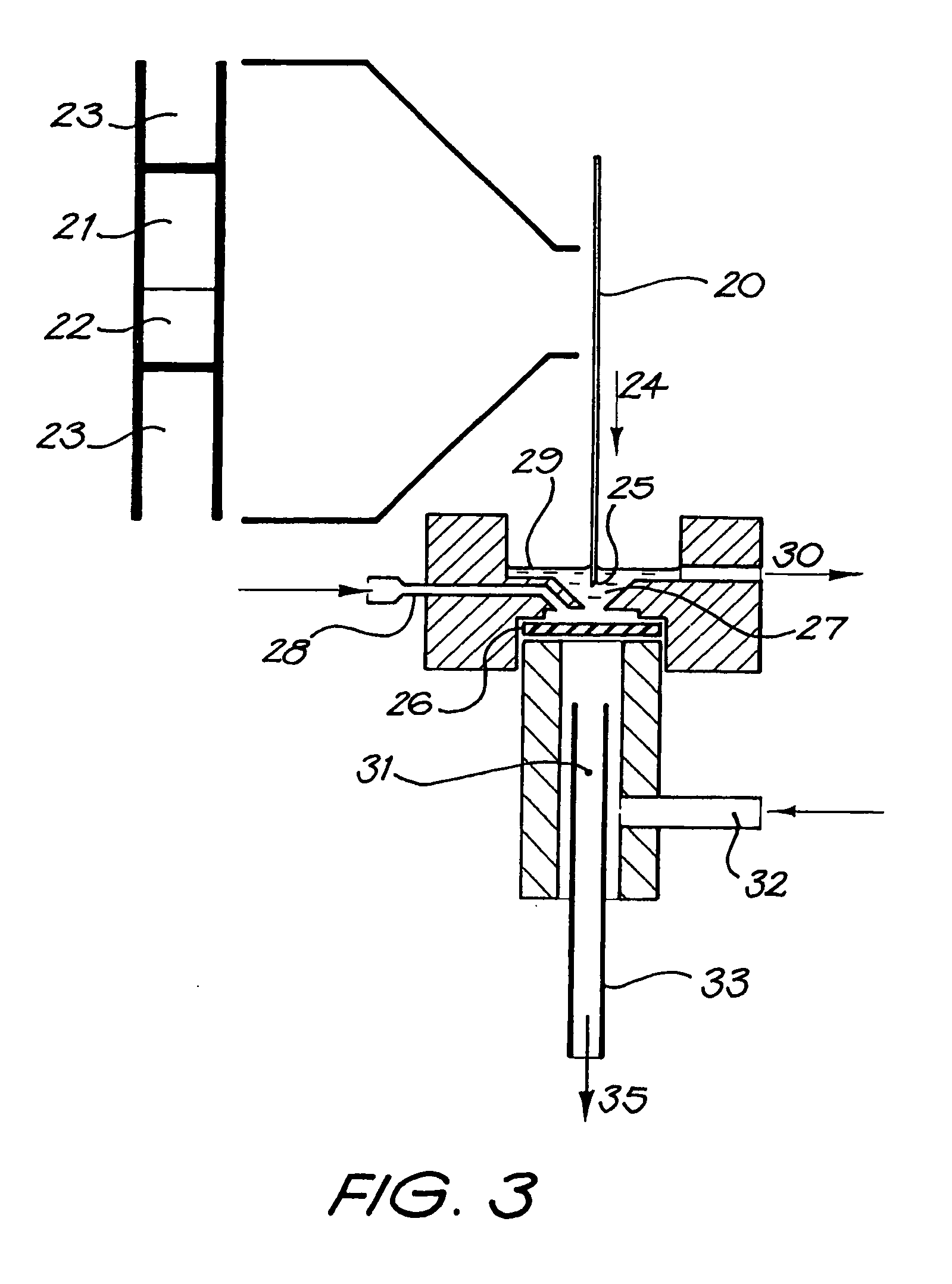

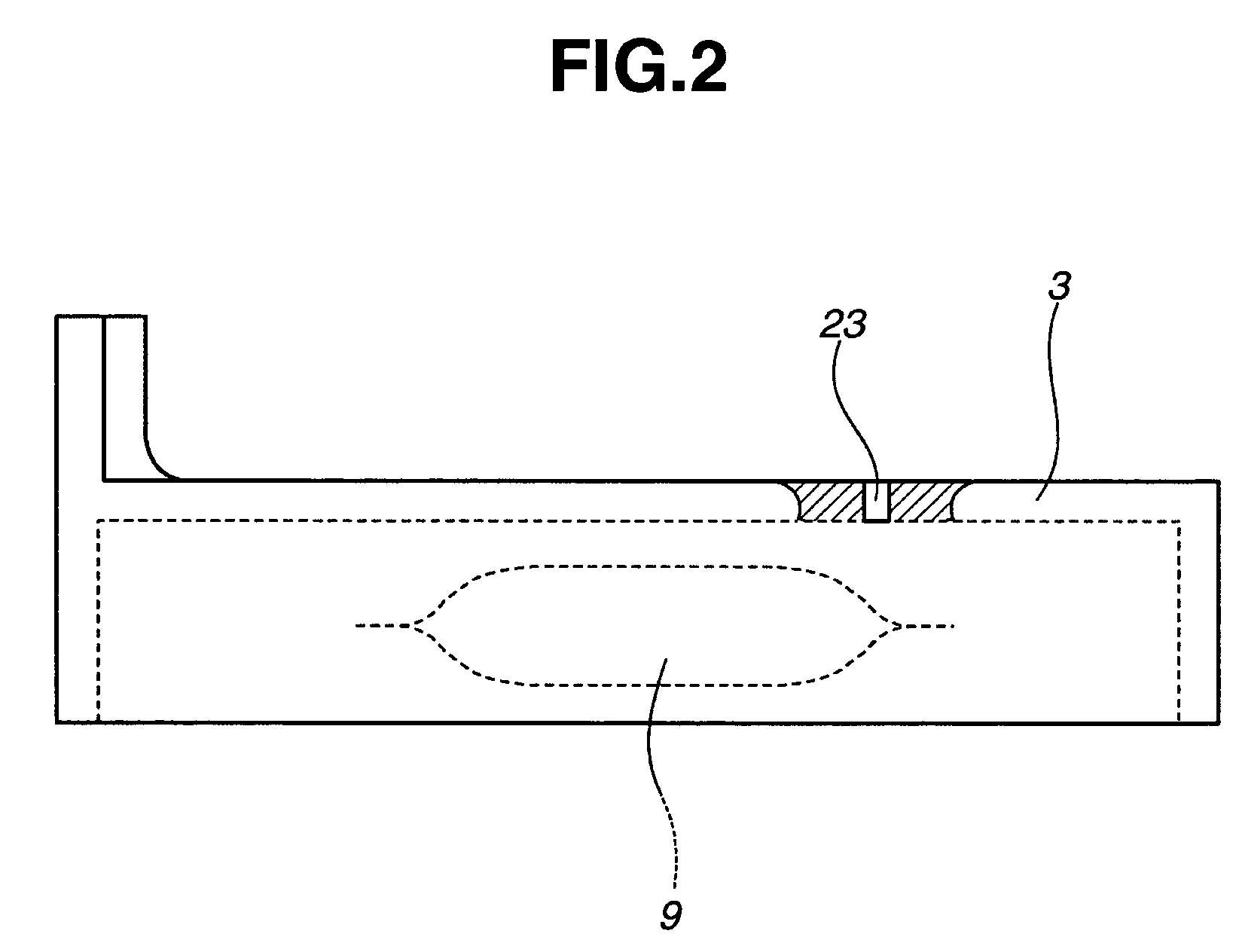

The present invention provides a thermal cycling device including: a heat exchanger body (3) having a longitudinal axis and longitudinally divided to provide at least two segments which are able to be heated to different temperatures so that said body has peripheral surfaces of different temperatures; a conduit (2) extending about said body so as to be in thermal contact with said peripheral surfaces; a first delivery device to deliver a first fluid to said conduit to cause said fluid to pass therealong and therefore change in temperature as the fluid passes said segments; and a second delivery device to deliver a second fluid to said conduit so as to flow with said first liquid and therefore also change in temperature. The fluid then leaves the device by conduit (4). The invention also is directed to an injector means for use in the thermal cycling device of this invention, comprising: a septum (26); a needle (20) which is able to pierce the septum; a reservoir (27) in fluid contact with septum (26) having an inlet (28) and an outlet (30); wherein when in use, the needle is urged through the fluid in said reservoir and then through the septum while continually purging the reservoir with said purge fluid. The present invention also includes a scanning detector (5) fitted to the outside of the heat exchange body (3) which monitors the course of reaction inside the conduit (2).

Owner:QIAGEN GMBH

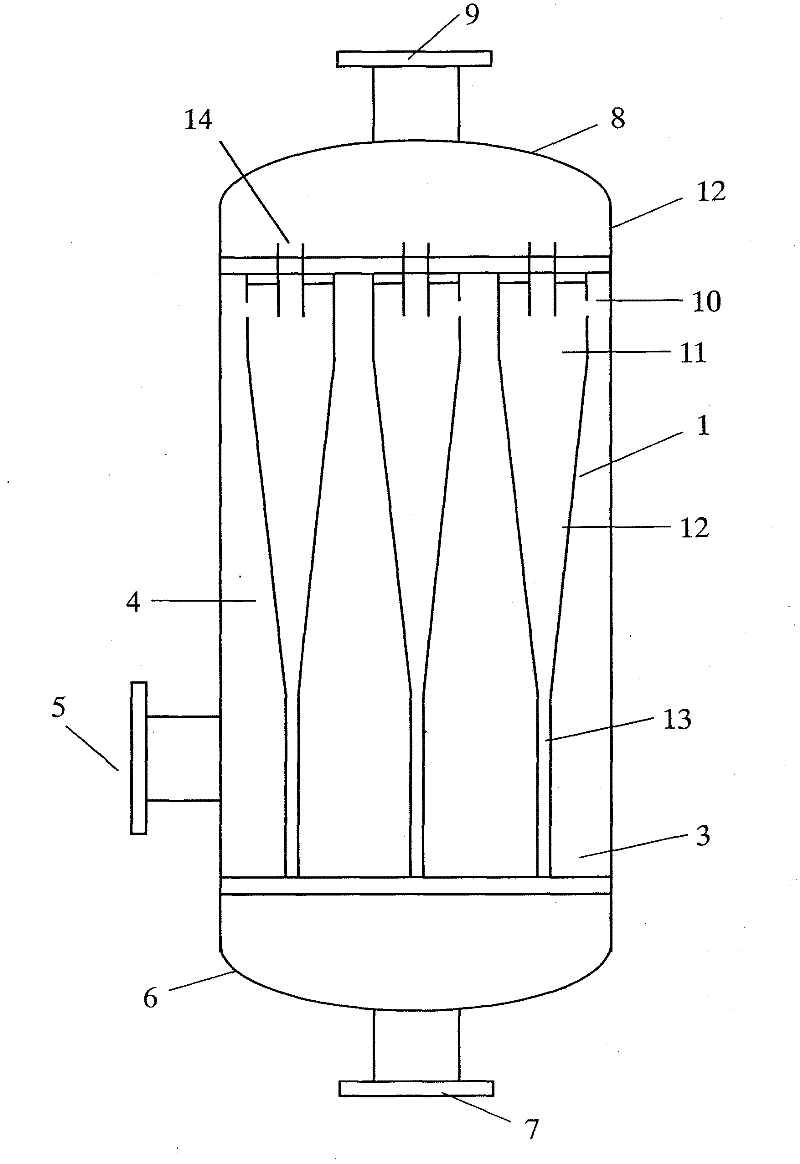

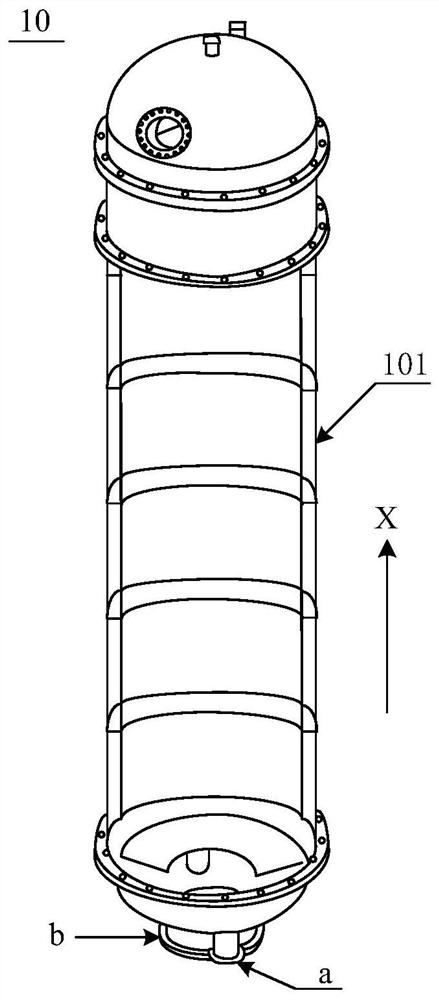

Flexible tube type solid-liquid processing machine with filtering, heat-exchange and hot compression function

InactiveCN1966129ALow costSimplify equipment componentsSemi-permeable membranesStationary filtering element filtersSlagEngineering

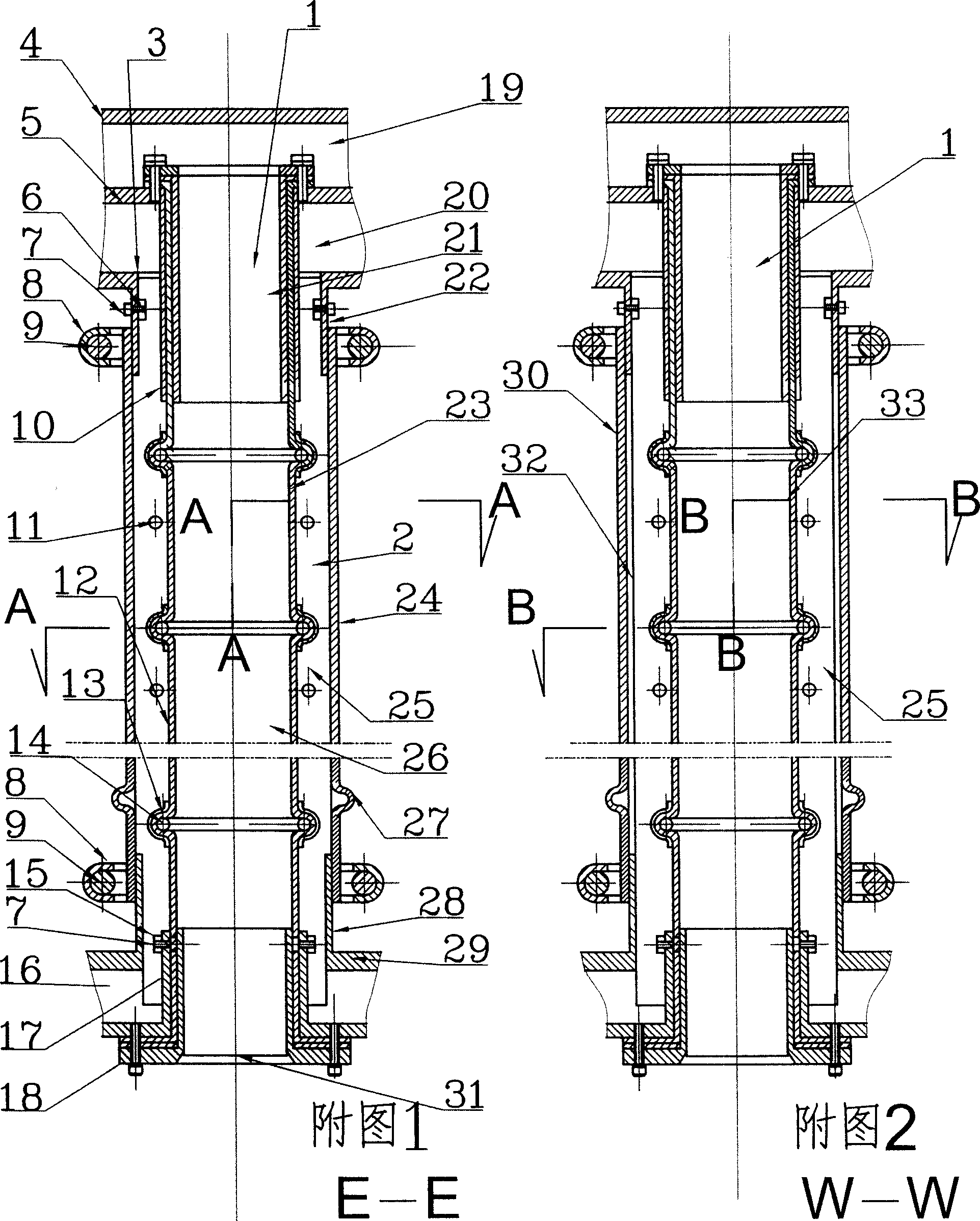

The invention relates to a flexible tubular solid liquid processor, with filter, heat exchange and thermal extraction functions, wherein the filter element at least comprises one flexible tubular membrane unit, upper flange room and lower flange room; the hydraulic extracting system comprises pressure container, extract pump and tubes; the material liquid of container can be filtered by the tubular filter membrane of membrane unit, and said material liquid can be used as work medium to extract the concentrated material liquid in the filter room of membrane unit and discharge filter slag; the pressure container or the filter room of membrane unit can be filled with medium to exchange heat, to realize thermal filter or extraction; the filter element is arranged on the bearing base inside the pressure container; the filter rotator can rotate the filter element to realize cross-flow filter; and the invention can be arranged with gas or water reverse tube and vacuum filter tube; the slag discharge system comprises slag discharger or tubular inner / outer membrane scraper, or vibration slag discharger, or compression slag discharger.

