Apparatus and method for atomic layer deposition

A technology of atomic layer deposition and deposition cycle, which is applied in the field of atomic layer deposition devices and methods, can solve problems such as copper diffusion and damage to device integrity, and achieve the effect of increasing flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

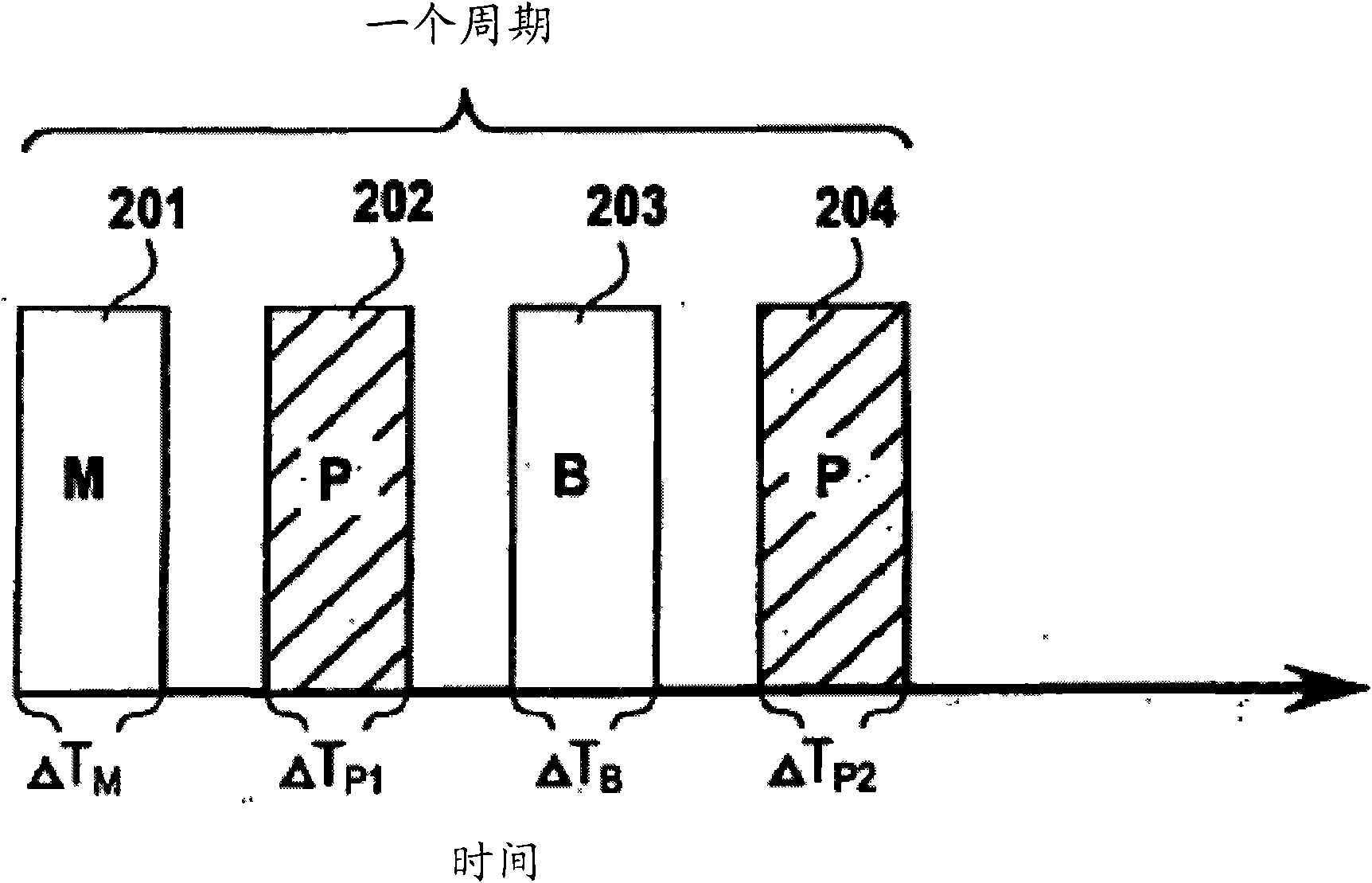

[0034] Some exemplary embodiments of ALD apparatus and methods using proximity heads are provided. The proximity head ALD apparatus and method improves ALD processing throughput and allows pre-treatment and post-treatment of ALD deposition in the same apparatus. It should be understood that the present invention can be implemented in various ways, including process, method, apparatus or system. Some innovative embodiments of the present invention are described below. It will be apparent to one skilled in the art that the present invention may be practiced without some or all of the specific details set forth herein.

