Mechanical seal device of screw power machine

A mechanical sealing device and power machine technology, applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of end faces kept on a plane for a long time, static ring bellows twisted, torn, poor fixation stability, etc. Achieve the effect of solving the problem of different expansion coefficients, good structural stability, and convenient installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

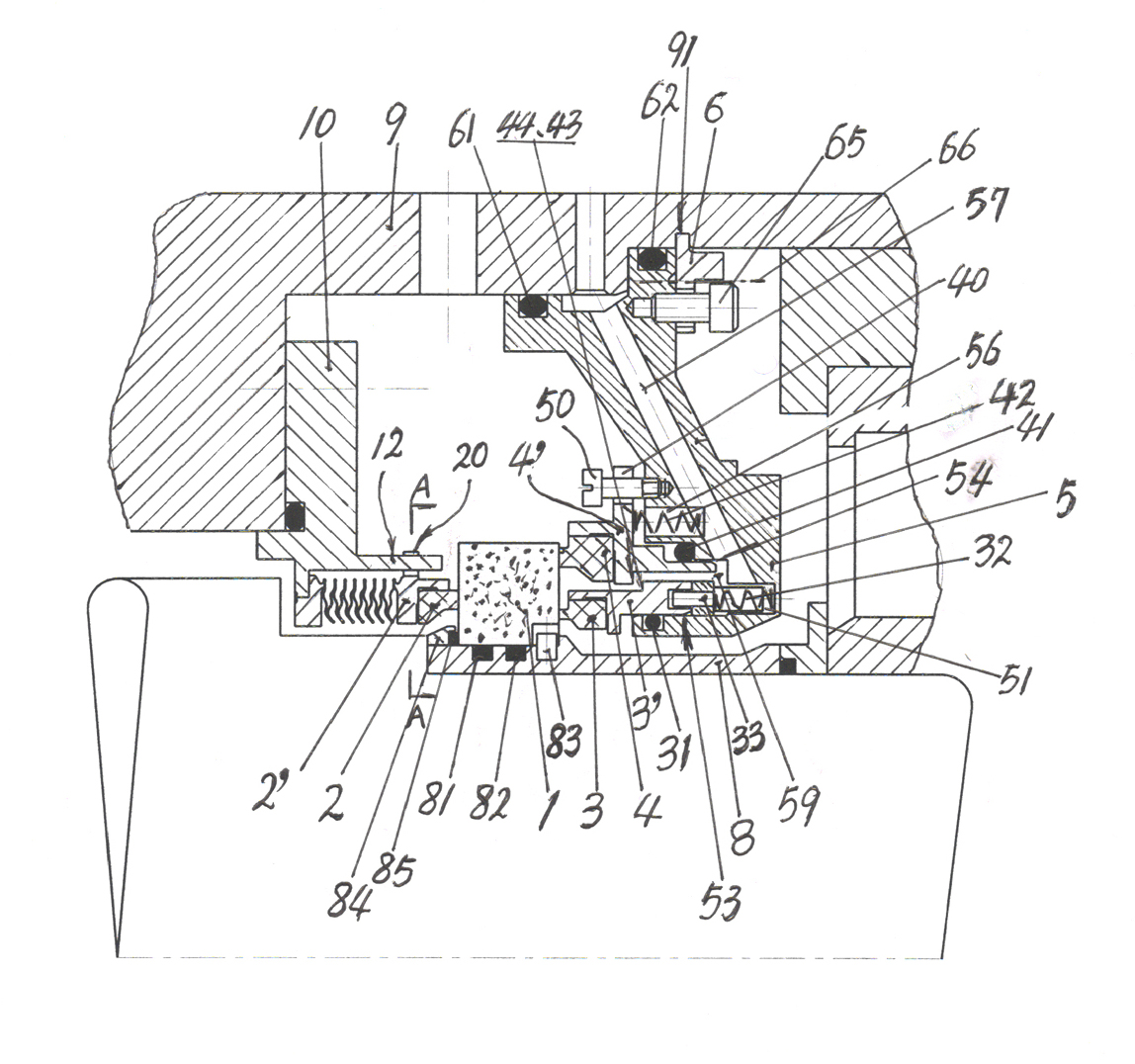

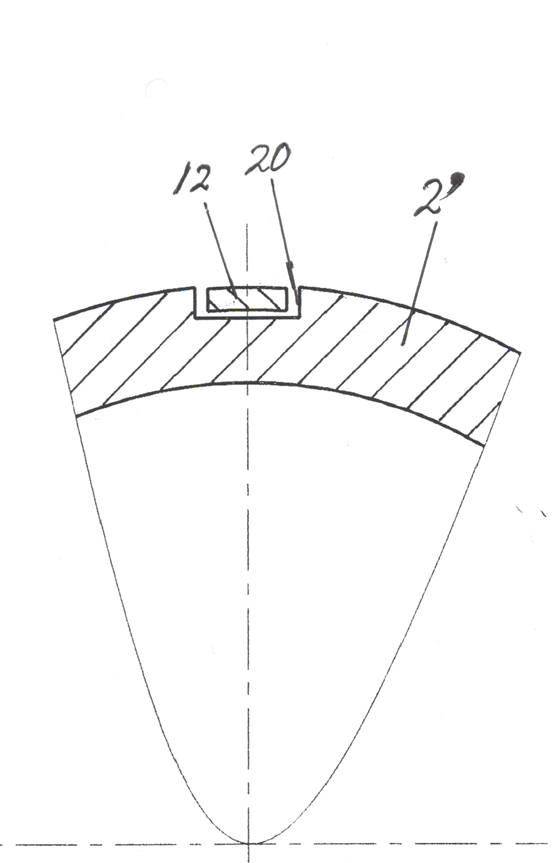

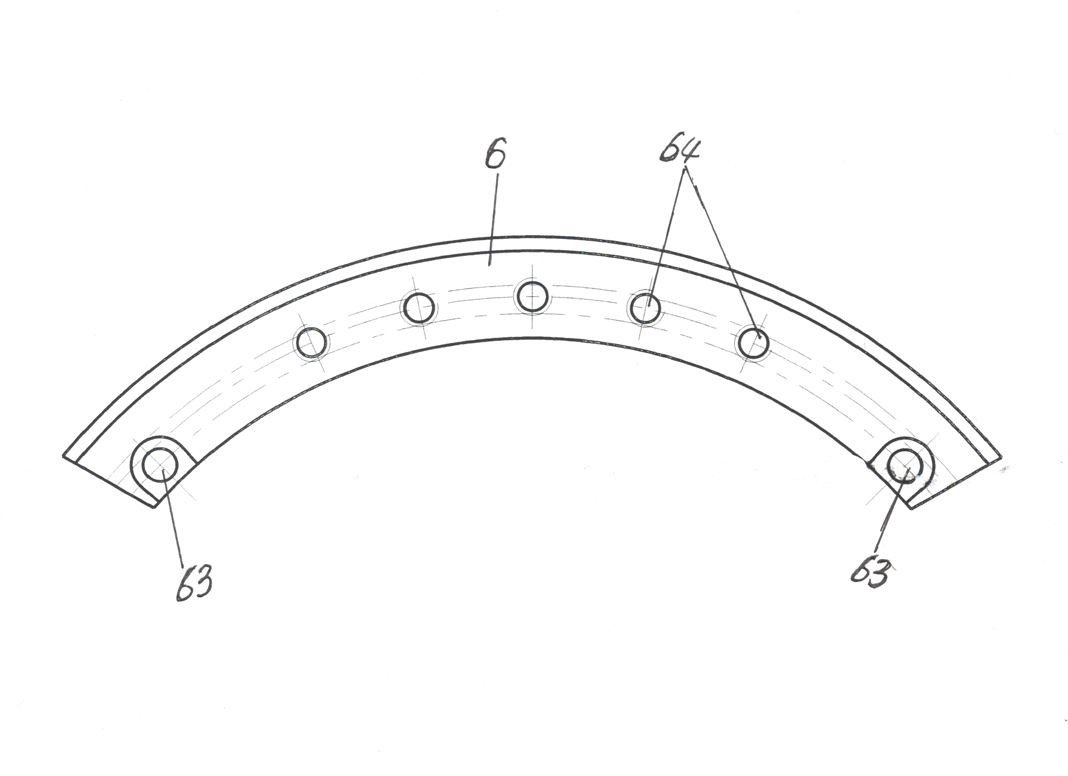

[0015] Screw power machine of the present invention The mechanical seal device consists of the moving ring 1 fixedly installed on the rotor shaft sleeve 8, the metal bellows respectively arranged on the left side of the moving ring 1 to compensate the static ring 2 and the spring on the right side to compensate the inner static ring 3 and the outer static ring 4 , The static ring seat 5 is formed to form an axial double-end face and a radial double-end mechanical seal mechanism. The metal bellows compensating static ring 2 is fixedly connected with the mouth of the body 9 through its connecting seat 10, and the ring 2' of the bellows compensating static ring 2 and its connecting seat 10 are respectively provided with mutually matching card slots 20 and The bump 12 prevents the bellows from compensating the excessive torsion of the front end of the static ring 2; the moving ring 1 is installed in cooperation with the spigot of the shaft sleeve 8, and two auxiliary sealing ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com