Negative material SnOxS2-x/graphene composite for lithium ion battery and preparation method thereof

A technology of lithium-ion batteries and negative electrode materials, applied in battery electrodes, nanotechnology for materials and surface science, circuits, etc. The whole process is reversible, the cycle stability and the specific capacity are low, so as to improve the electrochemical activity, reduce the polarization effect and enhance the reversibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Disperse 0.3 parts (by weight, g) of graphene oxide into 20 parts of deionized water under the action of ultrasonic waves, and form a hydrogel dispersion after ultrasonic treatment for 30 minutes. Then add 100 parts of pre-configured molar concentrations of 0.05M SnCl 4 and 0.2M thioacetamide mixed solution. After stirring for 30 minutes, sonicate for another 90 minutes. The treated reaction solution was vacuum filtered, rinsed with 10 parts of 50% hydrazine hydrate, and finally washed with deionized water until neutral. After the filter cake is dried, SnO can be obtained x S 2-x / graphene composite.

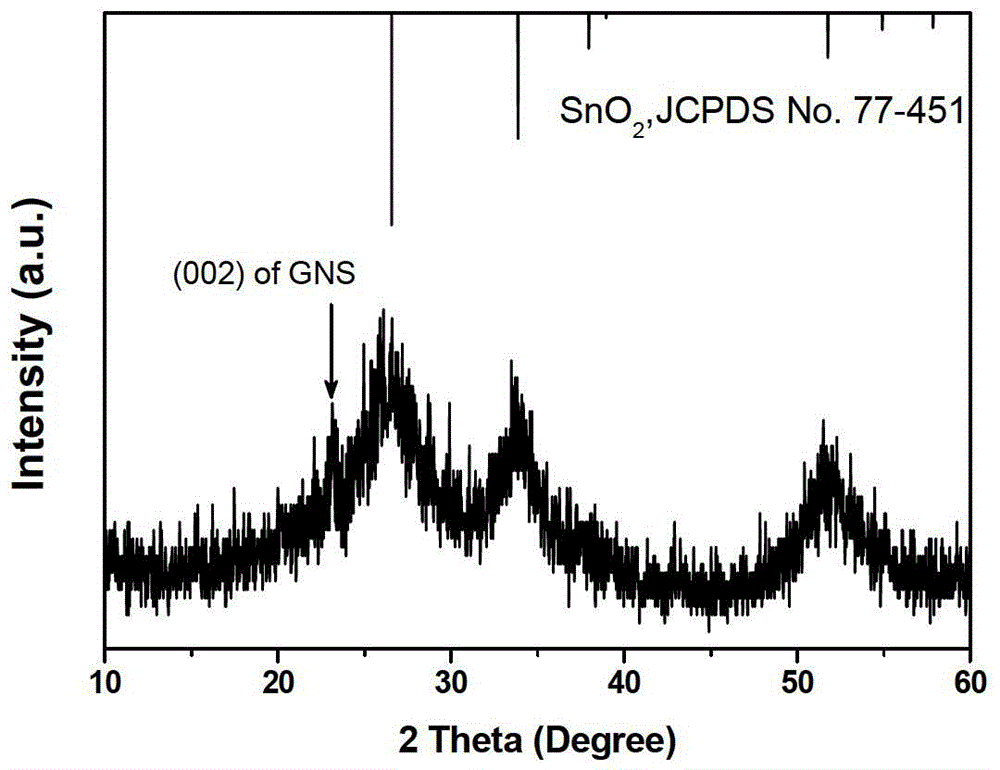

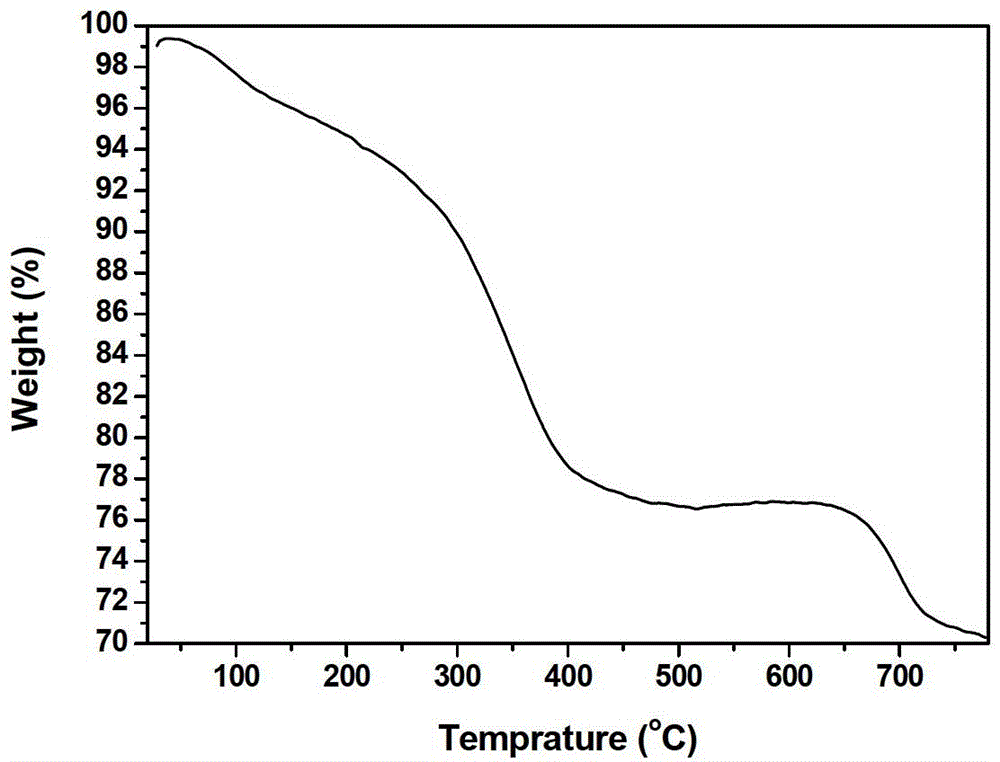

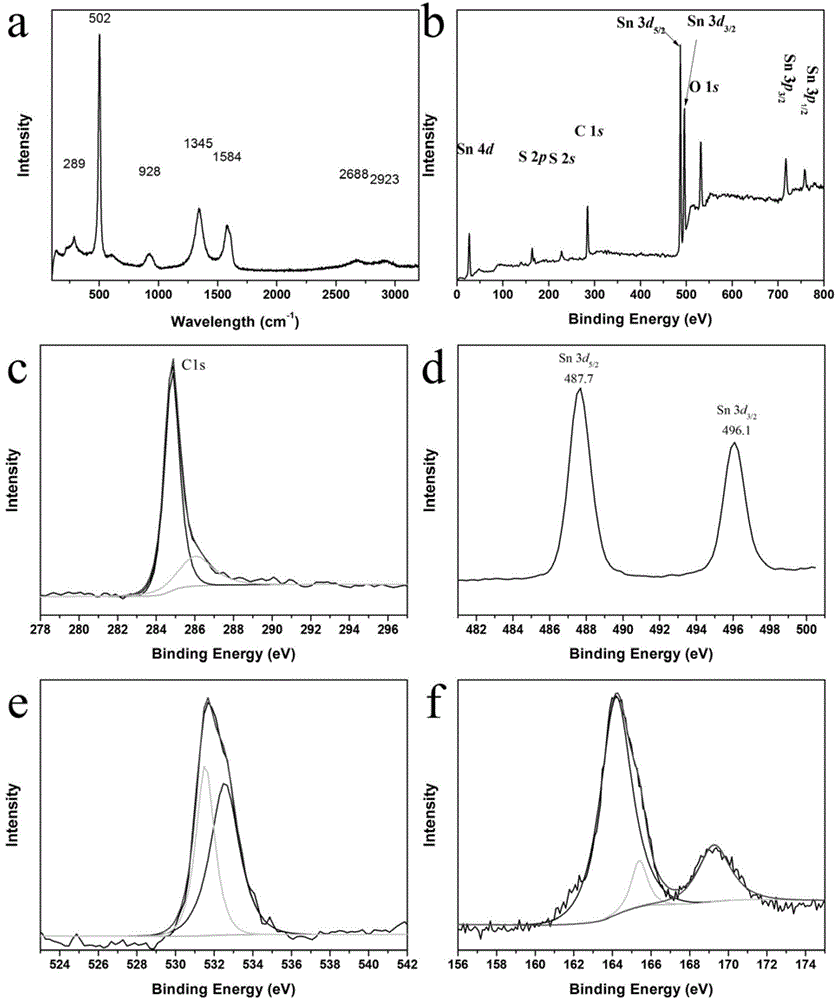

[0050] From SnO x S 2-x / XRD spectrum of the graphene composite ( figure 1 ) shows that the main diffraction peaks of the product are similar to those of cassiterite-type SnO 2 (JCPDS No.77-451); at the same time, the weak diffraction peak at 23.2° should be attributed to the (002) plane of graphene. The thermogravimetric diagram of the composite ( figure 2 ) ...

Embodiment 2

