High performance magnetic pump

A magnetic pump, high-performance technology, used in pumps, pump components, components of pumping devices for elastic fluids, etc., can solve problems such as magnetic rotor overheating, burnt equipment, spindle bearing damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

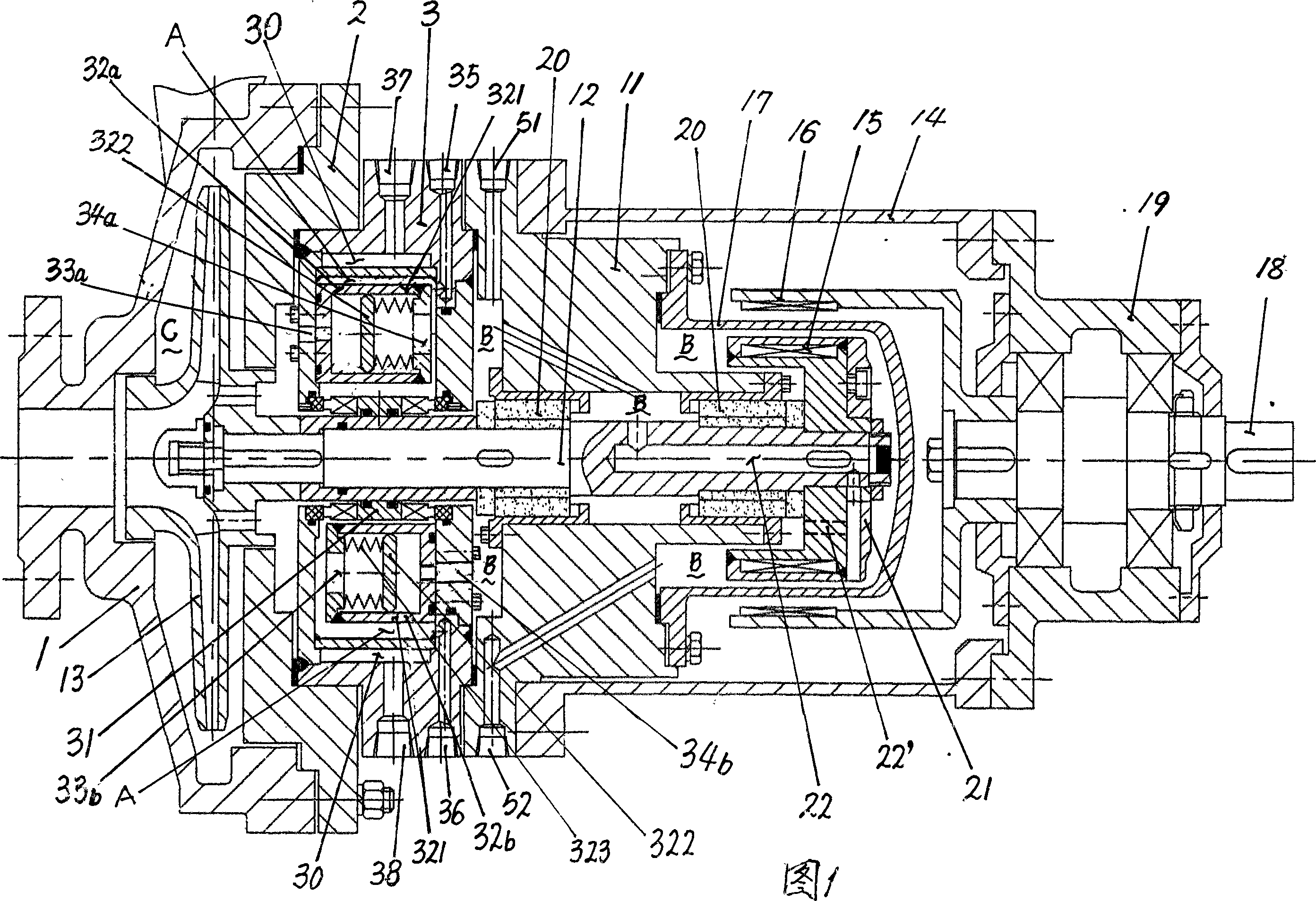

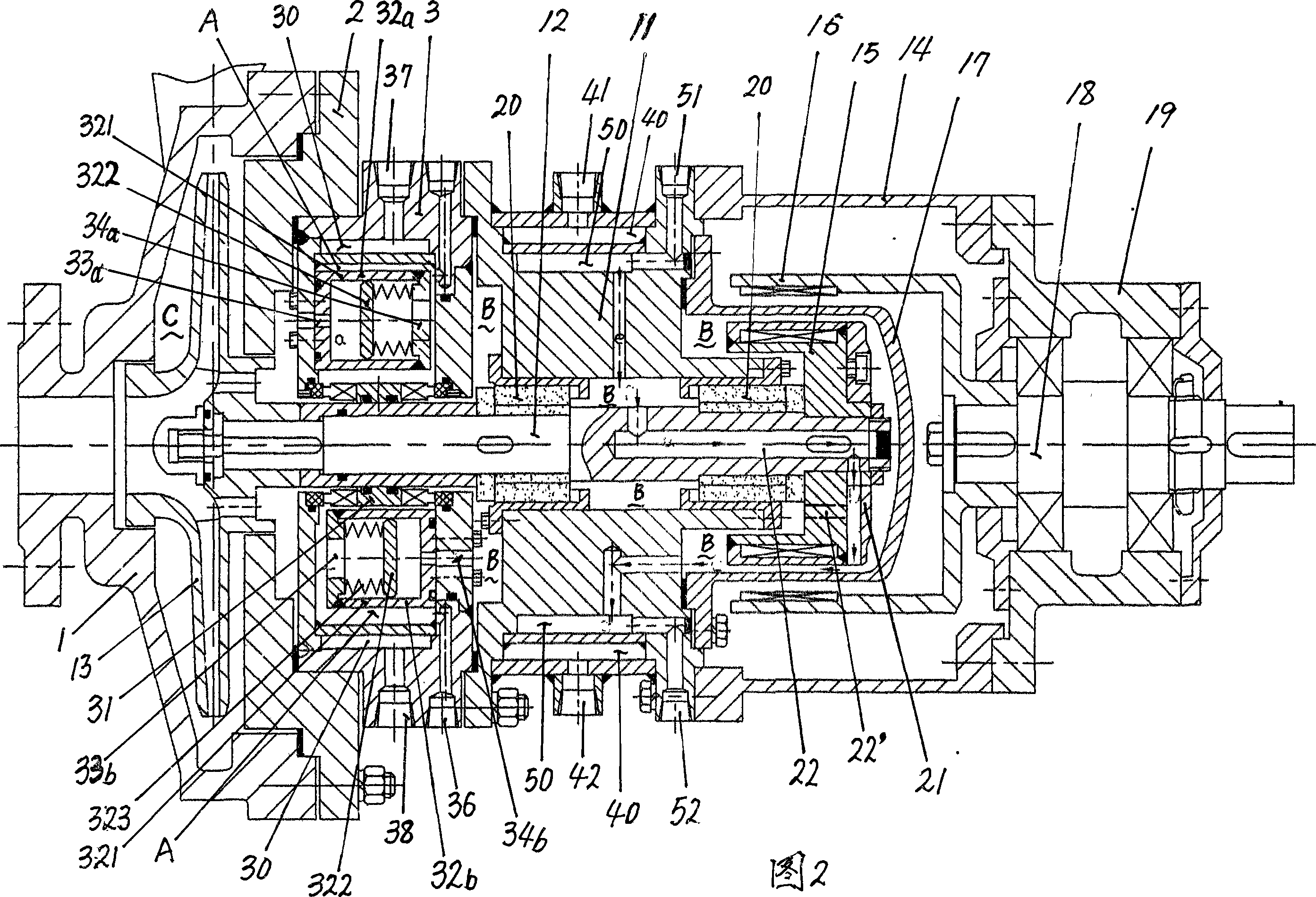

[0010] Referring to Figure 1, the present invention includes a pump body 1, a pump cover 11, a pump shaft 12, an impeller 13, a coupling frame 14, an inner magnetic rotor 15, an outer magnetic rotor 16, an isolation sleeve 17, a drive shaft 18, and a drive shaft The bearing box 19, the pump shaft 12 and the pump cover 11 are installed and connected through rolling bearings or sliding bearings 20, the coupling frame 14 is fixedly connected with the pump cover 11, the drive shaft bearing box 19 is docked and fixedly connected with the coupling frame 14, and the inner magnetic rotor 15 is fixed Installed on the shaft end of the pump shaft 12, the outer magnetic rotor 16 is fixedly installed on the shaft end of the drive shaft 18, and a spacer 17 is arranged between the inner magnetic rotor 15 and the outer magnetic rotor 16, and the spacer 17 is sealed and fixedly connected with the pump cover 11, Between the pump body 1 and the pump cover 11, a front pump cover 2 and a sealing bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com