Mechanical sealing device of vapour-liquid full flow screw power machine

A mechanical seal device and power machine technology, which is applied in the direction of engine seals, mechanical equipment, engine components, etc., can solve the problems of poor mechanical seal compensation ring motion, affecting the lubrication of bearings and gears, aging of rubber auxiliary seals, etc., to achieve reliable operation , Strong resistance to jamming, and the effect of reducing the temperature of the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

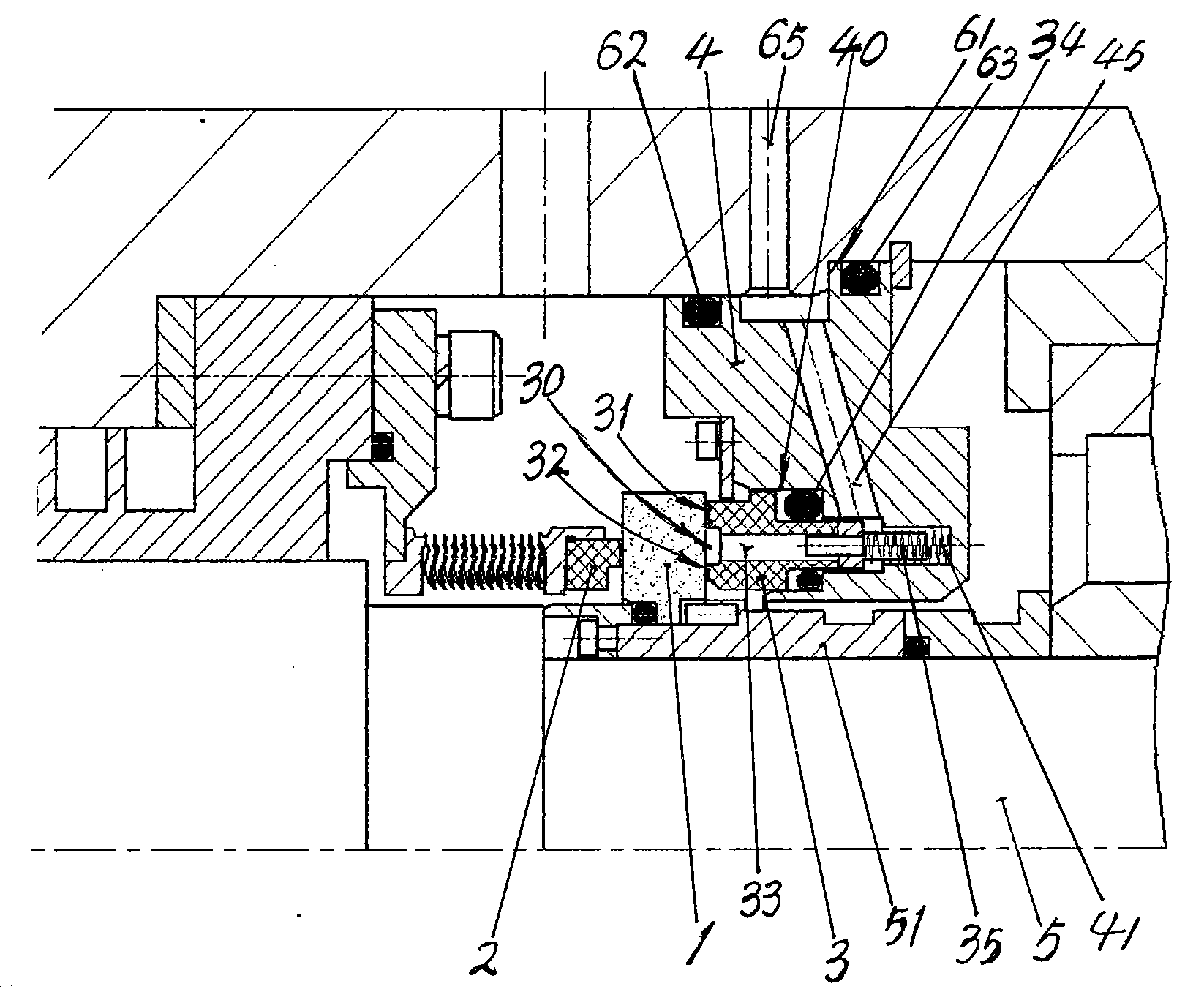

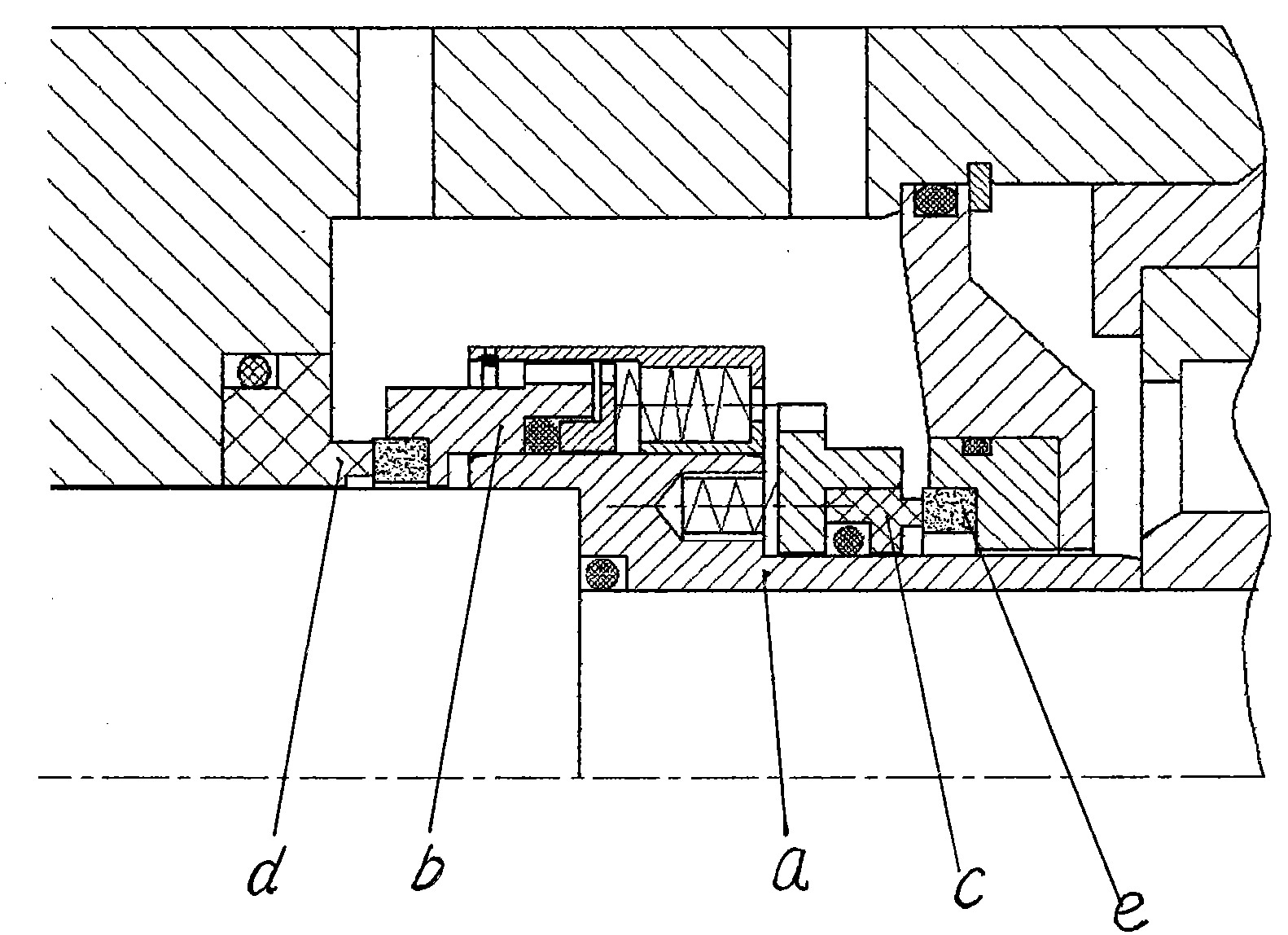

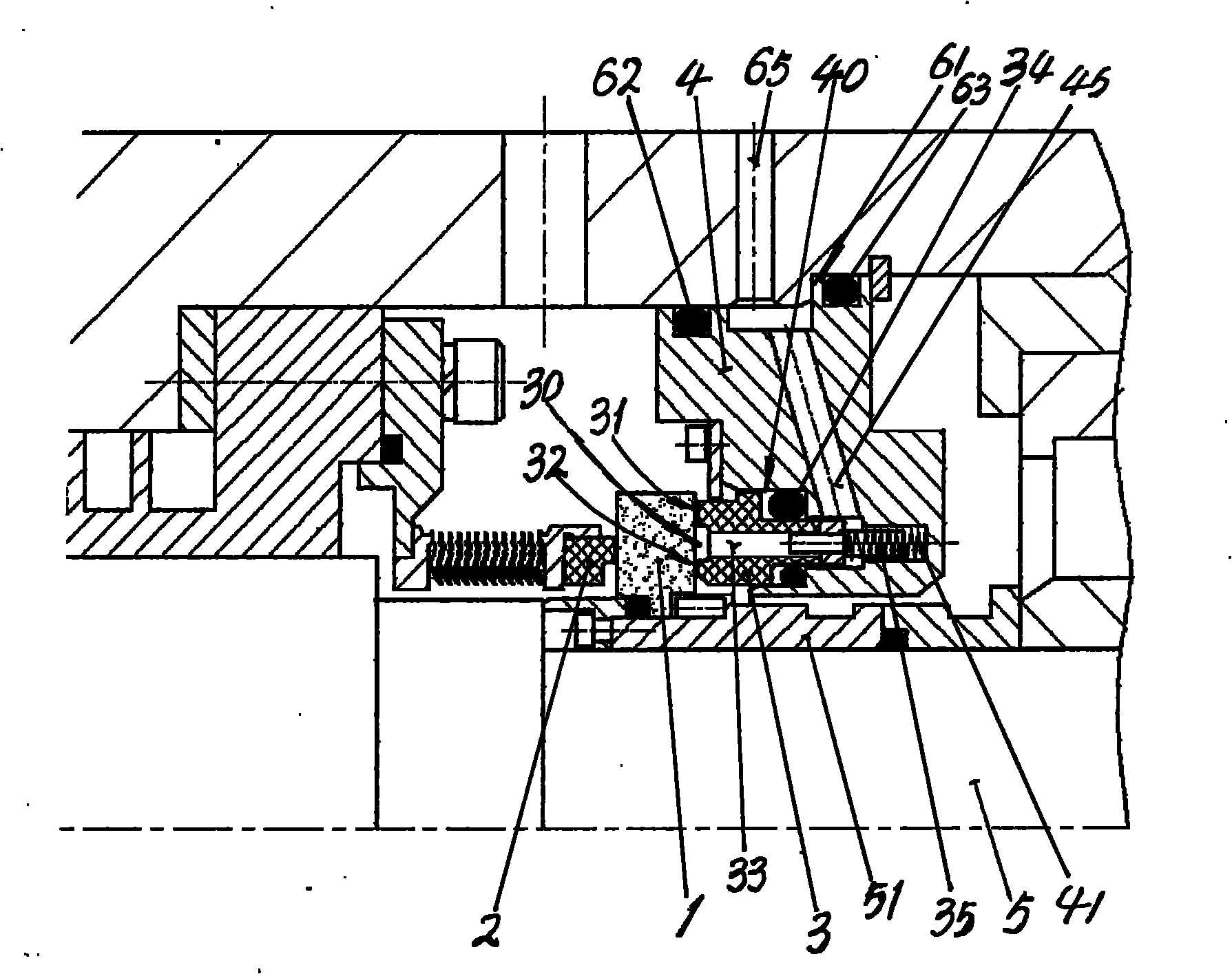

[0009] The vapor-liquid full-flow screw power machine mechanical seal device of the present invention consists of the moving ring 1 installed on the rotor shaft 5 or the shaft sleeve 51, the wave tube compensation static ring 2 respectively arranged on the left side of the moving ring 1 and the spring compensation radial direction on the right side. The double-end static ring 3 is composed of an axial double-end surface and a radial double-end mechanical seal mechanism. The radial double-end static ring 3 is slidably fitted in the installation groove 40 on the static ring seat 4, and is set in the installation groove 40. There is a rubber auxiliary sealing ring 34, and the compensation spring 35 distributed along the circumference is installed in the spring installation hole 41 opened on the static ring seat 4 and acts on the rear end of the static ring 3, and the static ring seat 4 and the end seat 6 shaft holes pass through the stop The port 61 is sealed and fixedly connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com