Owner:张民良

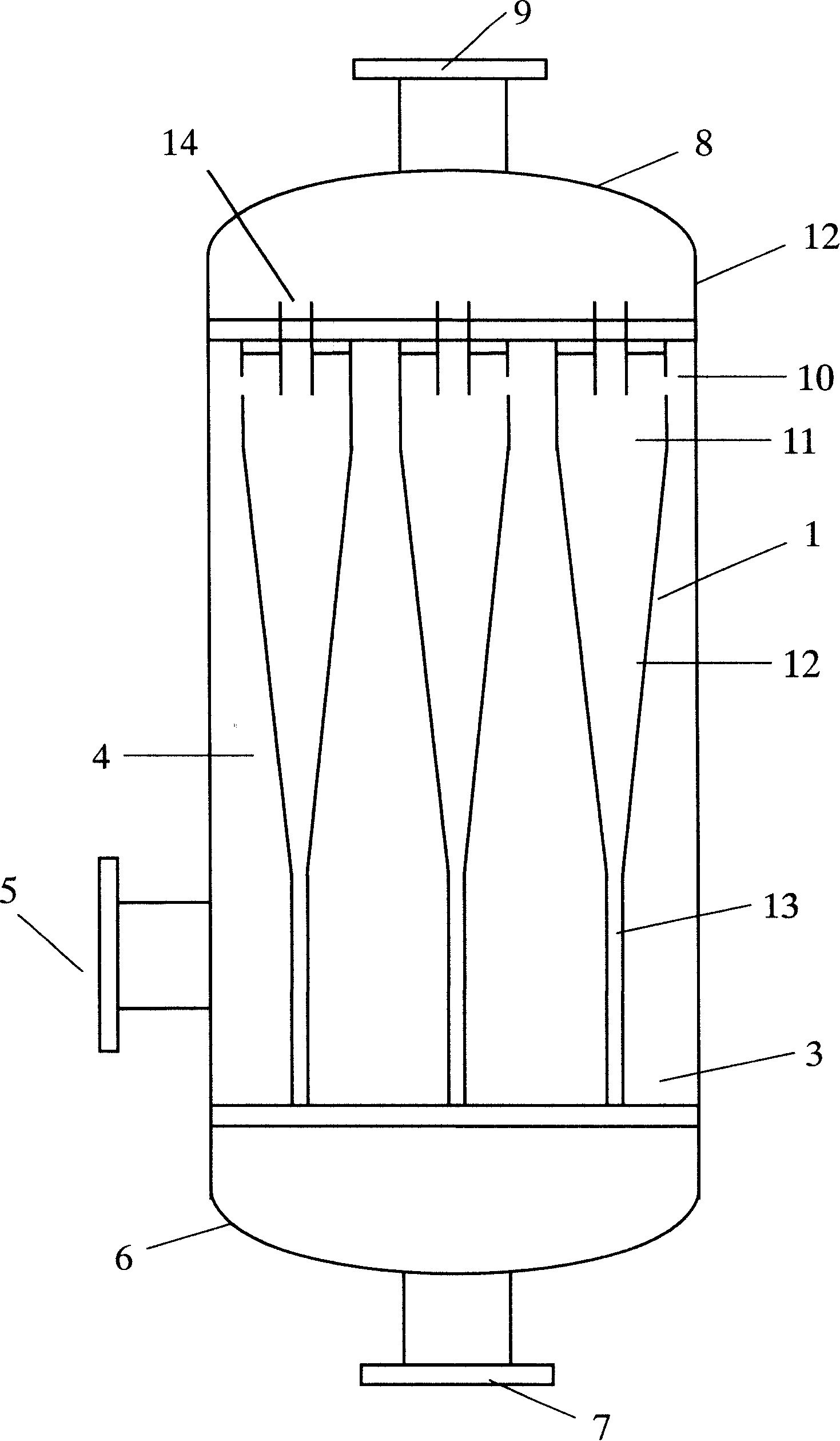

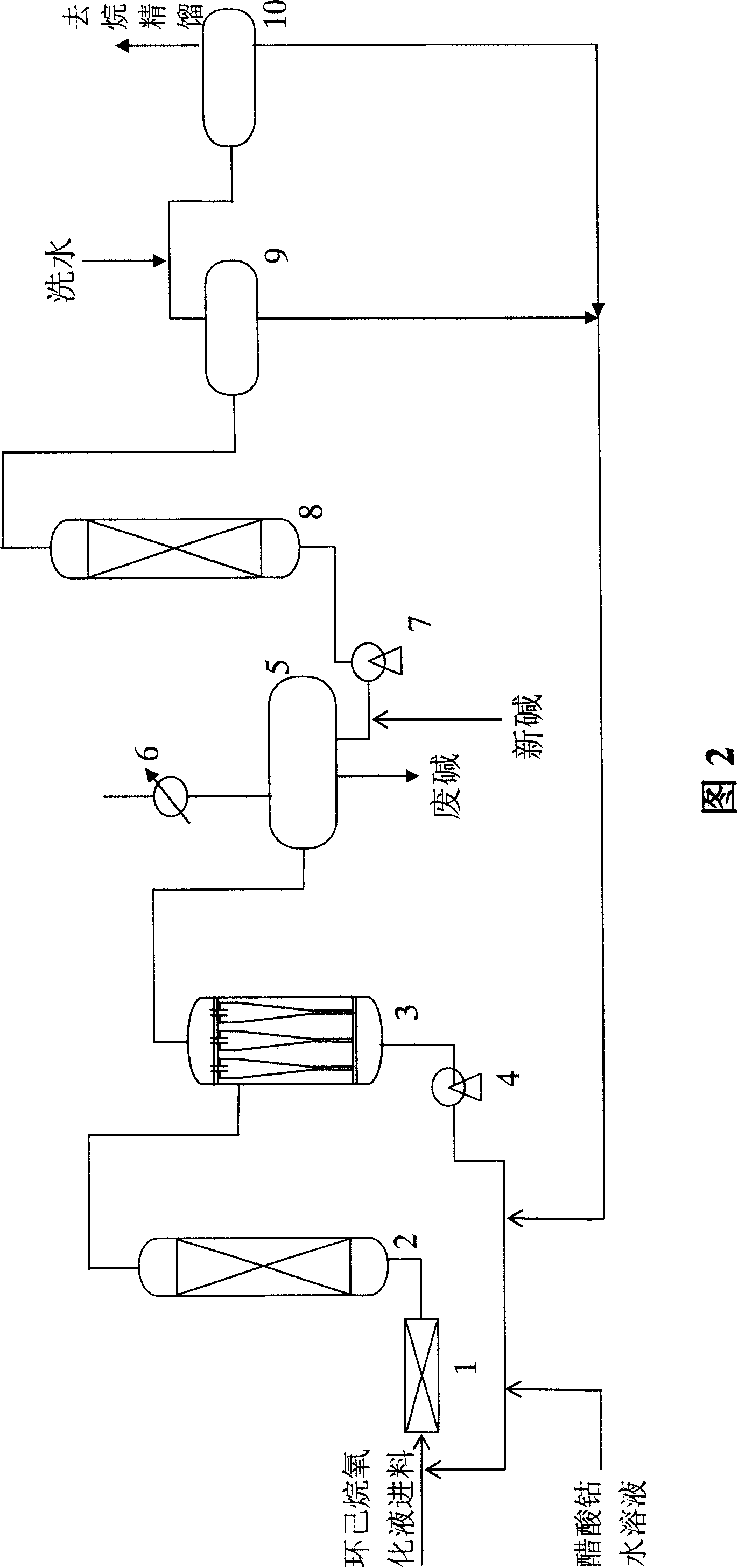

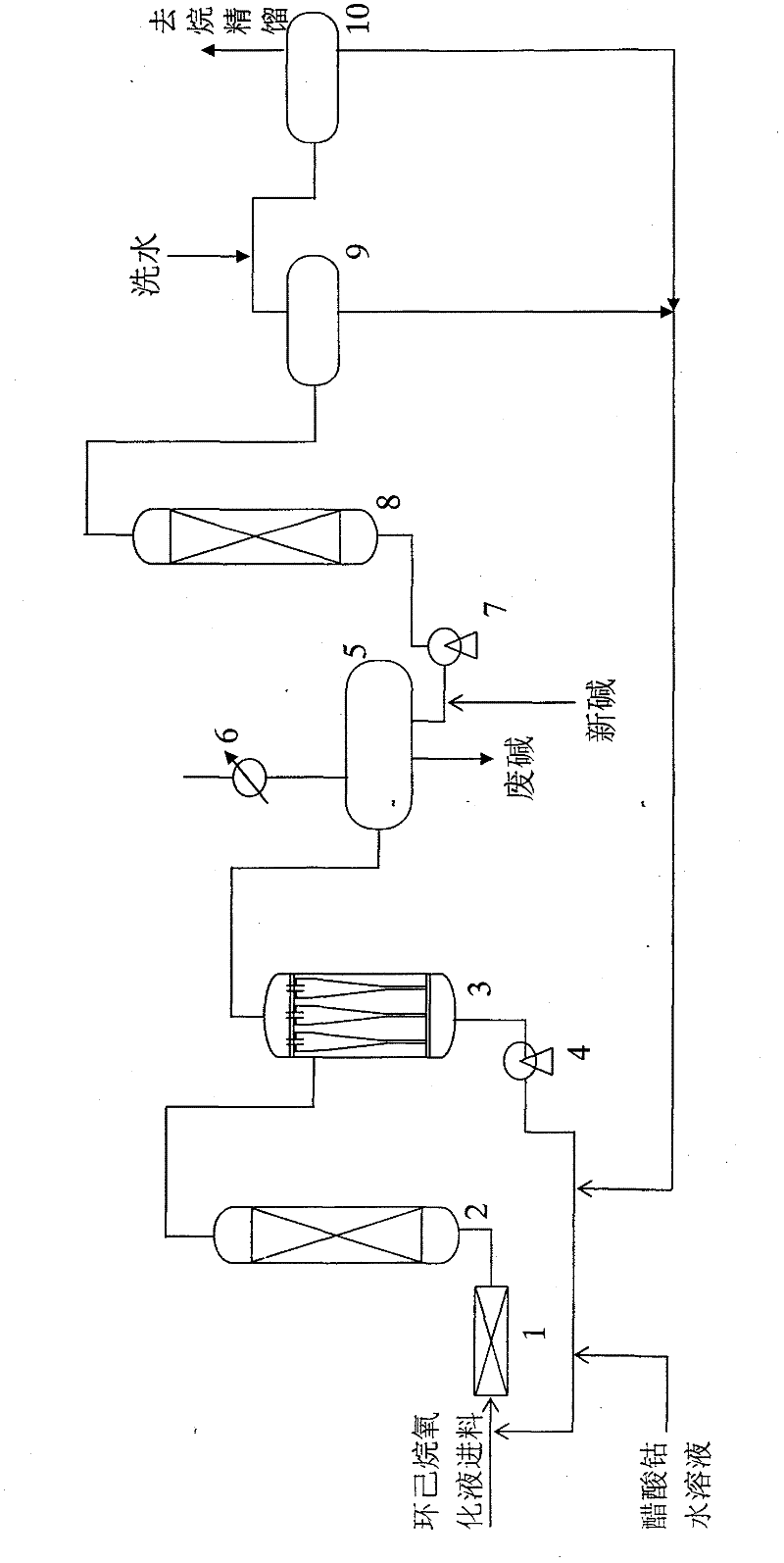

Improved process for producing cyclohexanol and pimelinketone

InactiveCN101172931AGood dispersionIncrease interface areaOxygen compounds preparation by hydrocarbon oxidationCyclohexanoneHydrogen peroxide breakdown

The invention discloses an improved method for preparing cyclohexanol and cyclohexanone. The invention is characterized in that the decomposition reaction of cyclohexyl peroxide is accomplished with two steps; during the first decomposition reaction, the flow of circulated alkaline is equal to or larger than that of cyclohexane oxydic liquid, thereby ensuring the alkaline water phase to become a continuous phase of the material in the first decomposition reaction; the cyclohexane phase is dispersed; the decomposition reaction is accomplished under an emulsification state, or is called even phase decomposition; the compound from the decomposition reaction is rough separated through a hydrocyclone separator; a large amount of alkaline liquid is separated from the lower outlet of the hydrocyclone separator to be recycled; the material of cyclohexane from the upper outlet of the hydrocyclone separator is changed to the continuous phase, while little alkaline liquid is changed into the dispersing phase; the waste alkaline liquid is separated by lifting a separation groove through gravity; the second decomposition reaction is then accomplished to ensure a full decomposition reaction. With the technical improvement, the total mol yield of the oxidation of cyclohexane prepared cyclohexanol and the cyclohexanone device is increased by 5 percent.

Owner:肖藻生

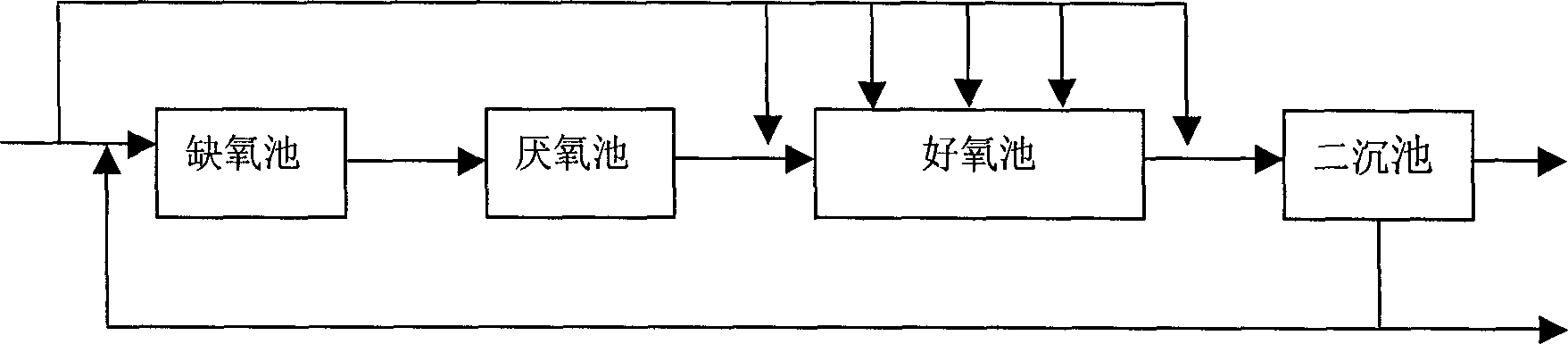

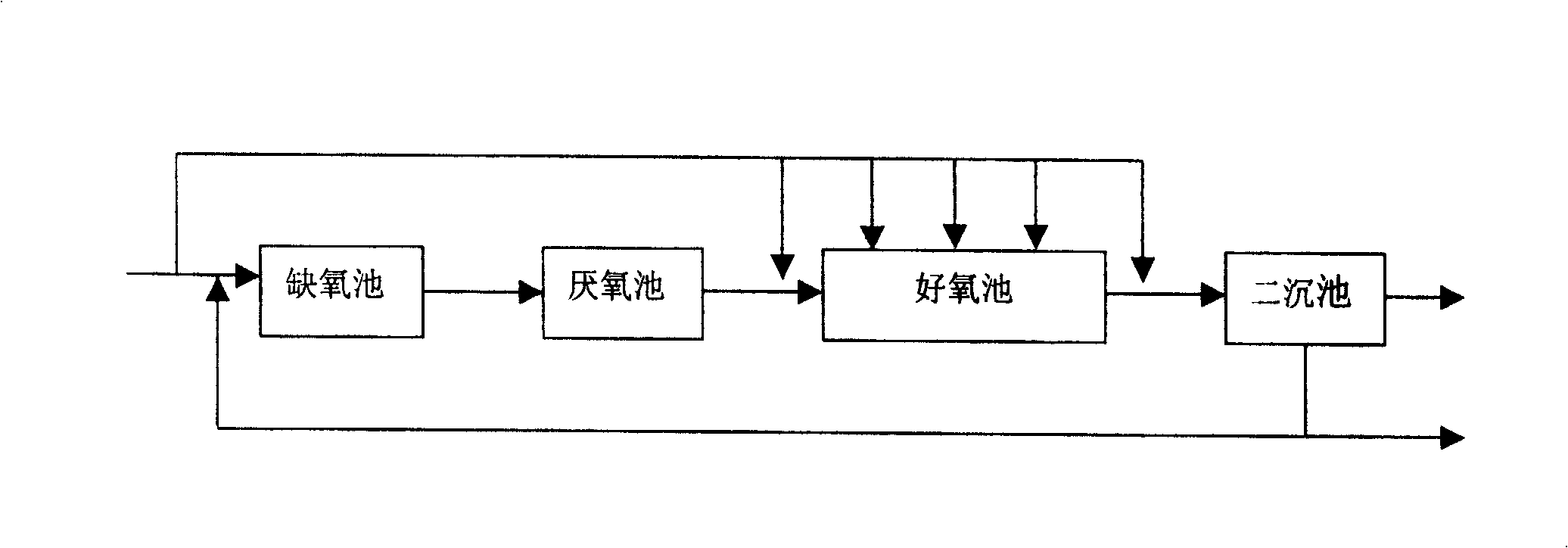

High efficiency nitrification process of biological sewage treatment

InactiveCN1772655AShorten the aeration timeSimple processTreatment with aerobic and anaerobic processesMunicipal sewageNitrification

The present invention is high efficiency nitrification process of biological sewage treatment, especially suitable for city sewage treatment. The sewage treating process includes shunting sewage in certain ratio, treating partial sewage in no-aeration tank comprising anoxic tank and anaerobic tank, making partial sewage enter to the aerobic tank directly, mixing the sewage from the no-aeration tank and the directly entering sewage and aerating in the aerobic tank, and final solid-liquid separation in the secondary settling tank. Compared with available technology, the present invention has the features of short treating period, high efficiency, simple technological process, high denitrification effect, etc.

Owner:CHINA UNIV OF MINING & TECH

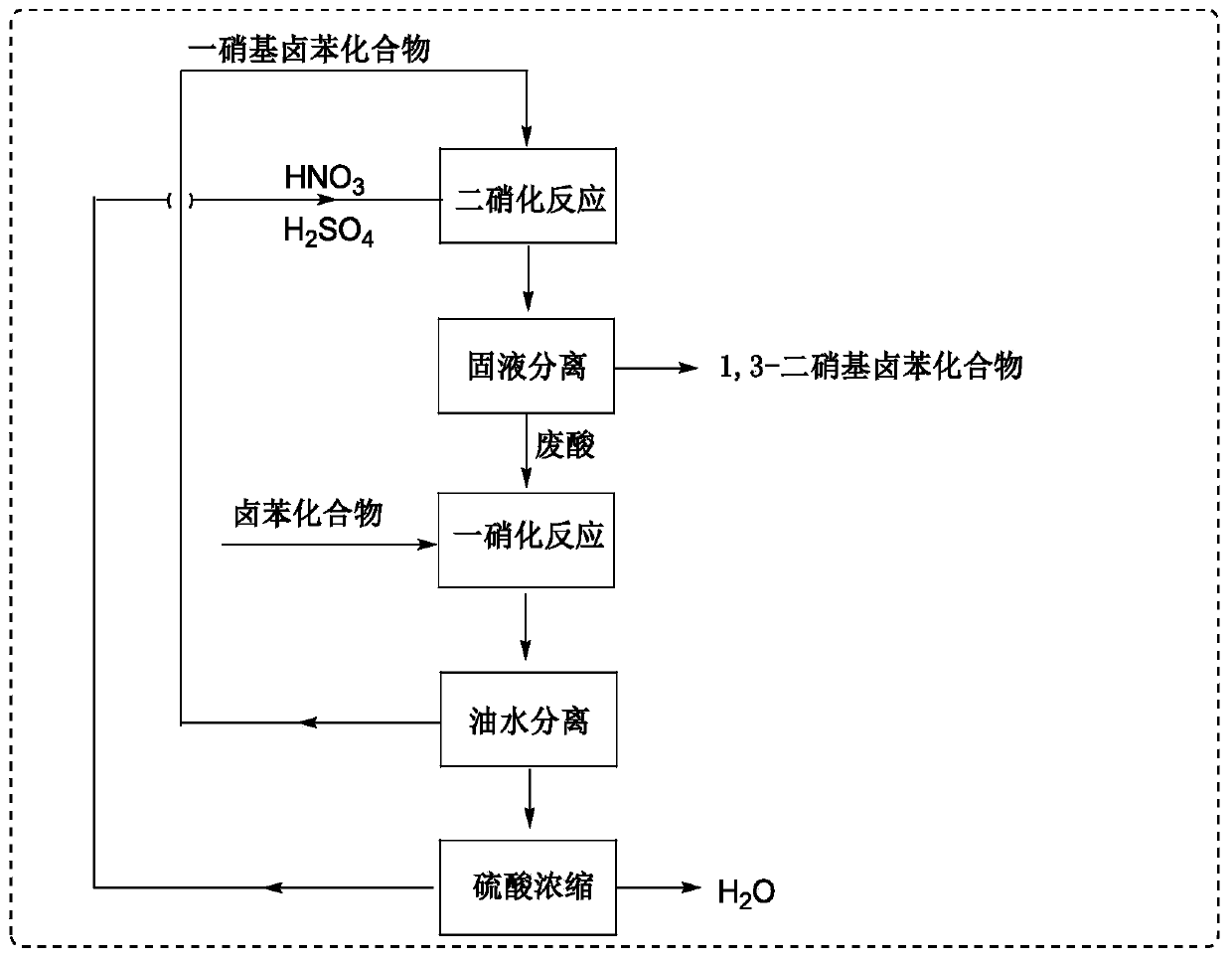

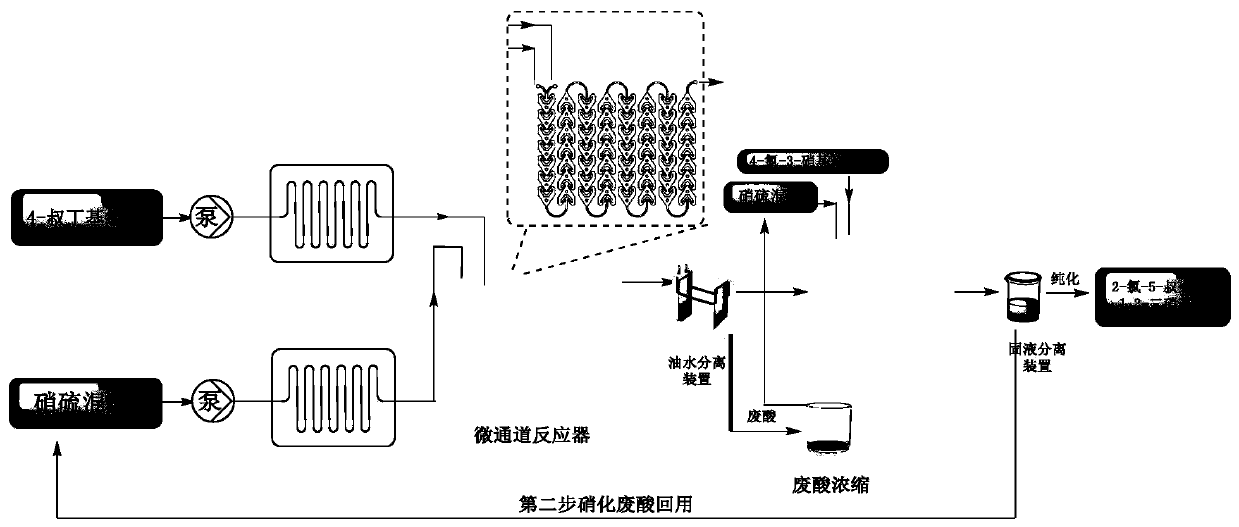

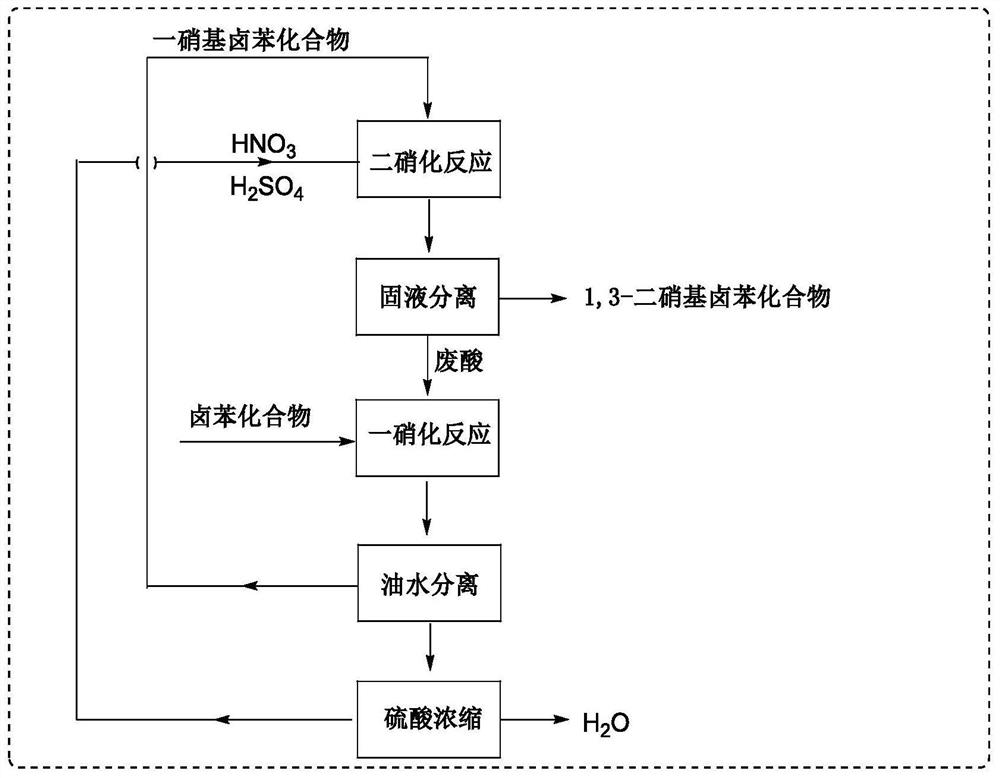

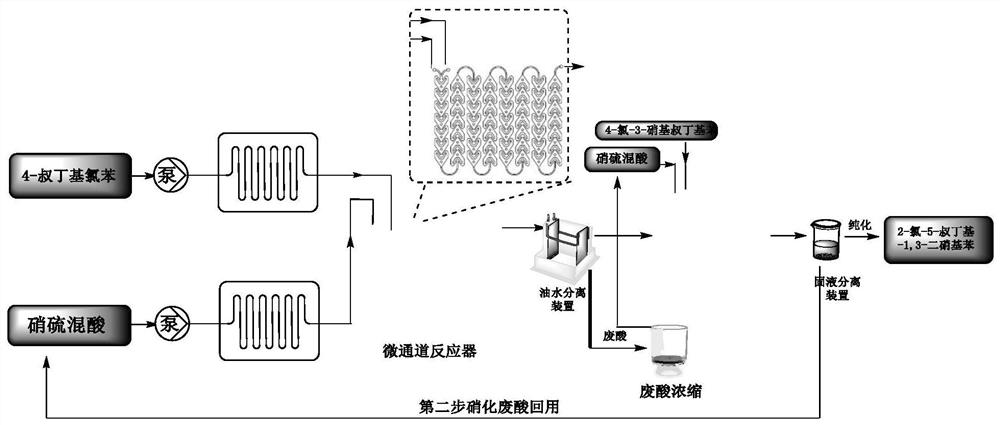

Method for synthesizing 1,3-dinitrohalobenzene compound

ActiveCN109970566ADropping time is longLong reaction heatSequential/parallel process reactionsChemical/physical/physico-chemical microreactorsMicroreactorNitration

The invention provides a method for synthesizing a 1,3-dinitrohalobenzene compound. The method comprises the following steps that A) a halogenated benzene compoundand mixed acid of nitric acid and sulfuric acid are subjected to a first nitrification reaction in a first-stage continuous flow microreactor, and oil-water separation is conducted to obtain a mononitrohalobenzene compound and first waste acid; B) the mononitrohalobenzene compound is drained into a second-stage continuous flow microreactor, a second nitrification reaction is conducted with the mixed acid of the nitric acid and the sulfuric acid, a generated nitration mixture is quenched at the outlet of the second-stage continuous flow microreactor, and filtering is conducted to obtain the 1,3-dinitrohalobenzene compound and second waste acid; C) the second waste acid is recycled to the first-stage continuous flow microreactor, a third nitration reaction with the halobenzene compound is carried out, the oil-water separation is conducted to obtain the mononitrohalobenzene compound and third waste acid, and steps B) and C) are repeated; the halobenzene compound has a structure shown in the formula I. The reaction time is short, the waste acid is less, and continuous production is achieved.

