Patents

Literature

45results about How to "Improve dynamic sealing performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

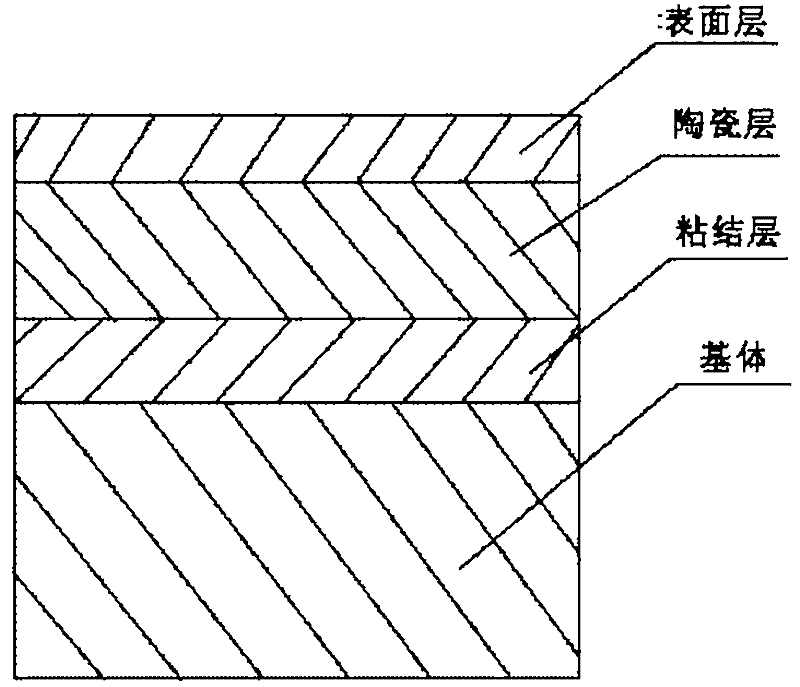

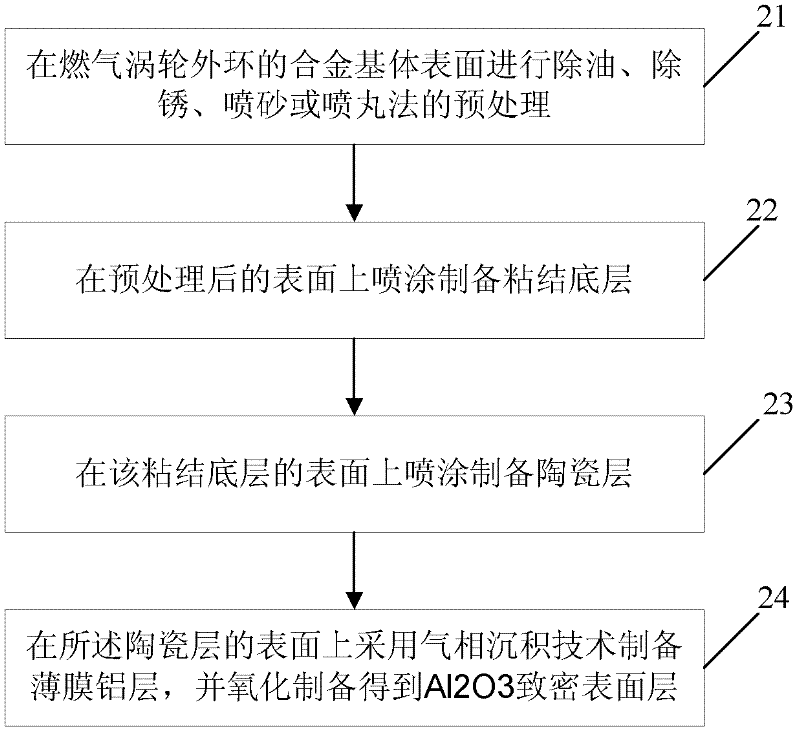

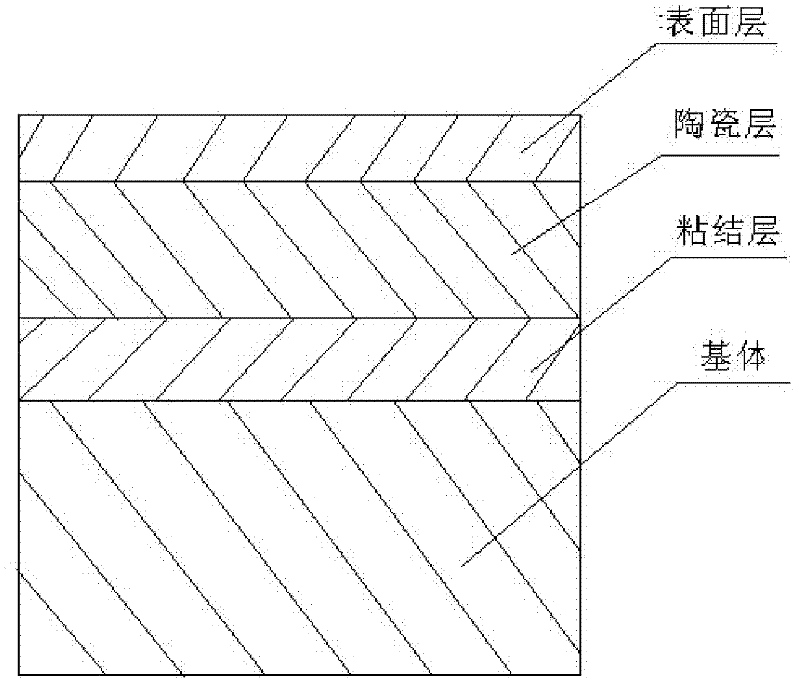

Novel coating with composite structure and preparation method thereof

InactiveCN102534613AImprove adhesionImprove performanceMolten spray coatingVacuum evaporation coatingEngine efficiencySurface layer

Embodiments of the invention discloses a novel coating with a composite structure and a preparation method thereof; the coating is a composite coating with a three-layer structure, wherein a bonding layer is prepared on a turbine alloy substrate surface by a high speed flame spraying method; a porous zirconia ZrO2 ceramic layer is prepared on the bonding layer surface by plasma spraying; a film aluminium layer is prepared on the ceramic layer surface by vapour deposition technology, and is oxidized into a dense alumina Al2O3 surface layer. The composite coating prepared by the method can reduce oil consumption of the turbine engine, and increase engine efficiency and thermal cycling resistance; and the service life of the turbine and the whole performance of the equipment are improved.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

