All-glass heat pipe type vacuum heat collecting pipe with CPC condenser

A technology of vacuum heat collection tube and glass heat pipe, which is applied in the field of solar heat collection to achieve good light transmission, reduce costs, and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

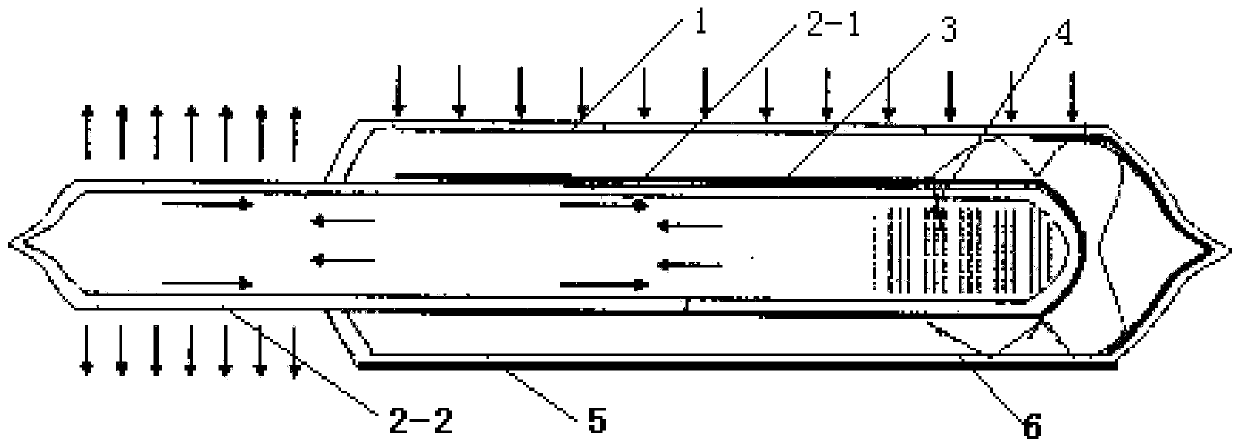

[0032] Example 1, such as Figure 1-2 As shown, the all-glass heat-pipe vacuum heat collecting tube with the CPC concentrator in this embodiment includes a glass outer tube 1, a glass heat pipe that extends into the glass outer tube and is seamlessly fixedly connected with the opening of the glass outer tube 2. The vacuum degree in the cavity between the glass outer tube and the glass heat pipe is less than 1×10-4Pa, and a support structure 6 and a getter are placed in it, and a heat transfer medium 4 is installed in the glass heat pipe, and the glass heat pipe The part of the heat pipe inside the glass outer tube becomes the heating section 2-1, and the part outside the glass outer tube is inserted into the hot water tank to become the condensation section 2-2. The outer wall of the heating section is coated with a heat-absorbing coating 3, so The glass outer tube and the glass heat pipe adopt the same glass, and a CPC concentrator 5 is arranged between the glass outer tube a...