Owner:SHANDONG HIMILE CHEM TECH

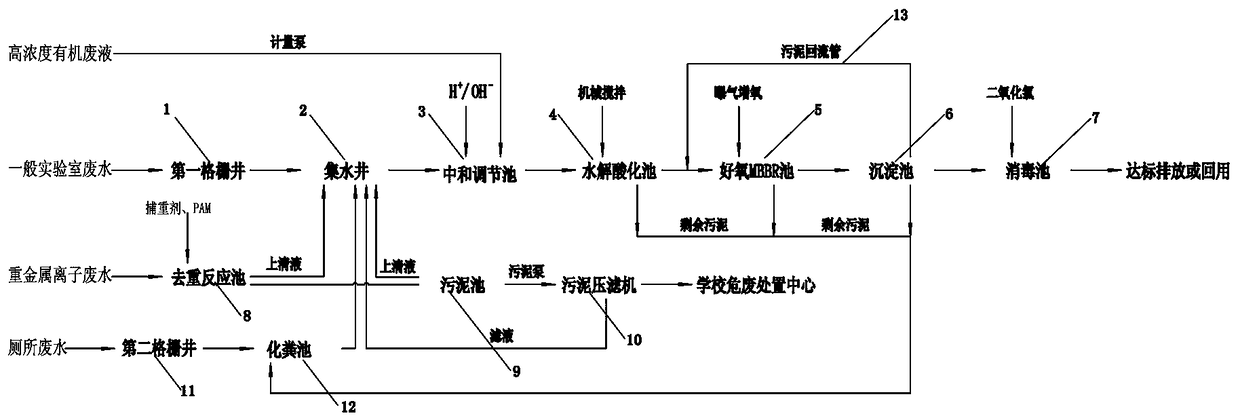

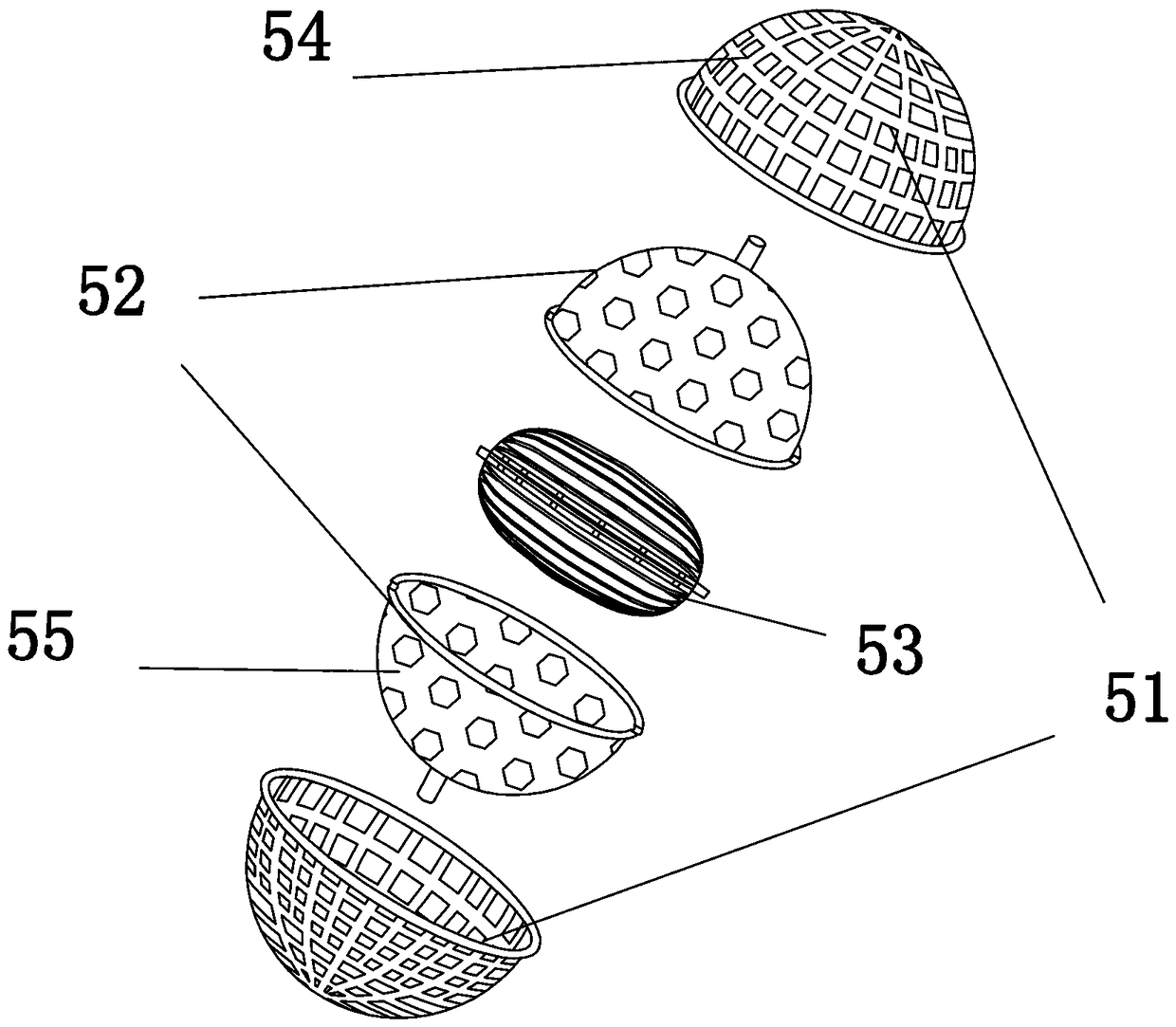

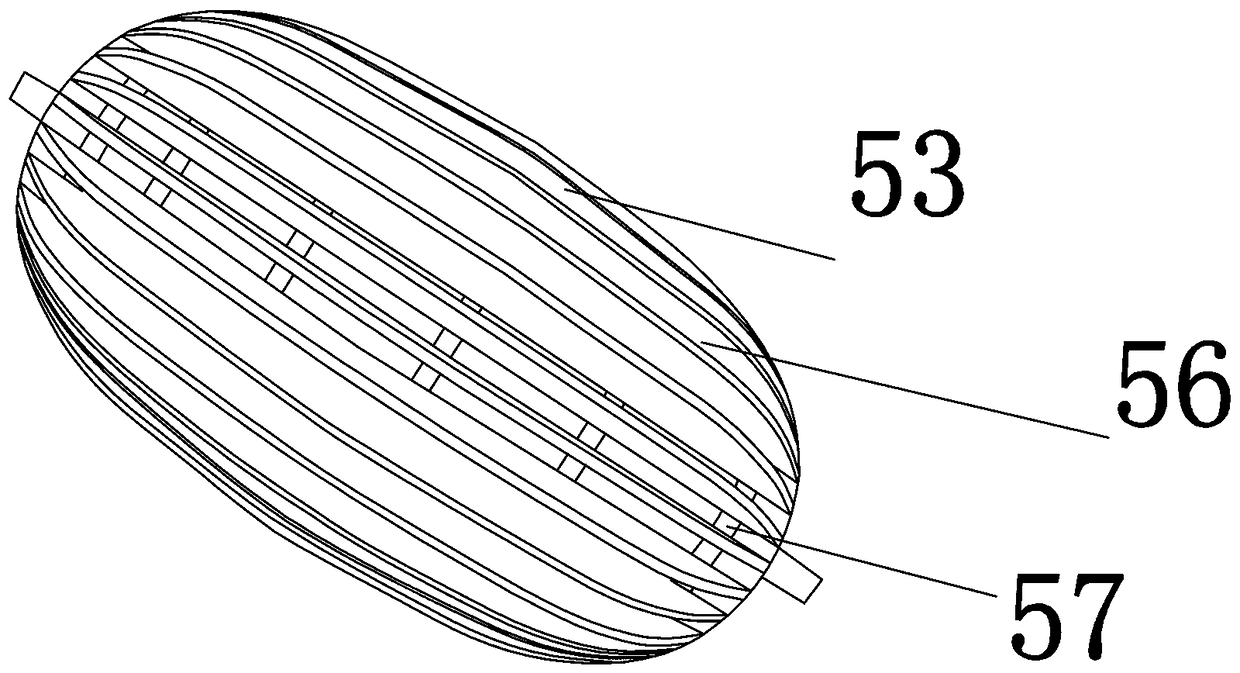

System and method for comprehensive laboratory wastewater treatment

InactiveCN109020049AEasy to handleSmall footprintSludge treatment by de-watering/drying/thickeningTreatment involving filtrationHigh concentrationActivated carbon

The invention discloses a system for comprehensive laboratory wastewater treatment. The system comprises a pretreatment unit, a neutralizing and equalizing tank, a hydrolysis-acidification tank, an aerobic MBBR tank, a sedimentation tank and a disinfection tank which are sequentially connected, and a spherical suspended biofiller and powdered activated carbon are added into the aerobic MBBR tank,wherein the pretreatment unit comprises four treatment channels which are a high-concentration organic waste liquid channel, a general laboratory wastewater channel, a heavy metal ion wastewater channel and a toilet wastewater channel respectively. The system and a method for comprehensive laboratory wastewater treatment adopt a classification collection, hydrolysis acidification, aerobic MBBR andchlorine dioxide disinfection treatment process. The method can greatly improve the treatment effect of laboratory wastewater and reduce the construction and operation cost of sewage treatment facility, and is a new laboratory wastewater treatment process worthy of promotion.

Owner:ZHEJIANG WORLD CLEAN ENVIRONMENT ENG CO LTD

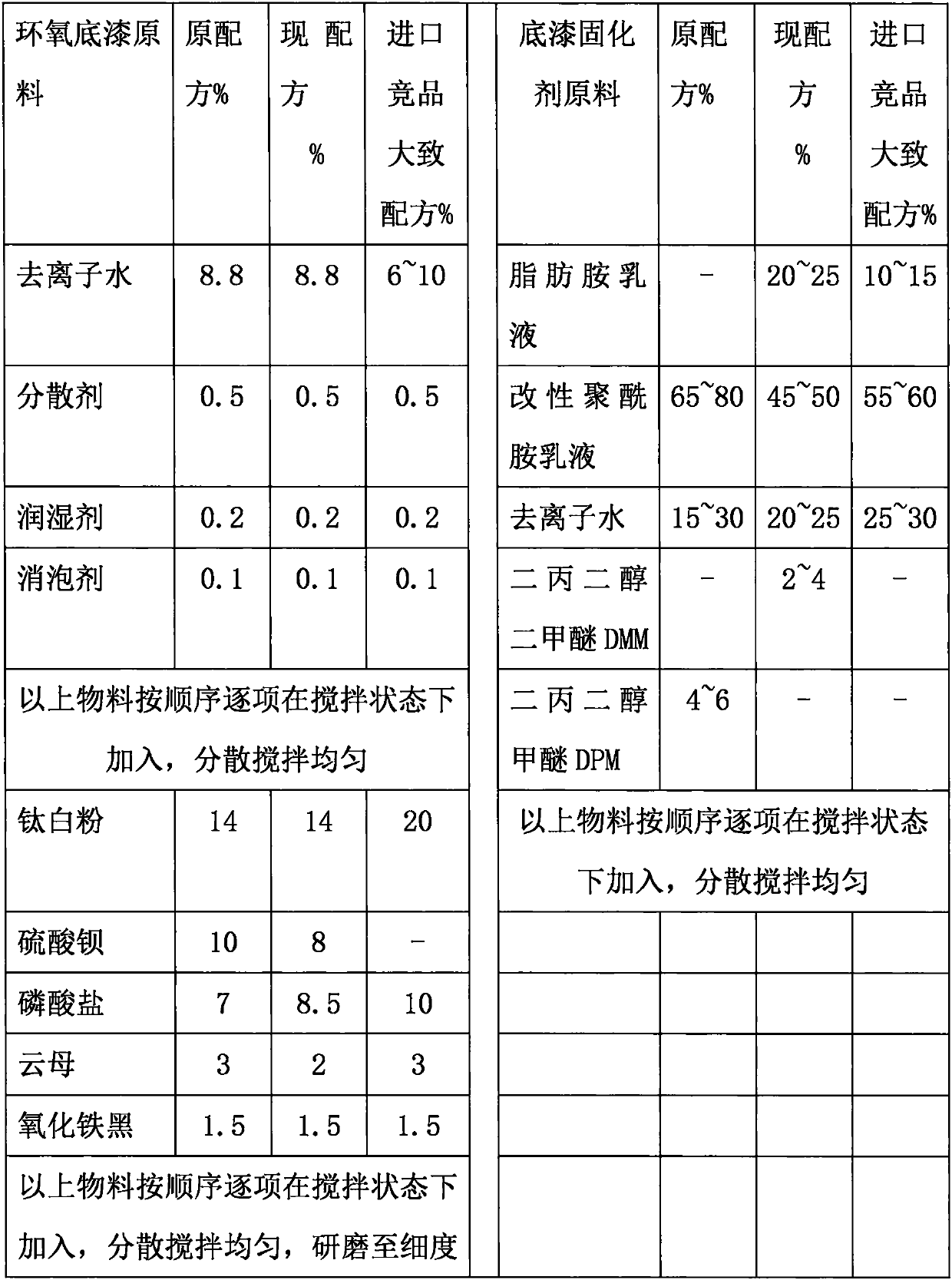

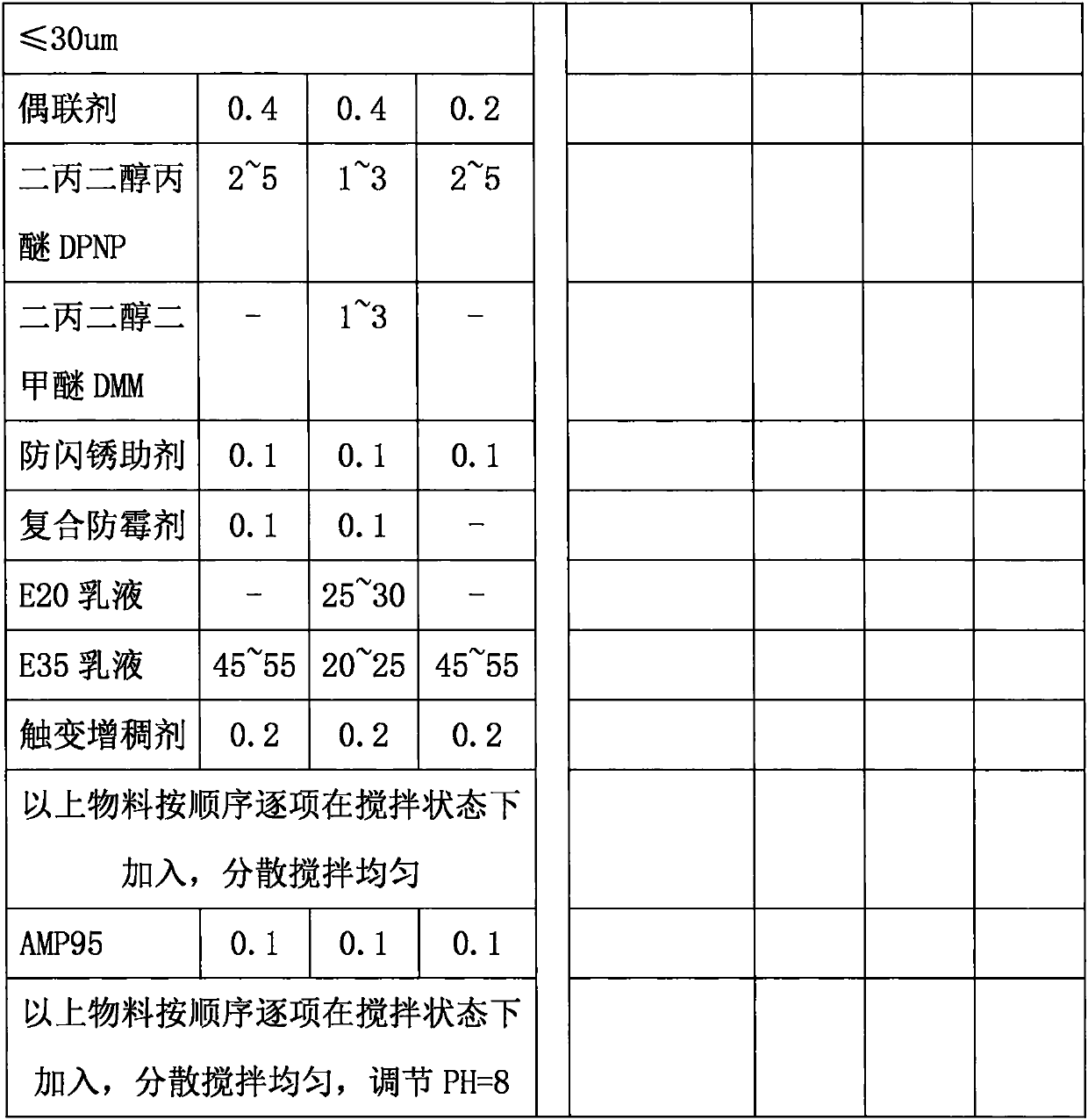

Special two-component water-based paint for buses and coating process of two-component water-based paint

InactiveCN110551437ALow VOCImprove film formationPretreated surfacesAnti-corrosive paintsWater basedEpoxy

The invention provides special two-component water-based paint for buses. The special two-component water-based paint comprises a two-component water-based epoxy primer, two-component water-based intermediate paint and two-component water-based finishing paint. While maintaining the original physical and chemical properties without reducing, compared with traditional solvent-based bus paint, the use of organic solvents can be significantly decreased, and VOC is lowered; compared with existing water-based bus paint on the market, the flash drying time can be shortened, the production pace is speeded up, and the more efficient coating efficiency can be obtained.

Owner:上海时佳涂料有限公司

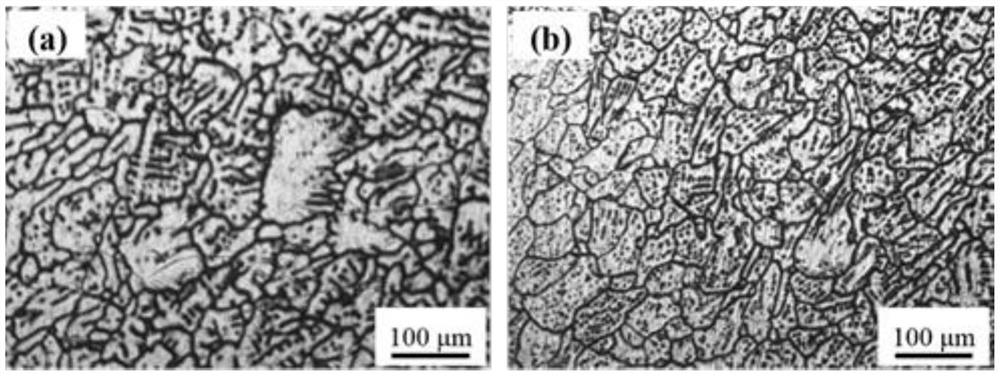

Preparation method of high-strength stress-corrosion-resistant aluminum alloy profile

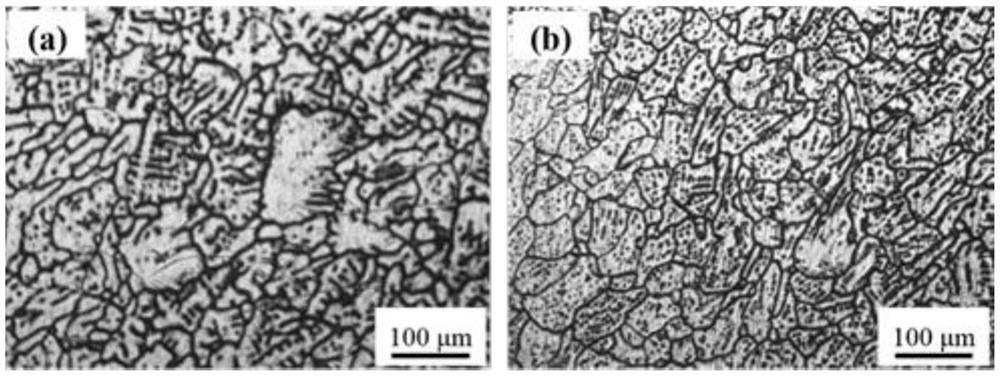

The invention relates to a preparation method of a high-strength stress-corrosion-resistant aluminum alloy profile. The preparation method comprises the following steps that a remelted refined aluminum ingot, cathode copper, a zinc ingot, a magnesium ingot, an aluminum-silicon intermediate alloy, an aluminum-manganese intermediate alloy, an aluminum-titanium intermediate alloy, an Al-10% Y intermediate alloy, an Al-5% Sc intermediate alloy and an Al-10% Sr intermediate alloy are smelted; then homogenization treatment is carried out, skin turning and saw cutting are carried out after cooling, and then heating treatment, extrusion forming treatment, solid solution quenching treatment, first-time stretching treatment, first-stage aging treatment, second-time stretching treatment, second-stage aging treatment and cooling are carried out to obtain the high-strength stress-corrosion-resistant aluminum alloy profile; and the speed of the second-time stretching treatment is slower than that of the first-time stretching treatment. The aluminum alloy profile treated by the method has the effects of improving the strength, plasticity and stress corrosion resistance, and the obtained aluminum alloy profile is high in surface quality and uniform and fine in structure.