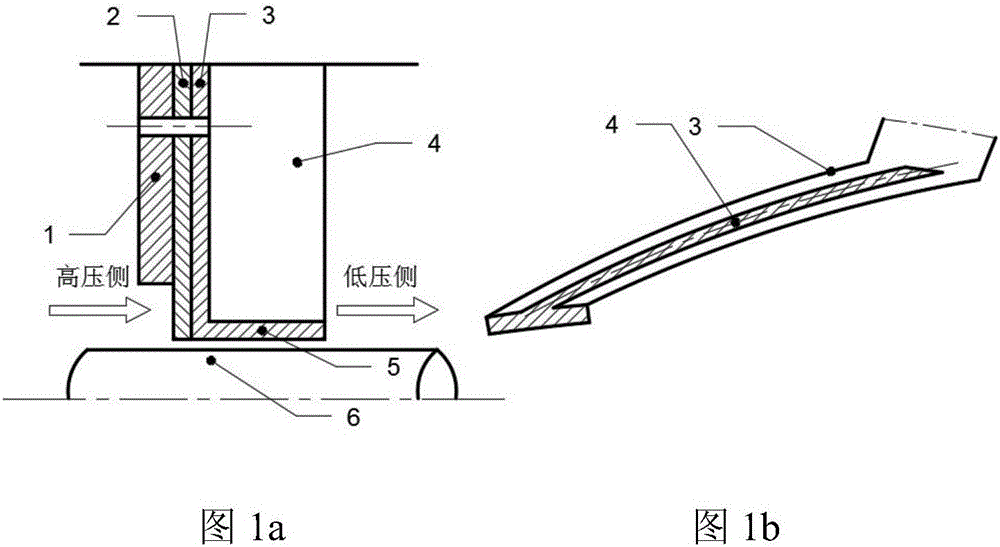

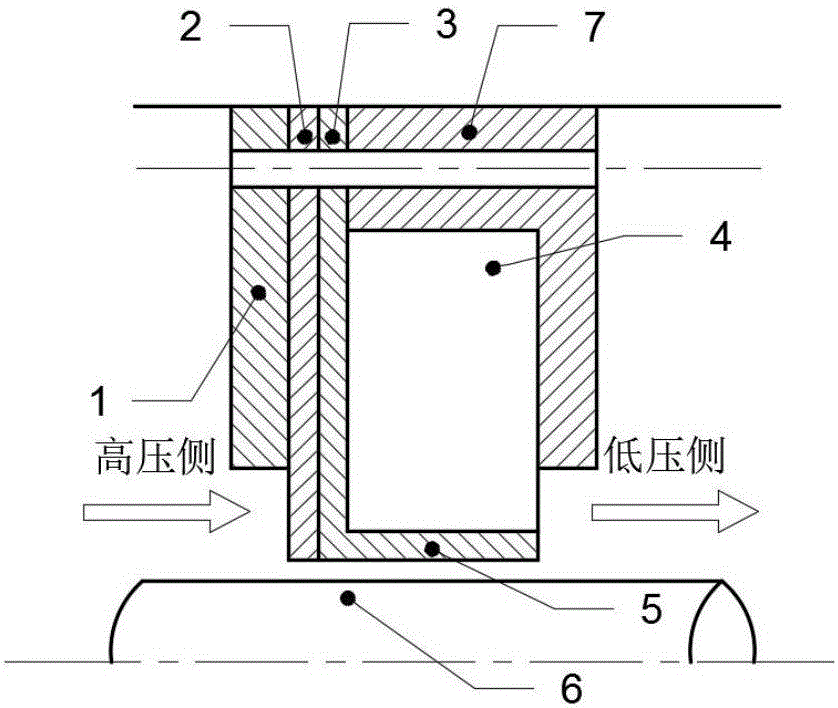

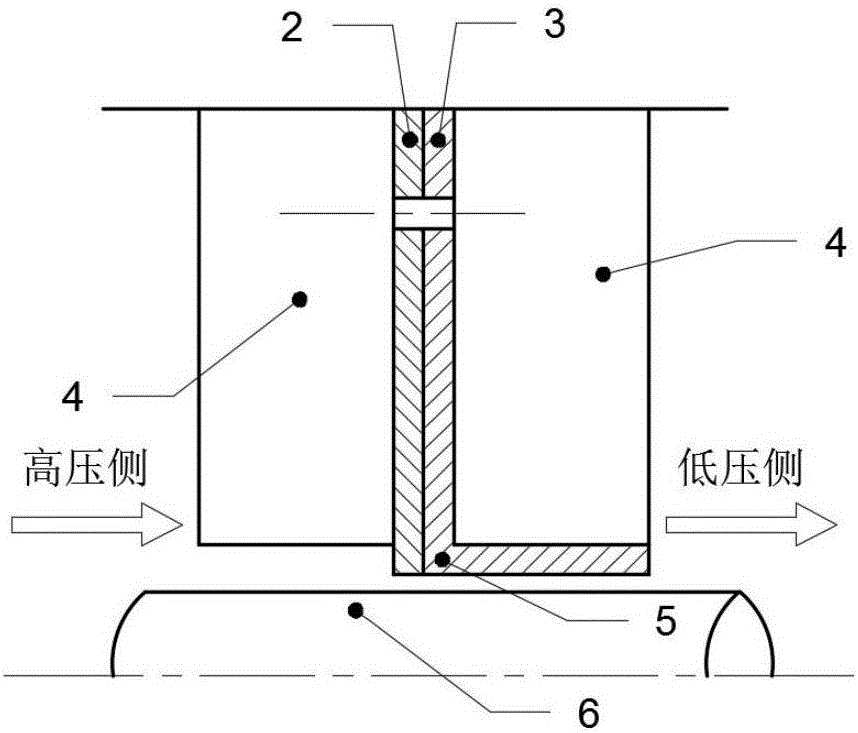

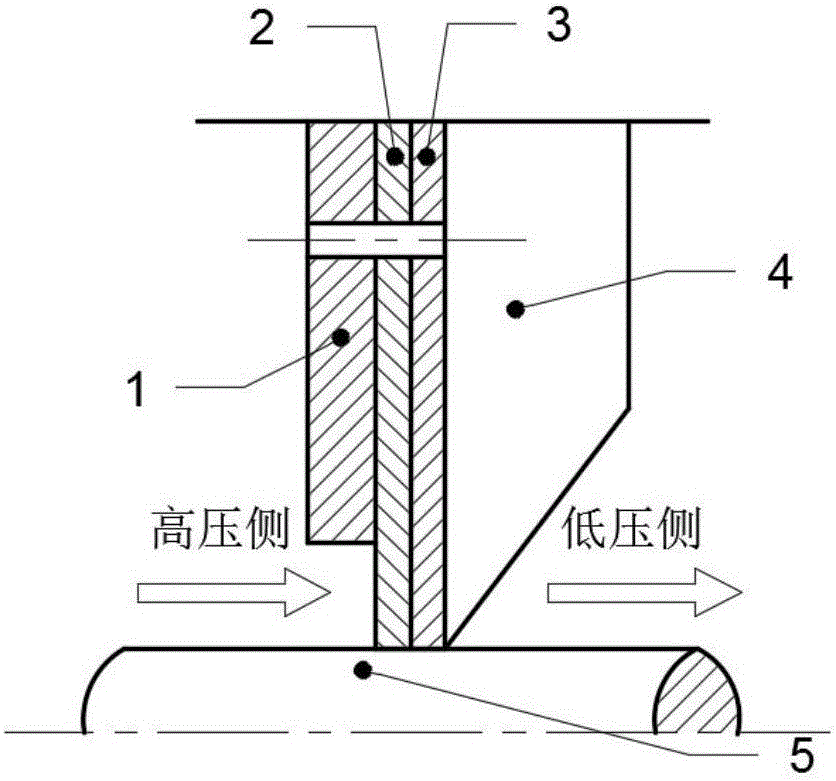

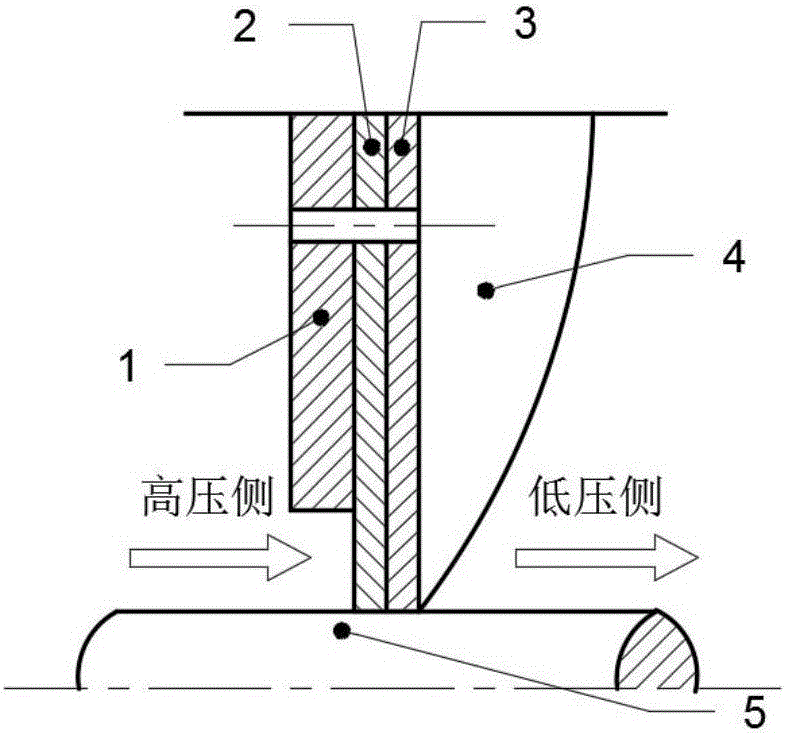

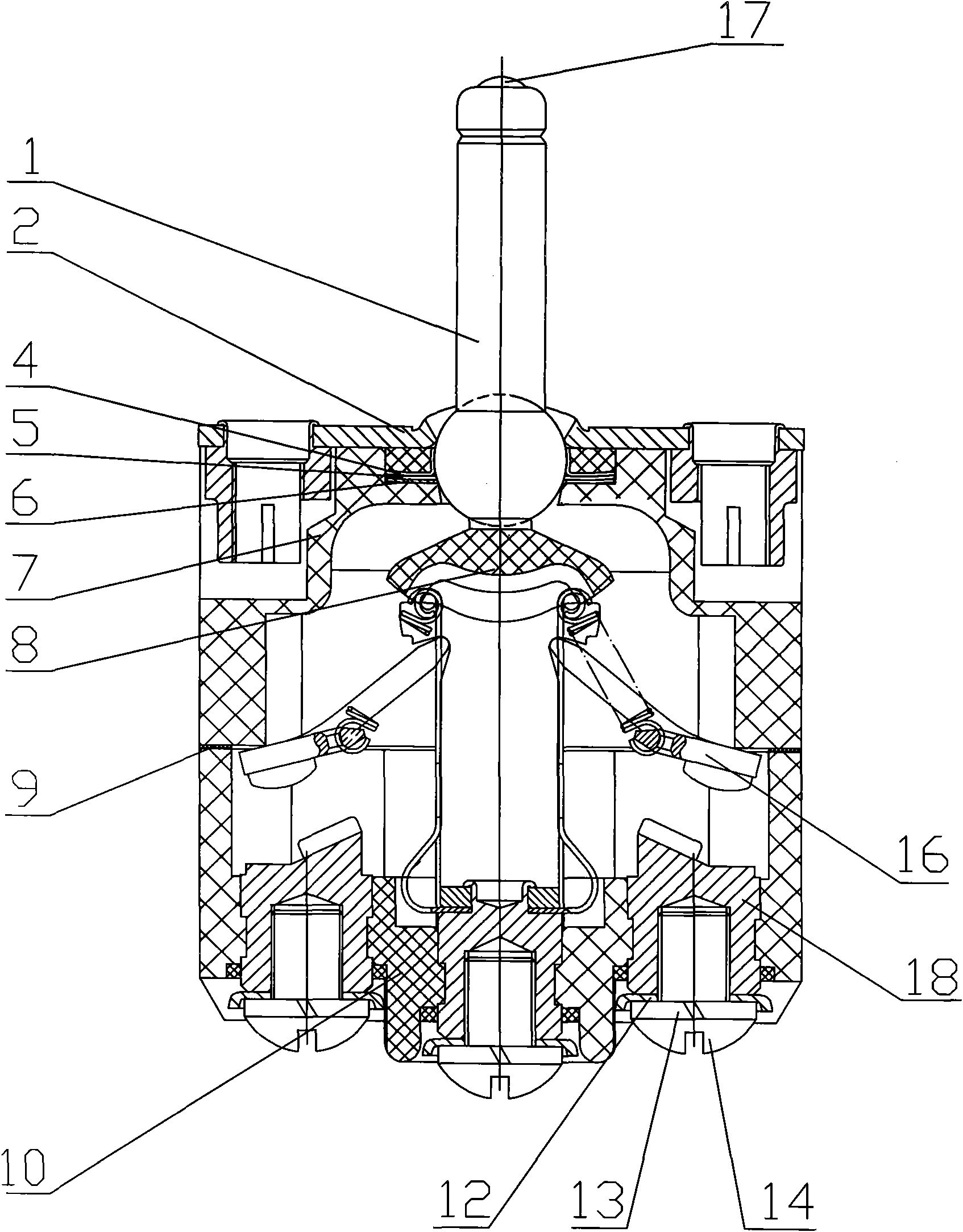

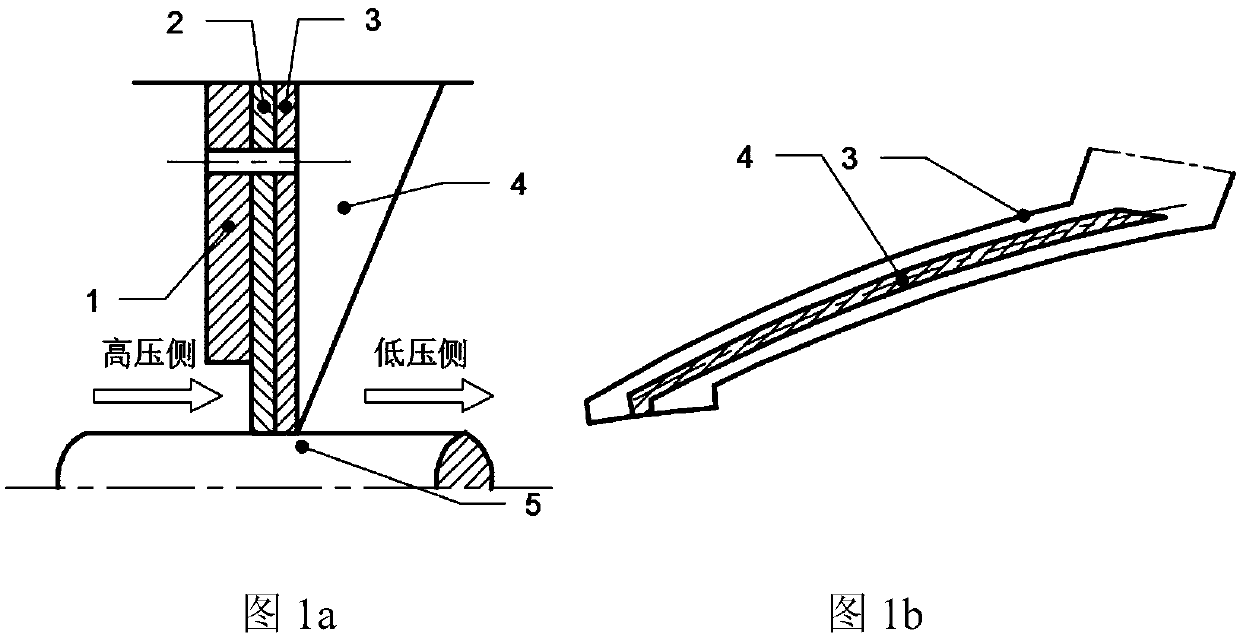

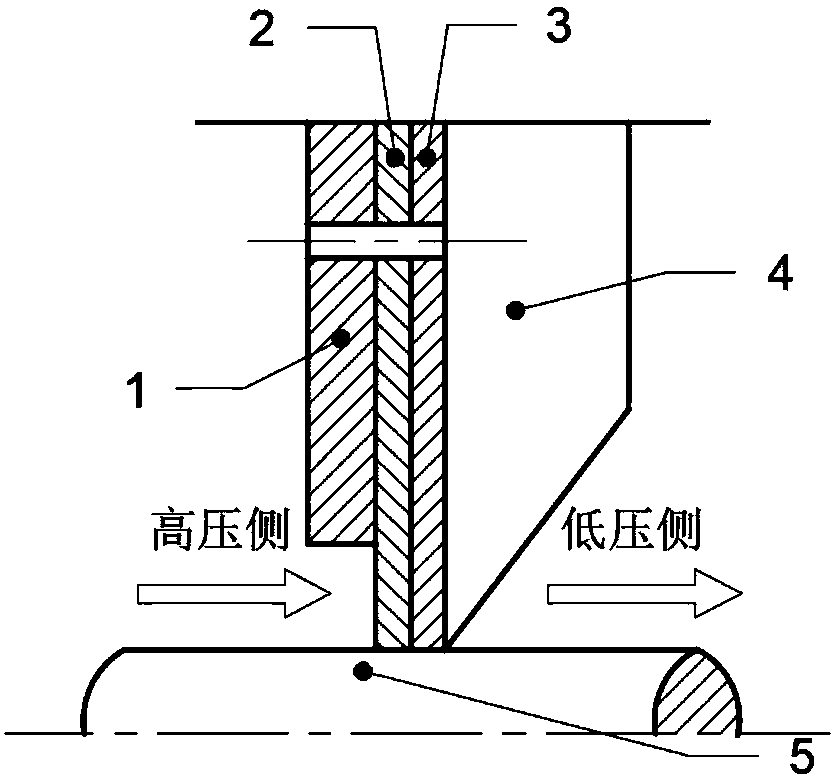

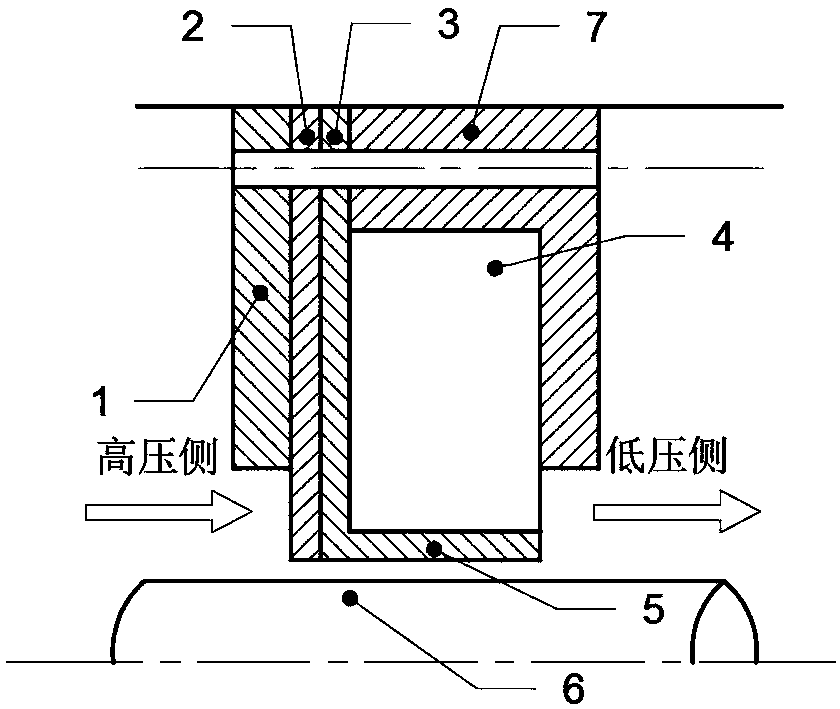

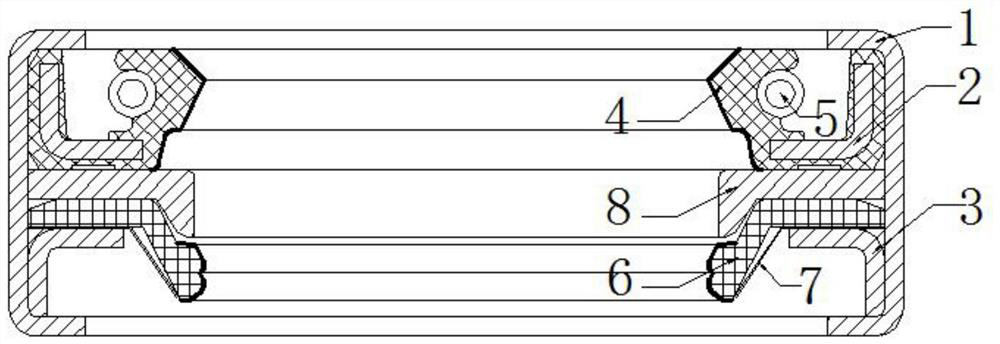

Non-contact fingertip sealing device with fin

ActiveCN106246242AImprove dynamic sealing performanceGood ability to withstand high pressure differenceLeakage preventionMachines/enginesHydrostatic pressureEngineering

A non-contact fingertip sealing device with a fin comprises a non-contact fingertip sealing device part matched with a rotor, wherein the non-contact fingertip sealing device part is formed by sequentially connecting a front baffle, a rear baffle, a high-pressure fingertip sheet and a low-pressure fingertip sheet with a fingertip boot structure; the fin that is arranged in a T shaped manner together with a low-pressure side surface of a fingertip beam and the fingertip boot structure is arranged on the low-pressure fingertip sheet; the fin and a low-pressure fingertip boot utilize hydrodynamic pressure and hydrostatic pressure effects; a lifting force is generated by the action of a front and rear pressure difference and rotation of the rotor to lift the fingertip sheets off the surface of the rotor, so as to achieve sealing and no contact with the rotor; when the rotor has radial displacement, the structure can more effectively and automatically adjust gestures of the fingertip sheets; the motion of the fingertip sheets adapts to radial runout of the rotor; a sealing effect is ensured and a non-contact state is kept at the same time; an effect of reducing and even eliminating the conventional non-contact fingertip sealing 'lag effect' is exerted; and the dynamic sealability of non-contact fingertip sealing is improved.

