A kind of production method of epoxidized soybean oil

A technology of epoxidized soybean oil and production method, which is applied in the direction of organic chemistry, can solve the problems of difficult control of reaction temperature, high cost of sewage treatment, slow epoxidation speed, etc., to reduce sewage production, save sewage treatment burden, and react The effect of less by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

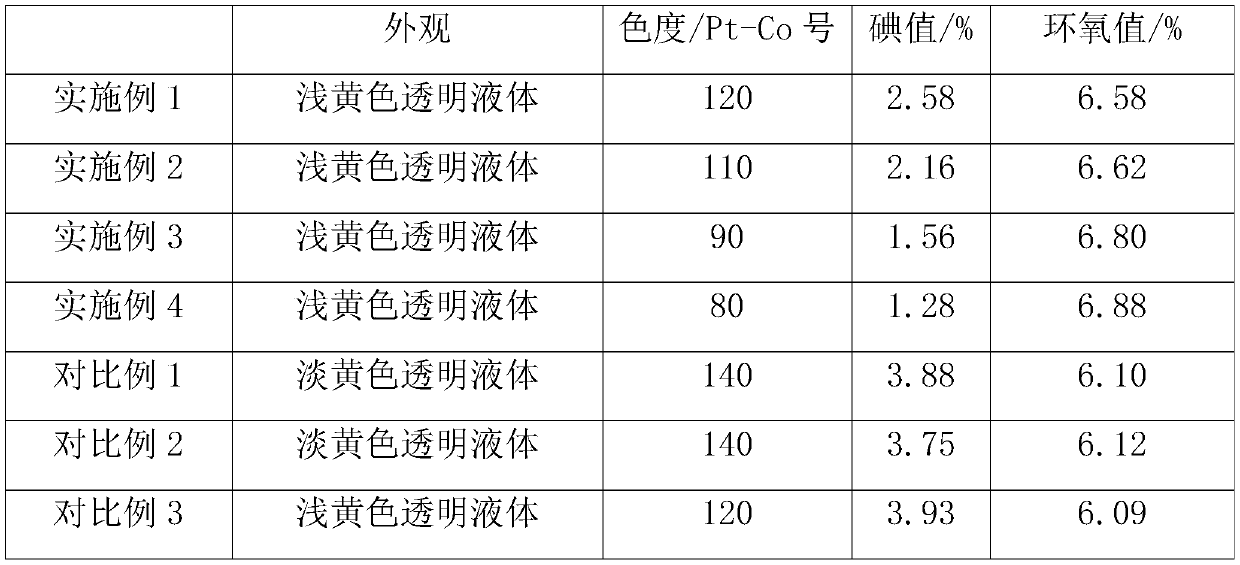

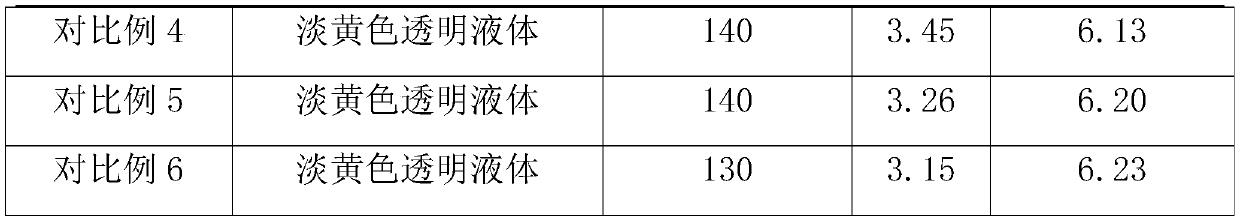

Examples

Embodiment 1

[0033] (1) Take 100g of hydrogen peroxide, 3g of formic acid, 0.1g of phosphotungstic heteropolyacid and 0.2g of manganese benzoate with a concentration of 55%, add them to the autoclave successively, stir for 2h at a speed of 200rpm, cool to 50°C, and obtain peroxyformic acid mixture;

[0034] (2) in the formic acid peroxide mixture that step (1) obtains, slowly drip 120g soybean oil, control the flow rate of soybean oil, make it drop completely in 0.8h; During the dropping process, feed 10L oxygen, control The stirring speed is 200rpm, the temperature is 60°C, the pressure is 0.9Mpa, the reaction is 2h, and the crude epoxy soybean oil is obtained;

[0035] (3) The crude epoxidized soybean oil obtained in step (2) is subjected to alkali washing, water washing, and vacuum distillation according to conventional technical means to obtain the finished epoxidized soybean oil.

Embodiment 2

[0037] (1) Take 65% hydrogen peroxide 100g, 10g formic acid, 0.3g phosphotungstic heteropoly acid and 0.6g manganese benzoate, add them to the autoclave successively, stir for 1h at a speed of 450rpm, cool to 60°C, and get peroxyformic acid mixture;

[0038] (2) In the peroxyformic acid mixture obtained in step (1), slowly add 180g of soybean oil dropwise, control the flow rate of soybean oil, and make it drop completely within 1h; during the dropwise addition, feed 50L of oxygen and control the stirring The speed is 450rpm, the temperature is 60°C, the pressure is 1.2Mpa, the reaction is 1h, and the crude product of epoxidized soybean oil is obtained;

[0039] (3) The crude epoxidized soybean oil obtained in step (2) is subjected to alkali washing, water washing, and vacuum distillation according to conventional technical means to obtain the finished epoxidized soybean oil.

Embodiment 3

[0041](1) Take 100g of hydrogen peroxide, 8g of formic acid, 0.05g of phosphotungstic heteropolyacid and 0.25g of manganese benzoate at a concentration of 60%, add them to the autoclave successively, stir for 1h at a speed of 300rpm, and cool to 55°C to obtain peroxyformic acid mixture;

[0042] (2) in the formic acid peroxide mixture that step (1) obtains, slowly drip 160g soybean oil, control the flow rate of soybean oil, make it drop completely in 0.5h; During the dropping process, feed 15L oxygen, control The stirring speed is 450rpm, the temperature is 60°C, the pressure is 1.0Mpa, the reaction is 1.5h, and the crude epoxy soybean oil is obtained;

[0043] (3) The crude epoxidized soybean oil obtained in step (2) is subjected to alkali washing, water washing, and vacuum distillation according to conventional technical means to obtain the finished epoxidized soybean oil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com