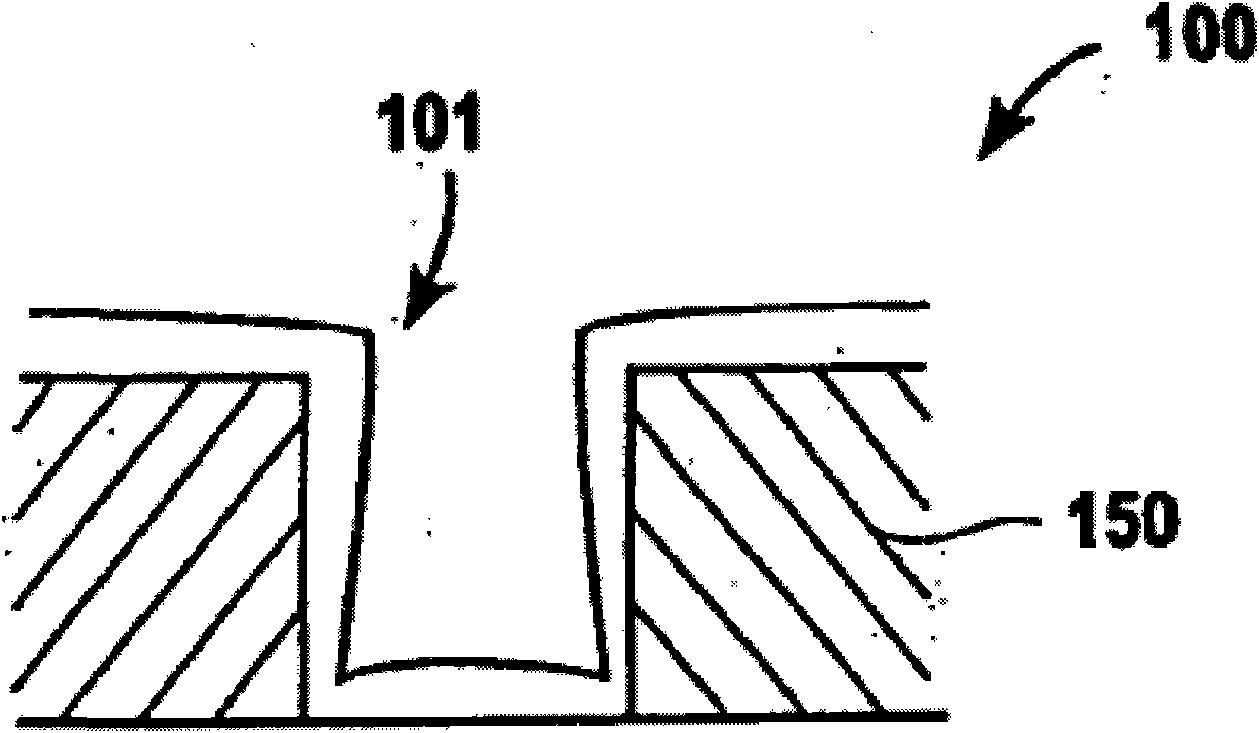

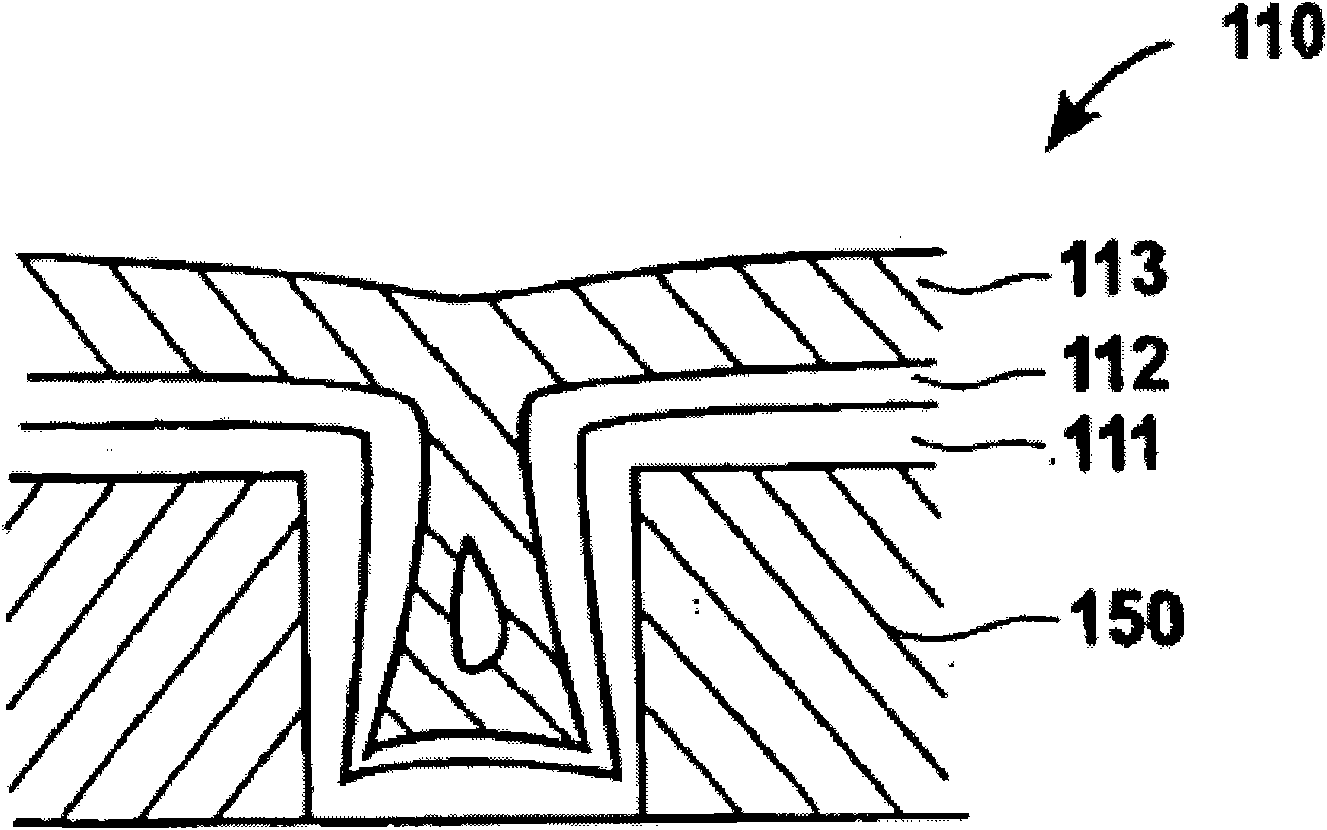

[0035] like Figure 1A As shown, it is known that the barrier protrusion 101 near the top of the interconnect structure 100 produced by a conventional physical vapor deposition (PVD) process can lead to metal interconnection due to poor step coverage during copper void filling. Copper voids in lines or vias. like Figure 1A As shown, limited deposition of barr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com