Owner:TSINGHUA UNIV

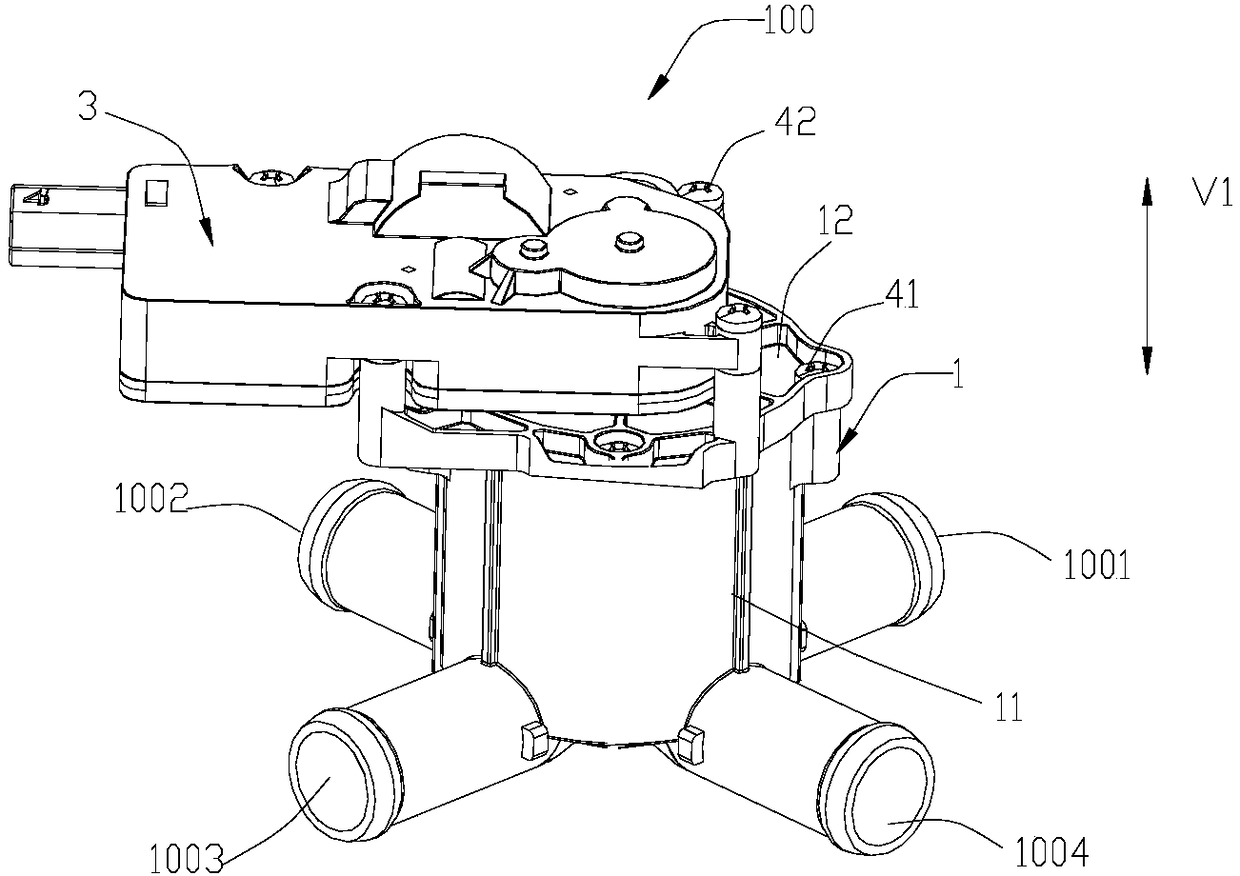

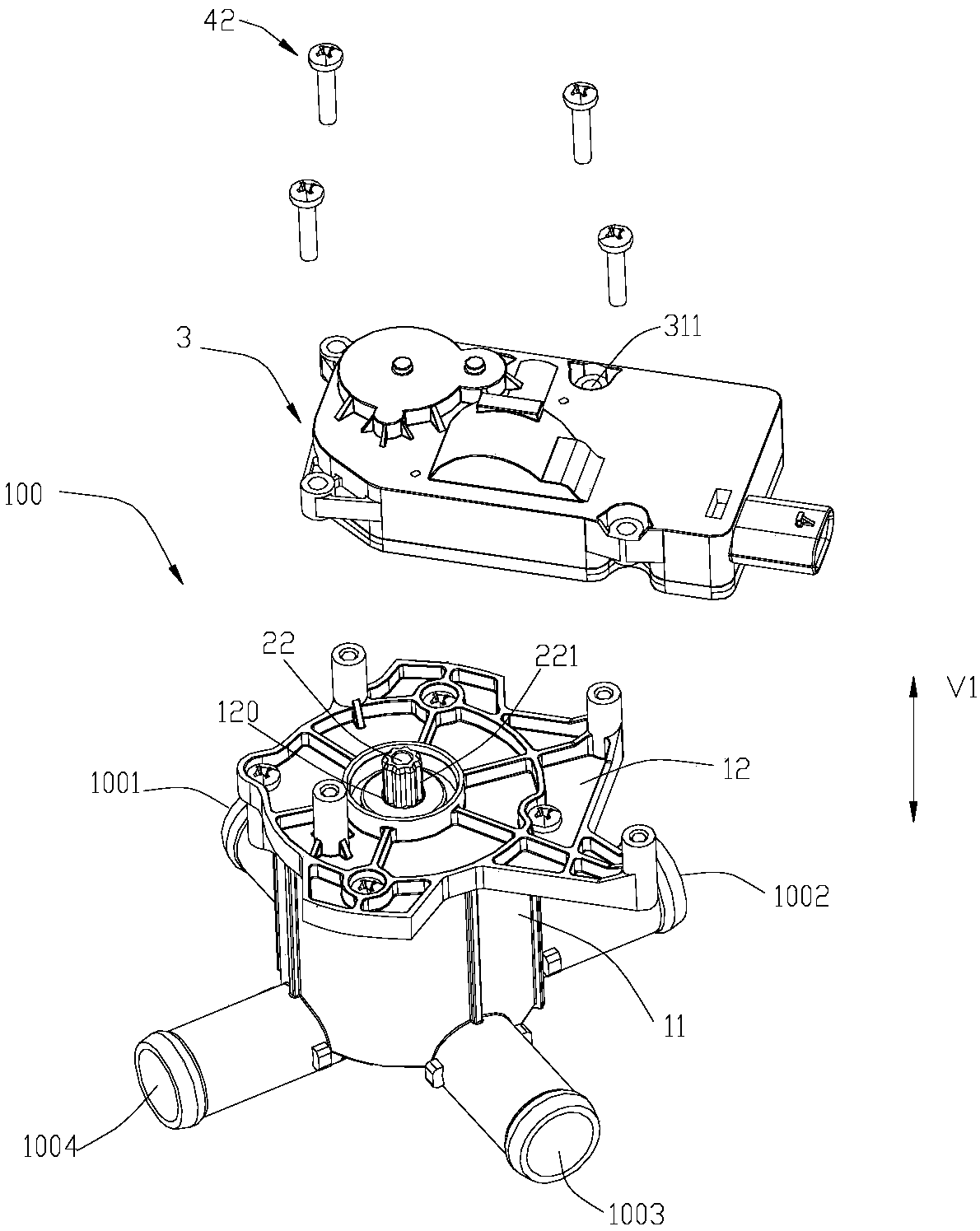

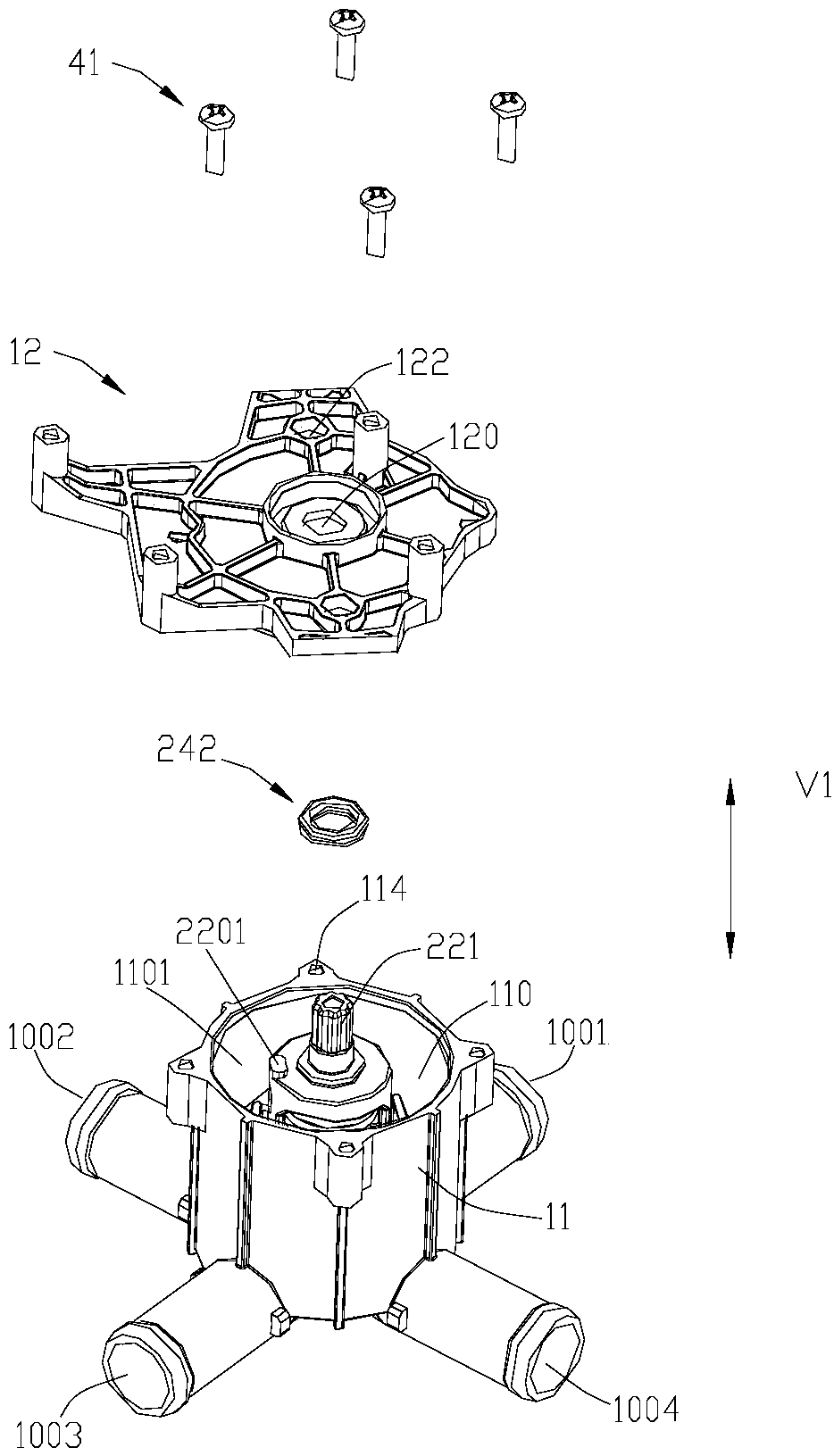

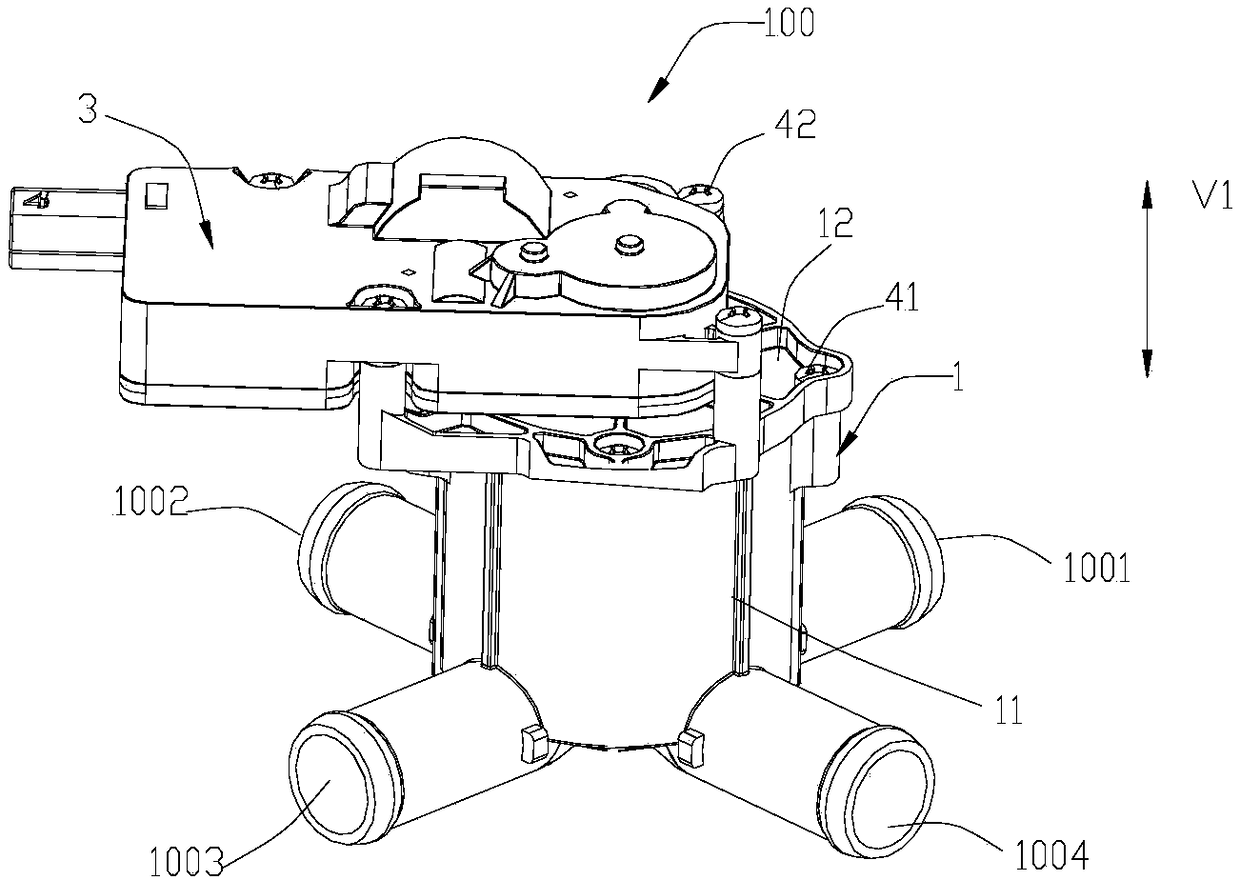

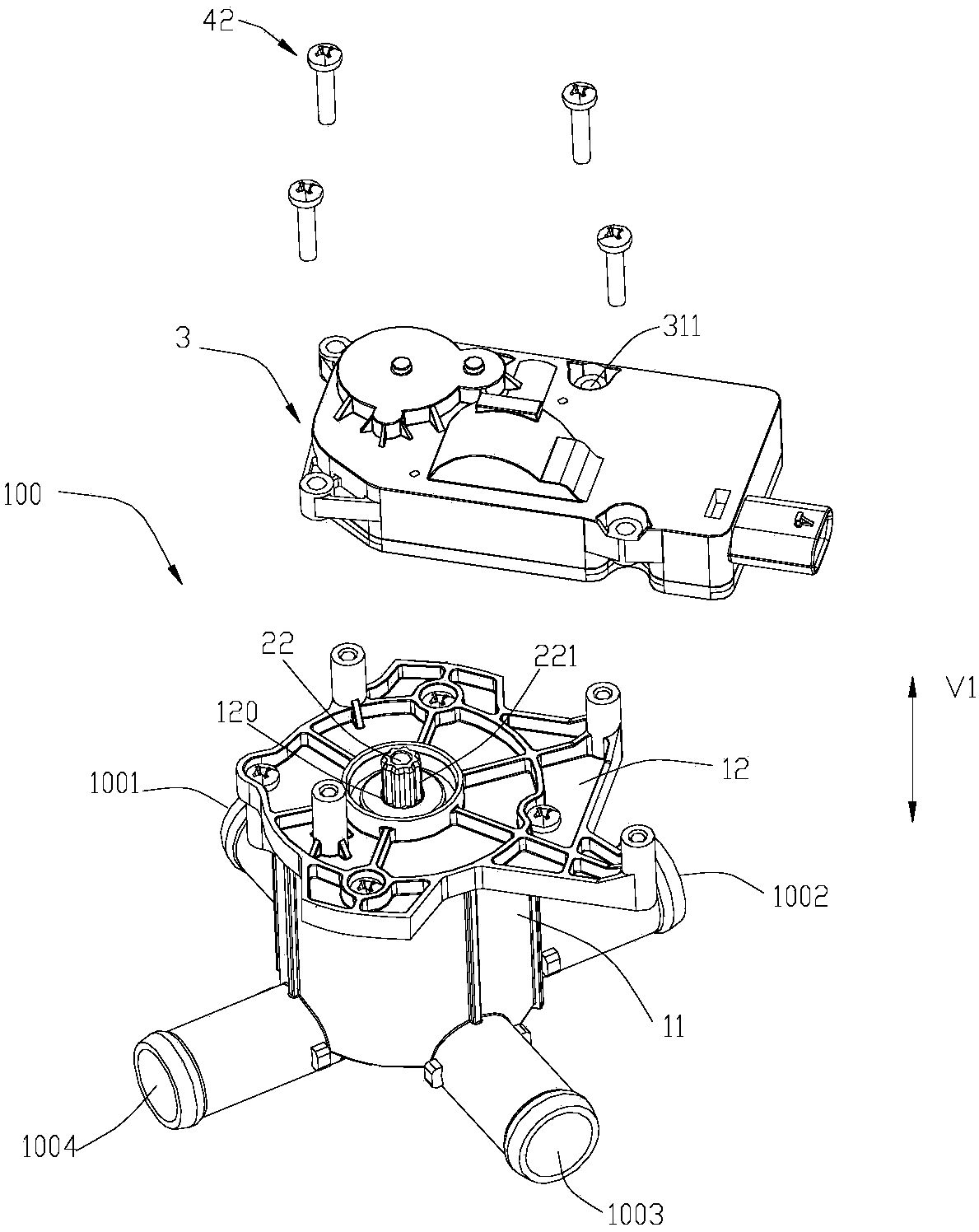

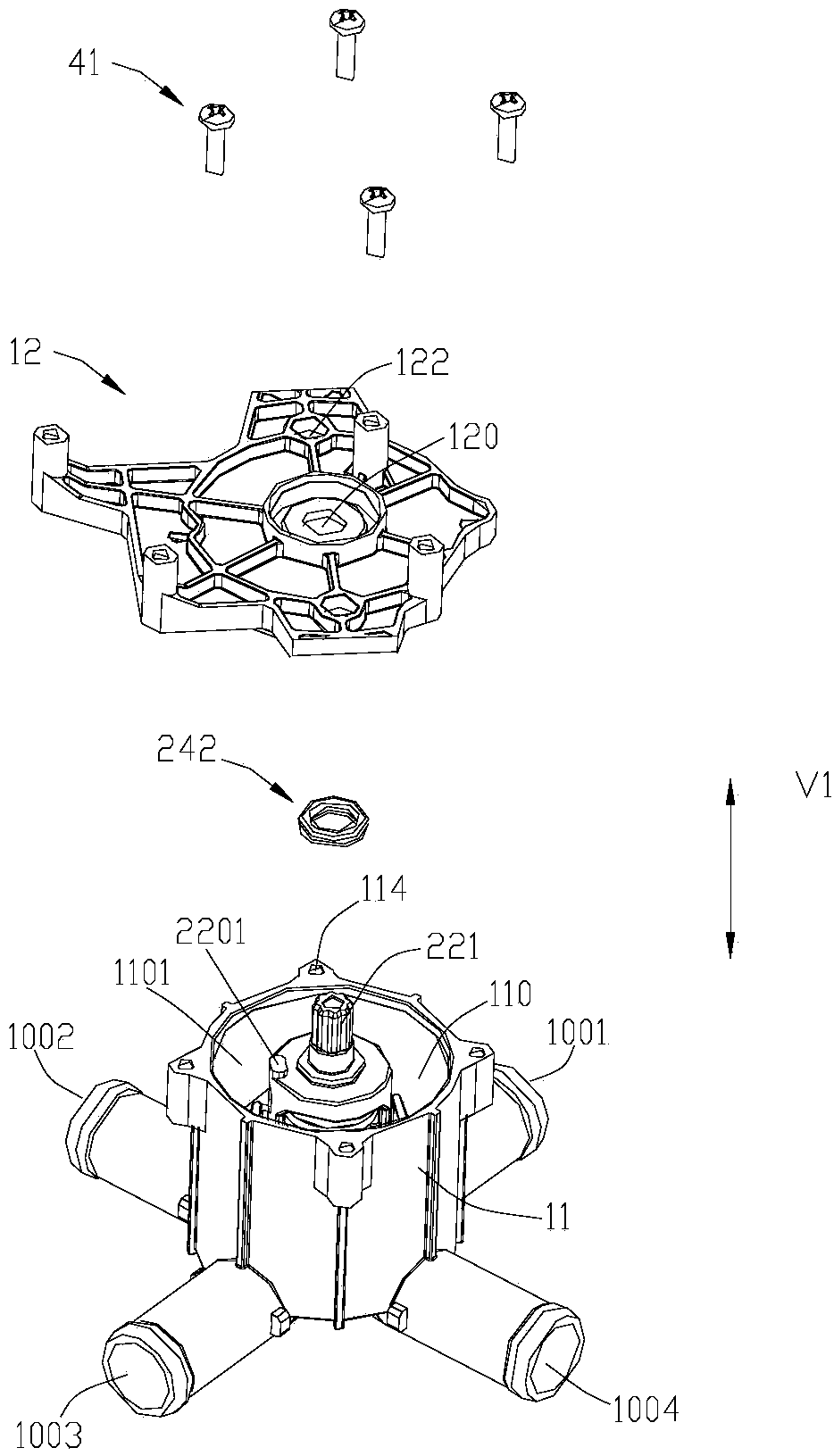

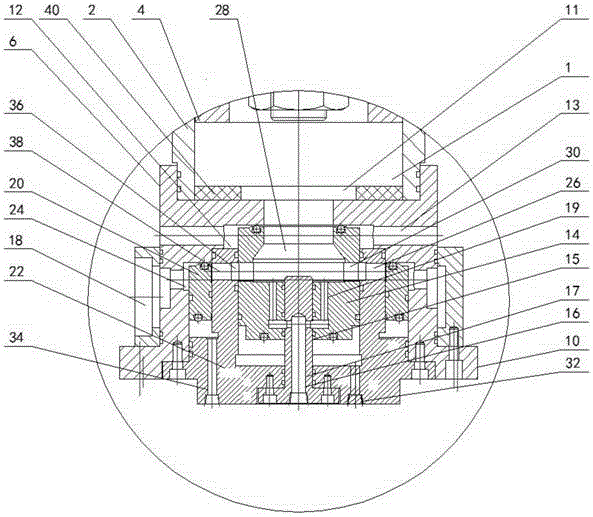

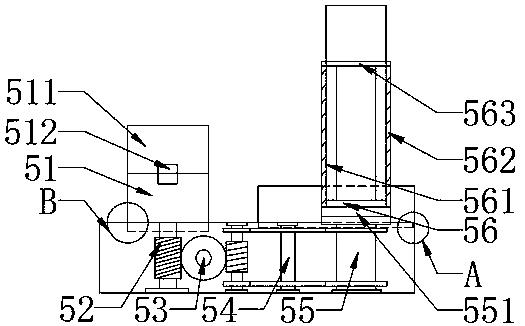

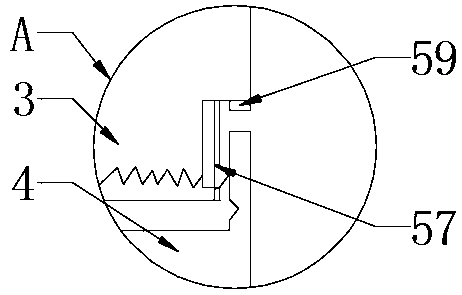

Flow control device

PendingCN109210238AImprove dynamic sealing performanceReduce leakageMultiple way valvesSlide valveButt jointEngineering

The invention discloses a flow control device for a heat exchange system. The device comprises a movable valve piece, a transmission piece and an elastic piece, wherein a first valve piece and the transmission piece are assembled, the flow control device is provided with a mounting area located between the first valve piece and the transmission piece, the elastic piece is located in the mounting area, a limiting stop part of the flow control device is located on the outer side of the elastic piece in the radial direction, and along the vertical direction where the central axis of the elastic piece locates, the first end part of the elastic piece is in butt joint with a first pressure bearing surface of the first valve piece, and the second end part of the elastic piece is in butt joint with the second pressure bearing surface of the transmission piece. According to the device, the elastic piece which is not easy to fall off is arranged so as to press downwards the movable valve piece,the dynamic sealing performance between the movable valve piece and a matched part is improved, and the internal sealing performance of the flow control device can be improved by relatively reducing internal leakage of a working medium.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

