Improved process for producing cyclohexanol and pimelinketone

A technology of cyclohexanol and cyclohexanone, which can be used in the preparation of oxygen-containing compounds by hydrocarbon oxidation, organic chemistry and other directions, and can solve the problems of low yield and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

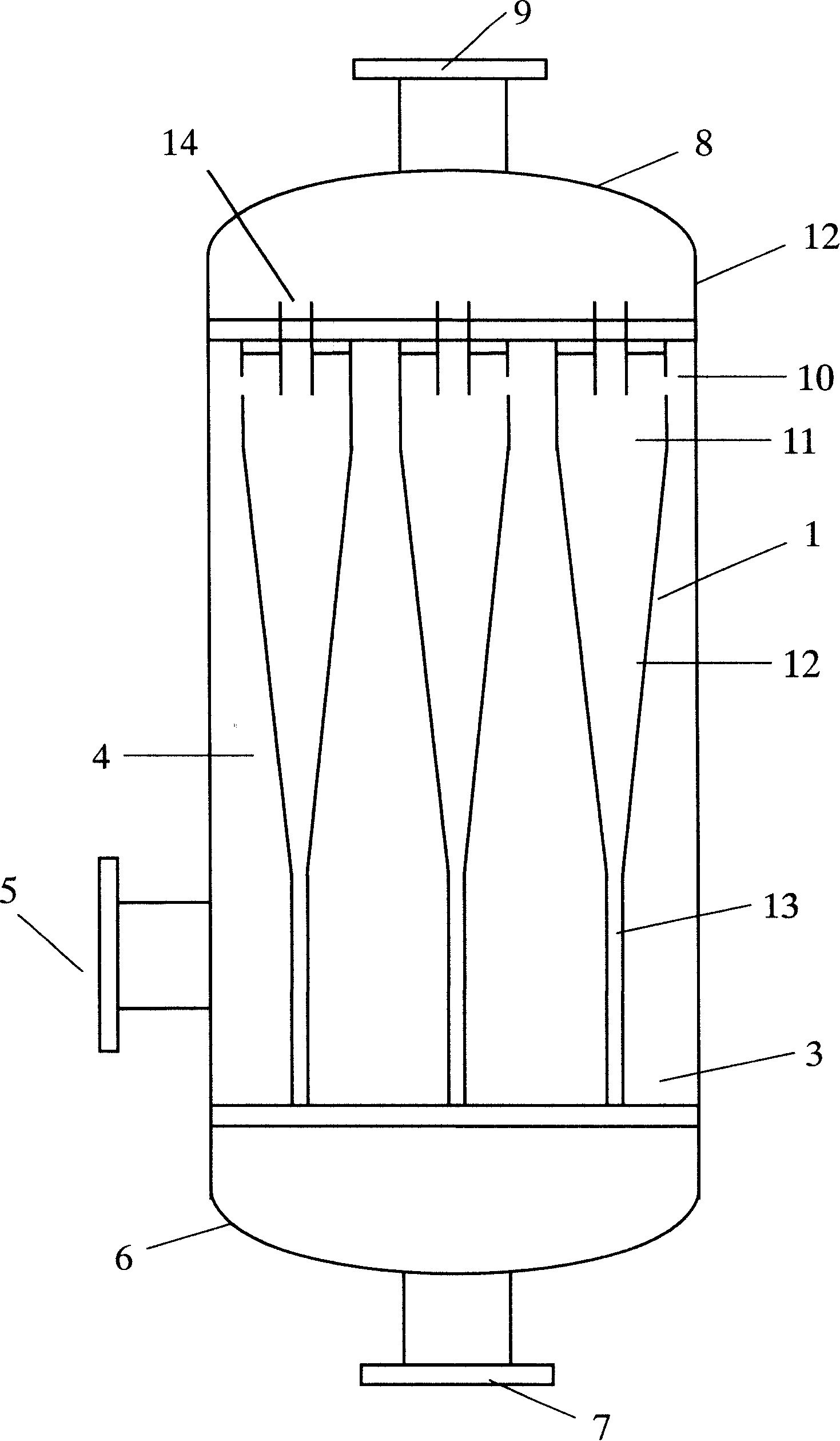

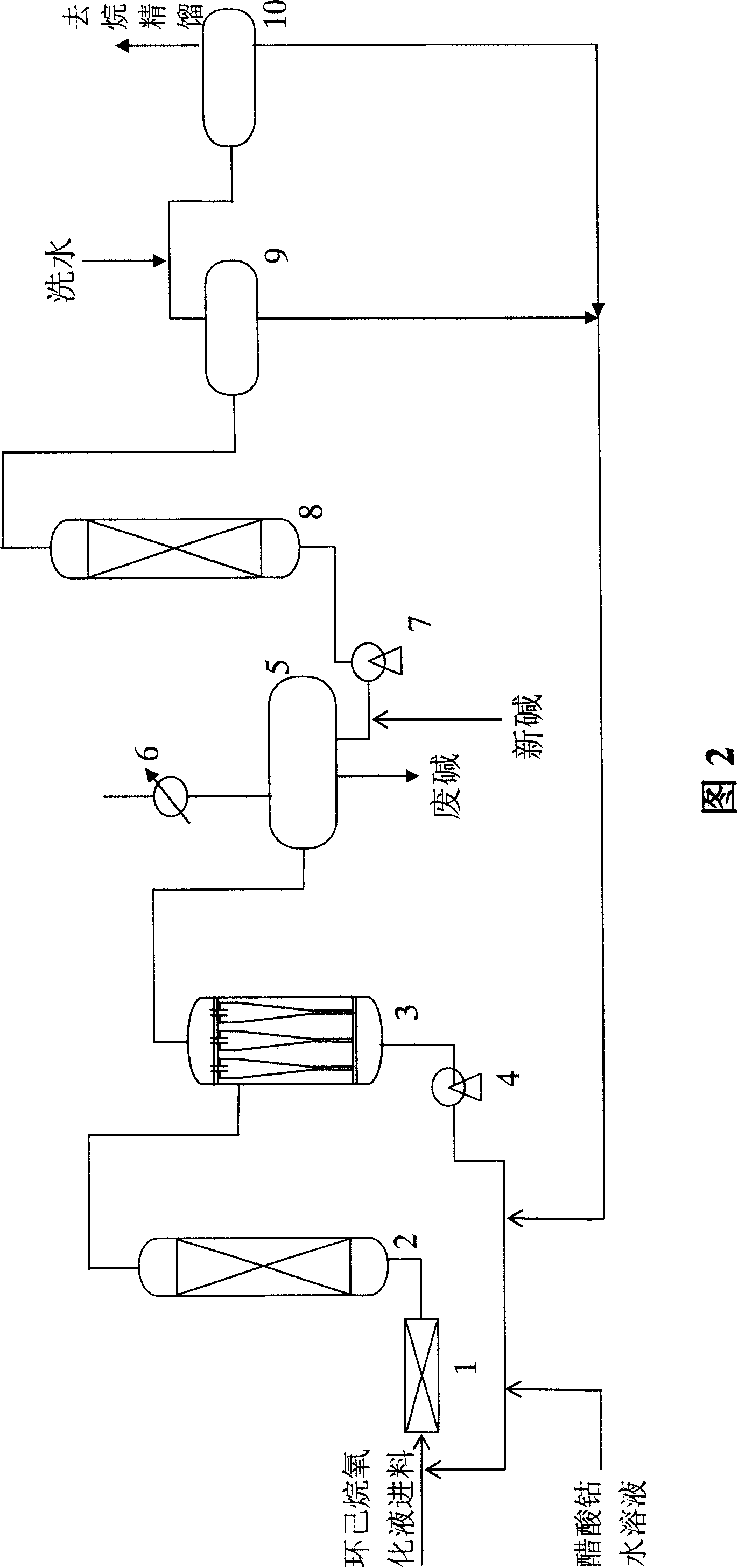

[0010] Embodiment: This embodiment uses the schematic diagram of the pseudo-homogeneous decomposition process flow diagram of cyclohexyl hydroperoxide shown in FIG. 2 . The cyclohexane oxidation liquid of 379 tons / hour passes through heat exchanger from oxidation process, cooler, and temperature drops to 60 ℃, contains cyclohexyl hydroperoxide 3.4% (Wt%), cyclohexanone in this cyclohexane oxidation liquid 0.35%, cyclohexanol 0.7%, organic carboxylic acid 0.2%, other components 0.2%, cyclohexane is 95.15%, this cyclohexane oxidation liquid and the 500m that comes from lye circulation pump 4 3 / hour circulating alkali and 40m from the alkali separator 9 and the washing water separator 10 3 / h Alkali aqueous solution is mixed in a static mixer, and 40 liters of aqueous solution containing 300 ppm of cobalt acetate is added at the same time; the cyclohexane phase is a dispersed phase, and the alkali solution is an emulsion of a continuous phase, and then enters the first step dec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com