Waste heat discharge pump for nuclear power plant

A technology for removing waste heat from pumps and nuclear power plants. It is applied to pumps, components of pumping devices for elastic fluids, and pump components, and can solve problems such as large axial force, inconvenient maintenance, and damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to better understand the technical solution of the present invention, it will be described in detail below through specific embodiments in conjunction with the accompanying drawings:

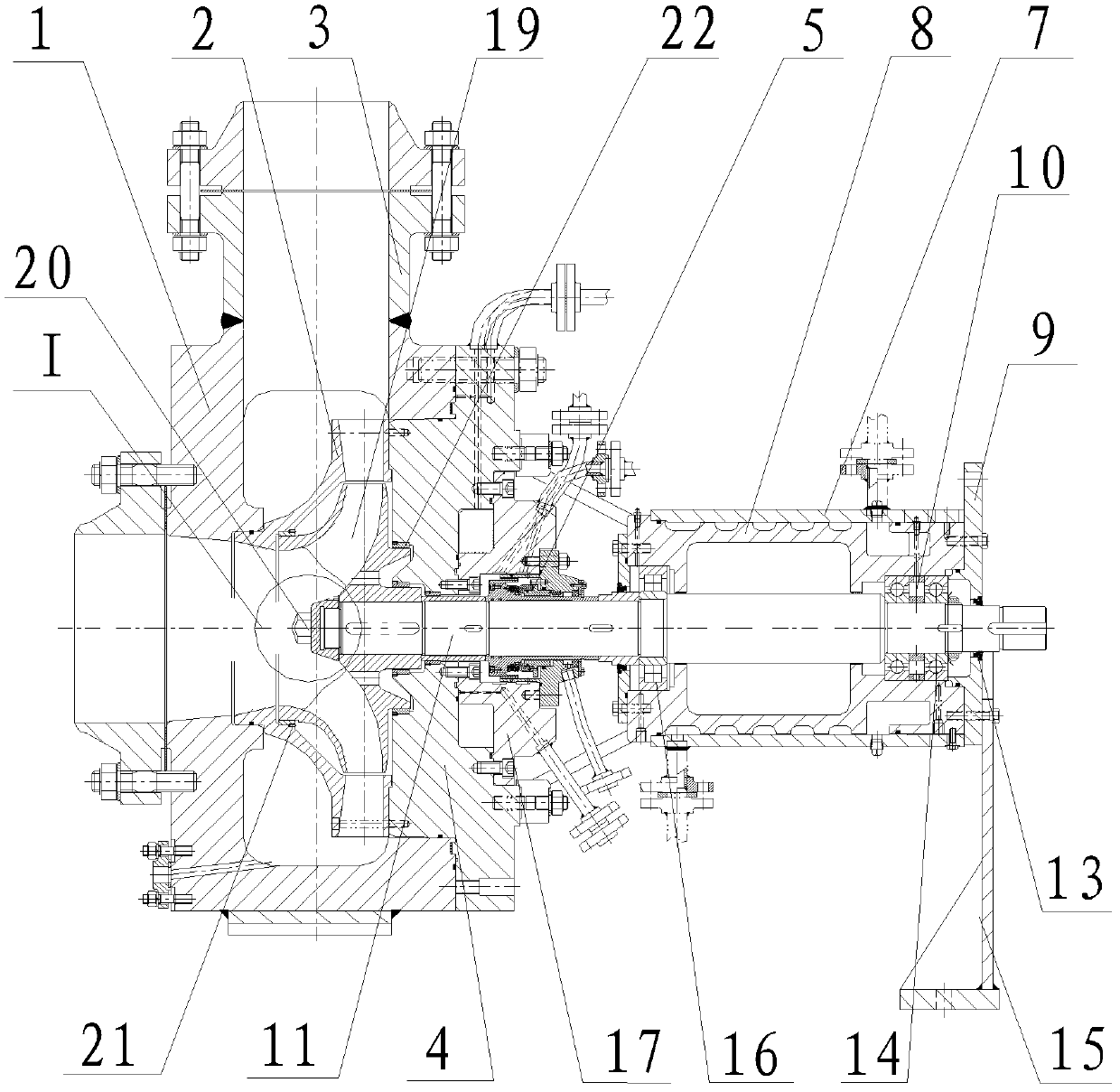

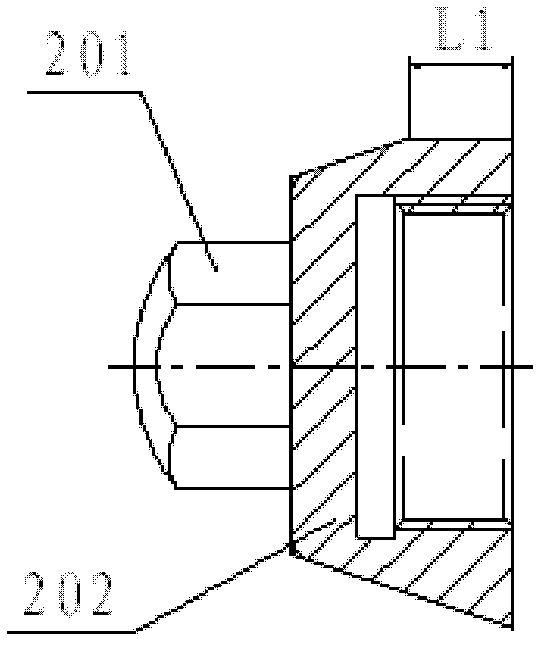

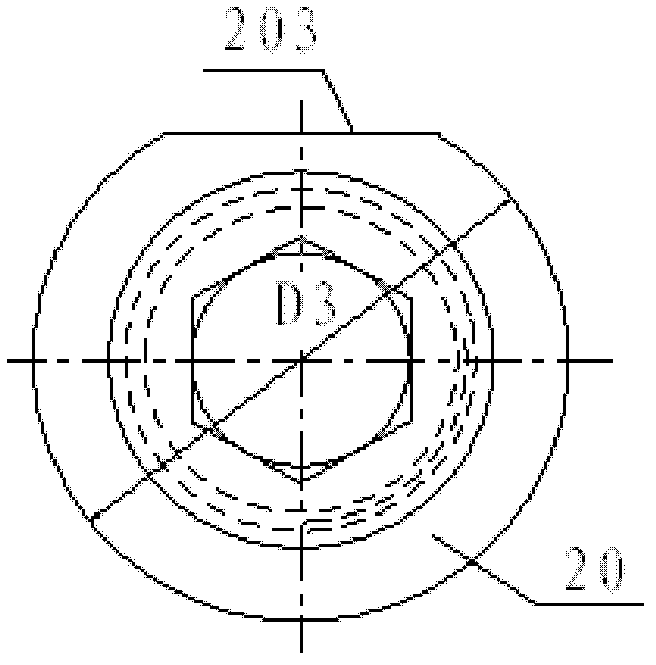

[0047] see figure 1 , a nuclear power plant waste heat discharge pump according to the present invention includes a stator component, a rotor component, a bearing component and a shaft sealing device 5 .

[0048] The stator part includes the pump casing 1, the guide vane 2 set in the inner cavity of the pump casing 1, the pump cover 3 connected to the front end of the pump casing 1 and the sealing box body 17 connected to the front end of the pump cover 4, wherein:

[0049] The inlet and outlet of the pump casing 1 are vertically arranged, and the inner cavity of the pump casing 1 is a ring-shaped extrusion chamber; the pump casing 1 has a simple structure, strong pressure bearing capacity, and uniform thermal deformation, ensuring high-temperature medium and earthquake conditions....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com