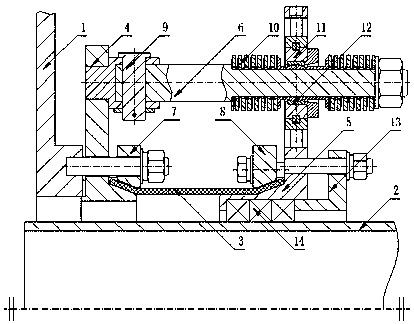

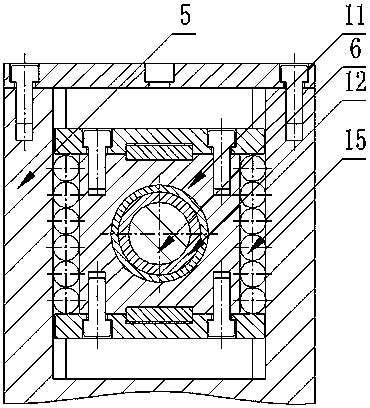

Machining process for rotating vane type hydraulic steering engine

ActiveCN105666070AQuality improvementImprove running stabilitySteering ruddersNumerical controlWire cutting

The invention discloses a machining process for a rotating vane type hydraulic steering engine. The machining process comprises the following machining procedures: machining a rotor, a cylinder and a fixed blade, assembling the cylinder and the fixed blade, machining the rotor body of the rotating vane type hydraulic steering engine and machining a sealing groove of the fixed blade, wherein in the rotor body machining procedure, a moveable blade and a substrate are separately machined; in the cylinder machining procedure, the casted and molded blank is subjected to coarse turning, precise turning, pneumatic grinding, polishing with sand bags, round angle trimming and oil hole machining on a numerical control vertical lathe; in the machining procedure of the fixed blade of the rotating vane type hydraulic steering engine and the assembling procedure of the fixed blade and the cylinder, the casted and molded blank is subjected to coarse turning, ageing, semi-precise turning, linear cutting, cover plate mounting hole boring, clamping, boring first mounting threaded holes of the cylinder, fixing cylinder and the fixed blade, machining pin holes and threaded holes for assembling the cylinder and the fixed blade, clamping, hydraulic valve mounting hole drilling, sealing groove boring and milling, fixing the cylinder and the fixed blade, precise turning of inner holes of the assembled fixed blade, threaded holes and sealing groove machining, and facing-up with the cylinder cover, so as to finish machining.

