Direct-connected swing spider immersible impeller of motor

A submersible flow propeller, direct-connected technology, applied in mixers, mechanical equipment, gear transmissions, etc., can solve the problems of low mechanical efficiency, poor sealing effect, and many dynamic sealing links, etc., to improve dynamic sealing performance, Improved impact resistance, easy lifting and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

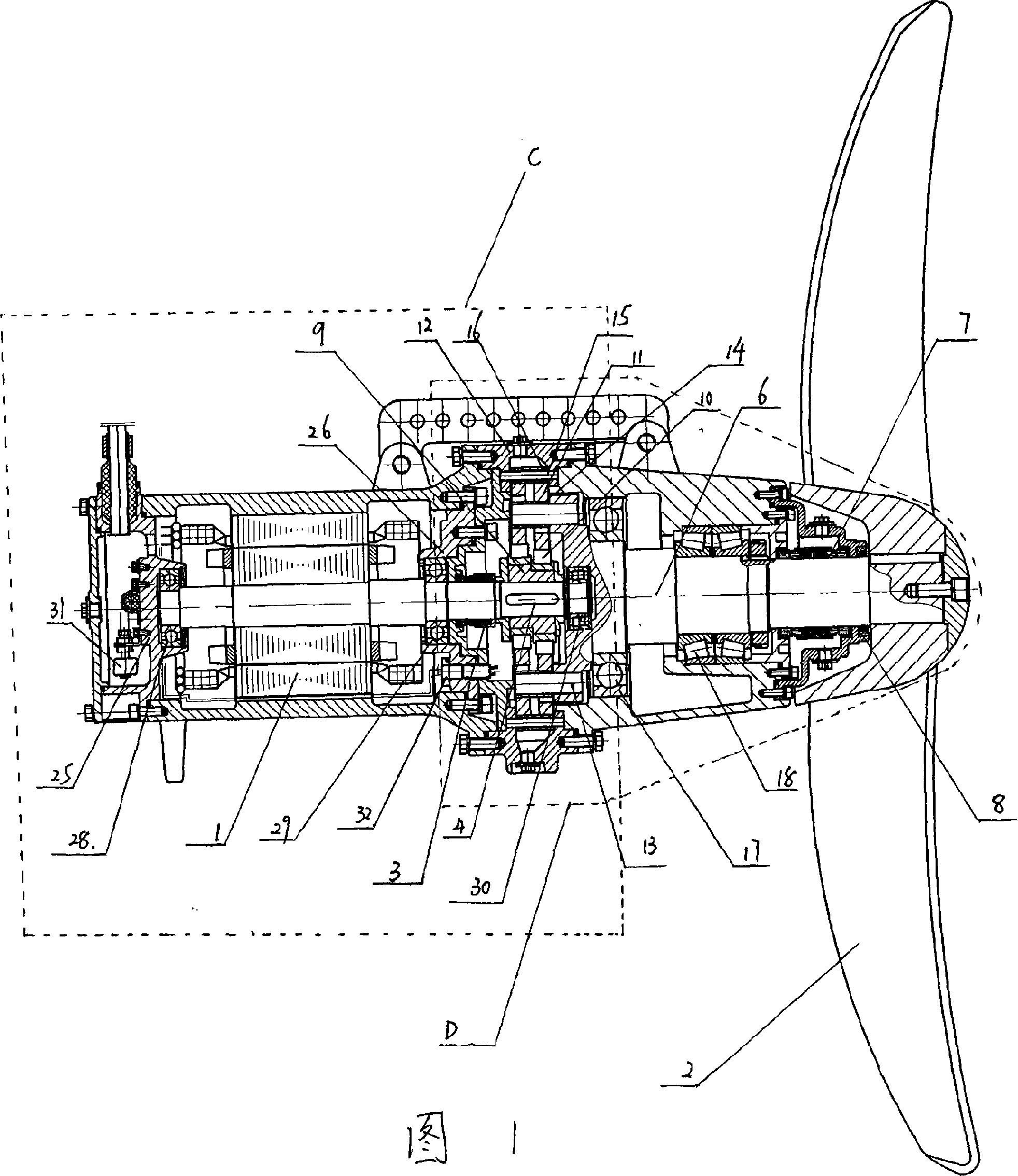

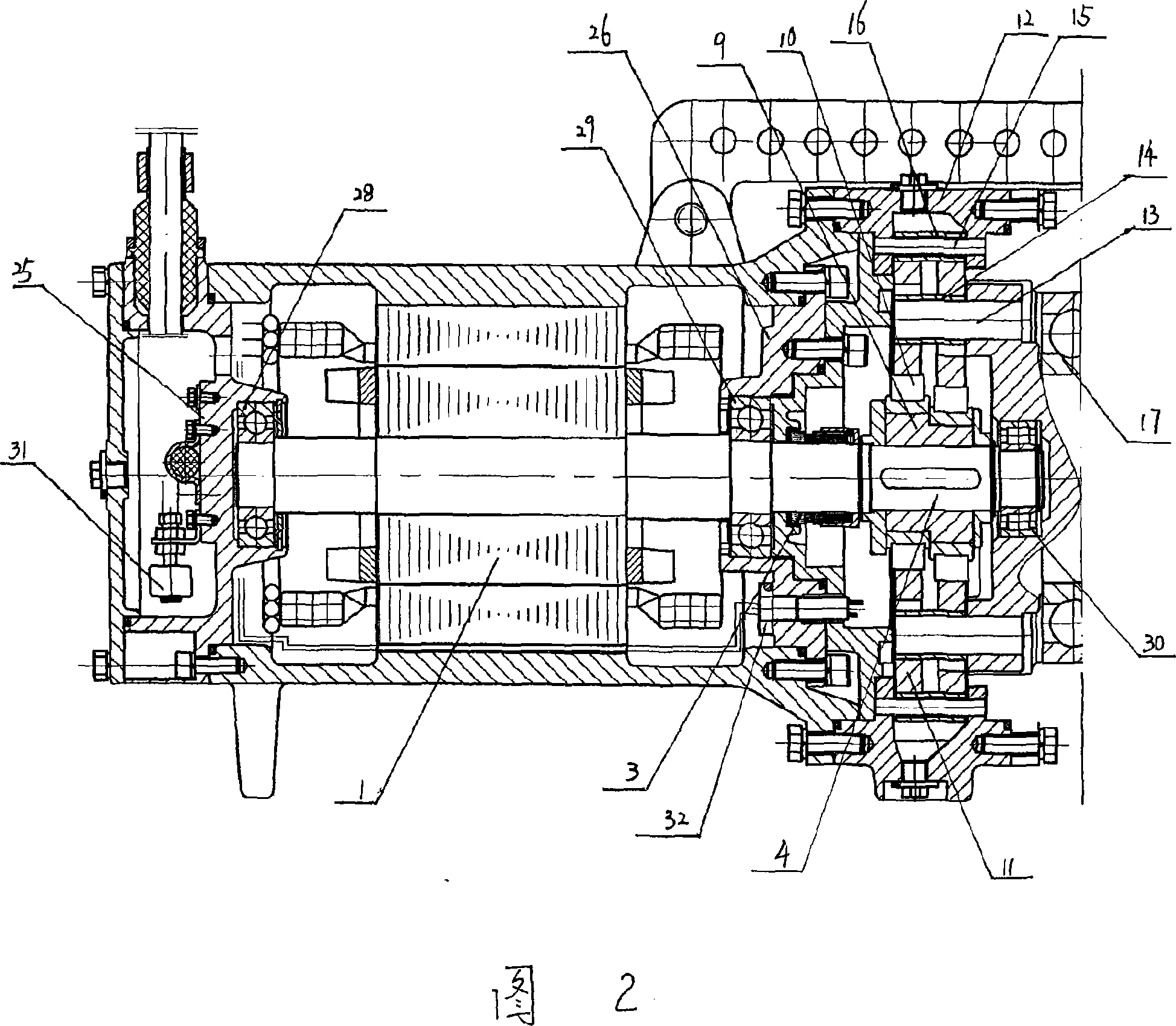

