Process for separating and recovering ethane and heavier hydrocarbons from LNG

a technology of ethane and hydrocarbons, which is applied in the field of processing gasses, can solve the problems of uncontrollable “rollovers” in the storage of lng

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

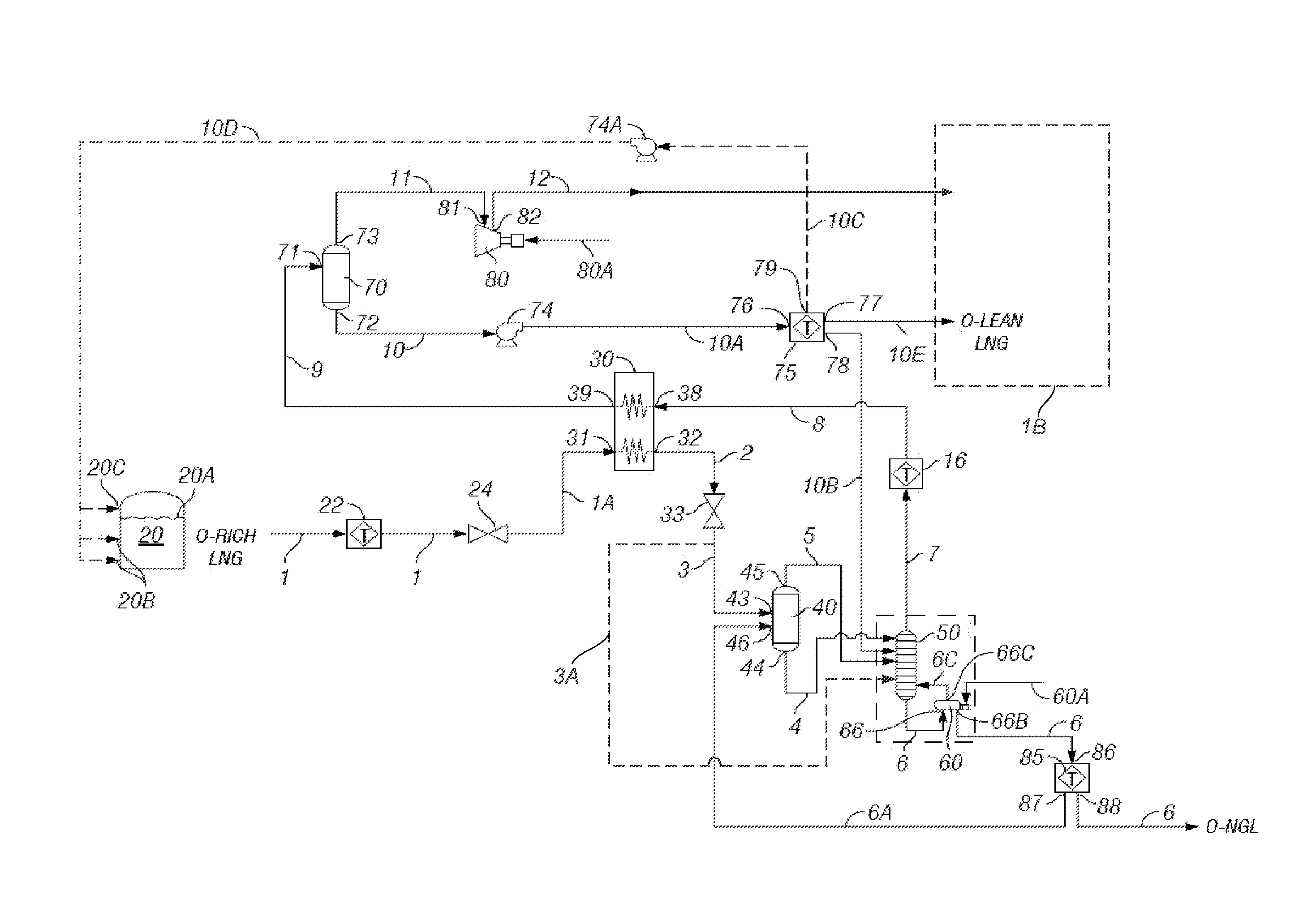

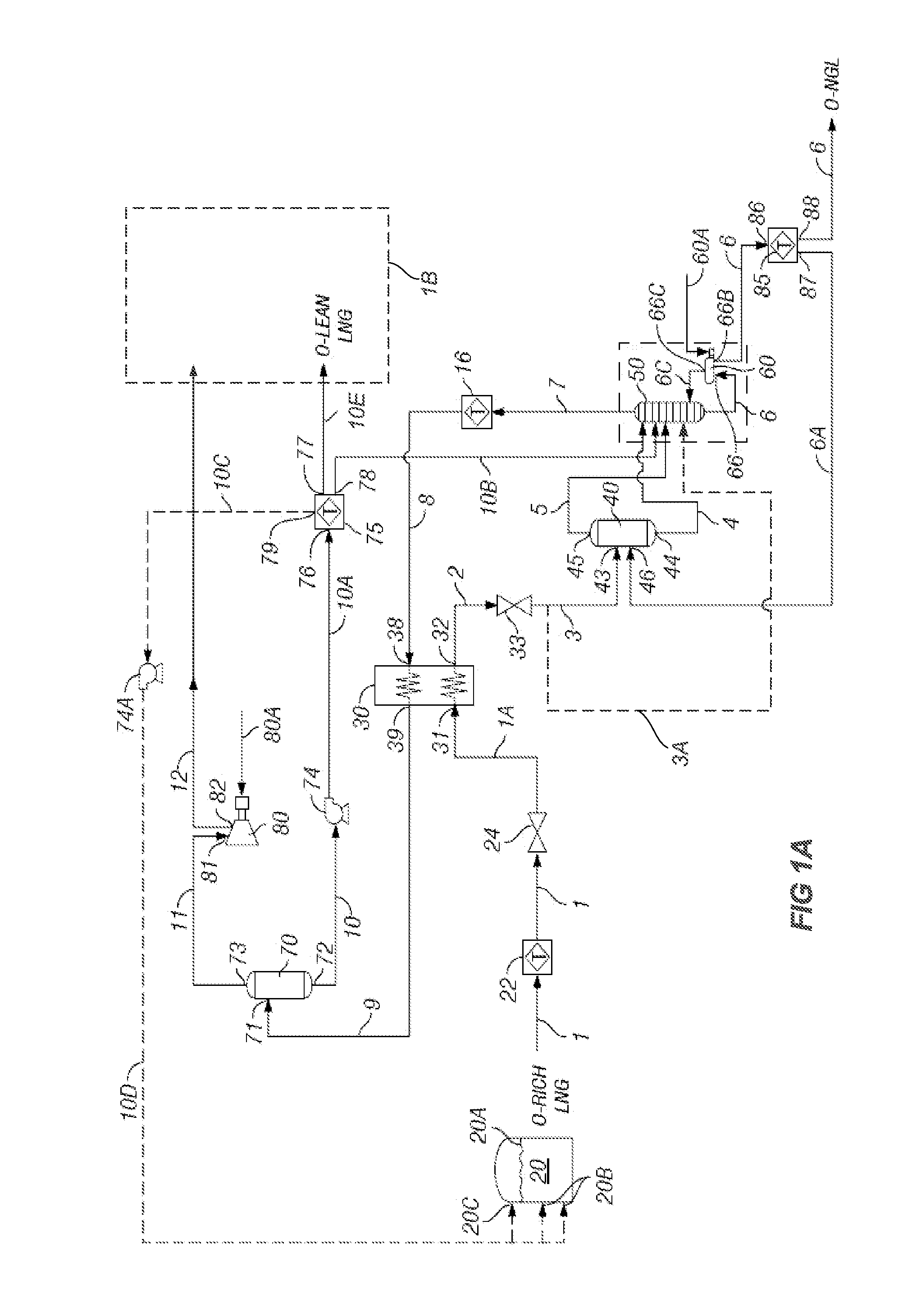

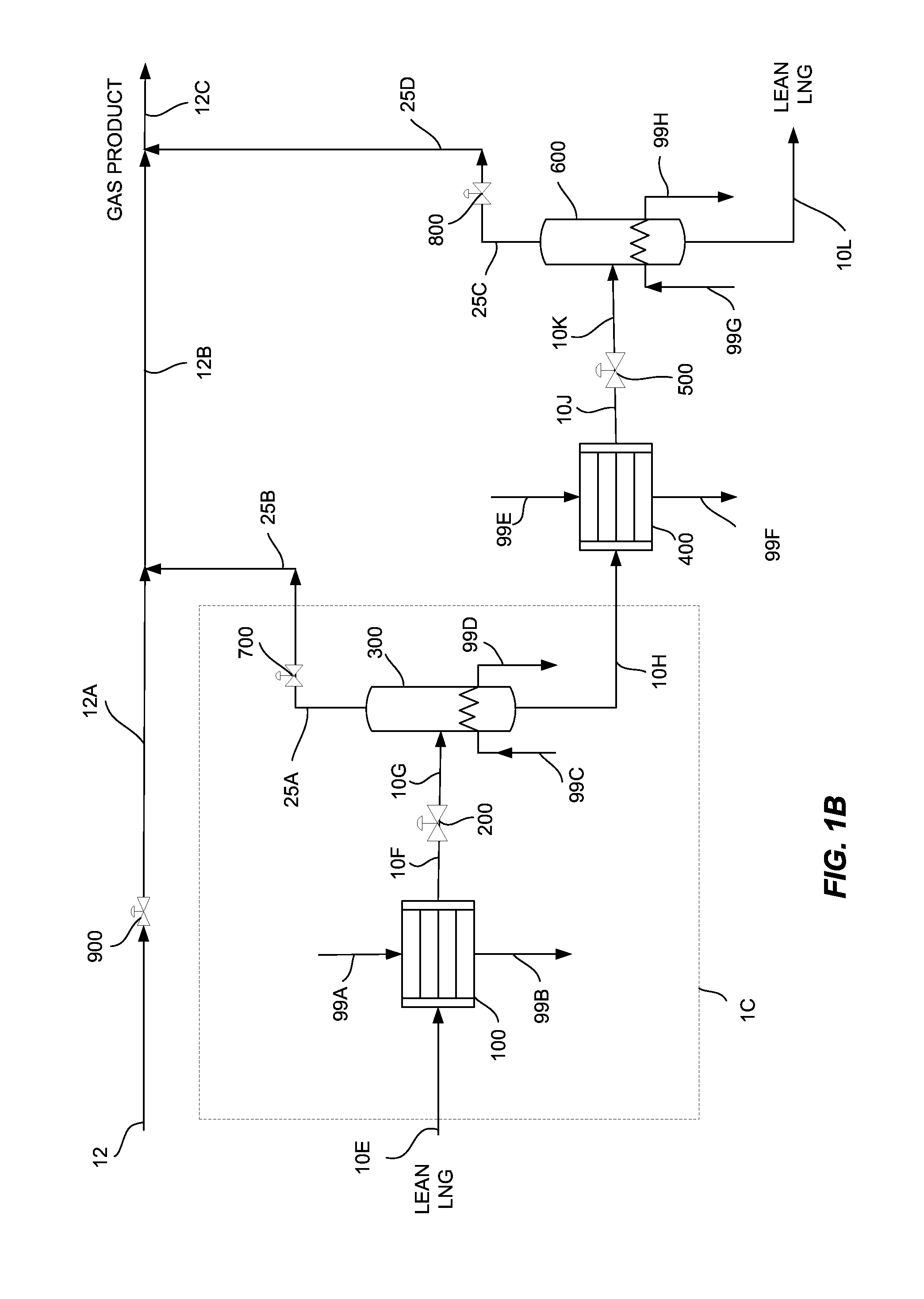

[0043]The present invention is generally concerned with the practical recovery or separation of less volatile components from a mix of other components as for example in this instance methane rich stream is separated from a stream of less volatile components than methane as may consist in LNG and such streams.

[0044]Also disclosed are designs for a novel but practical method and an arrangement, management and control of it to achieve such separation while at the same time providing means and direction for achieving practical sizing and / or design and / or operation of the equipment used in performing the separations.

[0045]It further is designed and shown as for in this instance to take a “rich” in varying degrees, in lower volatile components than methane in LNG (termed “rich LNG”) stream, from its storage or transport conditions of but particularly liquid form, as far as possible maintain that phase or form while cross exchanging its cold energy condition to absorb heat from one of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com