Owner:JIANGSU UNIV OF TECH

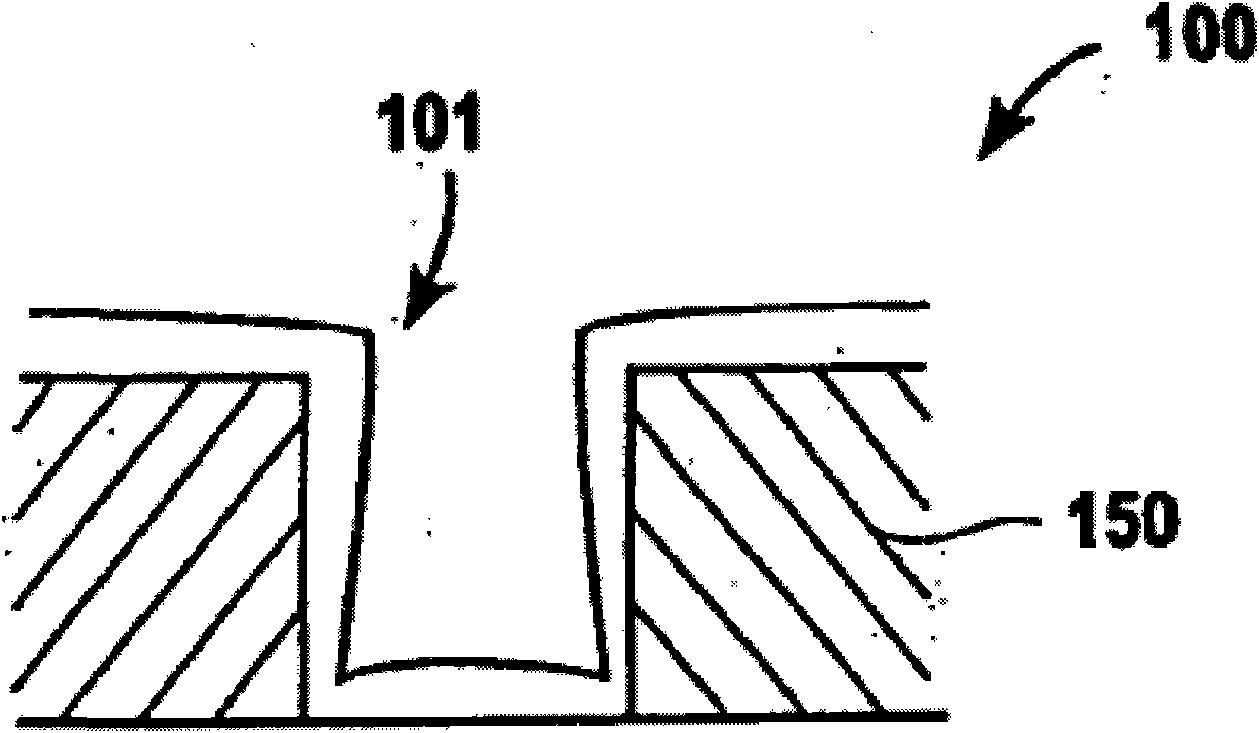

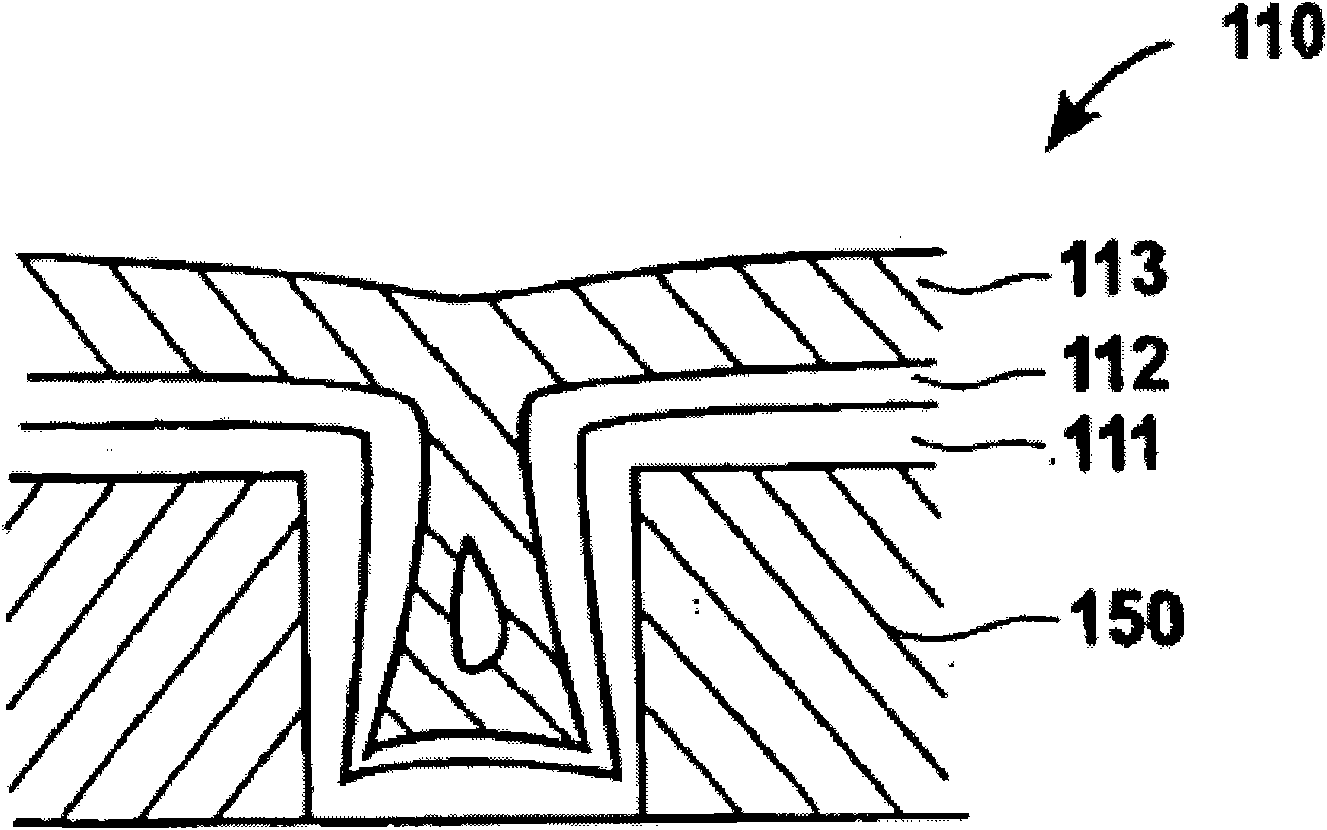

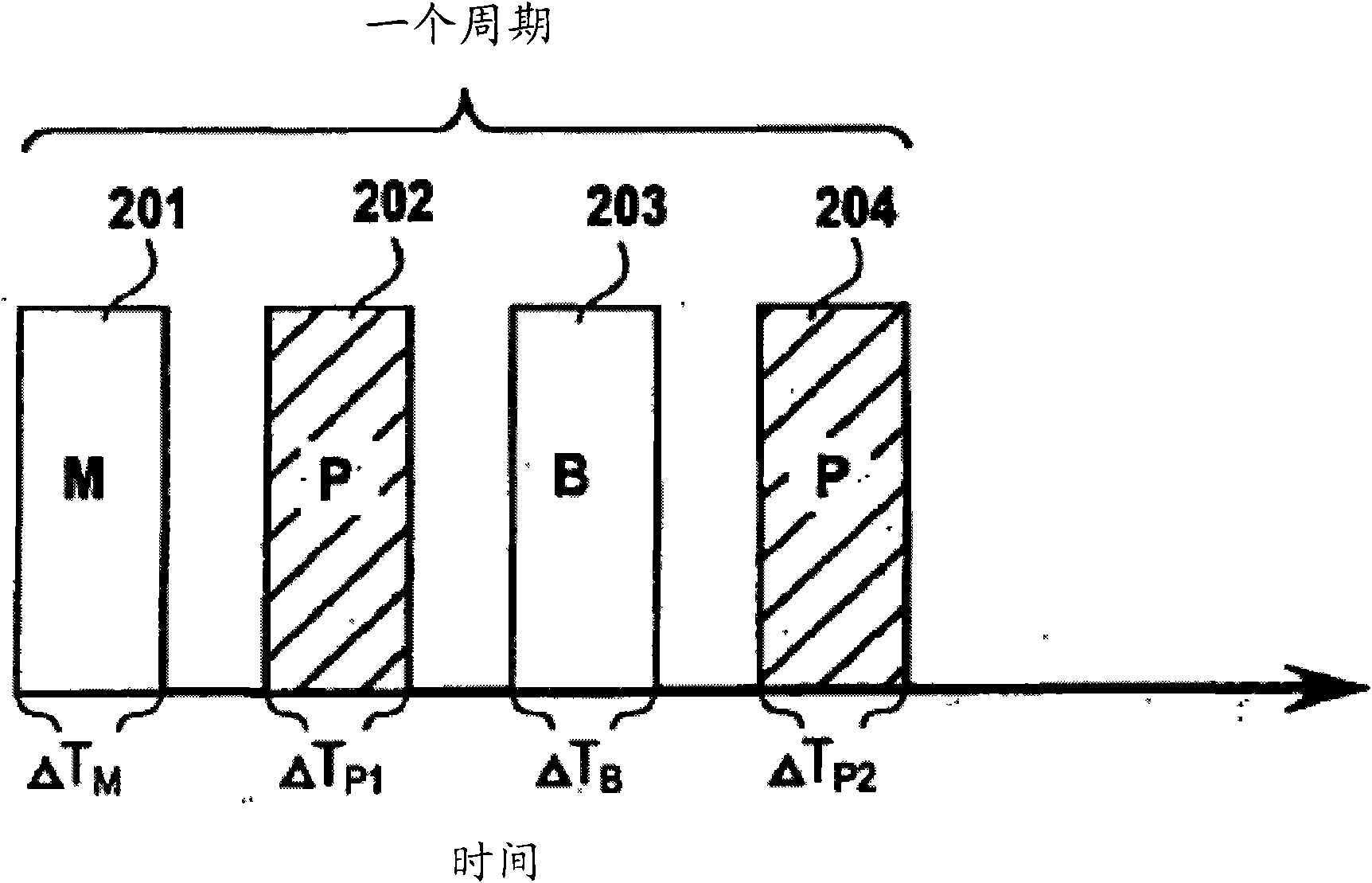

Apparatus and method for atomic layer deposition

InactiveCN101663734AReduce reaction volumeImprove throughputSemiconductor/solid-state device manufacturingChemical vapor deposition coatingProcess regionEngineering

The embodiments provide apparatus and methods of depositing conformal thin film on interconnect structures by providing processes and systems using an atomic layer deposition (ALD). More specifically,each of the ALD systems includes a proximity head (430) that has a small reaction volume right above an active process region of the substrate surface (410). The proximity head small amount of reactants and purging gas to be distributed and pumped away from the small reaction volume between the proximity head and the substrate in relatively short periods, which increases the through-put. In an exemplary embodiment, a proximity head for dispensing reactants and purging gas to deposit a thin film by atomic layer deposition (ALD) is provided. The proximity head is configured to sequentially dispensing a reactant gas (445, 443) and a purging gas (441) to deposit a thin ALD film under the proximity head. The proximity head covers an active process region of a substrate surface. The proximity head also includes at least one vacuum channel (465) to pull excess reactant gas, purging gas, or deposition byproducts from a reaction volume (450) between a surface of the proximity head facing the substrate and the substrate. The proximity includes a plurality of sides, each side being configured to dispense either a reactant gas or a purging gas on the substrate surface underneath the proximityhead. Each side has at least one vacuum channel.

Owner:LAM RES CORP

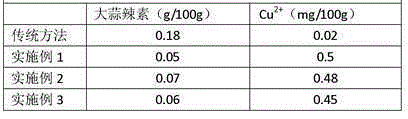

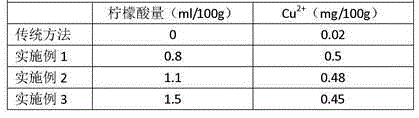

Rock sugar pickled garlic and preparation method thereof

The invention discloses rock sugar pickled garlic in garlic processing. The rock sugar pickled garlic comprises materials as follows: 100 parts of fresh garlic, 100-130 parts of purified water, 15-20 parts of salt, 15-20 parts of white granulated sugar, 0.2-0.3 parts of pyruvic acid, 1-2 parts of citric acid, 3-4 parts of honey and 2-3 parts of green tea powder. According to the prepared rock sugar pickled garlic, the garlic odor is reduced, further, the original spicy stimulation of the garlic is reduced, the edible feeling is enhanced, and the cupric ions required by a human body can also be supplemented.

Owner:WUCHUAN AUTONOMOUS COUNTY QINGXIANGYUAN VEGETABLE OIL FOOD CO LTD

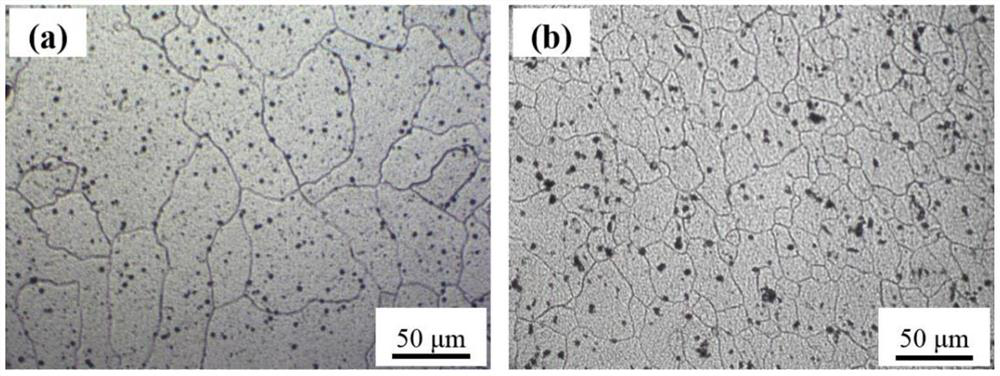

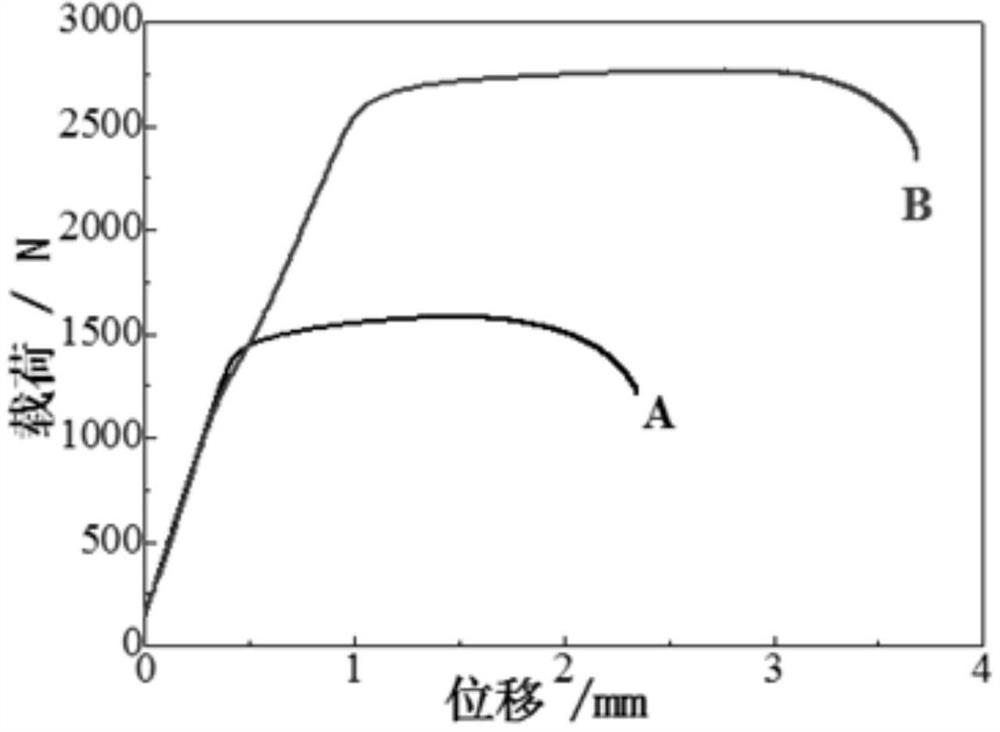

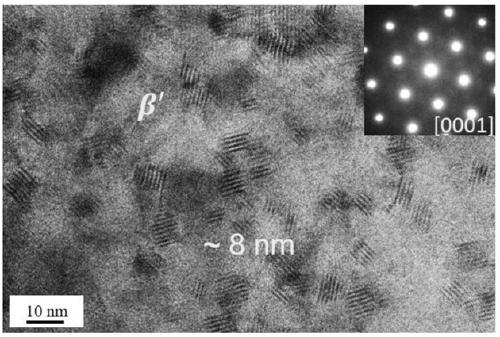

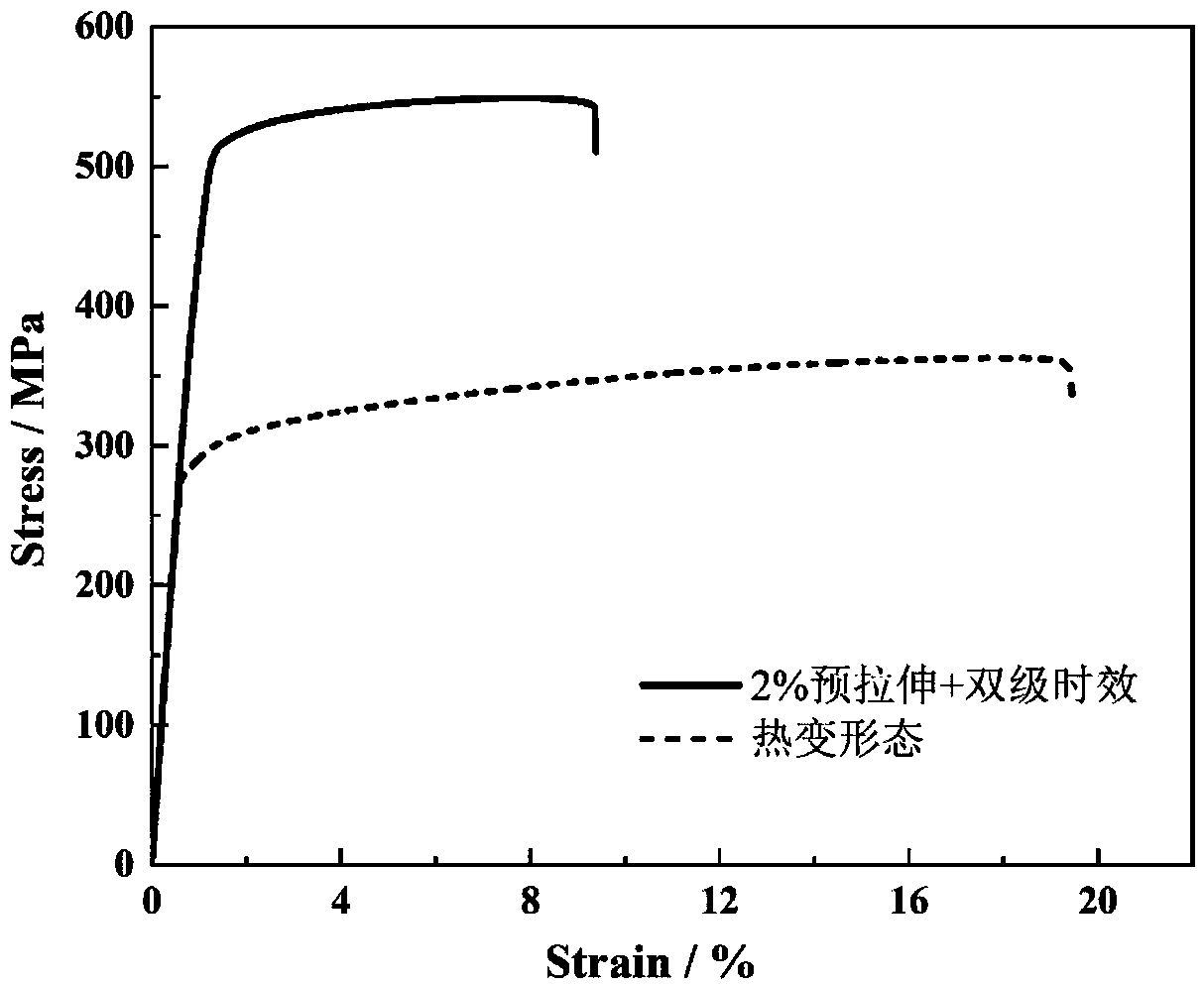

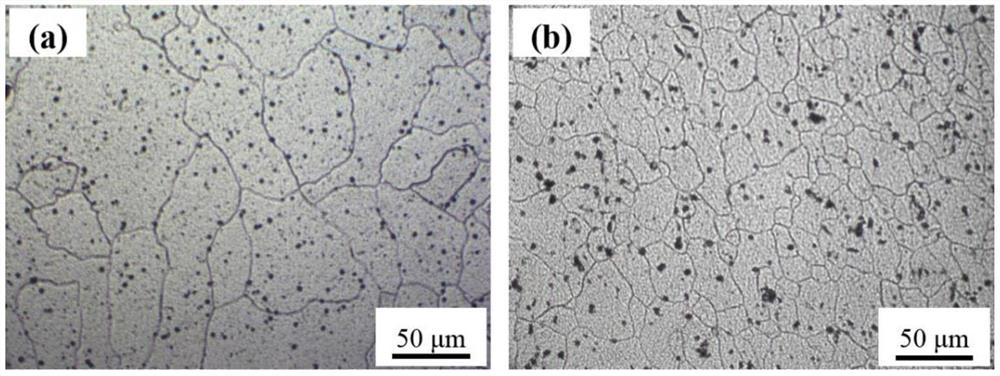

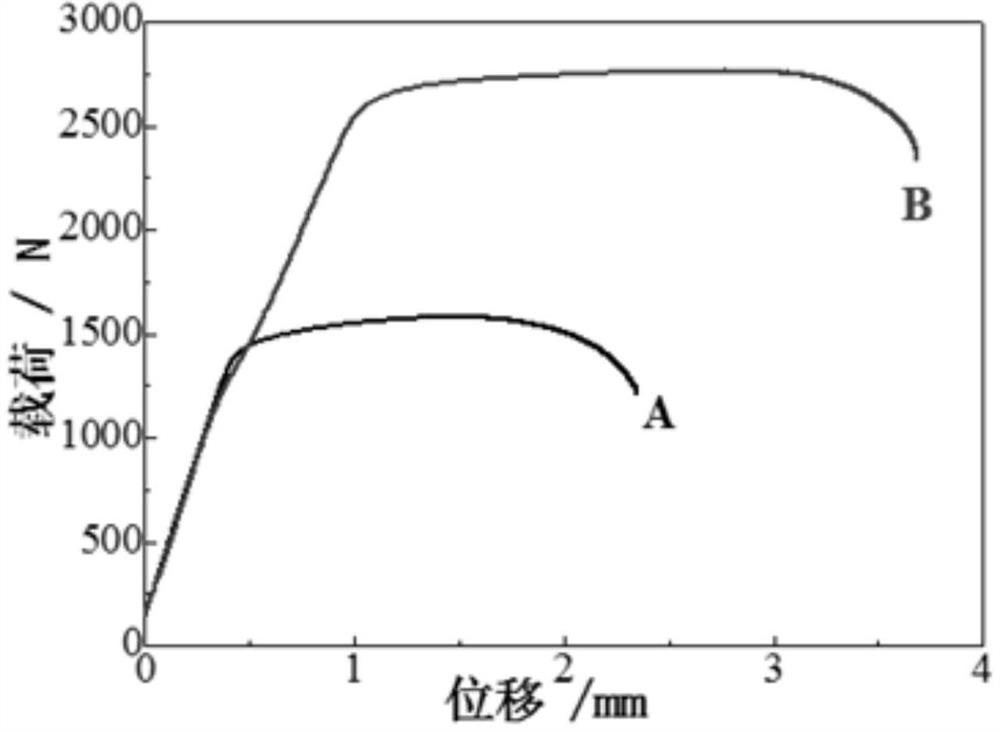

Ultrahigh-strength magnesium alloy preparation method adopting prestretching composite two-stage ageing technology

The invention discloses an ultrahigh-strength magnesium alloy preparation method adopting a prestretching composite two-stage ageing technology. The method comprises the steps that a thermal deformation magnesium alloy is subjected to prestretching deformation under a certain temperature, and the deformation is controlled to be within 0.5-20%; and then appropriate two-stage ageing treatment is performed, that is, water quenching cooling is performed after heat preservation is performed for 0.25-20 h under the temperature of 80-130 DEG C, then a sample is heated to 140-250 DEG C and subjected to heat preservation for 5-200 h, and an ultrahigh-strength magnesium alloy can be obtained. By means of the method provided by the invention, good plasticity can still be guaranteed while the yield strength of the magnesium alloy is effectively improved, equipment requirements are simple, and operation is easy; and the magnesium alloy with the excellent comprehensive mechanical performance can beprepared, and the industrial application prospects are wide.

