Double-end-surface mechanical seal

A mechanical seal and double-end technology, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of increasing the use and maintenance costs of mechanical seals, affecting product quality, and affecting stable production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

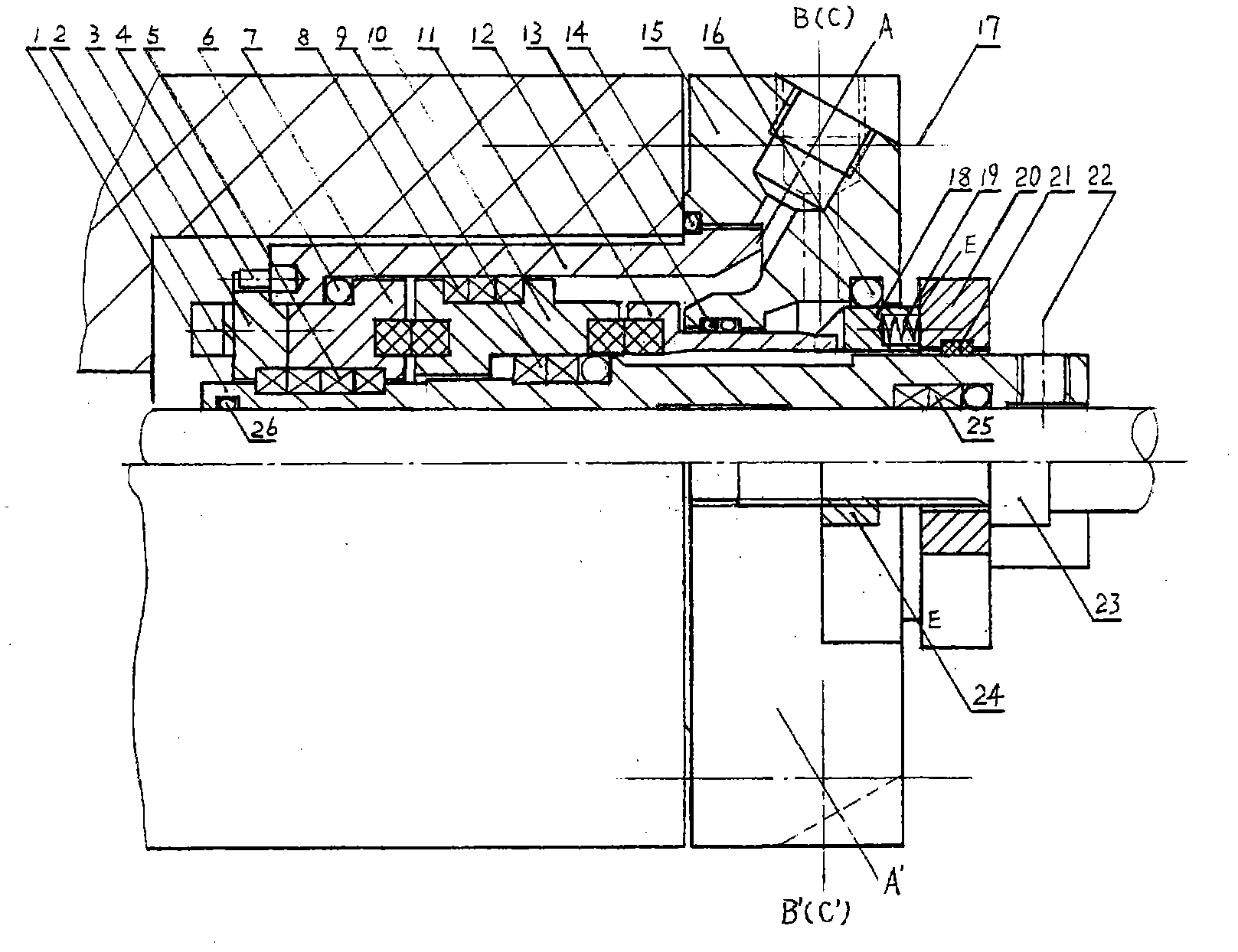

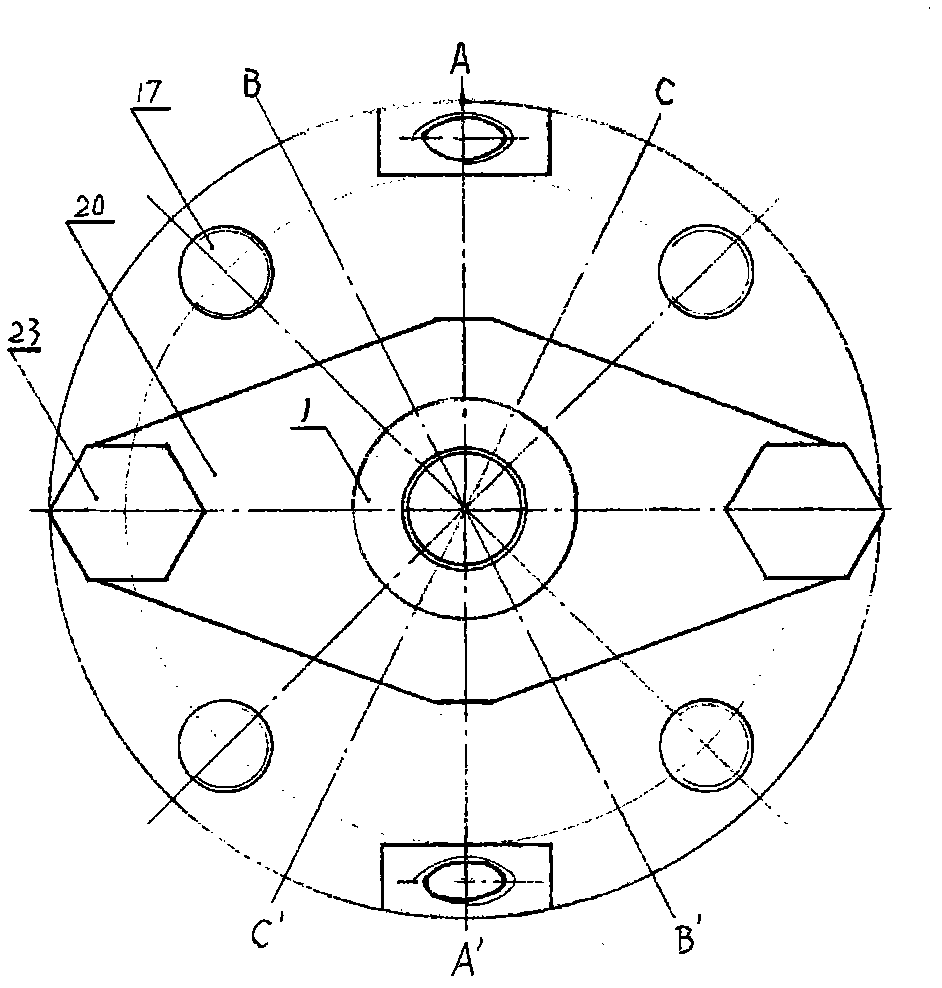

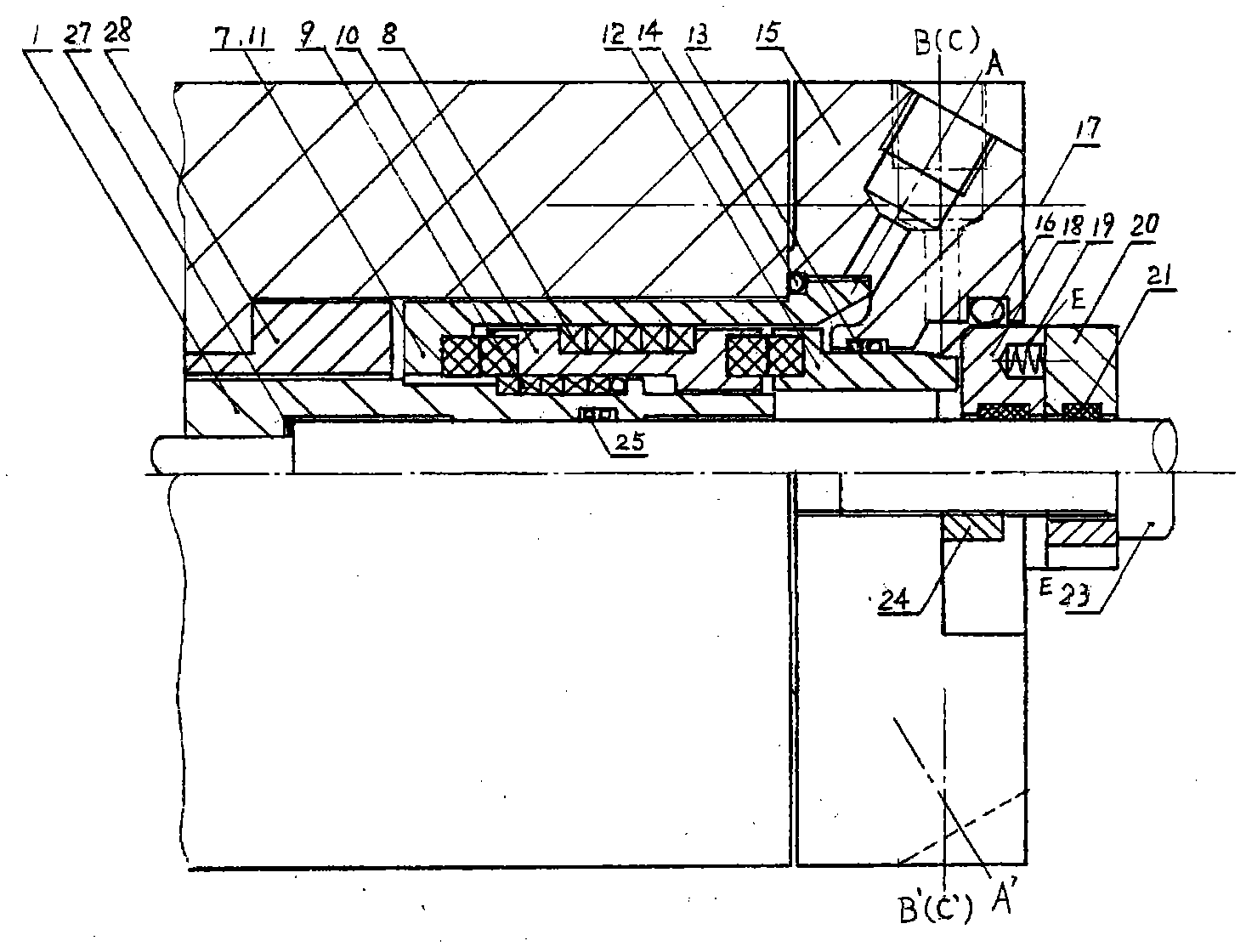

[0015] Below in conjunction with accompanying drawing, the present invention will be further described; figure 1 Shown is a schematic diagram of the standard structure of the double-end mechanical seal part of the entire equipment. The gland 15 is fixed on the stationary equipment body with gland bolts 17 and the gland sealing ring 16 is pressed tightly to prevent the sealed medium from leaking from here. The shaft sleeve 1 is fixed on the rotating shaft of the equipment with the shaft sleeve set screw 22 and rotates with the shaft. The shaft sleeve sealing ring assembly 25 and the front end sealing ring 26 of the shaft sleeve can effectively prevent the sealed medium from coming between the shaft sleeve and the shaft. Leakage in the radial gap, the static ring 7, the moving ring 10 and the compensation ring 12 are installed in series in the closed annular space composed of the sealing sleeve 11, the gland 15, the spring seat 18 and the shaft sleeve 1. The ring set screw 2 loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com