Mechanical seal stationary ring and rotating ring, and double-end mechanical seal composed of the same

A mechanical seal and static ring technology, applied in the direction of engine seals, mechanical equipment, engine components, etc., can solve problems such as affecting the sealing effect, fluctuation of the specific pressure of the sealing ring, and no discovery, and achieve good sealing effect, small sealing failure, and design. reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

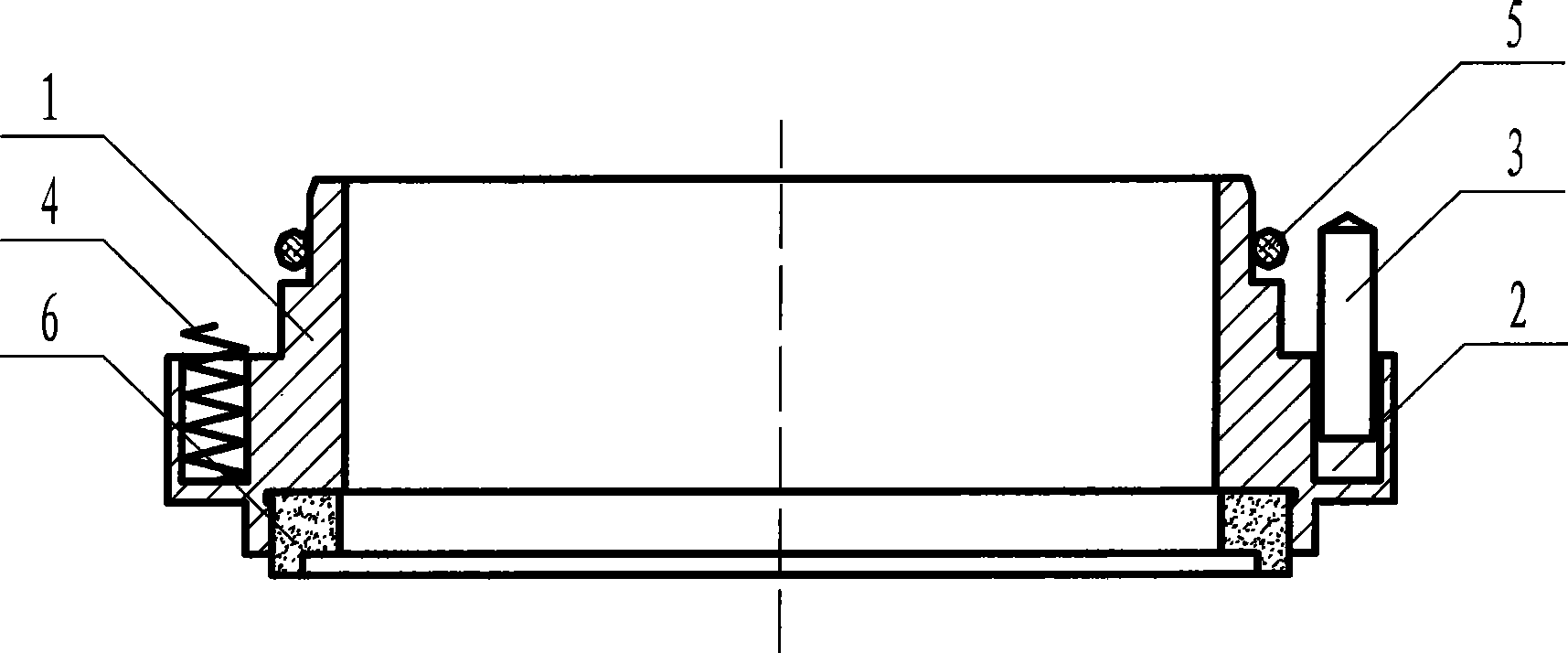