Owner:BEIJING UNIV OF TECH

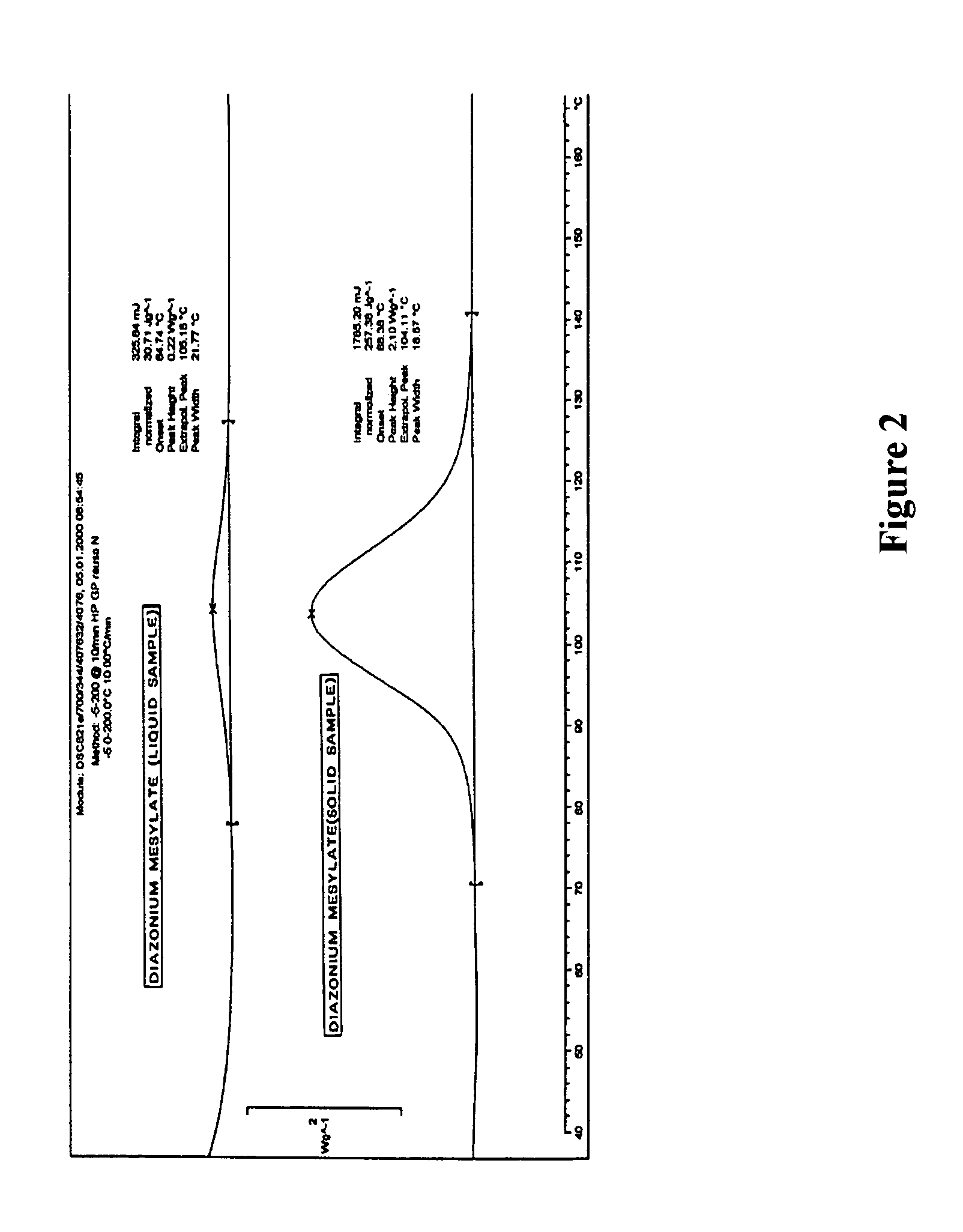

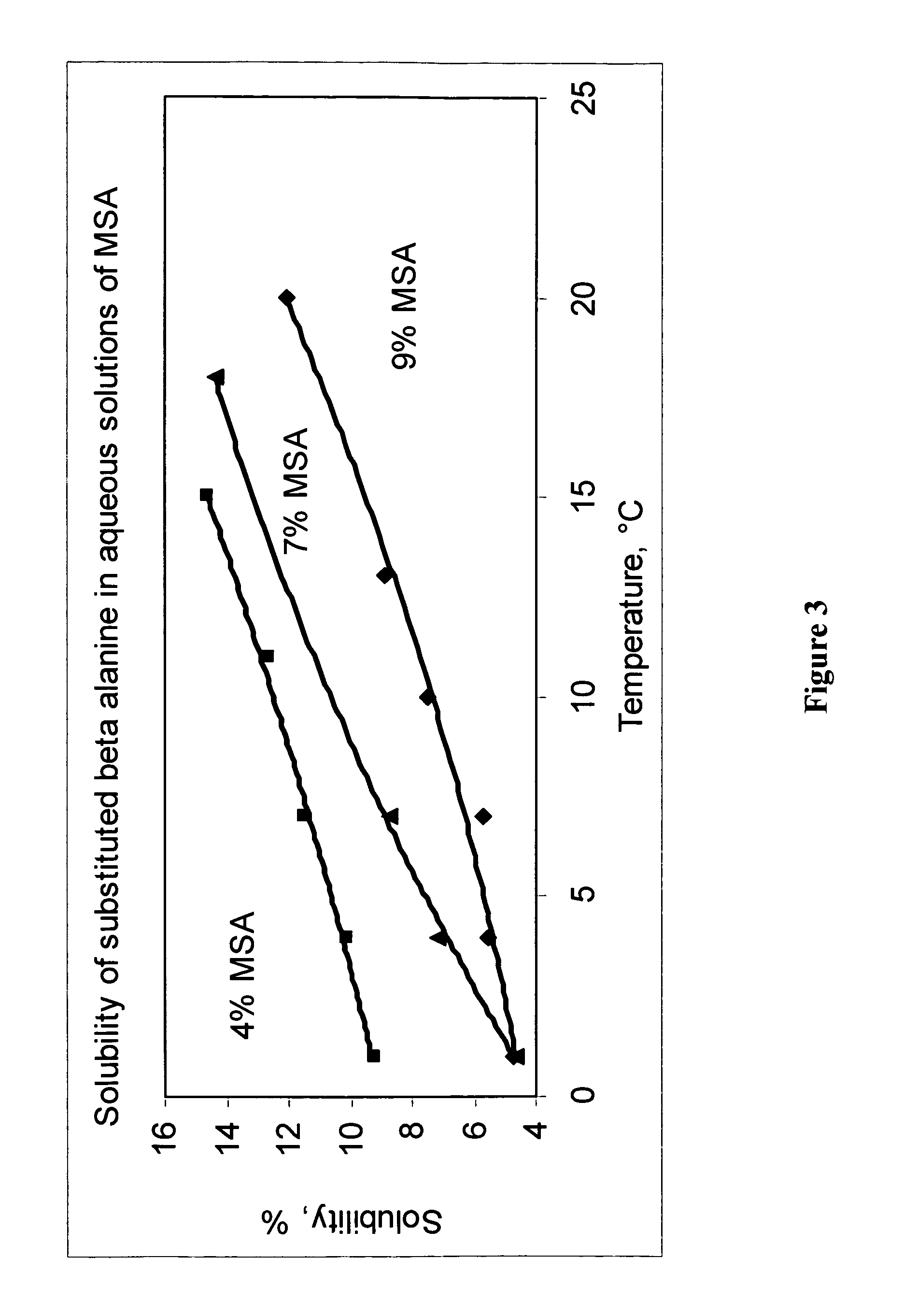

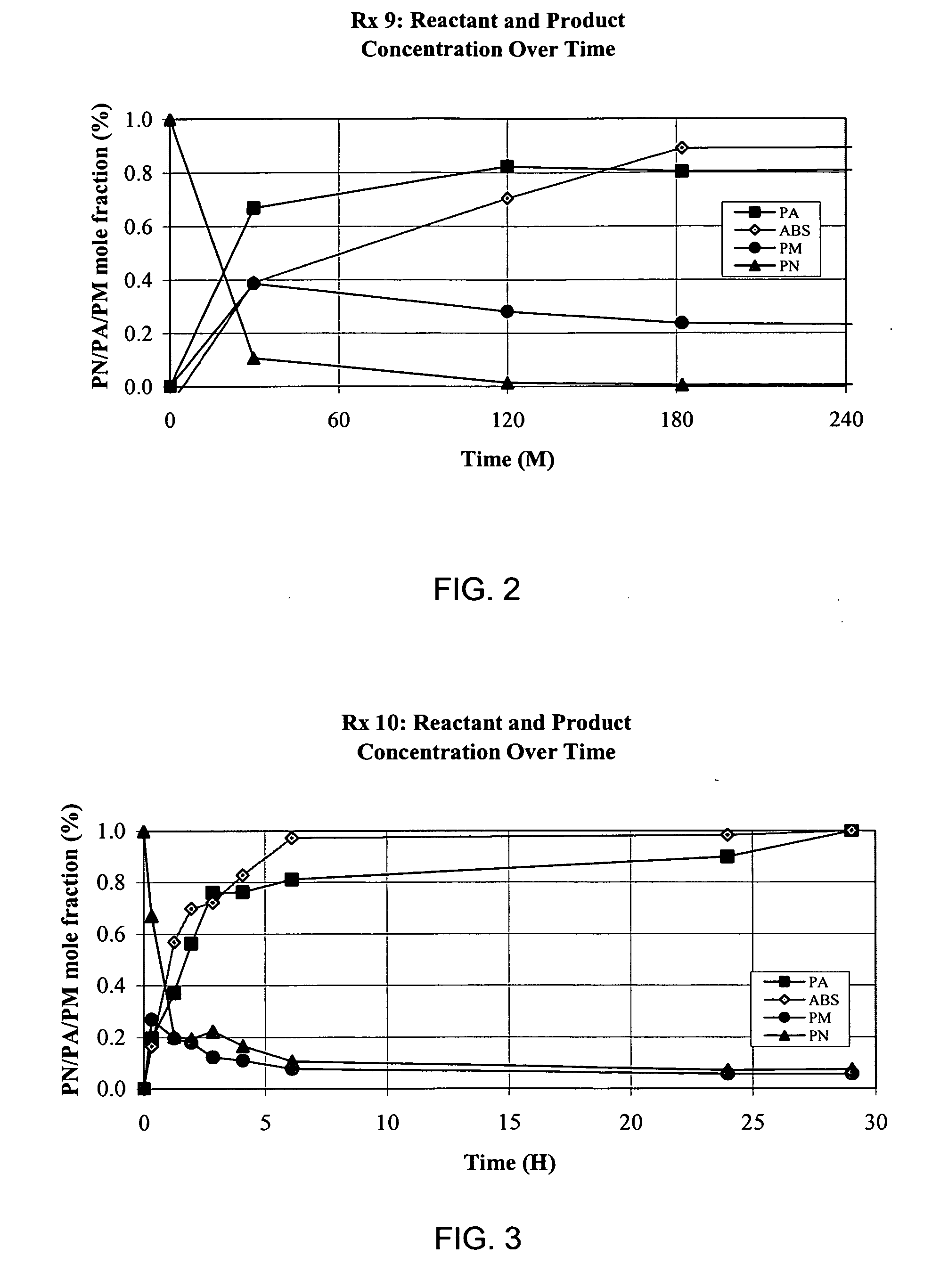

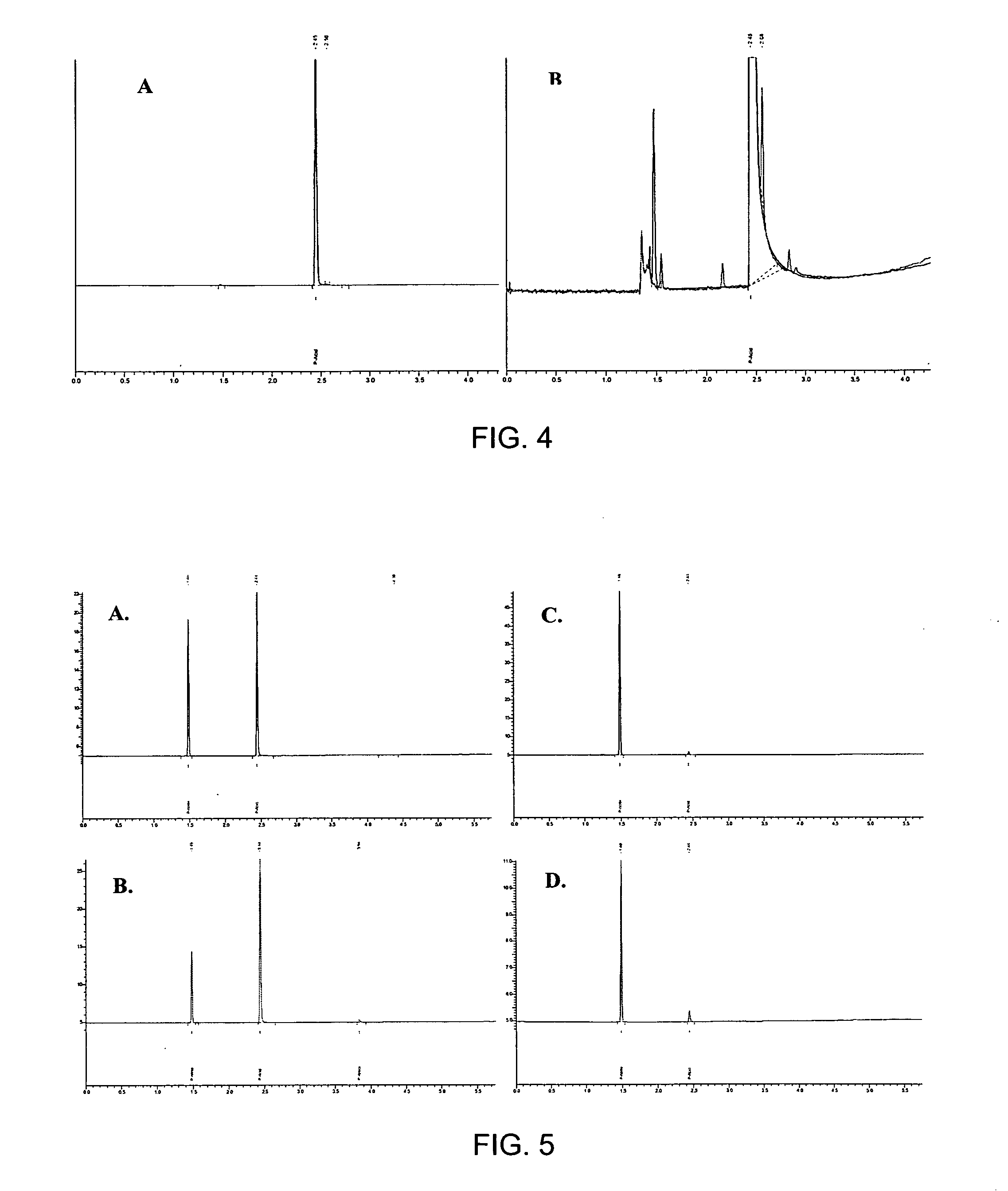

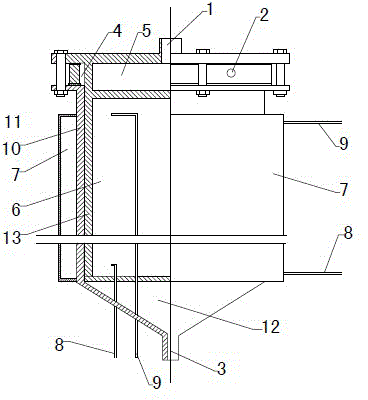

Safe process for the preparation of balsalazide

InactiveUS7271253B1Improve responseReduce solubilityMonoazo dyesOrganic chemistrySulfonateBalsalazide

A process for the preparation of Balsalazide and its pharmaceutically acceptable salts wherein the reaction comprises:a. the intermediate N-(4-aminobenzoyl)-β-alanine is converted to N-(4-ammoniumbenzoyl)-β-alanine sulfonate salt using a sulfonic acid in water,b. the N-(4-ammoniumbenzoyl)-β-alanine sulfonate salt is treated with aqueous sodium nitrite solution at low temperature to generate N-(4-diazoniumbenzoyl)-β-alanine sulfonate salt,c. the aqueous solution obtained is quenched with aqueous disodium salicylate to furnish Balsalazide disodium solution,d. the solution is acidified to allow isolation of Balsalazide, ande. optionally converting the Balsalazide to a pharmaceutically acceptable salt (such as disodium salt).

Owner:APOTEX PHARMACHEN INC

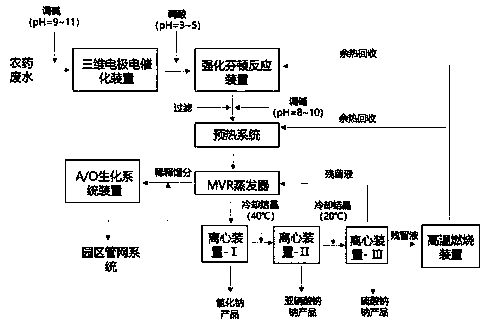

Method for disposing cymoxanil pesticide wastewater

InactiveCN110066077AImprove biodegradabilityGuaranteed uptimeWater contaminantsTreatment with aerobic and anaerobic processesFiltrationEvaporation

The invention relates to the field of advanced treatment of wastewater and provides a method for disposing cymoxanil pesticide wastewater. The method comprises the following steps that 1, solid sodiumhydroxide is utilized to perform alkali adjustment treatment on the cymoxanil wastewater; 2, after alkali adjustment, powdered activated carbon is added into the wastewater, stainless steel is used as a cathode, and graphite is used as an anode material to form a three-dimensional electrode to carry out an electrolytic catalytic reaction on the wastewater; 3, after the electrolytic catalytic reaction is finished, standing and filtering are carried out, and the acidity of a solution is adjusted by sulfuric acid after filtration; 4, after completion of an enhanced Fenton reaction, iron powder is filtered and recovered first, the pH is adjusted to be 8-9, standing is carried out, a supernatant is taken and placed into a preheating system, and the wastewater is conveyed into an evaporator forevaporation; 5, fractions obtained during evaporation are diluted with effluent of an A / O biochemical system and then subjected to biochemical treatment, and the wastewater after A / O biochemical treatment directly enters a garden pipe network system; 6, a residual liquid after evaporation is centrifuged and dried to obtain a sodium chloride product, a sodium nitrite product and a sodium sulfate product; 7, the remaining residual liquid is burned at the high temperature, and residual heat is recovered.

Owner:QUANZHOU INST FOR ENVIRONMENTAL PROTECTION IND NANJING UNIV

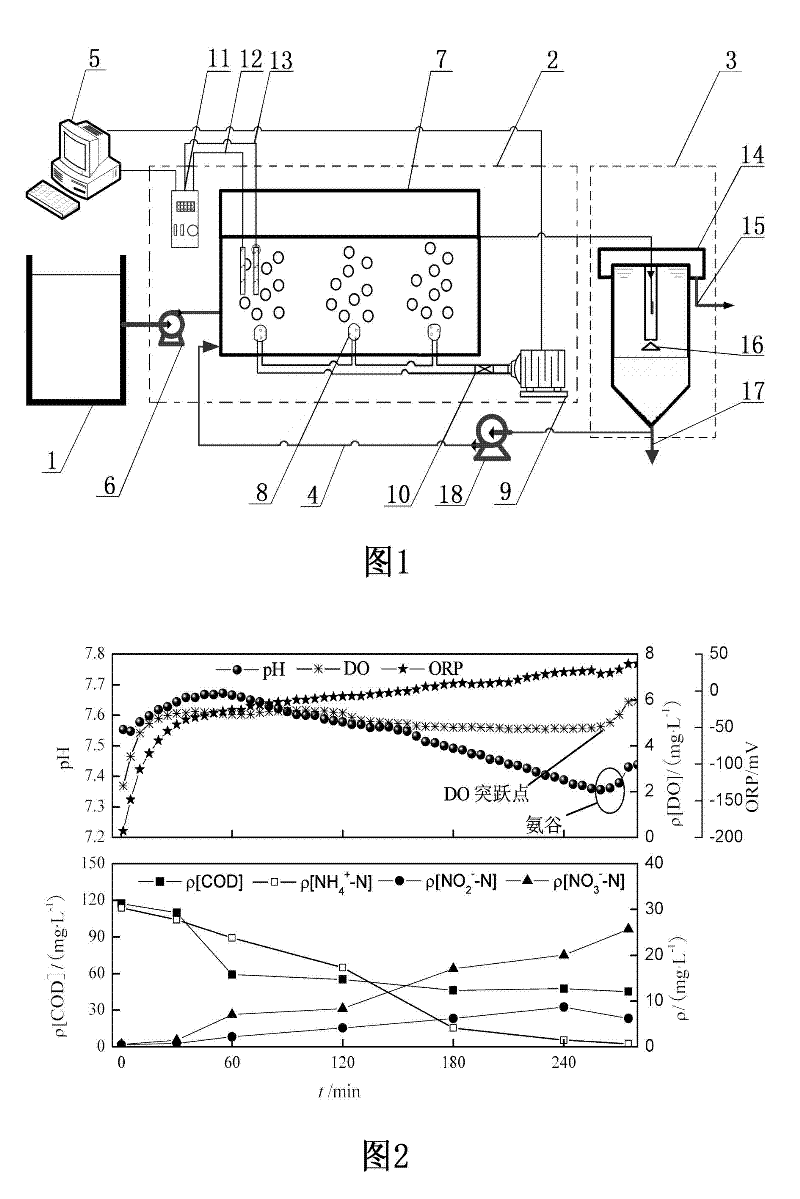

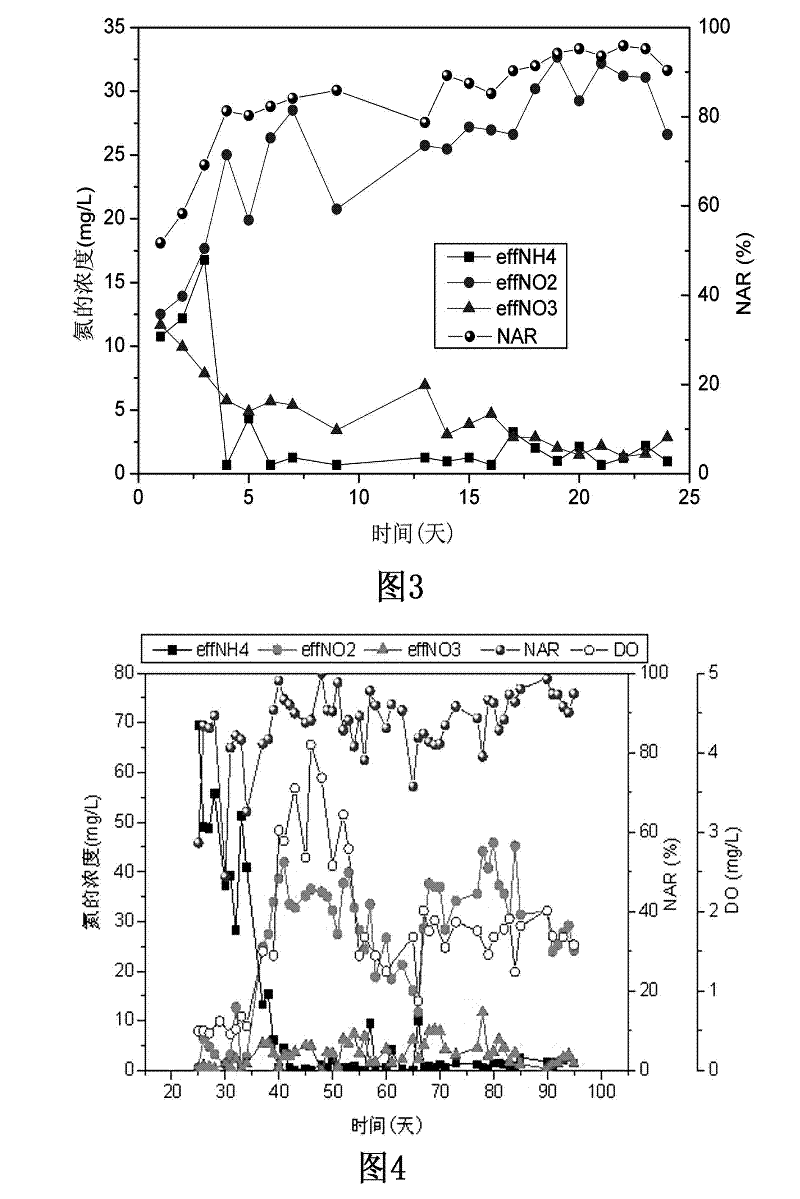

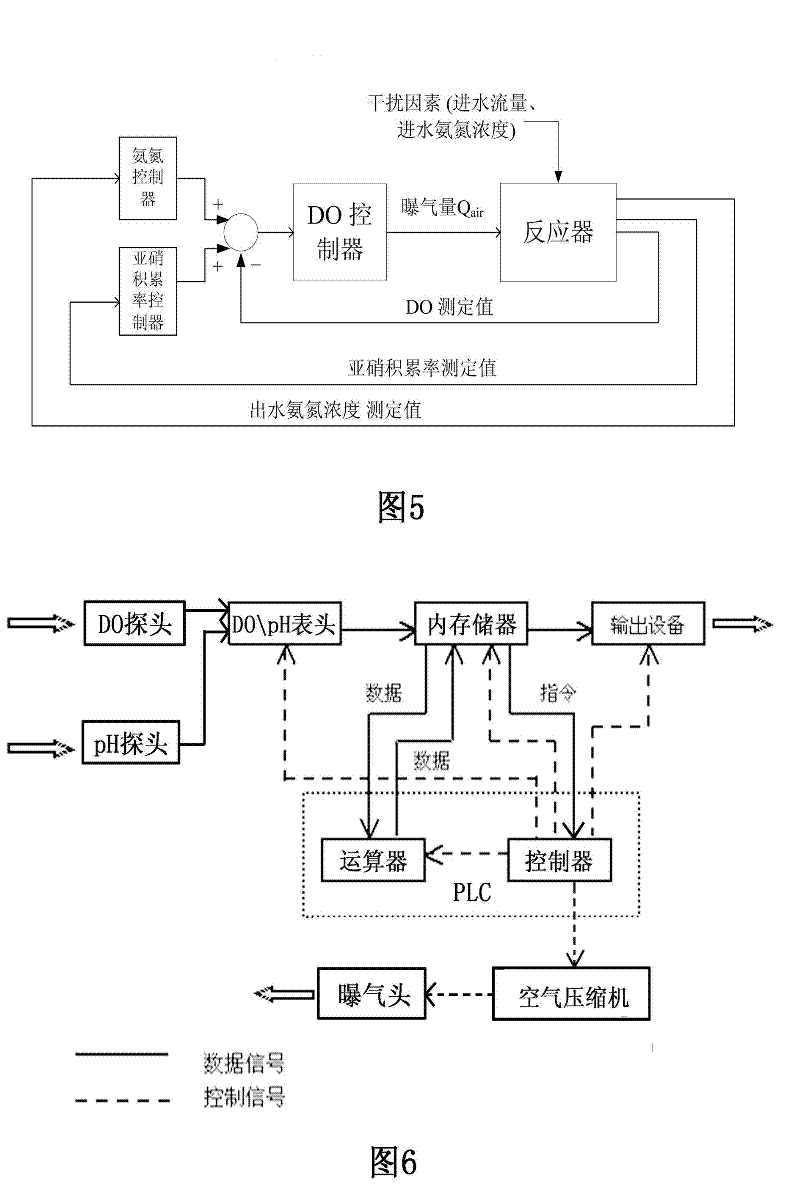

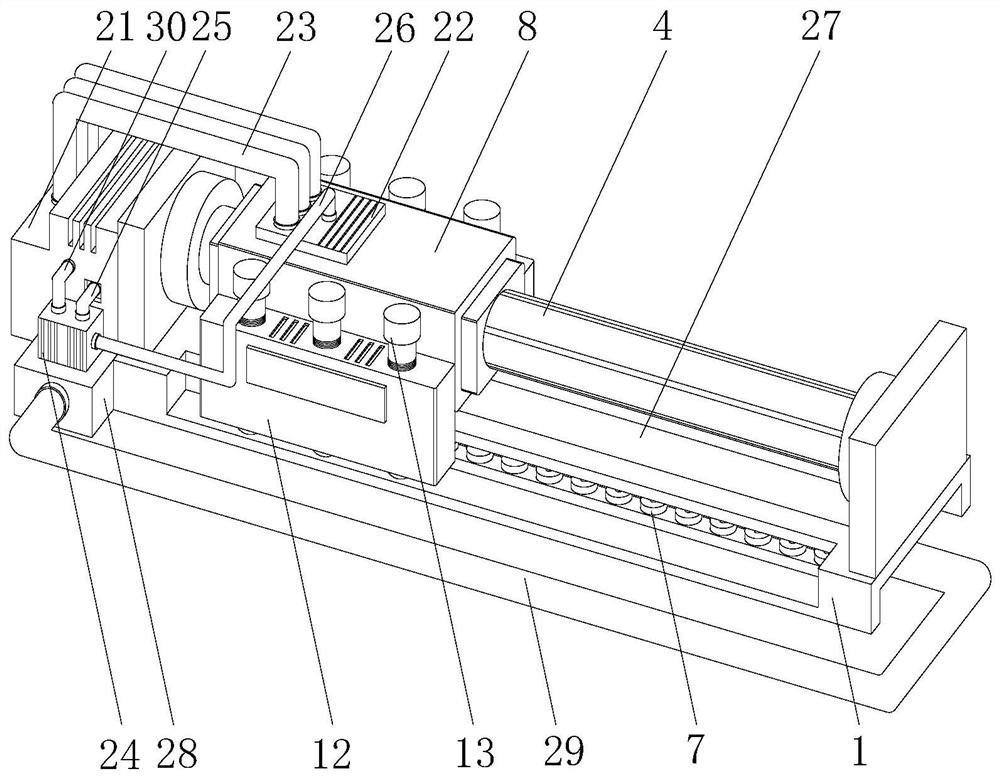

A method for rapidly achieving and stably maintaining short-cut nitrification in a continuous flow process