Embodiment 2

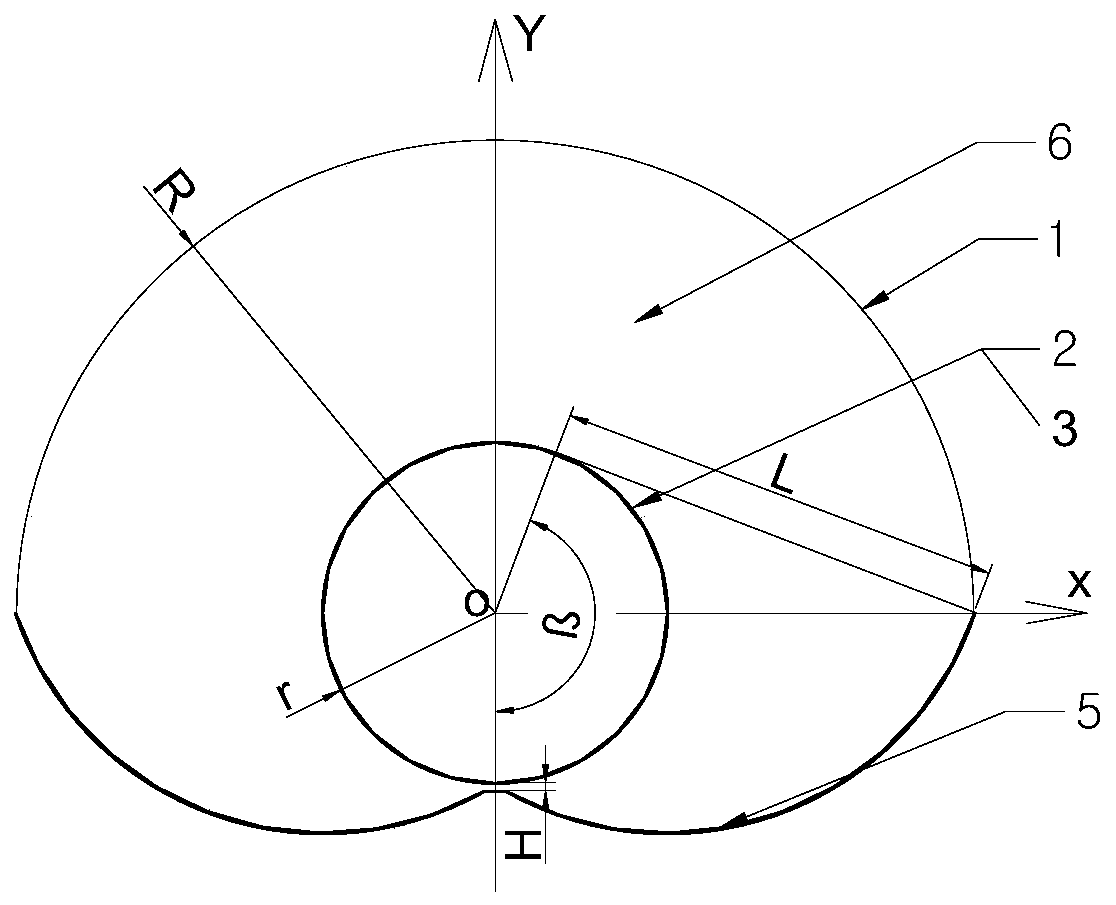

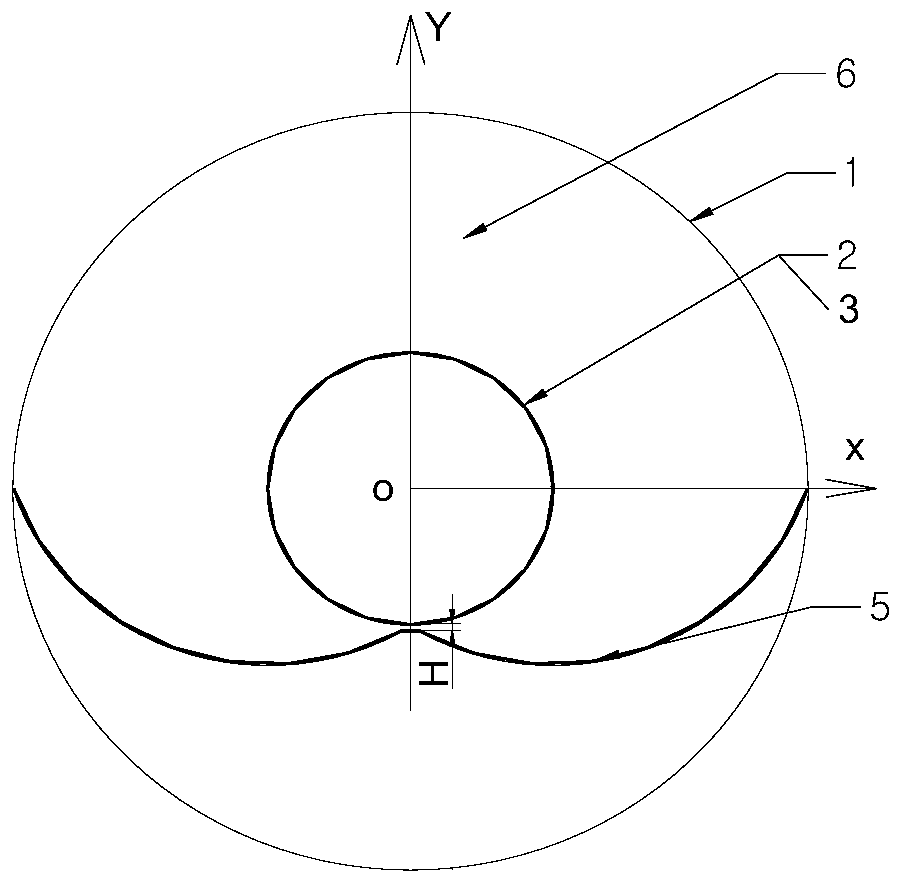

[0048] The difference between this embodiment and Embodiment 1 is that the all-glass heat pipe vacuum heat collector with a CPC concentrator described in this embodiment, the CPC concentrator includes a reflective plate of a CPC type structure, The CPC-type reflector is inserted into the cavity between the glass outer tube and the glass heat pipe, and the section profile of the CPC-type reflector is an involute and a transition platform in the middle, and the involute The base circle of is the cross-sectional circle of the heating section of the glass heat pipe, and the radius of the base circle is r, then the equation of the involute is:

[0049]

[0050] where L is the arc length of the involute angle β, and L:

[0051]

[0052] The involutes are distributed symmetrically. The involutes start from the lowermost end of the base circle and end when both sides are flush with the center of the base circle. The distance between the transition platform in the middle and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tube wall thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com