Honeycomb core stretching and dipping and curing integrated device and using method thereof

A technology of honeycomb core and honeycomb, which is applied in other household appliances, applications, household components, etc., can solve the problems of inapplicable small-batch and multi-variety honeycomb core material manufacturing, base material performance attenuation, poor connection, etc., to achieve reusability performance, excellent corrosion resistance, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail through the drawings and examples below. Through these descriptions, the features and advantages of the present invention will become more apparent.

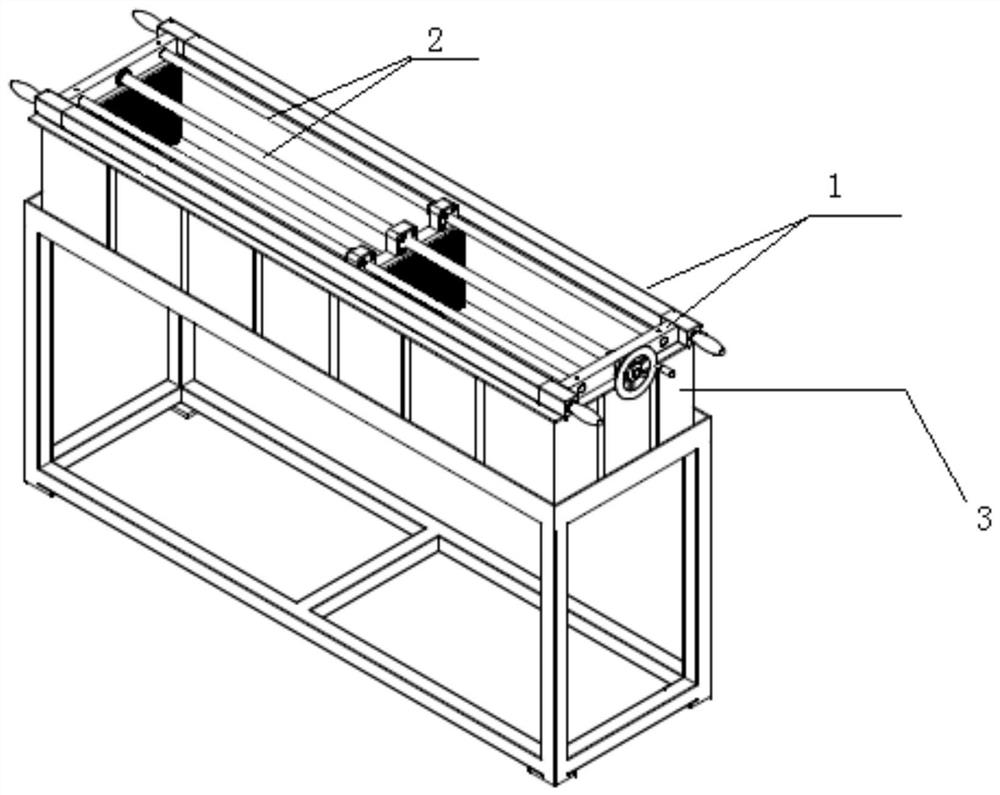

[0029] According to the first aspect of the present invention, such as figure 1 and figure 2 As shown, a honeycomb core stretching-impregnation-curing integrated device is provided, which includes a stretching frame 1, a transmission unit 2 carried by the stretching frame 1, and a dipping rubber under the stretching frame 1 Unit 3, where,

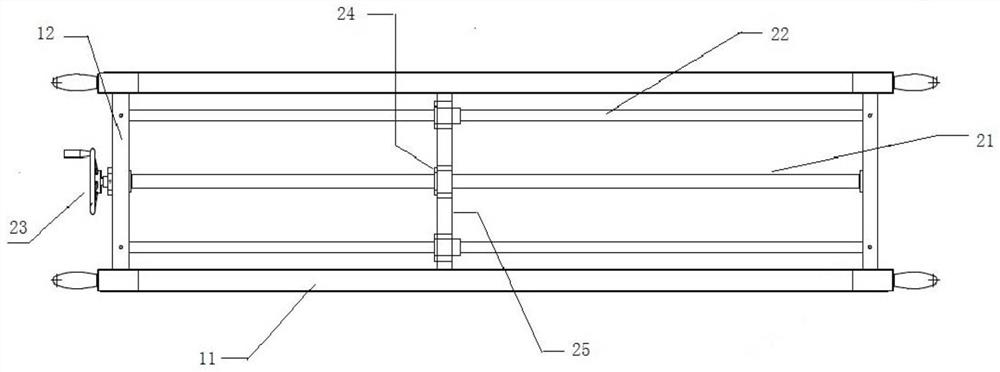

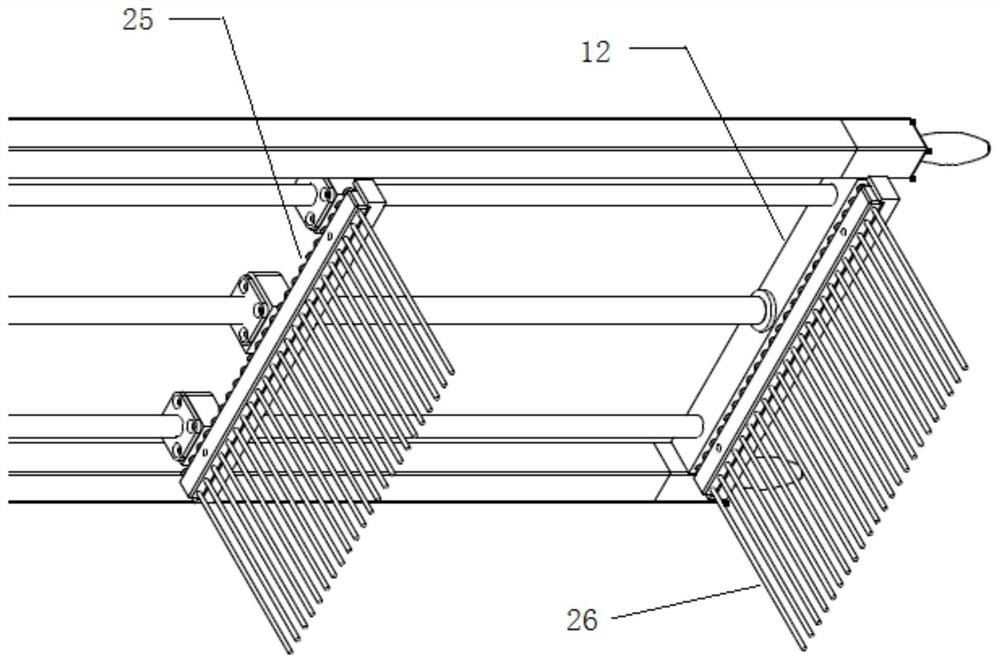

[0030] The stretching frame 1 comprises two parallel rectangular square tubes 11 for forming the long side of the stretching frame 1 and two parallel fixed blocks 12 for forming the short side of the stretching frame 1, and the fixed blocks 12 are installed At both ends of the rectangular square tube 11 and surrounded by two rectangular square tubes 11 to form a rectangle;

[0031] The transmission unit 2 includes a ball sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com