ActiveCN101759290BReduce outputPromote growthSustainable biological treatmentBiological water/sewage treatmentAeration systemControl system

Owner:彭永臻

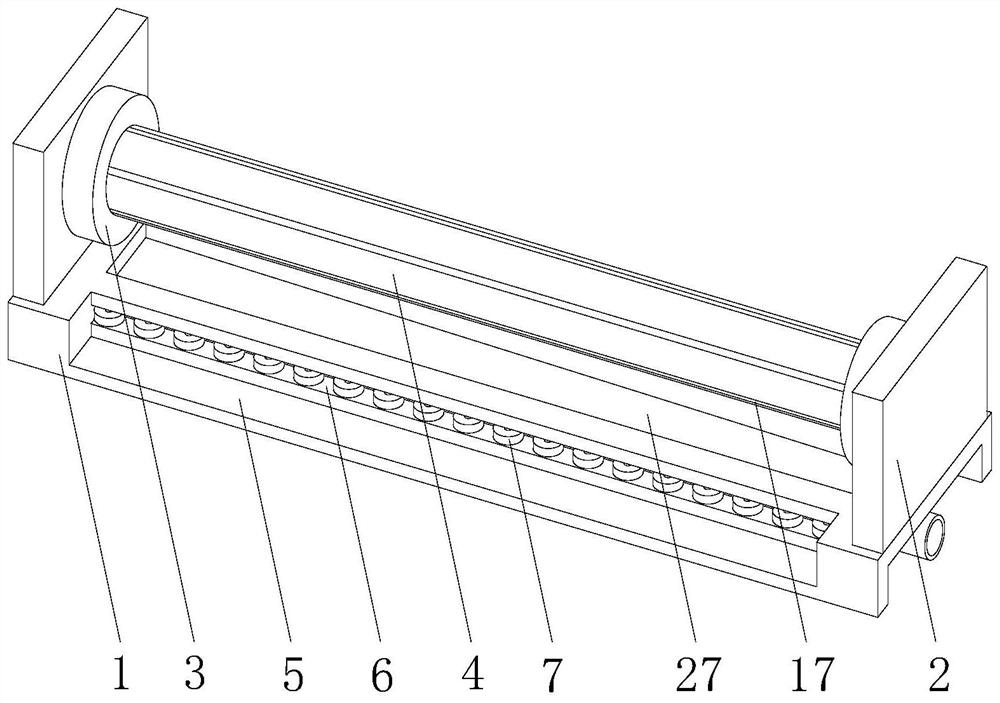

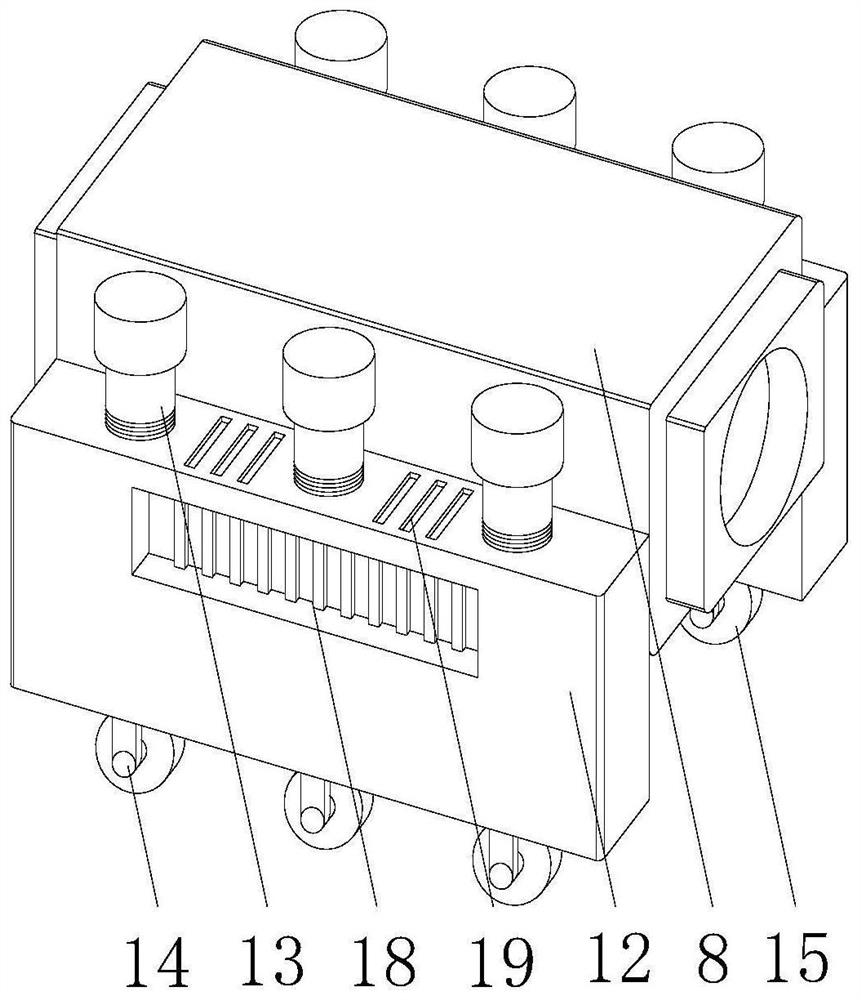

Low-energy-consumption linear motor special for hydrogen fuel cell

ActiveCN113904520AReduce reaction volumeReduce frictionCooling/ventillation arrangementPropulsion systemsThermodynamicsElectric machine

The invention discloses a low-energy-consumption linear motor special for a hydrogen fuel cell. The linear motor aims at solving the technical problem that the energy consumption is too high due to resistance friction resistance of linear movement between an existing linear motor and a guide rail. The linear motor comprises a bottom supporting seat, a motor shell arranged above the bottom supporting seat, and carrying shells installed at the front end and the rear end of the motor shell. According to the linear motor, water generated by combustion heat release of hydrogen fuel is pumped into the space between the inner sleeve cavity and the linear guide rail through the flow dividing pipe, and the friction force between the linear guide rail and the motor shell is reduced by using the water as a lubricating agent. Meanwhile, the motor shell moves on the bottom supporting seat, the friction force between the motor shell and the bottom supporting seat is reduced through the first rolling wheel and the second rolling wheel, extra electric energy consumption caused by overcoming the friction force between the structures when the linear motor moves along the linear guide rail is avoided, the reaction amount of hydrogen fuel is reduced, and the purposes of energy conservation and environmental protection are achieved.

Owner:SHENZHEN UNIV

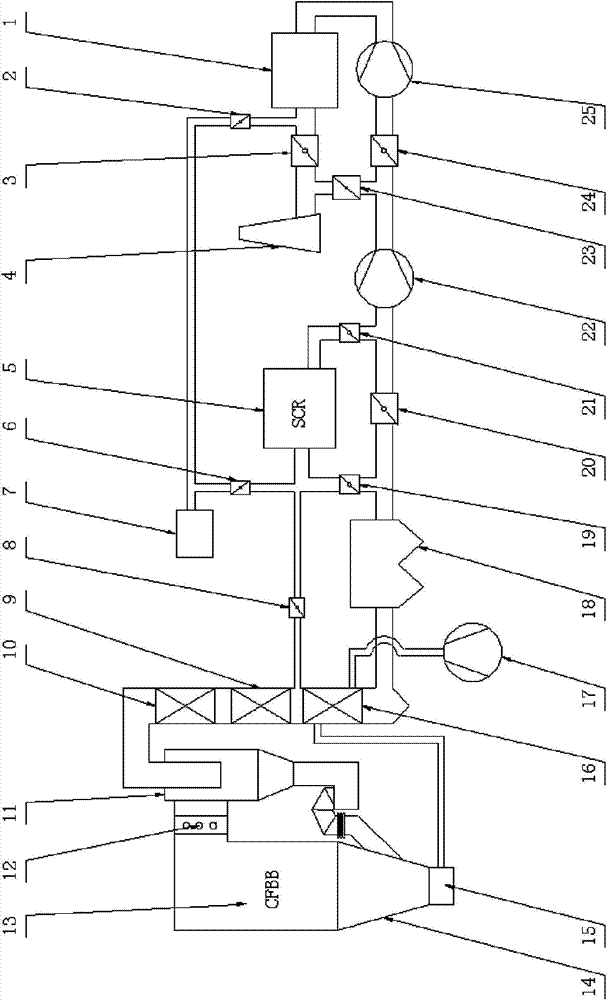

Clean emission system and method for fluidized bed boiler

ActiveCN104511234AImprove working environmentReduce sootFluidized bed combustionDispersed particle separationEmission standardHearth

A clean emission method for a fluidized bed boiler. A first desulphurization is conducted in a dense-phase zone in the fluidized bed boiler; a first denitration based on SNCR is conducted in an outlet of the hearth; the flue gas subjected to the first desulfurization and first denitration in the furnace is subjected to dust removal, heating and secondary denitration based on SCR; and the flue gas subjected to the secondary denitration is sent into a desulfurization system for secondary desulfurization. The invention also provides a corresponding system, which uses an SNCR+SCR combined denitrification mode, and an inside and outside desulfurization mode. Through precise control on parameters of combustion optimization technology and environmental protection system, the NOx and SO2 emission meets the gas turbine emissions standards in key areas of Emission standard of air pollutants for thermal power plants GB13223-2011. The invention has the advantages of high denitration efficiency, high desulfurization efficiency, high system reliability, strong condition compatibility, good controllability of NOx and SO2 emission, long operation cycle and low operating cost.

Owner:HUANENG CLEAN ENERGY RES INST

Improved process for producing cyclohexanol and pimelinketone

InactiveCN101172931BGood dispersionIncrease interface areaOxygen compounds preparation by hydrocarbon oxidationCyclohexanoneHydrogen peroxide breakdown

The invention discloses an improved method for preparing cyclohexanol and cyclohexanone. The invention is characterized in that the decomposition reaction of cyclohexyl peroxide is accomplished with two steps; during the first decomposition reaction, the flow of circulated alkaline is equal to or larger than that of cyclohexane oxydic liquid, thereby ensuring the alkaline water phase to become a continuous phase of the material in the first decomposition reaction; the cyclohexane phase is dispersed; the decomposition reaction is accomplished under an emulsification state, or is called even phase decomposition; the compound from the decomposition reaction is rough separated through a hydrocyclone separator; a large amount of alkaline liquid is separated from the lower outlet of the hydrocyclone separator to be recycled; the material of cyclohexane from the upper outlet of the hydrocyclone separator is changed to the continuous phase, while little alkaline liquid is changed into the dispersing phase; the waste alkaline liquid is separated by lifting a separation groove through gravity; the second decomposition reaction is then accomplished to ensure a full decomposition reaction. With the technical improvement, the total mol yield of the oxidation of cyclohexane prepared cyclohexanol and the cyclohexanone device is increased by 5 percent.

Owner:肖藻生

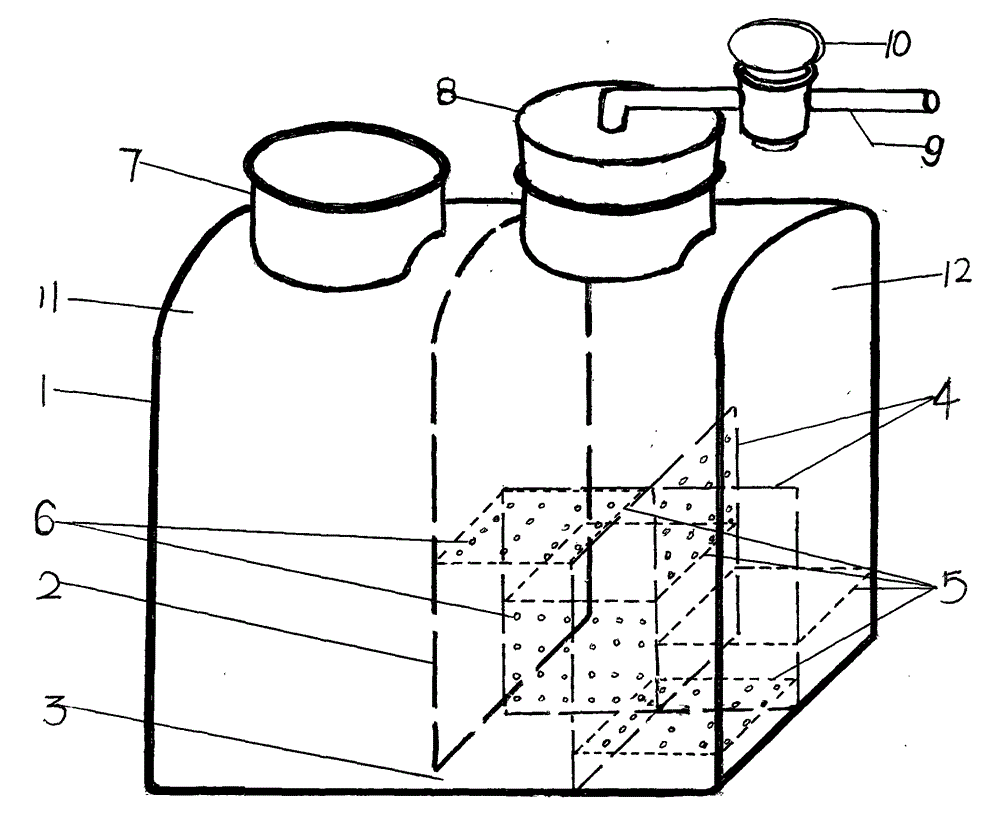

Novel chemical reaction flask

A novel chemical reaction flask is disclosed and belongs to the field of teaching aids. The novel chemical reaction flask comprises a rectangular column hollow flask body prepared from glass; the flask body is divided into a liquid reagent flask body and a solid reagent flask body by a vertical separation plate with the lower end having a narrow seam; the lower part of the solid reagent flask body is again divided into four solid reagent lattices by a vertical cross-shaped separation plate bestrewed with small holes; each solid reagent lattice is provided with a gangboard bestrewed with small circular holes, and the four gangboards are in step-shaped distribution in the solid reagent flask body according to horizontal height; the liquid reagent flask body and the solid reagent flask body are enclosed at upper ends and are respectively provided with a round flask neck at the center; and the flask neck of the solid reagent flask body is provided with a rubber plug, and a glass tube with a switch is inserted in the rubber plug. The four solid reagent lattices are filled with a solid reagent and are in step-shaped distribution, when the switch is on, a liquid reagent enters the solid reagent flask body through a through hole and contacts with the solid reagent successively, so that the chemical reaction amount is gradually increased, and when the switch is off, the chemical reaction amount is gradually reduced utile a reaction is thoroughly finished, so that chemical reagents are saved.

Owner:何小科

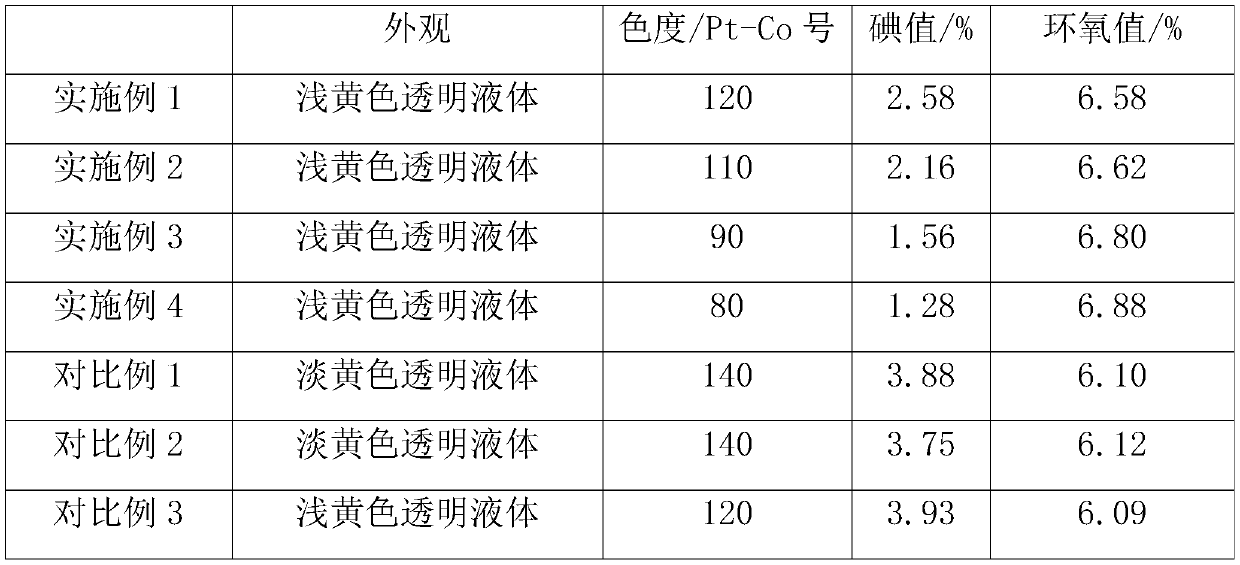

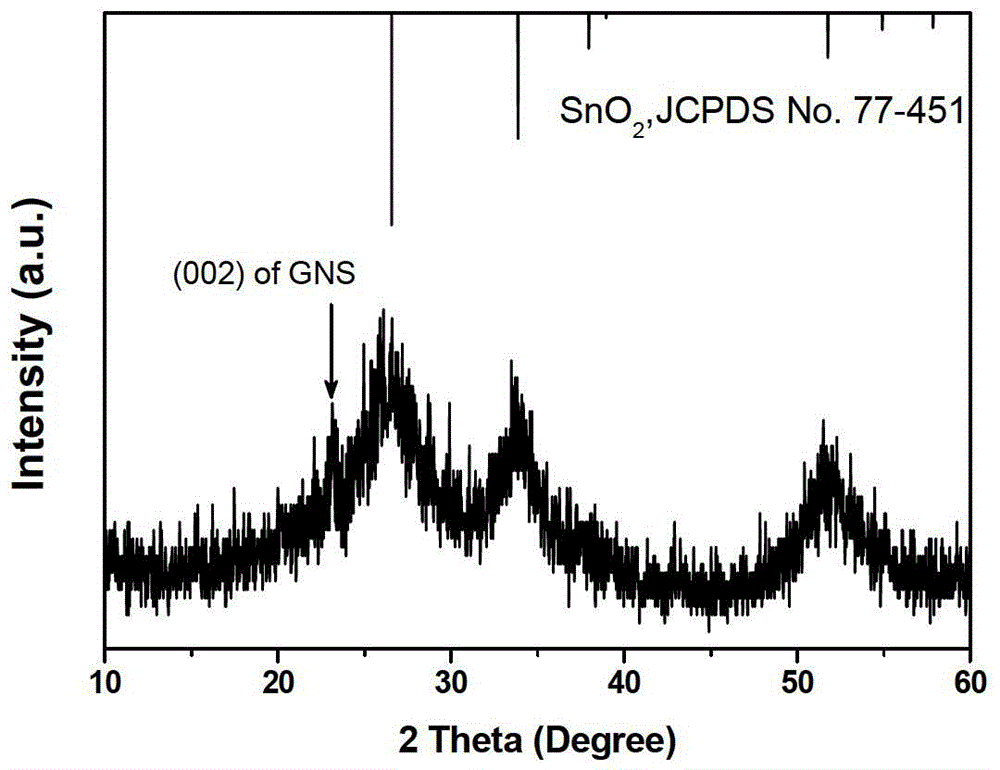

A kind of production method of epoxidized soybean oil

The invention discloses a production method of epoxidized soybean oil. The invention adopts a two-step synthesis method, and the method includes the steps of: (1) adding hydrogen peroxide, formic acidand a catalyst into a high-pressure reaction kettle, conducting stirring and cooling to obtain peroxyformic acid; (2) adding soybean oil dropwise into the peroxyformic acid obtained by step (1), introducing oxygen, performing stirring and carrying out pressurizing reaction to obtain a crude epoxidized soybean oil product; and (3) conducting alkali washing, water scrubbing and reduced pressure distillation on the crude epoxidized soybean oil product obtained by step (2) to obtain an epoxidized soybean oil finished product. Compared with the prior art, the method provided by the invention has the advantages of low cost, good reaction temperature controllability, fast reaction speed and few by-product, and the obtained product has good quality.

Owner:广东宏力达合成材料科技有限公司

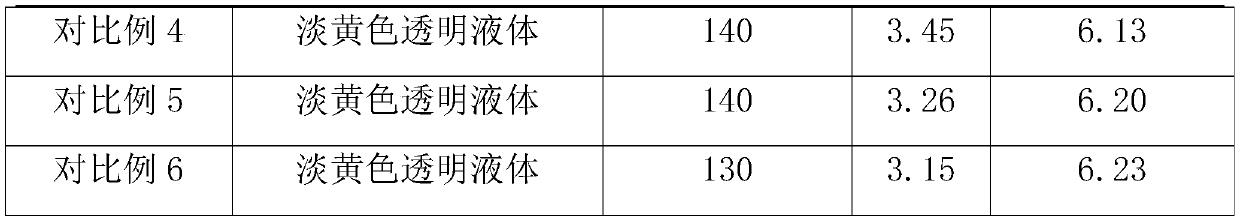

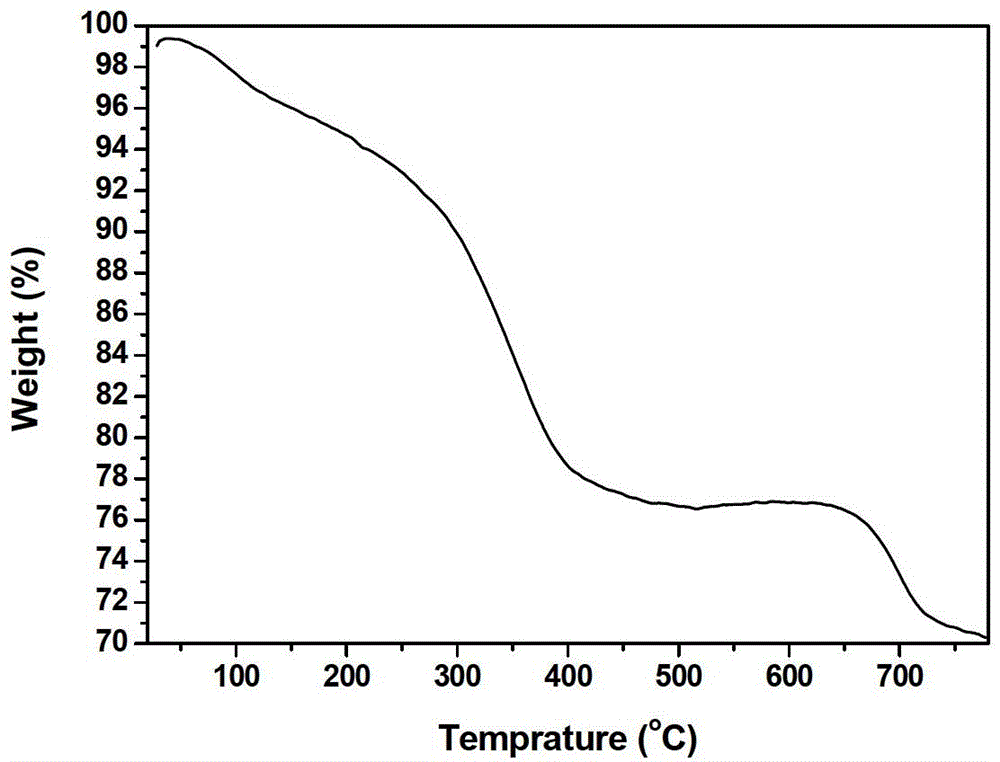

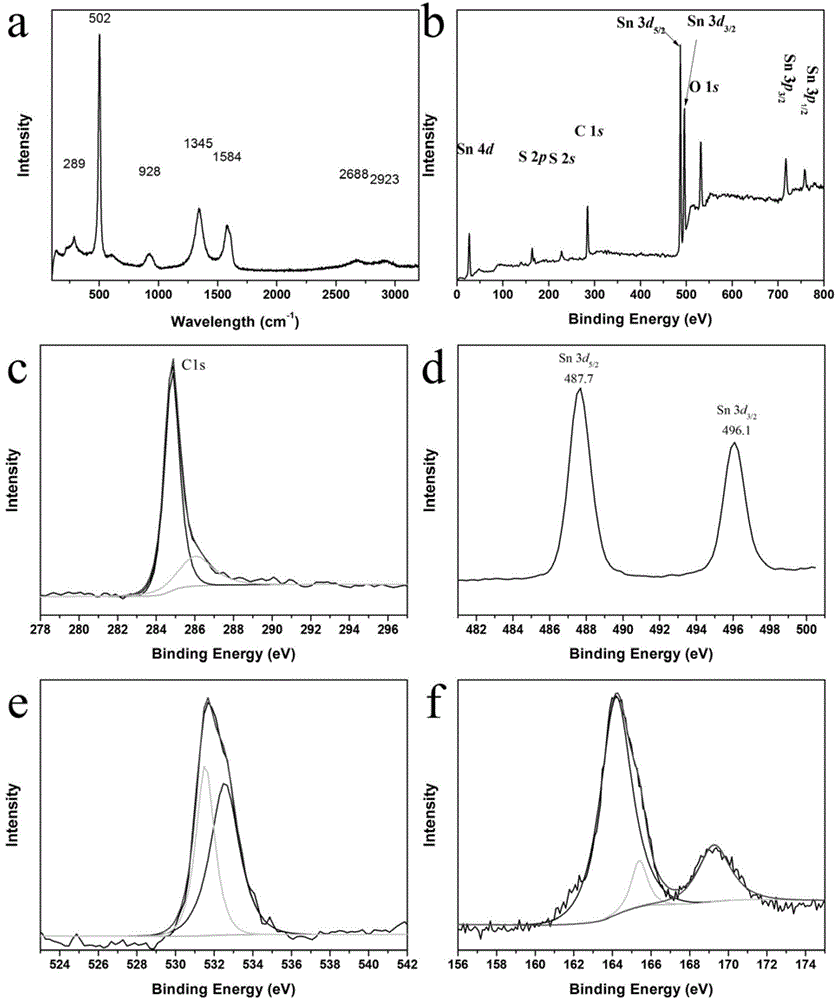

Negative material SnOxS2-x/graphene composite for lithium ion battery and preparation method thereof

ActiveCN102903891BAvoid inactivationInhibition of dissolutionMaterial nanotechnologyCell electrodesNanoparticleGraphene

The invention relates to a negative material SnOxS2-x / graphene composite for a lithium ion battery and a preparation method of the negative material SnOxS2-x / graphene compositein the technical field of batteries. The composite comprises graphene and SnOxS2-x nanoparticles; the SnOxS2-x nanoparticles are uniformly distributed between graphene sheet layers, wherein x is ranged from 0.1 to 1.9. The graphene in the composite is of 4.8 to 91.3% by mass fraction; and the particle diameter of SnOxS2-x nanoparticles ranges from 3 to 300nm. The invention also discloses a preparation method of the composites. The composite material prepared by the preparation method provided by the invention is stable in performance; the composite can be used as the negative electrode of the lithium ion battery, and is high in reversible specific capacity.