Owner:CHONGQING HUAYU HEAVY IND ELECTROMECHANICAL CO LTD

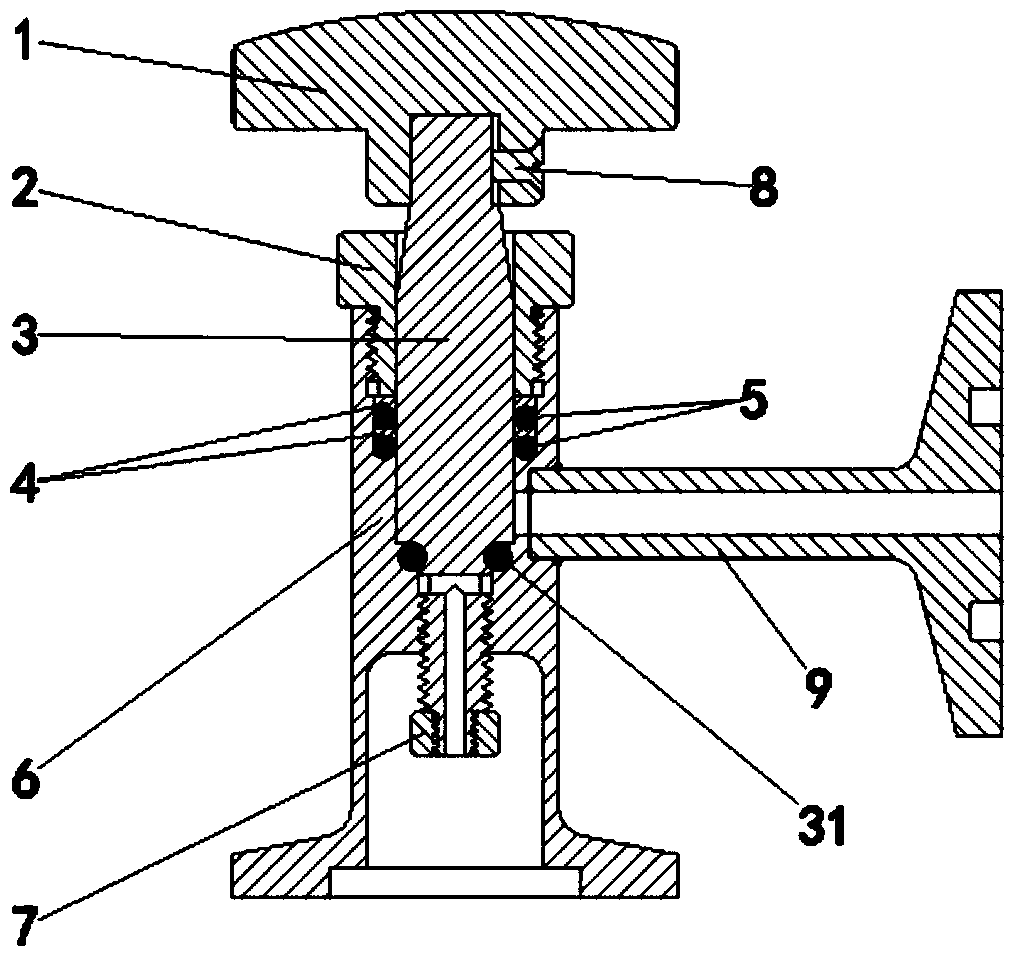

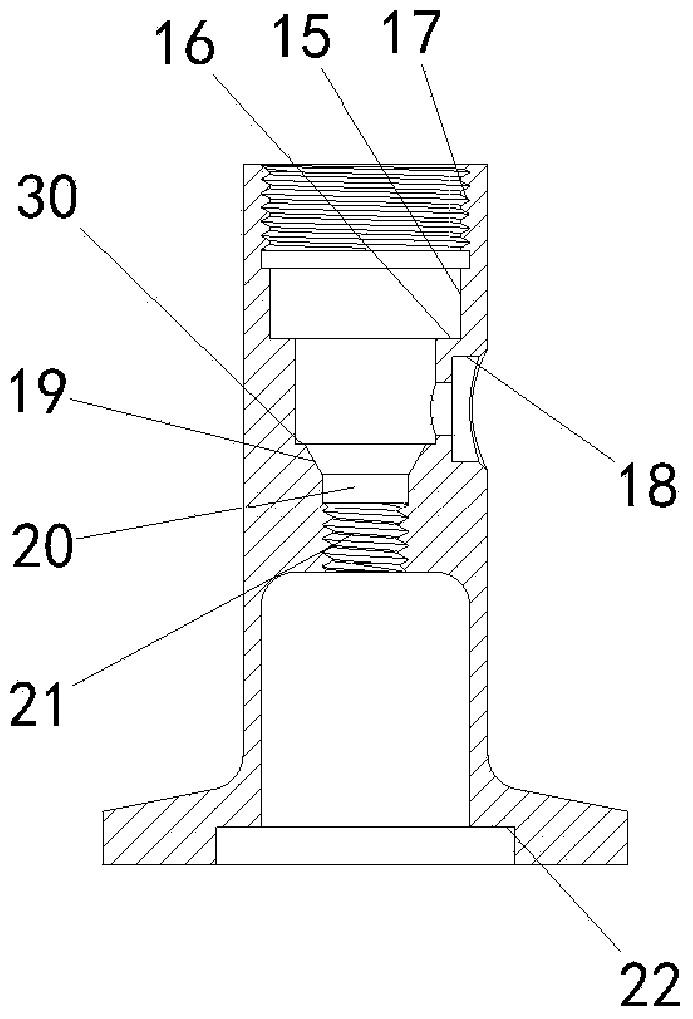

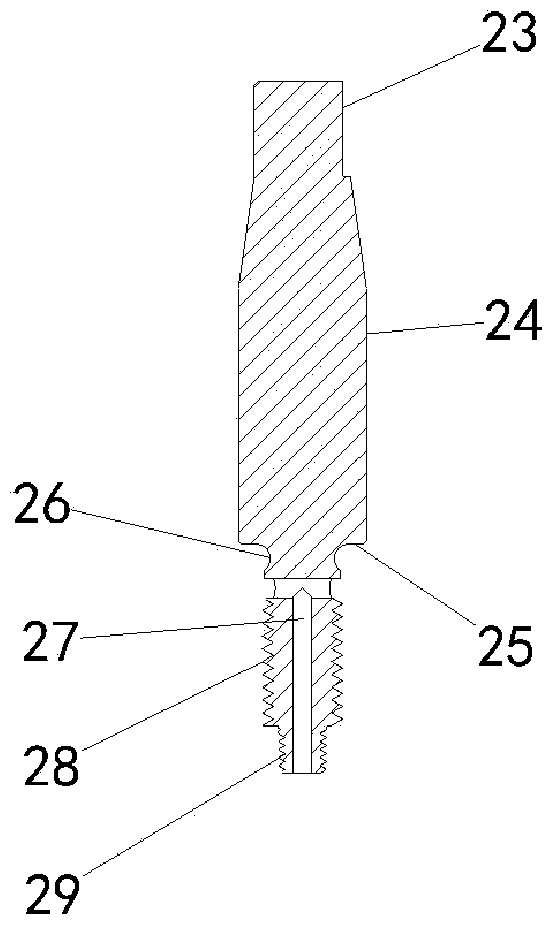

Free on-off vacuum valve device for high gas tightness and manufacture method thereof

ActiveCN104358881AGuaranteed tightnessImprove dynamic sealing performanceLift valveValve housingsContinuationEngineering

The invention discloses a free on-off vacuum valve device for high gas tightness and a manufacture method thereof. The free on-off vacuum valve device comprises a handle, a gland nut, a valve plug, a compression ring, an upper seal, a valve body, a retainer nut, a backing-up screw, a lower seal and a vacuum fitting. The free on-off vacuum valve device is arranged between a vacuum chamber at the cold end of a refrigerator and a vacuum pump for negative pressure exhaust, and controls the switch between a dead vacuum environment and a live vacuum environment. The free on-off vacuum valve device has the advantages of small number of parts, convenient operation and easy maintenance, and achieves the safe, reliable and oil-free dynamic seal effect. Through adoption of the free on-off vacuum valve device, the contradiction between the need for frequent on-off and the continuation of high gas tightness in the vacuum chamber in the practical application of a low-temperature refrigerator is solved. The invention has a very positive effect on the practical application of the low-temperature refrigerator.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

Magnetofluid sealed positive pressure explosion-proof motor

PendingCN110601420AEasy accessAchieving a static sealMagnetic circuit rotating partsSupports/enclosures/casingsPositive pressureShielding gas

The invention relates to the technical field of explosion-proof motors, in particular to a magnetofluid sealed positive pressure explosion-proof motor. The motor comprises a shell, a rotor, retainers,a positive pressure system and a protective shell; the rotor is installed in the shell, and the retainers sleeve the outer sides of the two ends of the rotor; a part, located outside the shell, of arotor rotating shaft is fixedly sleeved with a plurality of outer convex rings. The two retainers are embedded into embedding grooves in the two sides of the shell respectively; permanent magnets arearranged in the retainers; the shell is connected with the positive pressure system; the positive pressure system comprises a gas conveying pipe, a gas pressure detector and a protective gas tank; thegas conveying pipe is embedded in the outer wall of the shell; the other end of the gas conveying pipe is communicated with the protective gas tank. By the adoption of the technical scheme, a sealingring and lubricating oil are arranged between the outer end faces of the retainers and the shell in the sealing system, the sealing ring of the sealing system and the shell can achieve static sealing, an outer convex ring and an inner concave ring are matched with each other to form a zigzag dust blocking face, and the dust blocking effect is achieved.