[0063] Disperse 0.2 parts of graphene oxide into 20 parts of deionized water under the action of ultrasonic waves, and form a hydrogel dispersion after ultrasonic treatment for 30 minutes. Then add 100 parts of pre-configured molar concentrations of 0.05M SnCl 4 and 0.2M thioacetamide mixed solution. After stirring for 30 minutes, sonicate for another 90 minutes. The treated reaction solution was vacuum filtered, rinsed with 10 parts of 50% hydrazine hydrate, and finally washed with deionized water until neutral. After the filter cake is dried, SnO can be obtained x S 2-x / graphene composite.

[0064] From SnO x S 2-x / XRD spectrum of the graphene composite ( Figure 7 ) It can be seen that the diffraction peaks of the obtained composites are all trigonal chalchite SnS 2 (JCPDS No.23-667) characteristic diffraction peaks, no graphene, SnO2 Or the diffraction peaks of other tin-based sulfides. The possible reasons for not detecting the graphene (002) surface character...

Embodiment 3

[0070] Disperse 0.02 parts of graphene oxide into 10 parts of deionized water under the action of ultrasonic waves, and after ultrasonic treatment for 5 minutes, a hydrogel dispersion liquid is formed. Then add 100 parts of pre-configured molar concentrations of 0.05M SnCl 4 and 0.2M thioacetamide mixed solution. Sonicate for an additional 90 minutes without agitation. The treated reaction liquid was vacuum filtered, rinsed with 10 parts of 10% (weight ratio) aqueous ascorbic acid solution, and finally washed with deionized water until neutral. After the filter cake is dried, SnO can be obtained x S 2-x / graphene composite. The graphene content in the composite is 4.8%, and the ratio of S and O is 1:19, that is, X=0.1, from Figure 13 It can be seen that SnO x S 2-x It is a nanosheet with a diameter of 200-300; the obtained composite has a specific capacity of 526mAh / g after 40 cycles at a current density of 0.2A / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com