Owner:SHANGHAI SINOPOLY JIAHUA BATTERY TECH +1

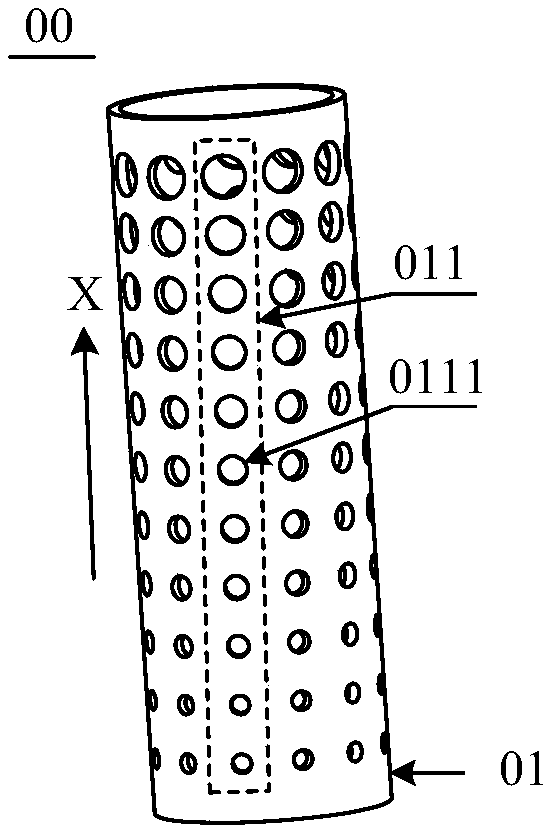

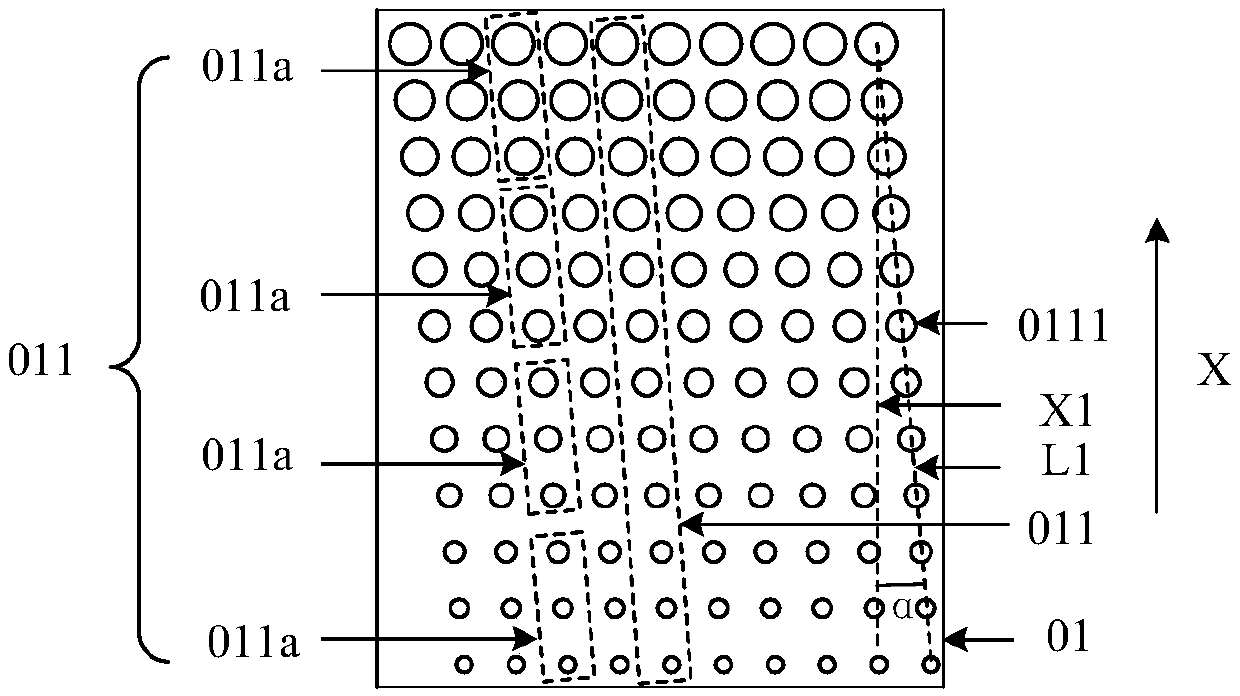

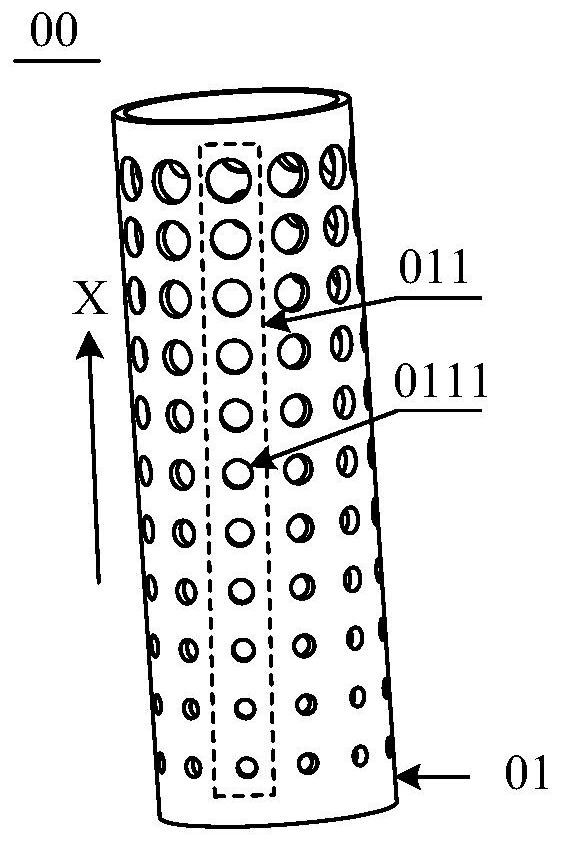

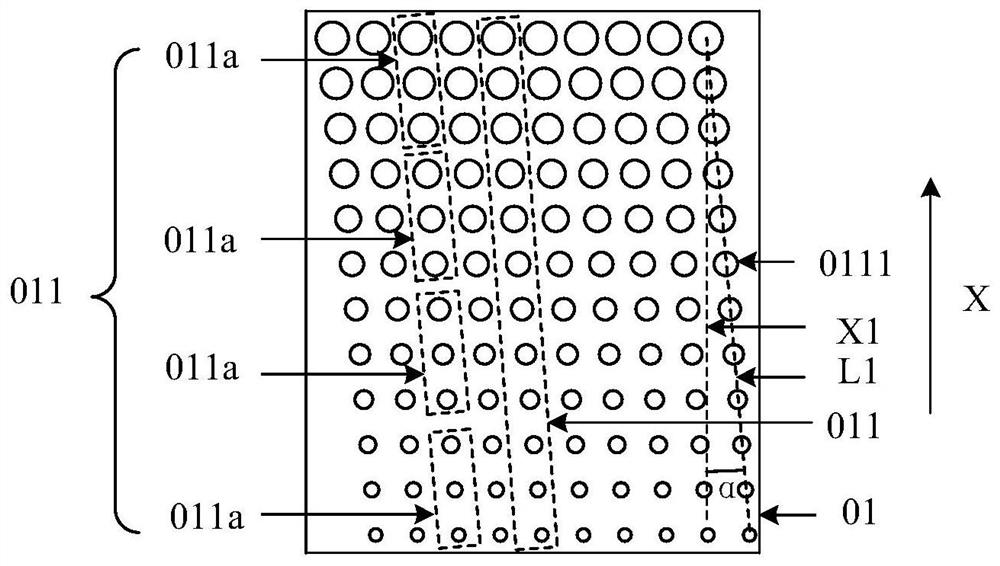

Catalyst basket and redox reaction device

ActiveCN110893332AGuaranteed reaction rateAvoid inactivationDispersed particle separationSulfur preparation/purificationPtru catalystReaction rate

The invention discloses a catalyst basket and a redox reaction device, and belongs to the technical field of redox reactions. The catalyst basket comprises at least a catalyst basket body, which is arranged in a reactor, wherein each catalyst basket body is provided with a plurality of hole rows, each hole row comprises a plurality of gas inlet holes, and the pore size of the gas inlet hole closeto the inlet of the reactor in each hole row is smaller than the pore size of the gas inlet hole far away from the inlet. With the application of the catalyst basket to carry out a redox reaction, thereaction amount in the catalyst basket close to the inlet of the reactor can be reduced, and the reaction amount far away from the inlet of the reactor is increased, so that the reaction amounts of all parts in the catalyst basket are balanced so as to avoid the problem of inactivation of the catalyst, close to the inlet, in the catalyst basket due to the high local temperature of the inlet of the reactor and ensure the reaction rate in the reactor.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

High efficiency nitrification process of biological sewage treatment

InactiveCN100412009CShorten the aeration timeSimple processTreatment with aerobic and anaerobic processesMunicipal sewageNitrification

The present invention is high efficiency nitrification process of biological sewage treatment, especially suitable for city sewage treatment. The sewage treating process includes shunting sewage in certain ratio, treating partial sewage in no-aeration tank comprising anoxic tank and anaerobic tank, making partial sewage enter to the aerobic tank directly, mixing the sewage from the no-aeration tank and the directly entering sewage and aerating in the aerobic tank, and final solid-liquid separation in the secondary settling tank. Compared with available technology, the present invention has the features of short treating period, high efficiency, simple technological process, high denitrification effect, etc.

Owner:CHINA UNIV OF MINING & TECH

A preparation method of high-strength and stress-corrosion-resistant aluminum alloy profiles

The invention relates to a method for preparing a high-strength stress-corrosion-resistant aluminum alloy profile, which comprises the following steps: remelting refined aluminum ingots, cathode copper, zinc ingots, magnesium ingots, aluminum-silicon intermediate alloys, aluminum-manganese intermediate alloys, and aluminum-titanium intermediate alloys. Alloy, Al-10% Y master alloy, Al-5% Sc master alloy and Al-10% Sr master alloy are smelted; then homogenization treatment is carried out, after cooling, car sawing is carried out, and then heat treatment and extrusion are sequentially carried out treatment, solution quenching treatment, first stretching treatment, primary aging treatment, second stretching treatment, secondary aging, after cooling, high-strength and stress-corrosion-resistant aluminum alloy profiles can be obtained; the second stretching treatment The rate is slower than that of the first stretching process. The aluminum alloy profile processed by the method of the invention has the effect of improving the strong plasticity and stress corrosion resistance, and the obtained aluminum alloy profile has high surface quality and uniform and fine structure.

Owner:JIANGSU UNIV OF TECH

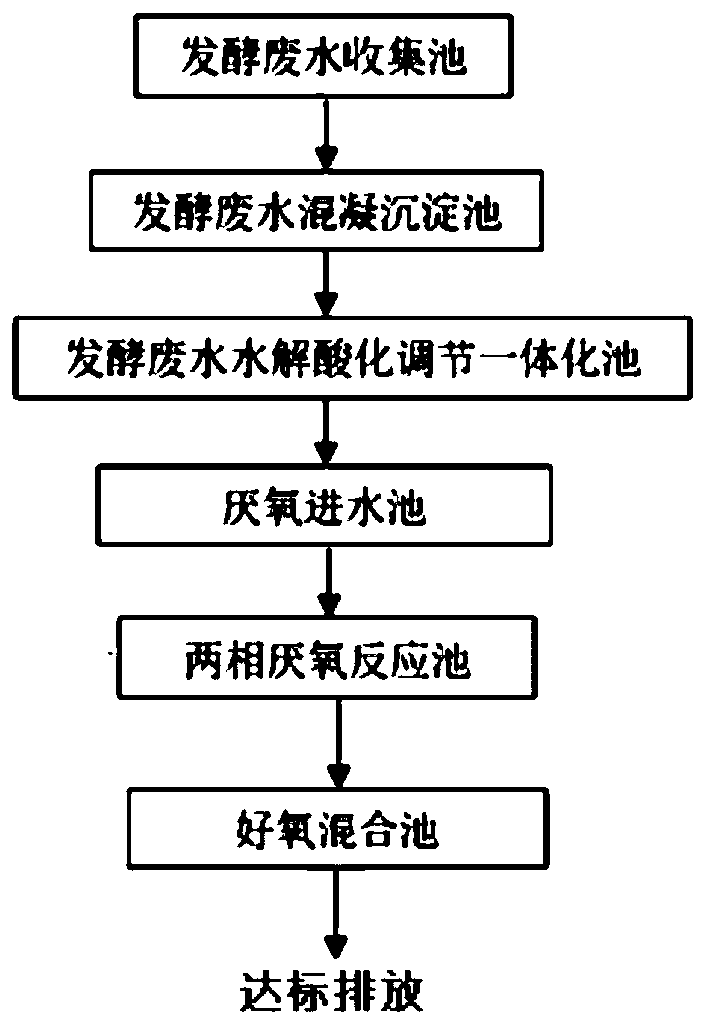

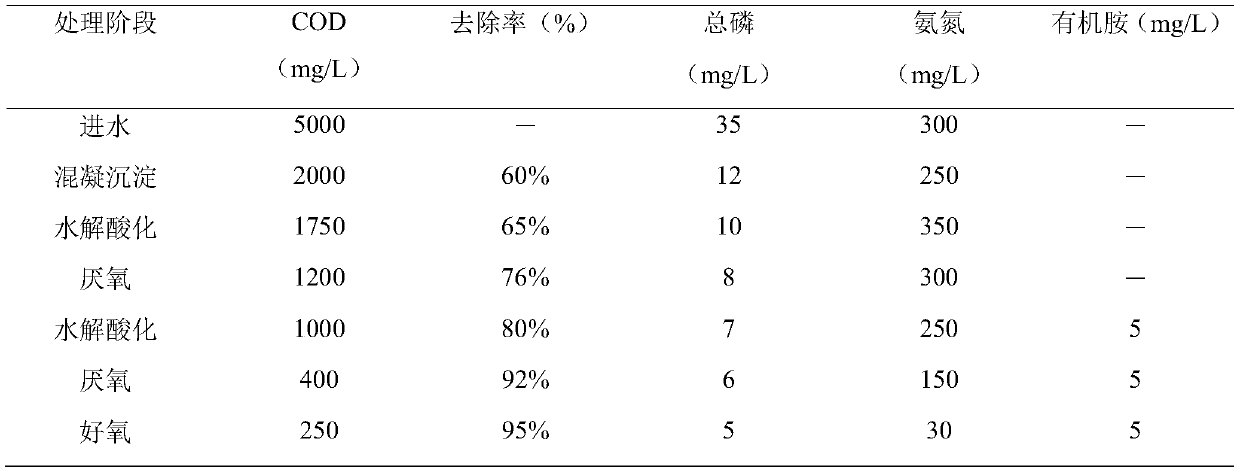

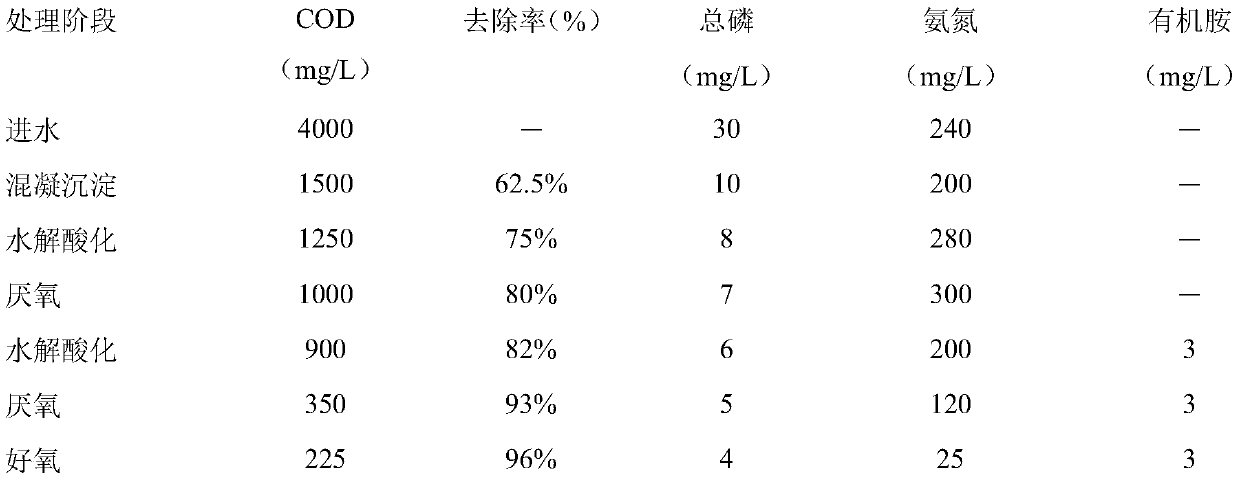

Acrylonitrile-containing fermentation wastewater treatment process

InactiveCN110171879AReduce concentrationGuaranteed uptimeWater treatment parameter controlWater contaminantsHigh concentrationAcrylonitrile

The invention discloses an acrylonitrile-containing fermentation wastewater treatment process and belongs to the field of wastewater treatment. The process comprises the following steps: 1) firstly, carrying out hydrolytic acidification treatment on wastewater; 2) carrying out anaerobic reaction treatment on the wastewater treated in the step 1); 3) sequentially carrying out hydrolytic acidification and anaerobic reaction treatment on the wastewater treated in the step 2); and 4) carrying out aerobiotic biochemical treatment on the wastewater treated in the step 3). In the step 3), a two-phaseanaerobic reactor is adopted for treatment, and a hydrolytic acidification reactor and an anaerobic reactor are serially connected by using the two-phase anaerobic reactor. According to the process,a two-stage hydrolytic acidification-anaerobic treatment method is adopted to treat acrylonitrile-containing fermentation wastewater, influence of acrylonitrile in the wastewater upon treatment of high-concentration complex organic matters is avoided, the treatment efficiency is high, and up-to-standard emission of treated wastewater is met.

Owner:NANJING UNIV +1

Catalyst basket and redox reaction device

ActiveCN110893332BGuaranteed reaction rateAvoid inactivationDispersed particle separationSulfur preparation/purificationPtru catalystReaction rate

The invention discloses a catalyst basket and an oxidation-reduction reaction device, belonging to the technical field of oxidation-reduction reaction. The catalyst basket includes: at least one catalyst basket body. The at least one catalyst basket case is disposed inside the reactor. Each of the catalyst baskets is provided with a plurality of hole rows, and each hole row includes a plurality of air inlet holes. The pore size of the gas inlet holes near the inlet of the reactor in each hole row is smaller than the hole diameter of the gas inlet holes farther from the inlet. When using the catalyst basket for redox reaction, the reaction amount in the catalyst basket near the reactor inlet can be reduced, and the reaction amount farther away from the reactor inlet can be increased, so that the reaction amount in the catalyst basket is more balanced. Therefore, the problem of deactivation of the catalyst in the catalyst basket near the inlet due to the relatively high local temperature at the inlet of the reactor can be avoided, and the reaction rate in the reactor is ensured.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

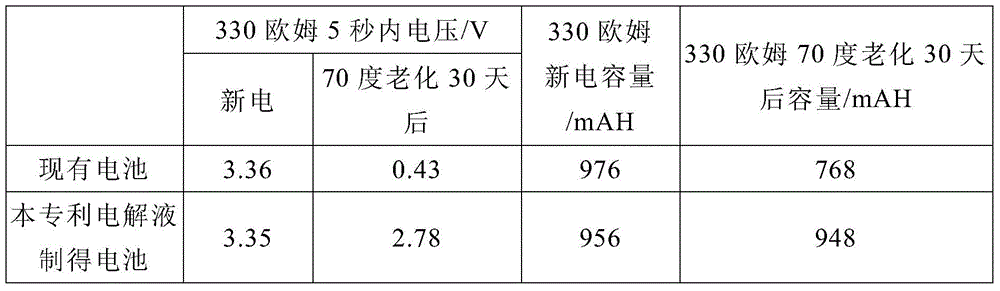

A kind of lithium thionyl chloride battery electrolyte preparation method

ActiveCN104835971BHigh direct reaction efficiencyShorten the timeNon-aqueous electrolyte cellsElectrolytesPhysical chemistryBattery electrolyte

A preparing method of an electrolyte of a lithium-thionyl chloride cell is disclosed. The method is characterized by including following steps of: a) weighing a lithium salt LiAlCl4 in a dry environment the dew-point temperature of which is lower than -35 DEG C into a dry container; b) feeding SO2 gas into the lithium salt LiAlCl4, and allowing the mixture to stand for 5-10 h after feeding of the SO2 gas is finished; and c) adding SOCl2 purified by rectification into the lithium salt product obtained after feeding of the SO2 gas is finished, and adding lithium sheets to prepare the electrolyte. The method is short in steps, short in SO2 reaction time, simple in operation, low in lithium sheet consumption amount, low in cost and safe.