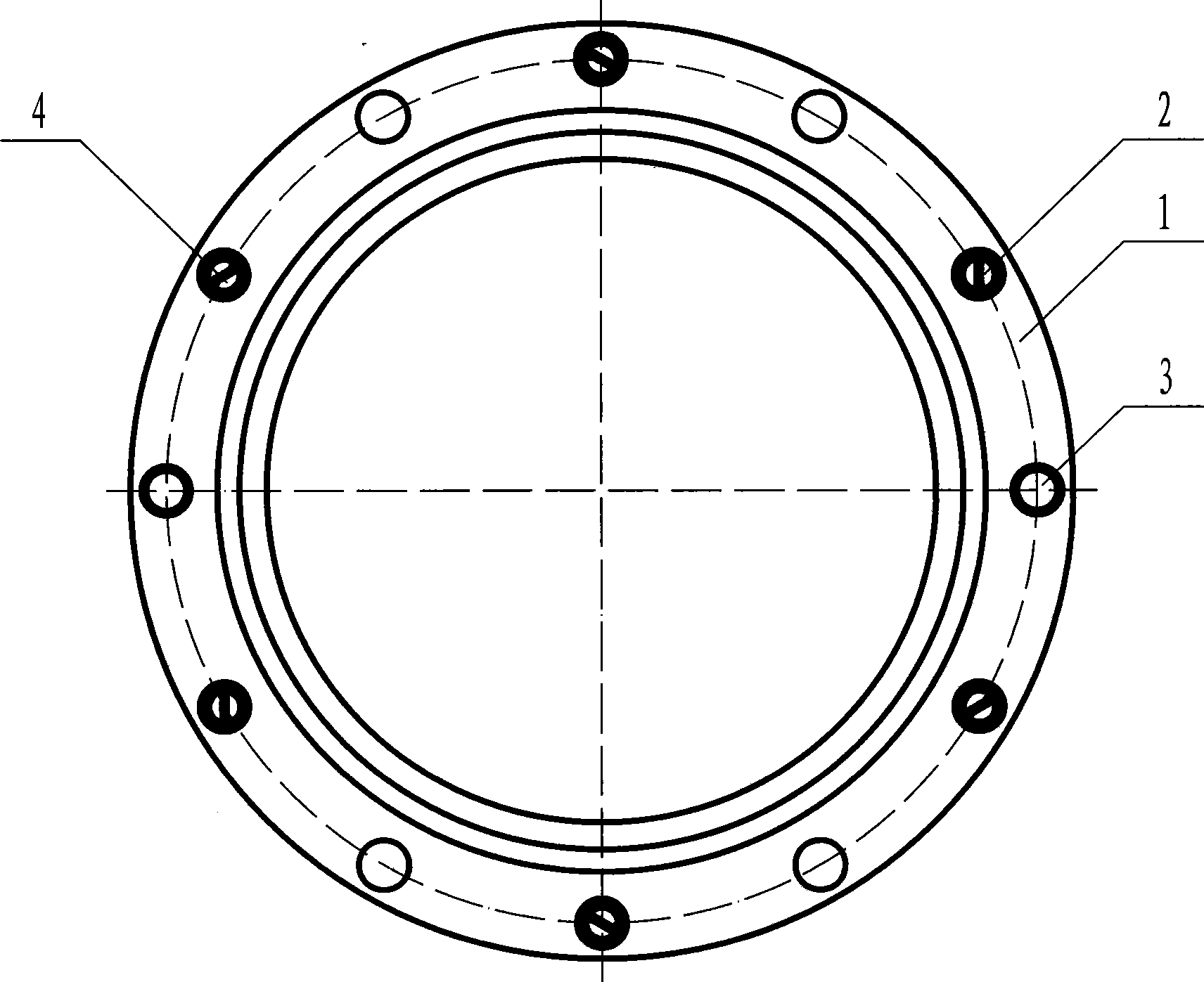

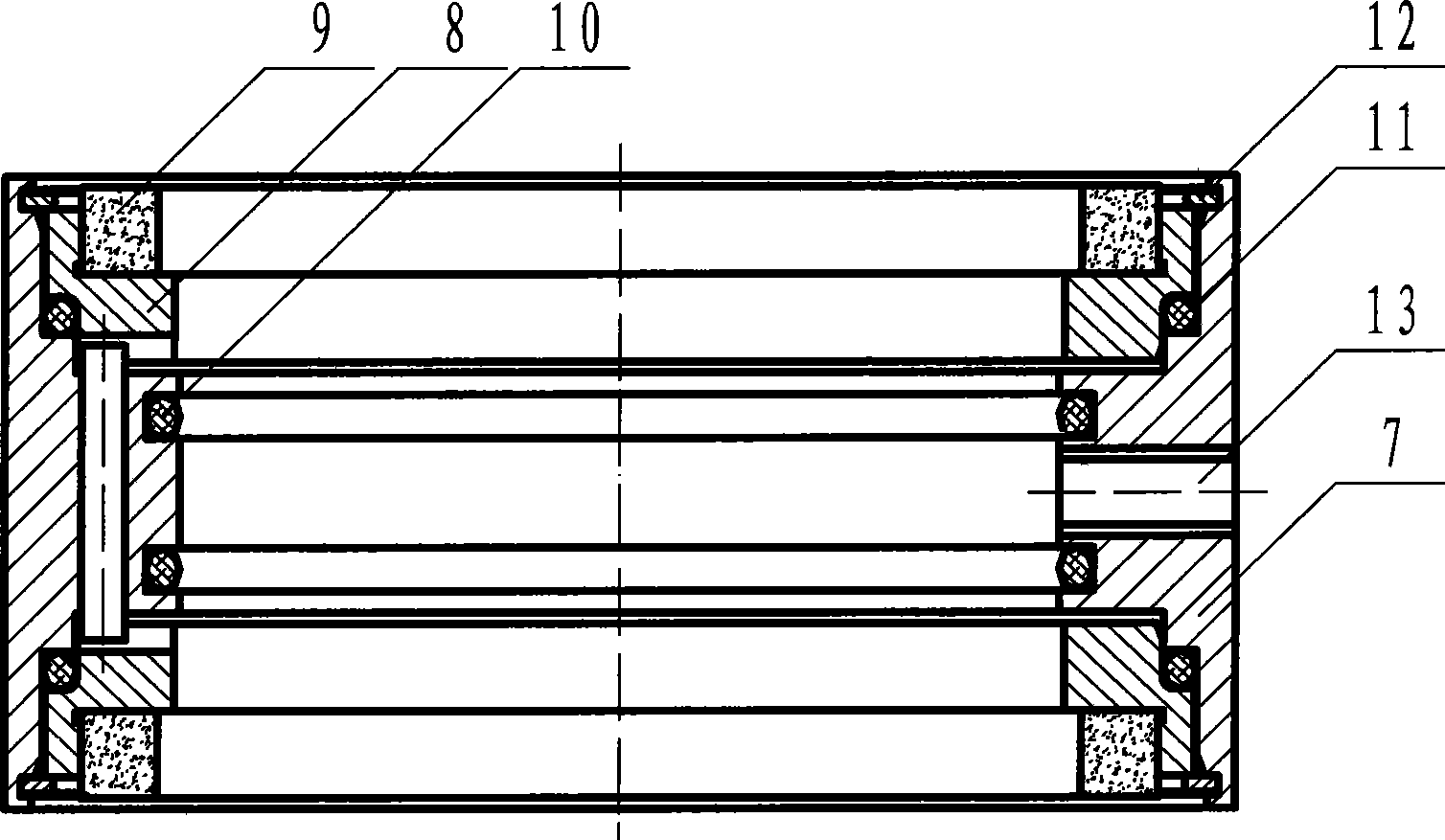

[0022] Attached below figure 1 -6 A mechanical seal static ring, a dynamic ring and the double-face mechanical seal constituted by the present invention will be described in detail below.

[0023] as attached figure 1 , 2 As shown, a mechanical seal static ring of the present invention has a structure including a circular static ring body 1, the side of the static ring body 1 has a stepped structure, and several blind holes are evenly opened on the upper surface of the lower end of the stepped structure. Holes 2 and blind holes 2 are provided with transmission pins 3 and small springs 4, O-rings 5 are provided on the outer surface of the upper end of the stepped structure, and static ring friction pairs 6 are provided on the lower surface of the static ring body 1 .

[0024] The small springs 4 are evenly distributed in the blind hole 2, and the number thereof is determined by the pressure. When the pressure is high, reduce the number of small springs appropriately, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com