Owner:HARBIN UNIV OF SCI & TECH

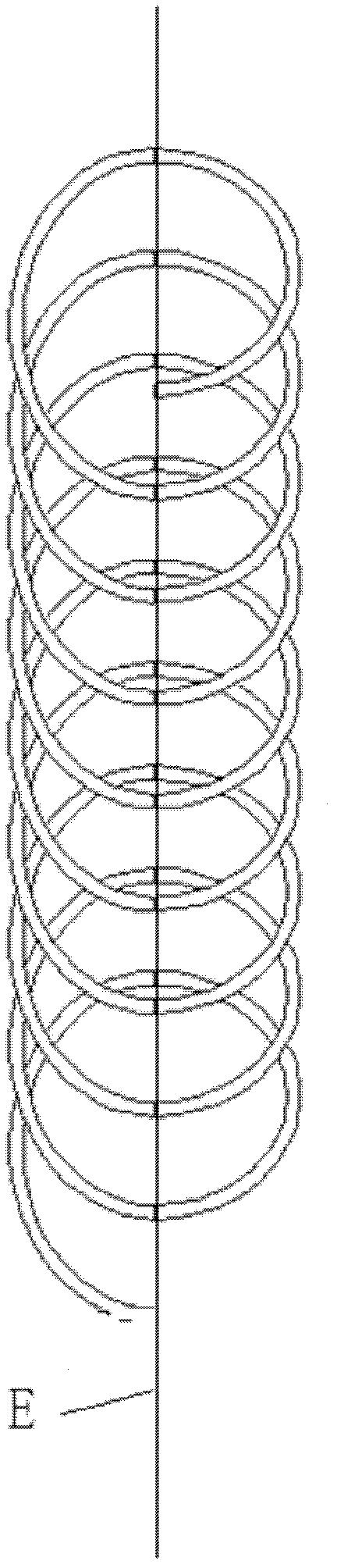

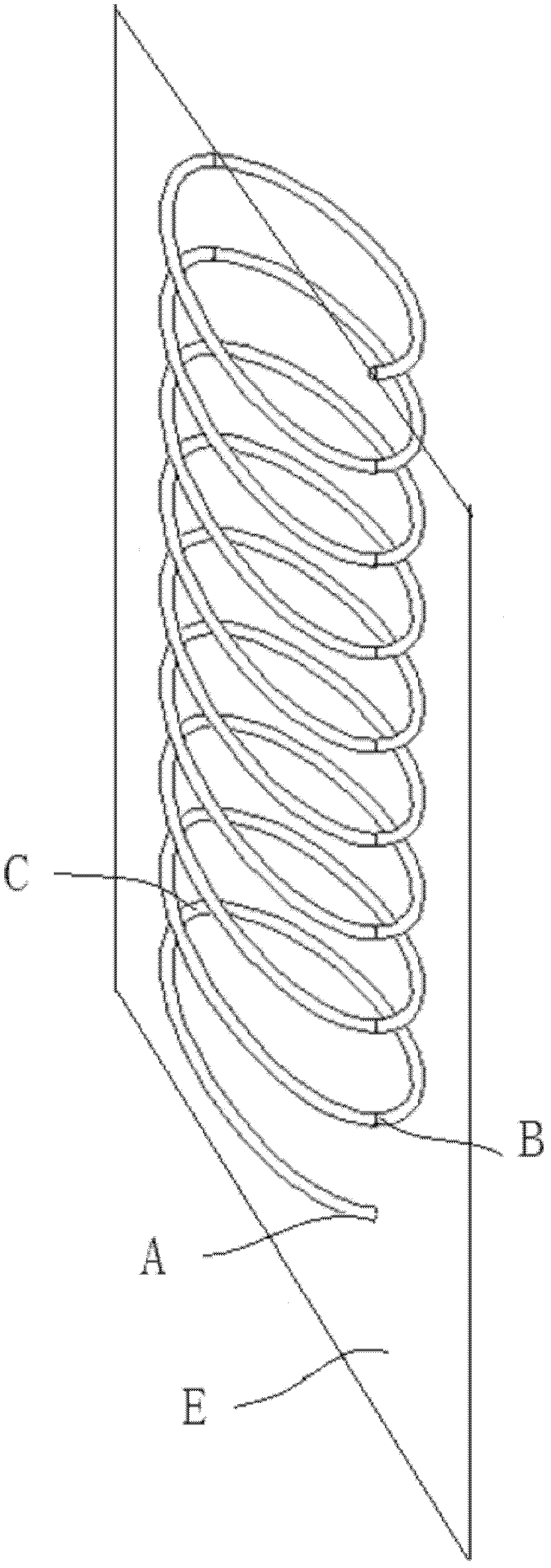

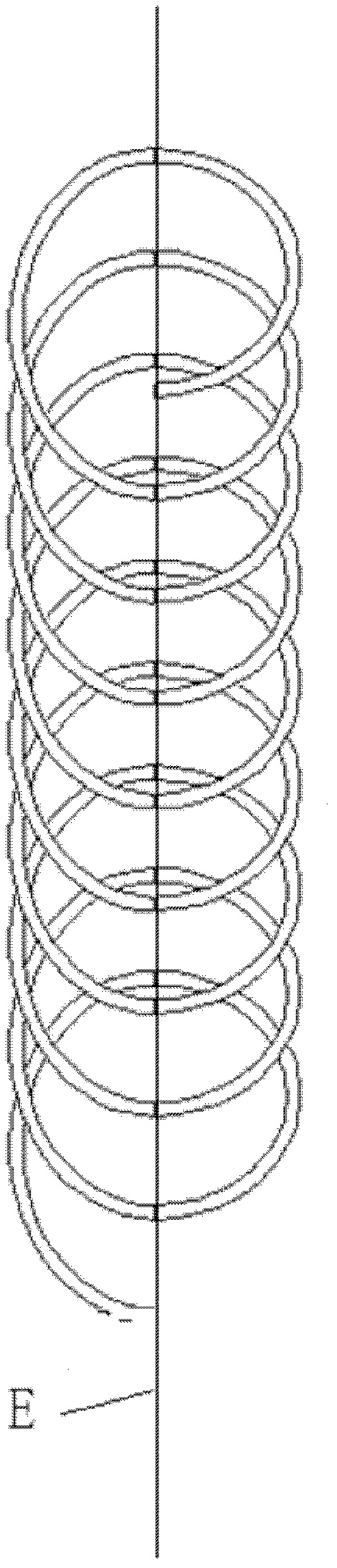

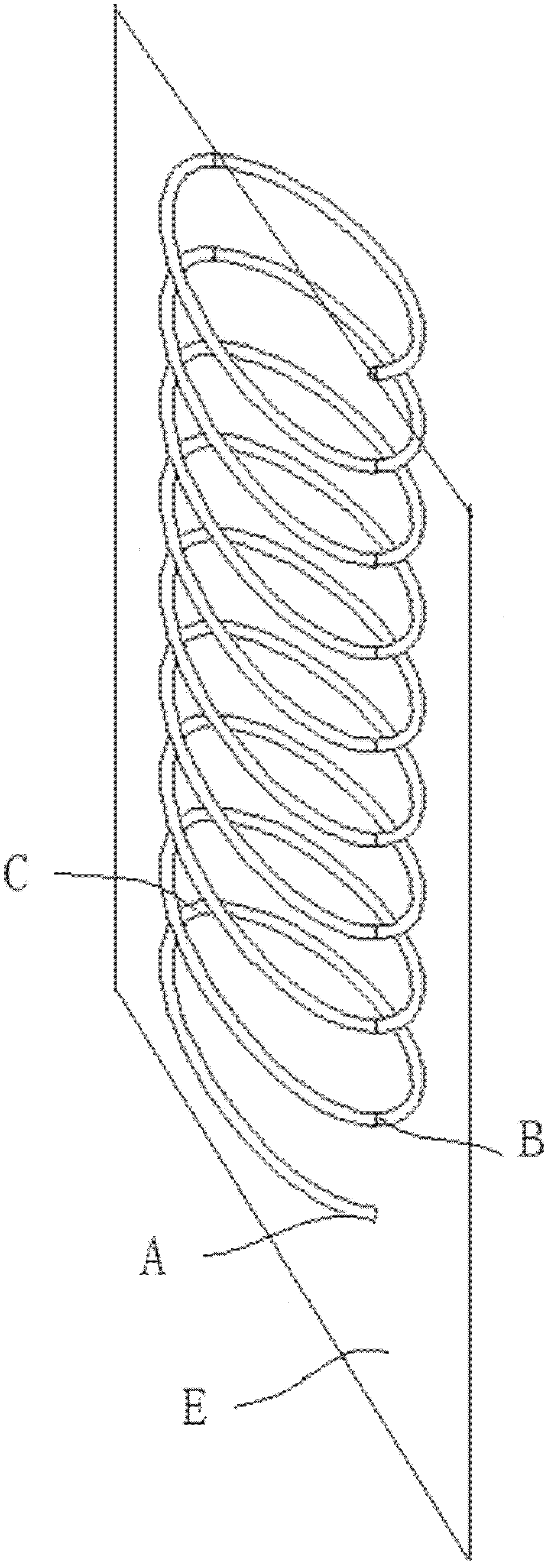

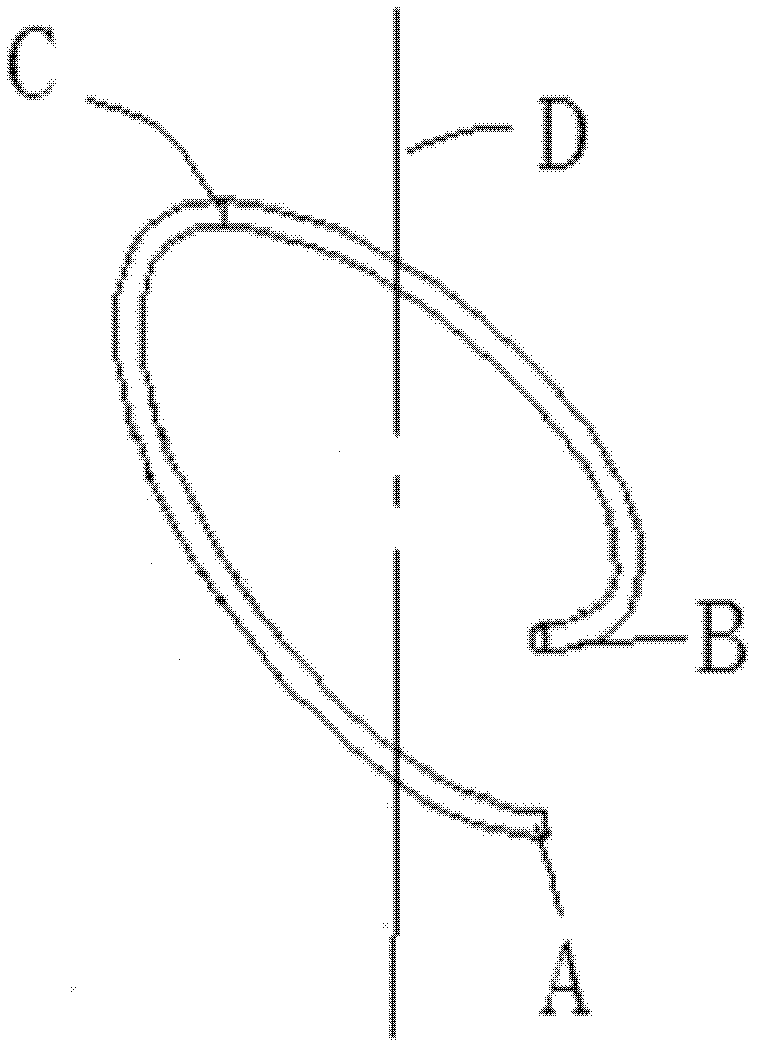

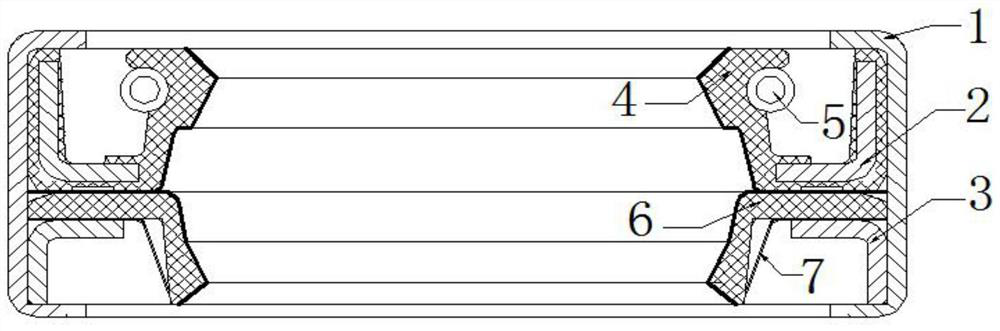

Lateral pressure spiral spring and sealing ring with same

InactiveCN102494067AStable preloadEffective stress compensationEngine sealsSpringsEngineeringBreaking point

The invention provides a lateral pressure spiral spring which is formed by rotating and bending a cylindrical body wound by using linear materials, wherein the axis of the cylindrical body is a central line of the spring, and basic parameters include a material linear diameter, an external diameter of the spring and a spiral angle; and the cylindrical body can be wounded into a cylinder or a ring shape connected end to end. The lateral pressure spiral spring is characterized in that the spiral angle is a variable. The front half circle of the spiral angle is a positive spiral angle, and the rear half circle of the spiral angle is a negative spiral angle; a transitional surface of break points of the spiral angle is formed between the front half circle and the rear half circle, and the absolute value of the positive spiral angle is larger than that of the negative spiral angle; and the spring is in a spiral raising structure as a whole. The spring can be applied to various mechanical application fields and particularly to the sealing field, is wide in stress range and can provide multidirectional stress compensation for elements, the stress compensation direction can be adjusted at any time along with the change of an external acting direction, and the spring can still provide enough stress compensation when pressure stress is not on the same horizontal surface but forms a certain angle with the horizontal surface.