Owner:武汉孚安特科技有限公司

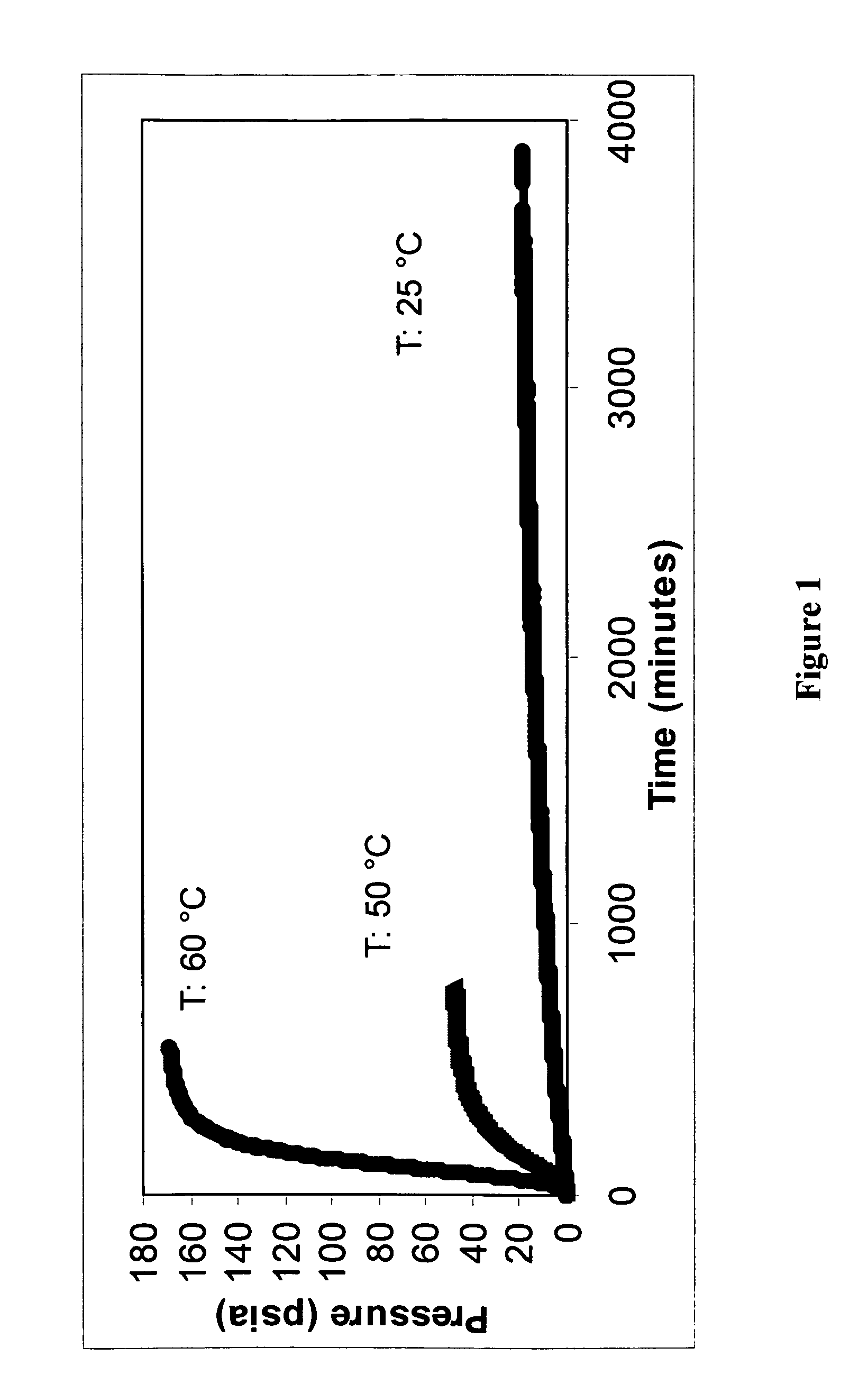

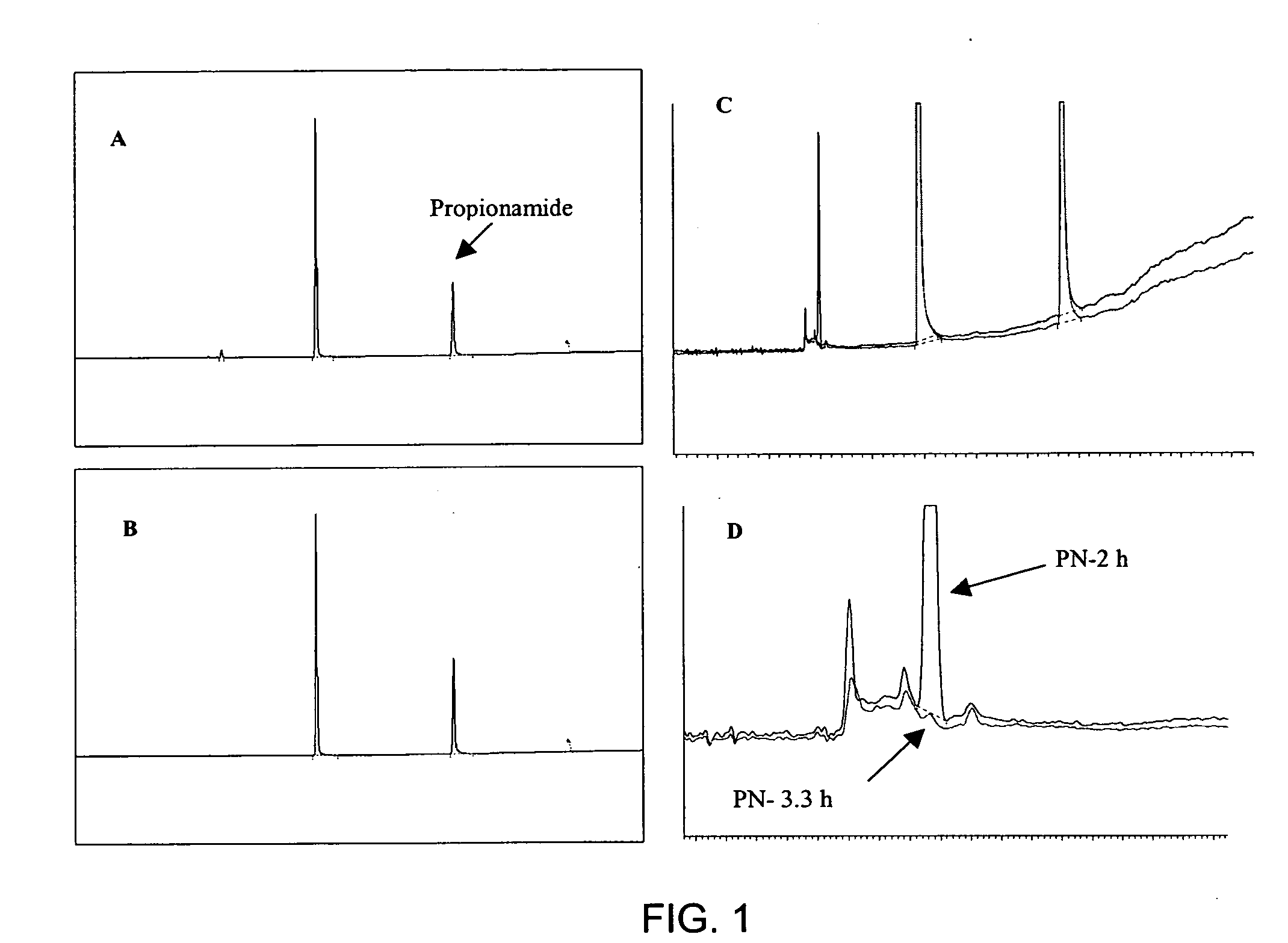

Simultaneous recovery and continuous extraction of substantially pure carboxylic acids and ammonium salts from acid hydrolysis reaction mixtures

InactiveUS20070161820A1Reduce reaction volumeHigh purityPreparation from nitrilesAsymmetric synthesesPropanoic acidAcid hydrolysis

A continuous or batch process for the production and recovery of substantially pure carboxylic acids and ammonium salts from a corresponding nitrile. By controlling the amount of water used in the reaction, a biphasic reaction mixture forms which facilitate simultaneous recovery of both fractions. In a preferred embodiment, using propionitrile as the starting material and strong sulfuiric acid, propionic acid of approximately 98% purity is produced in the upper phase. A combination of hydrochloric and sulfuric acid can reduce the total reaction volume.

Owner:KEMIN IND INC

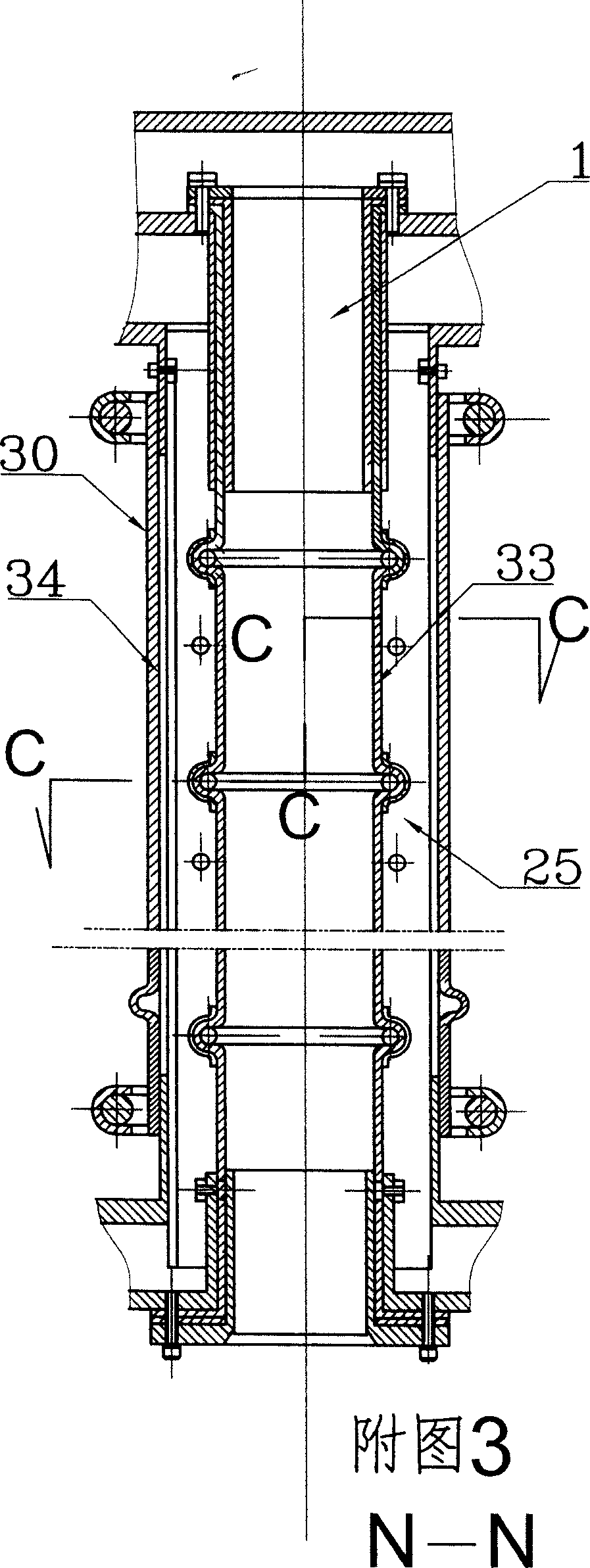

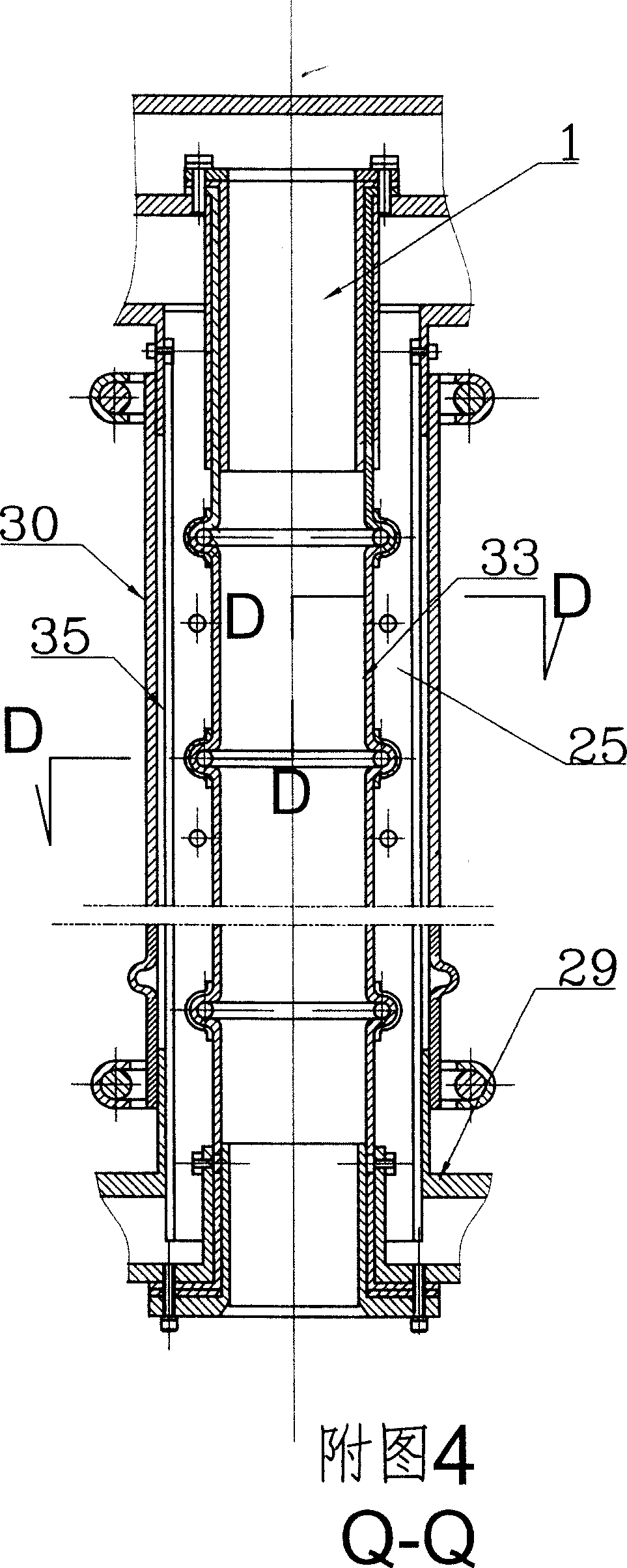

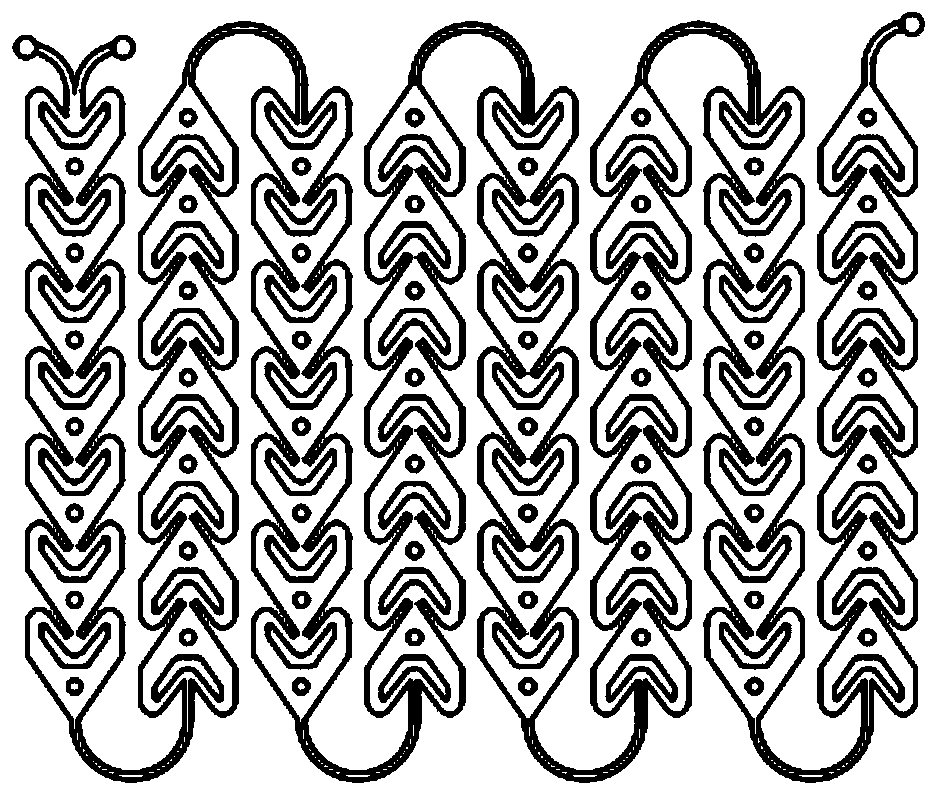

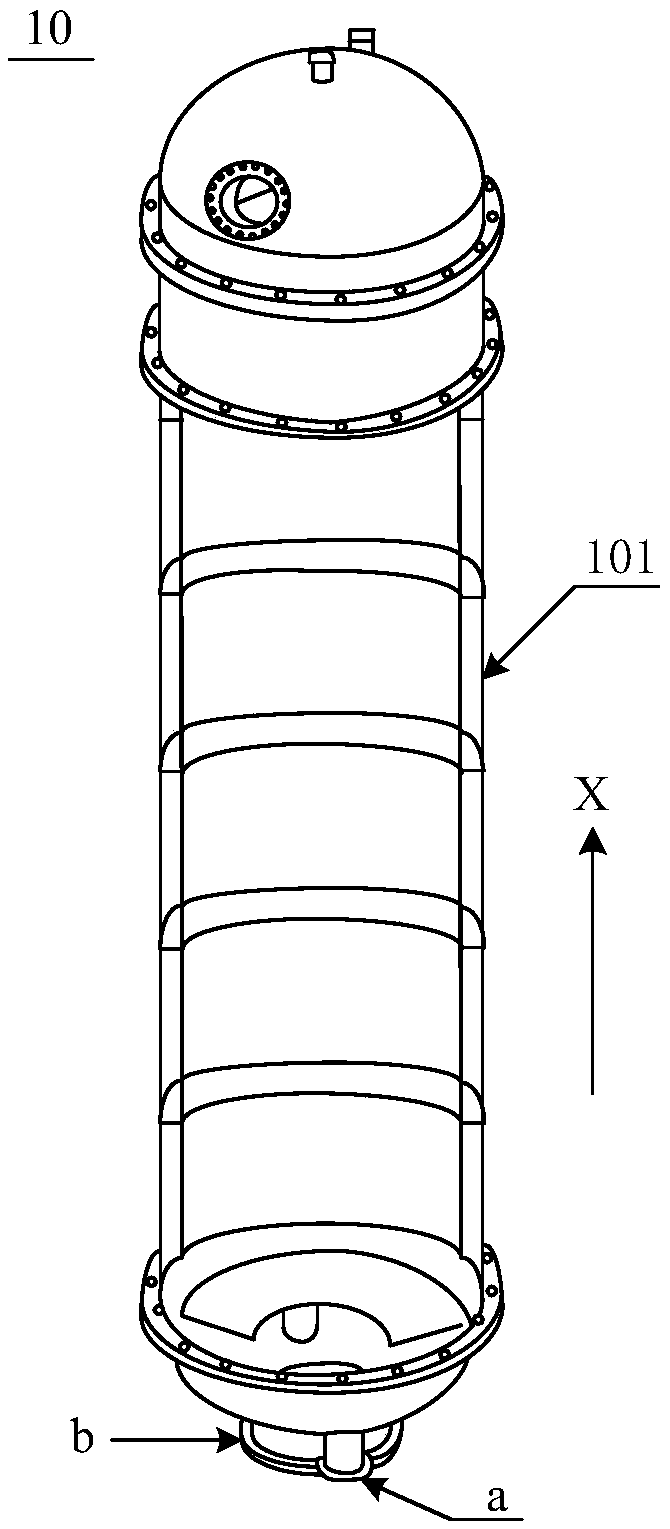

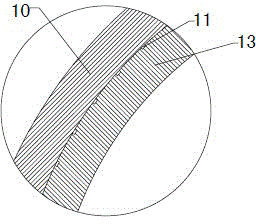

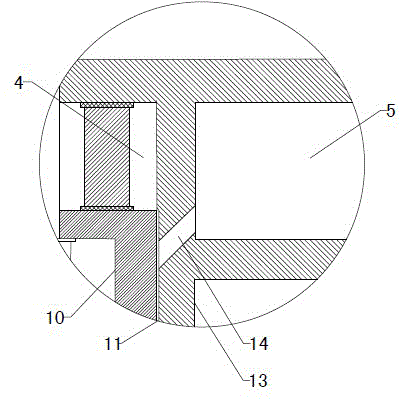

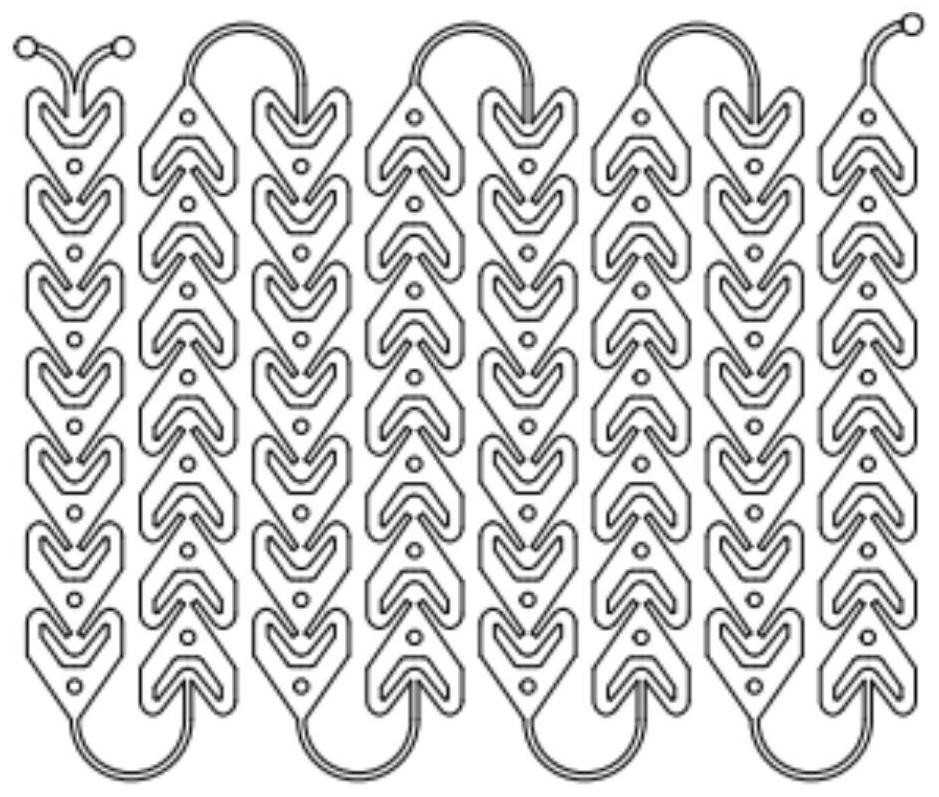

A microchannel reactor for large-scale production

ActiveCN104096525BNatural fitSolve the problem of expensive preparationChemical/physical/physico-chemical processesInterference fitProcess engineering

The invention discloses a micro-channel reactor capable of realizing large-scale production and belongs to the technical field of chemical micro-structure reaction devices. The micro-channel reactor capable of realizing the large-scale production is characterized in that a reactor body comprises an outer shell (10) and an inner shell (13) in an interference fit mode, at least one micro-channel reaction line (11) is arranged between the inner shell (13) and the outer shell (10), an inner secrete room and an outer secrete room are arranged at the top of the reactor body, the inner secrete room is an inner raw material gathering cabin (5), the outer secrete room is an outer raw material gathering cabin (4), and a first raw material inlet (1) is opened in the center of the inner raw material gathering cabin (5); a finished product gathering cabin (12) is arranged at the bottom of the reactor body; the micro-channel reaction line (11) is communicated with the raw material gathering cabin (4) and the finished product gathering cabin (12), and a cooling system is respectively arranged in and outside the reactor body. The micro-channel reactor capable of realizing the large-scale production eliminates the amplification effect of the micro-channel reactor and enables the total reacting dose to be increased while guaranteeing the micro-scale of each reaction line so that the industrialized mass production can be achieved.

Owner:泉州泰洋科技有限公司

A kind of synthetic method of 1,3-dinitrohalobenzene compound

ActiveCN109970566BDropping time is longLong reaction heatSequential/parallel process reactionsChemical/physical/physico-chemical microreactorsNitrationEnvironmental engineering

The present invention provides the synthetic method of 1,3-dinitrohalobenzene compound, comprises the following steps: A) halobenzene compound, and the mixed acid of nitric acid, sulfuric acid, carry out the first nitration reaction in one-stage continuous flow microreactor , through oil-water separation, to obtain a nitrohalobenzene compound and the first waste acid; B) diverting the mononitrohalobenzene compound into the secondary continuous flow microreactor, and carrying out the second nitration reaction with the mixed acid of nitric acid and sulfuric acid , the nitration mixture generated is quenched and filtered at the outlet of the secondary continuous flow microreactor to obtain 1,3-dinitrohalobenzene compound and the second waste acid; C) the second waste acid is recycled to the first-level continuous flow In the microreactor, carry out the third nitration reaction with the halobenzene compound, and separate the oil and water to obtain the mononitrohalobenzene compound and the third waste acid; repeat steps B), C); the halobenzene compound has the formula I structure. Short reaction time and less waste acid realize continuous production.

Owner:SHANDONG HIMILE CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com