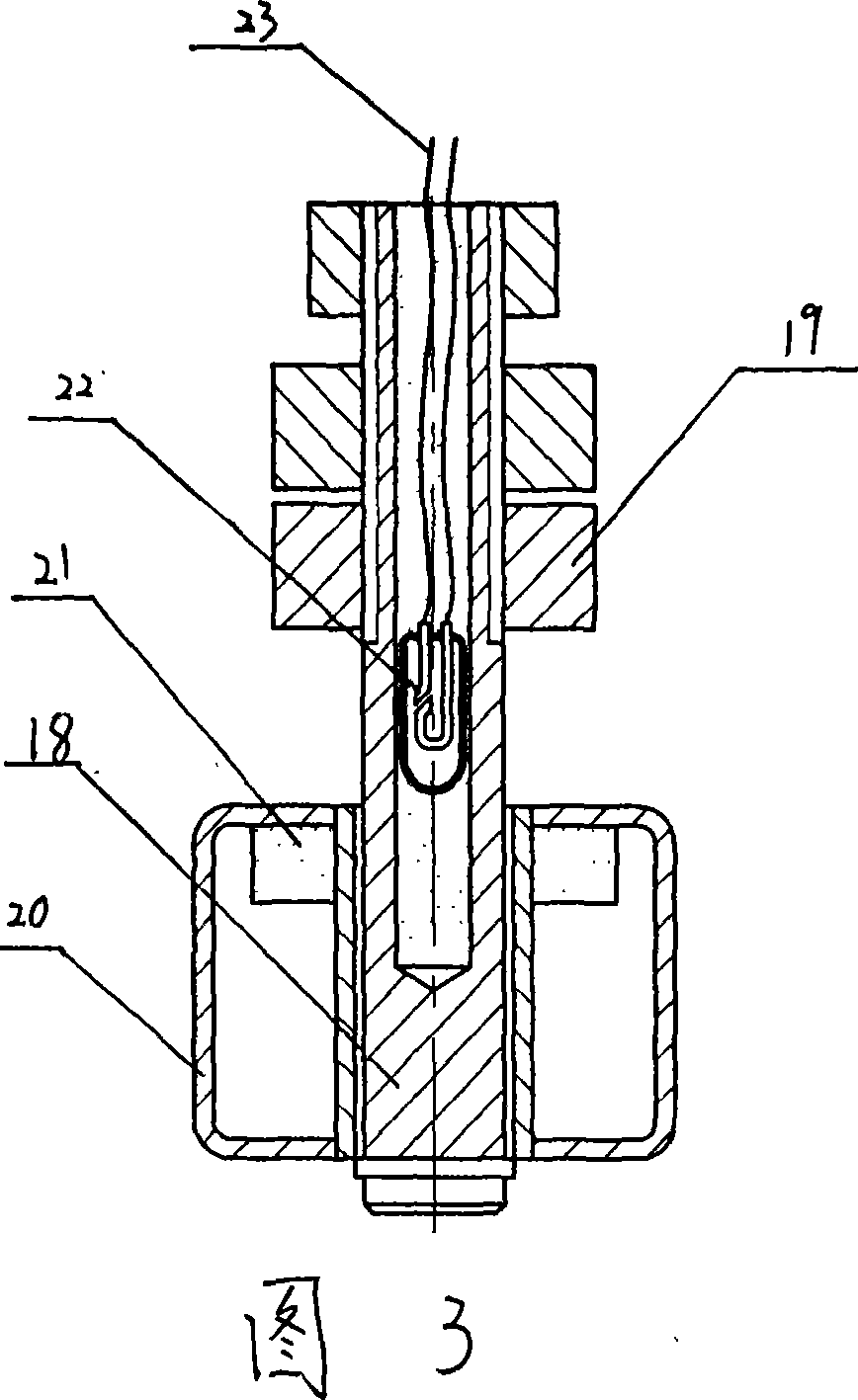

[0021]In Fig. 1, Fig. 2, Fig. 3, Fig. 4, Fig. 5, Fig. 6, Fig. 7, Fig. 8, Fig. 9, Fig. 10, Fig. 11 and Fig. 12, the present invention is a motor direct-connected cycloid star The wheel submersible thruster includes a motor direct-connected cycloidal star-wheel transmission system, and the motor direct-connection cycloidal star-wheel transmission system includes a motor 1, a reduction mechanism and an impeller 2, and the motor 1 is supported by a bearing III28 and a bearing IV29 at the front on the bearing cover 26 and the rear bearing cover 25, and finally transmit the force to the motor housing, the motor main shaft 4 extends out of the front bearing cover 26 as the output end of the motor 1, and the motor main shaft 4 is equipped with a single-end mechanical seal 3 and The transmission auxiliary bearing 30, the output shaft 6 of the deceleration mechanism is connected with the impeller 2, the motor 1 drives the deceleration mechanism to run, the deceleration mechanism drives t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com