Owner:上海大亚密封技术有限公司

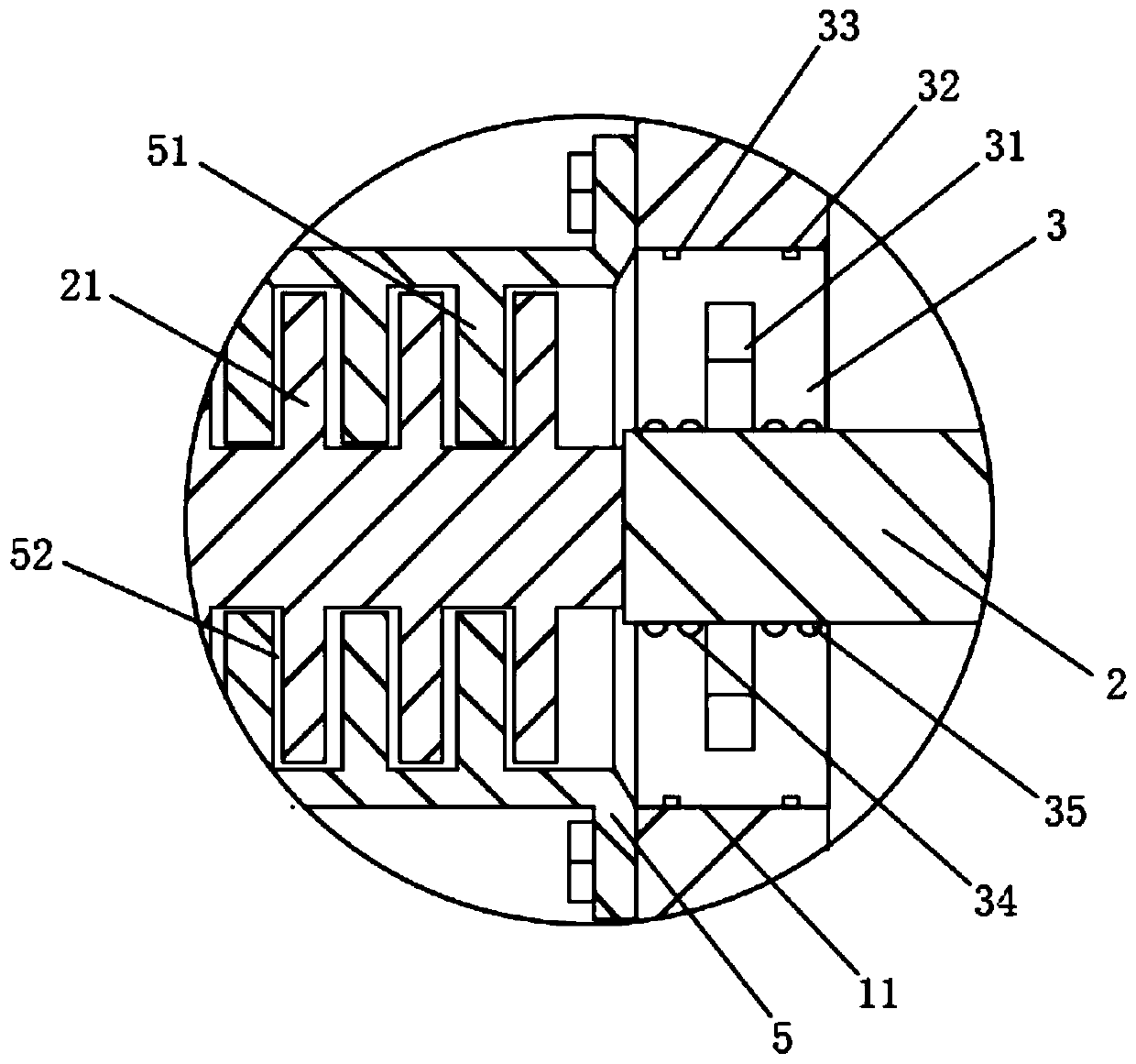

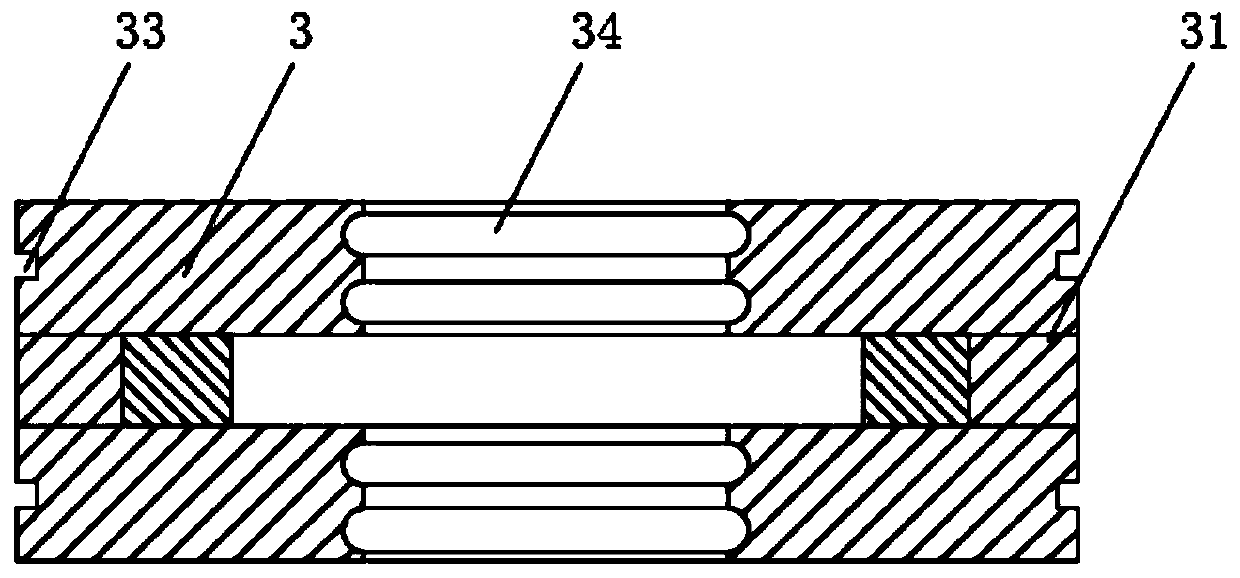

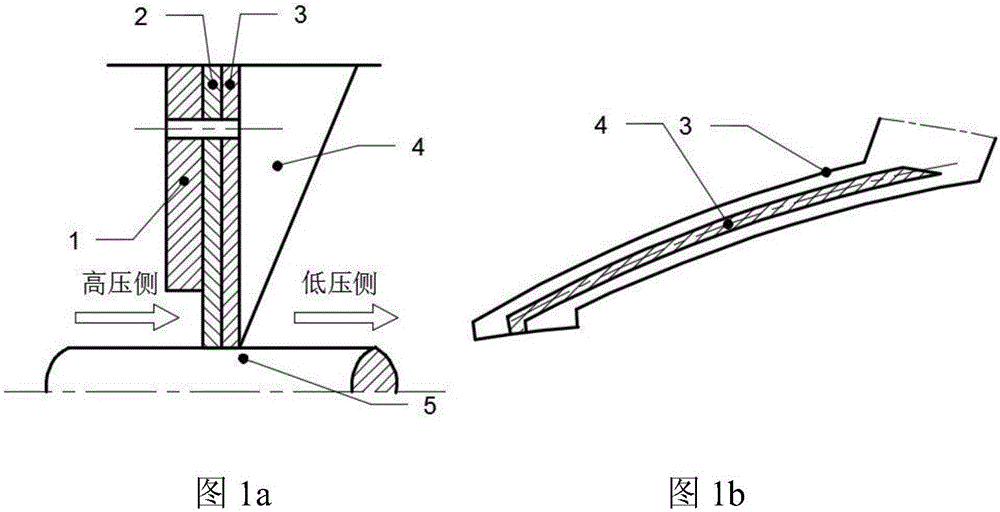

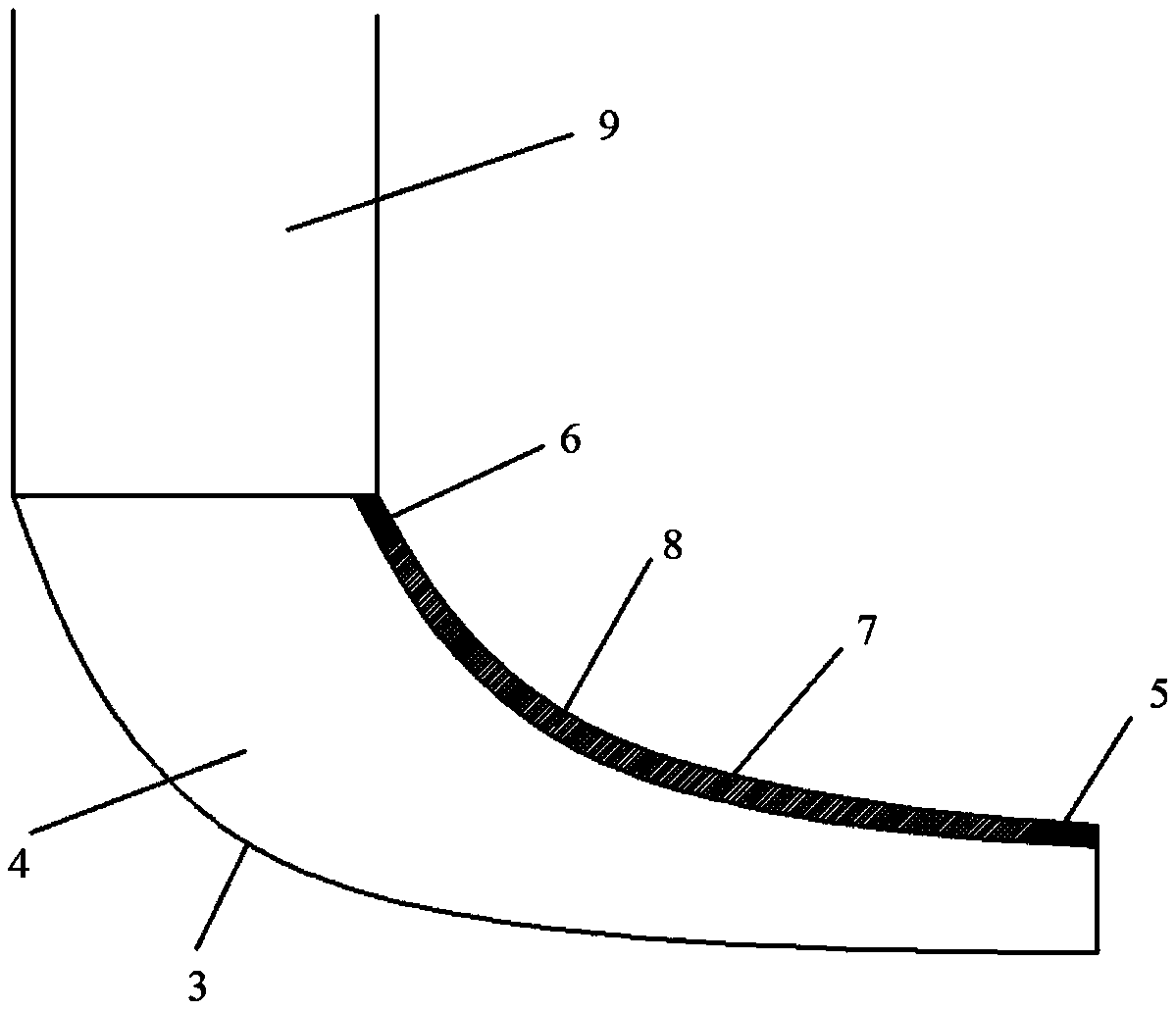

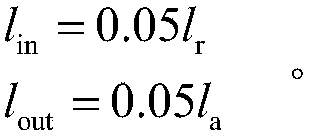

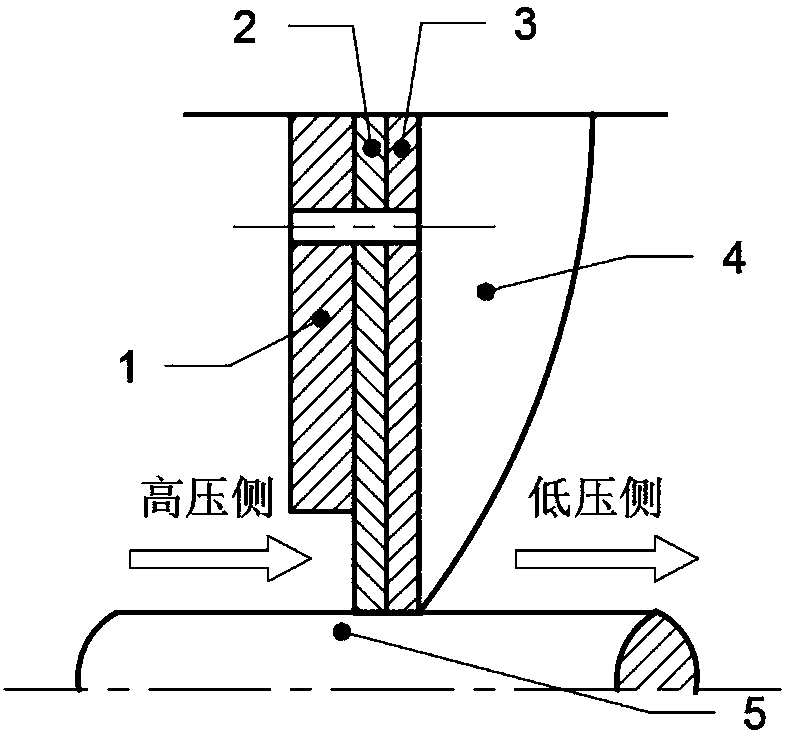

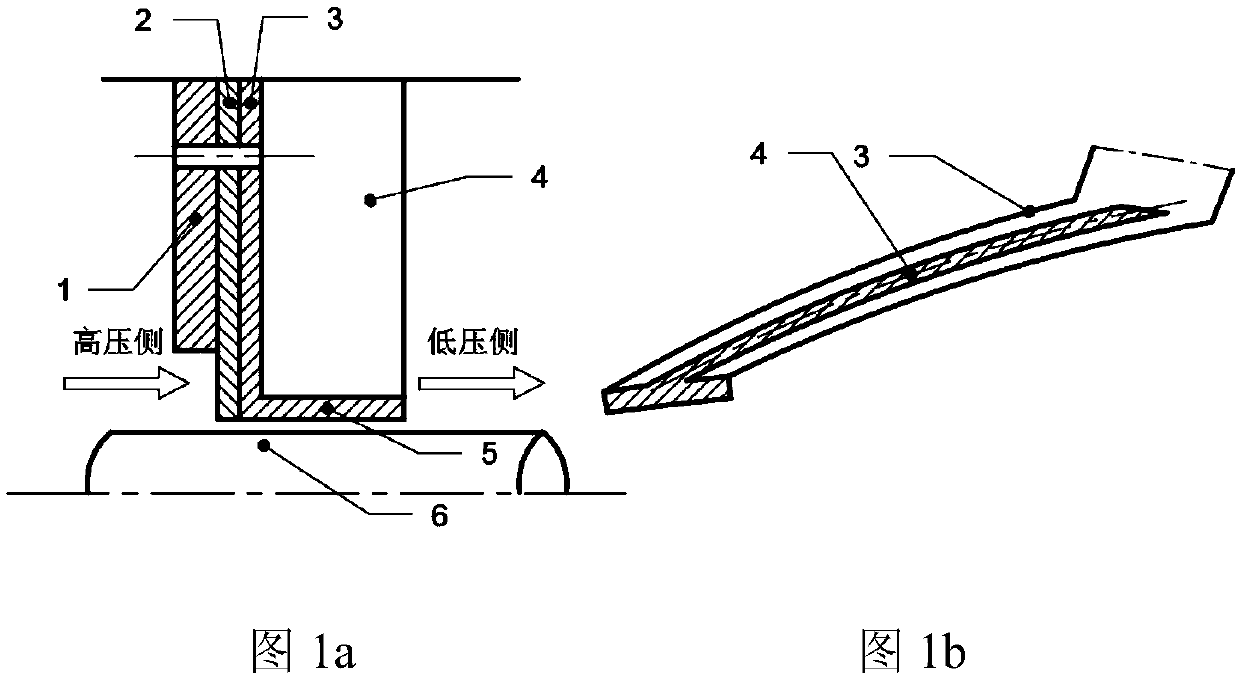

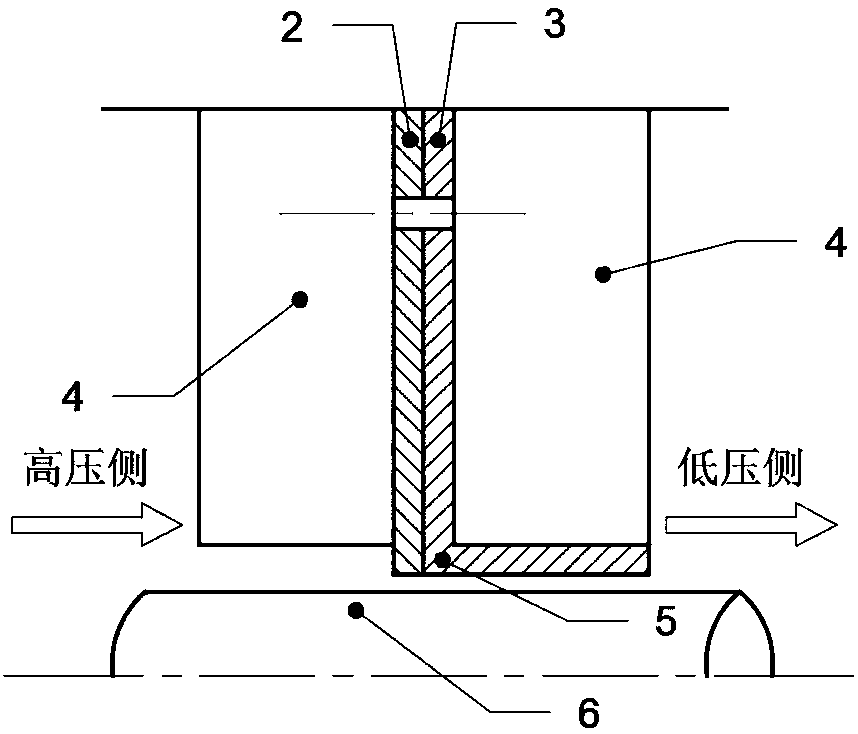

Low-hysteresis contact type fingertip seal with fin

ActiveCN106567747AImprove dynamic sealing performanceEliminate contact frictionLeakage preventionMachines/enginesHysteresisDifferential pressure

A low-hysteresis contact type fingertip seal with a fin comprises a contact type fingertip sealing device matched with a rotor. The contact type fingertip sealing device is formed by connecting a front baffle, a high-pressure fingertip sheet and a low-pressure fingertip sheet. The low-pressure fingertip sheet is provided with a fin structure, and the fin structure and the surface of the low-pressure side of a fingertip beam are arranged in a T-shaped mode. The fin structure has a certain width in the axial direction and accordingly can provide supporting force for resisting the front-back differential pressure for the fingertip sheet, so that the fingertip sheet is protected against axial deformation under the action of fluid pressure, and the fin structure plays a role in axially supporting a rear baffle in a conventional contact type fingertip seal. The rear baffle structure is omitted. The hysteresis effect caused by friction force between a low-pressure fingertip sheet and the rear baffle of the conventional contact type fingertip seal is reduced. The dynamic sealing performance of the contact type fingertip seal is improved.

Owner:TSINGHUA UNIV

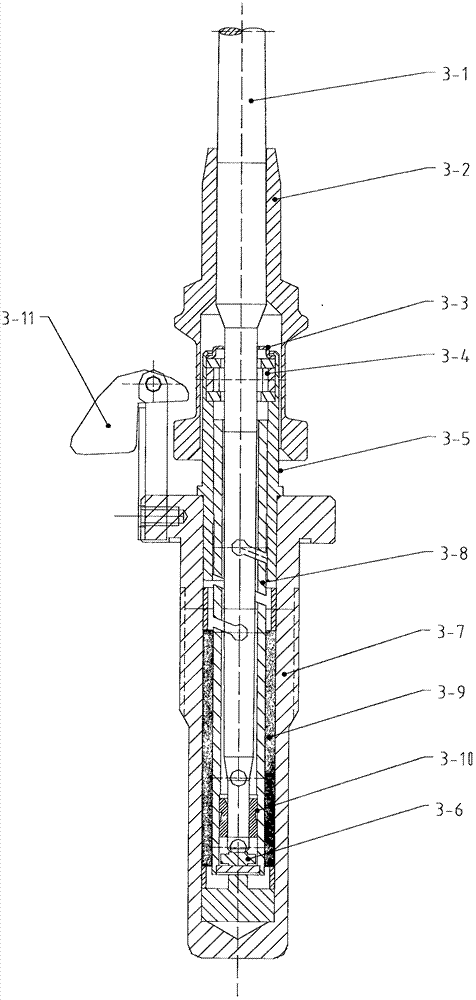

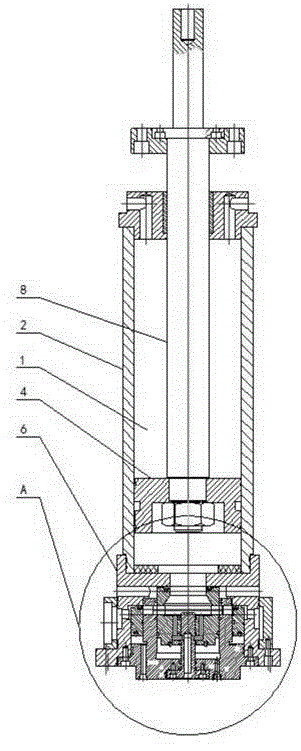

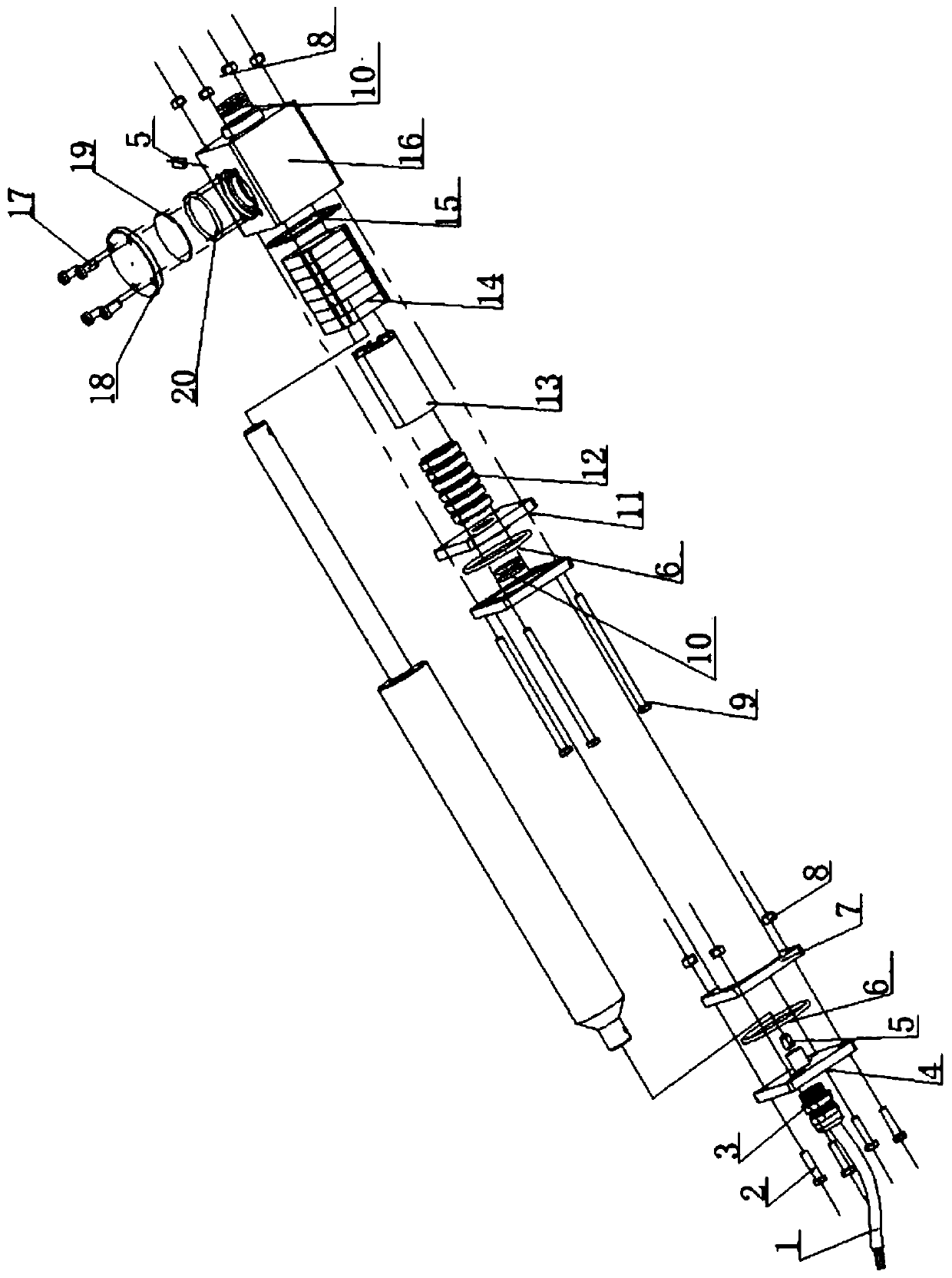

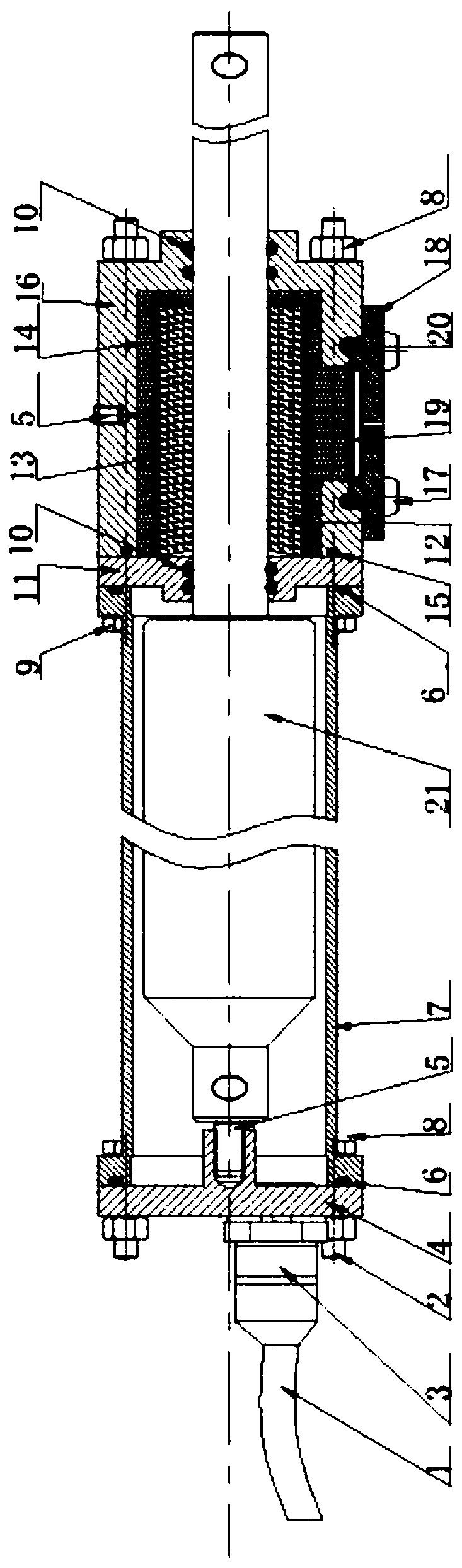

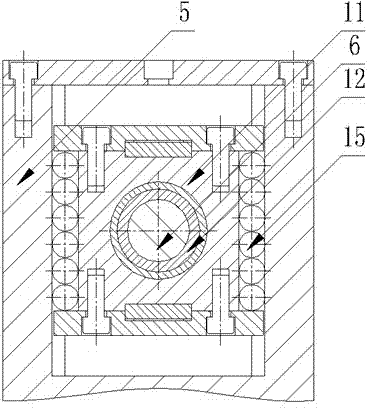

Coiled tubing motive sealing device

ActiveCN107989569AReduce frictionReduce wasteDrilling rodsCleaning apparatusCoiled tubingEngineering

The device provides a coiled tubing motive sealing device, and the technical scheme is that a lower part sealed oil scraping structure and an upper part righting mechanism are connected with a connecting bolt through a limiting support plate; the inner cavity of the support plate is a sealed cylinder; and a sealed basics sleeve, a sealed rubber core and an easily-changed rubber blanket are added on the inner cavity of the sealed cylinder, the sealed rubber core is arranged in the inner cavity of the sealed basics sleeve, thereby opening or closing the limiting support plate, and the sealed basics sleeve, the sealed rubber core or the easily-changed rubber blanket in the inner cavity of the sealed cylinder can be replaced. The coiled tubing motive seal device has the beneficial effects thatmultiple locating righting steel balls are increased to play a role of righting and reducing friction to the coiled tubing; through installing the sealed basics sleeve, the sealed rubber core and theeasily-changed rubber blanket which can be replaced in a split mode in the sealed cylinder, not only can motive sealing of the coiled tubing be realized, but also the replacement of the correspondingsealing elements is facilitated; and oil scraping device is added, the effect of motive sealing is improved, the service life of the coiled tubing is prolonged, and leakage accidents in the wellheadis avoided.

Owner:北京中海沃邦能源投资有限公司

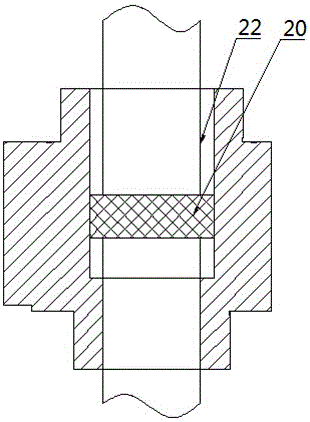

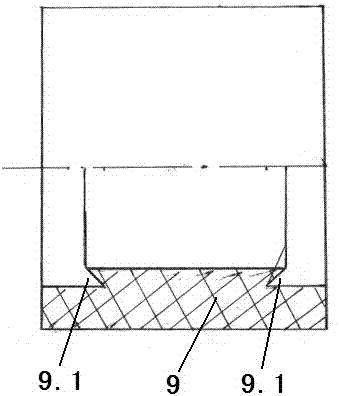

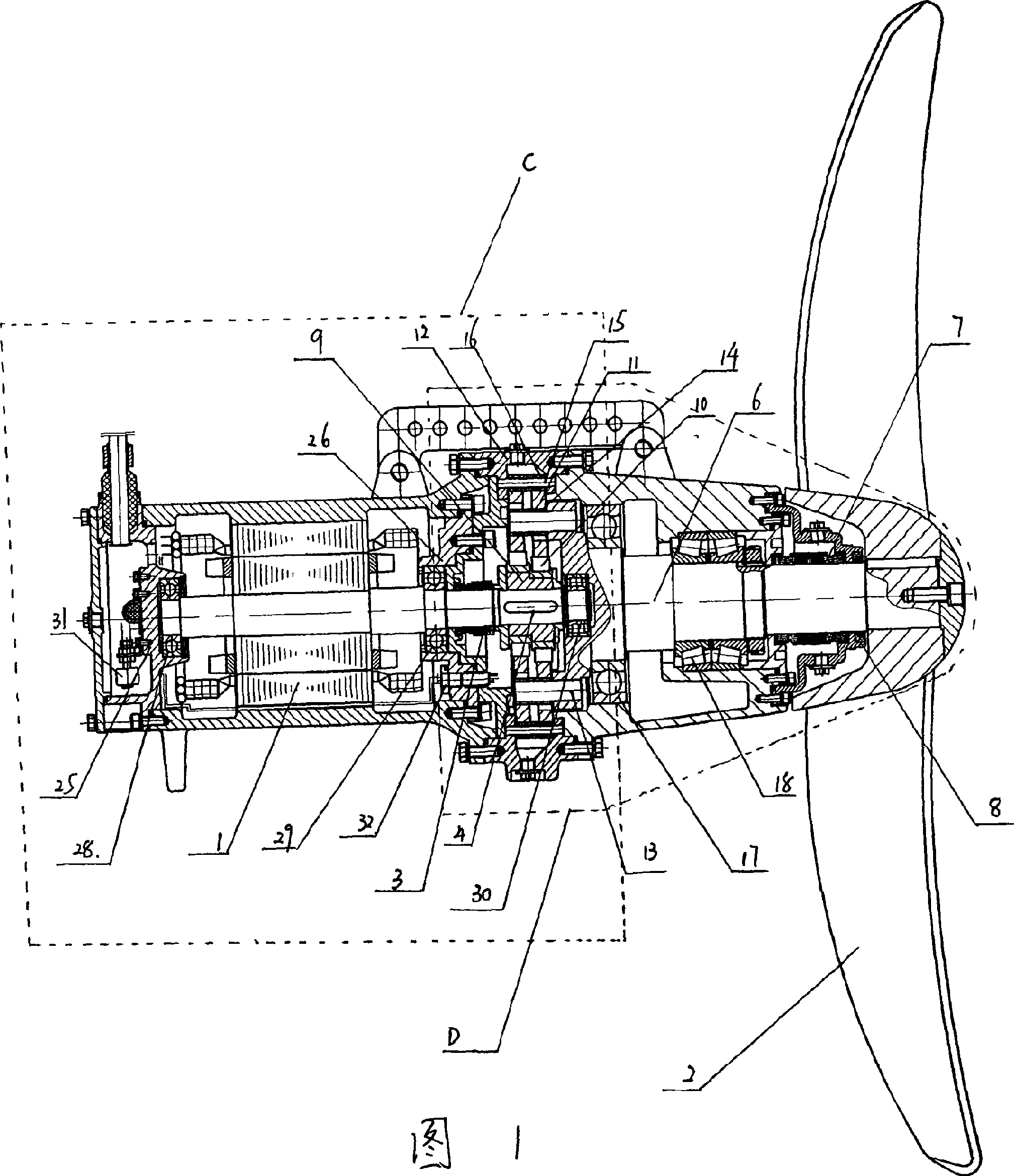

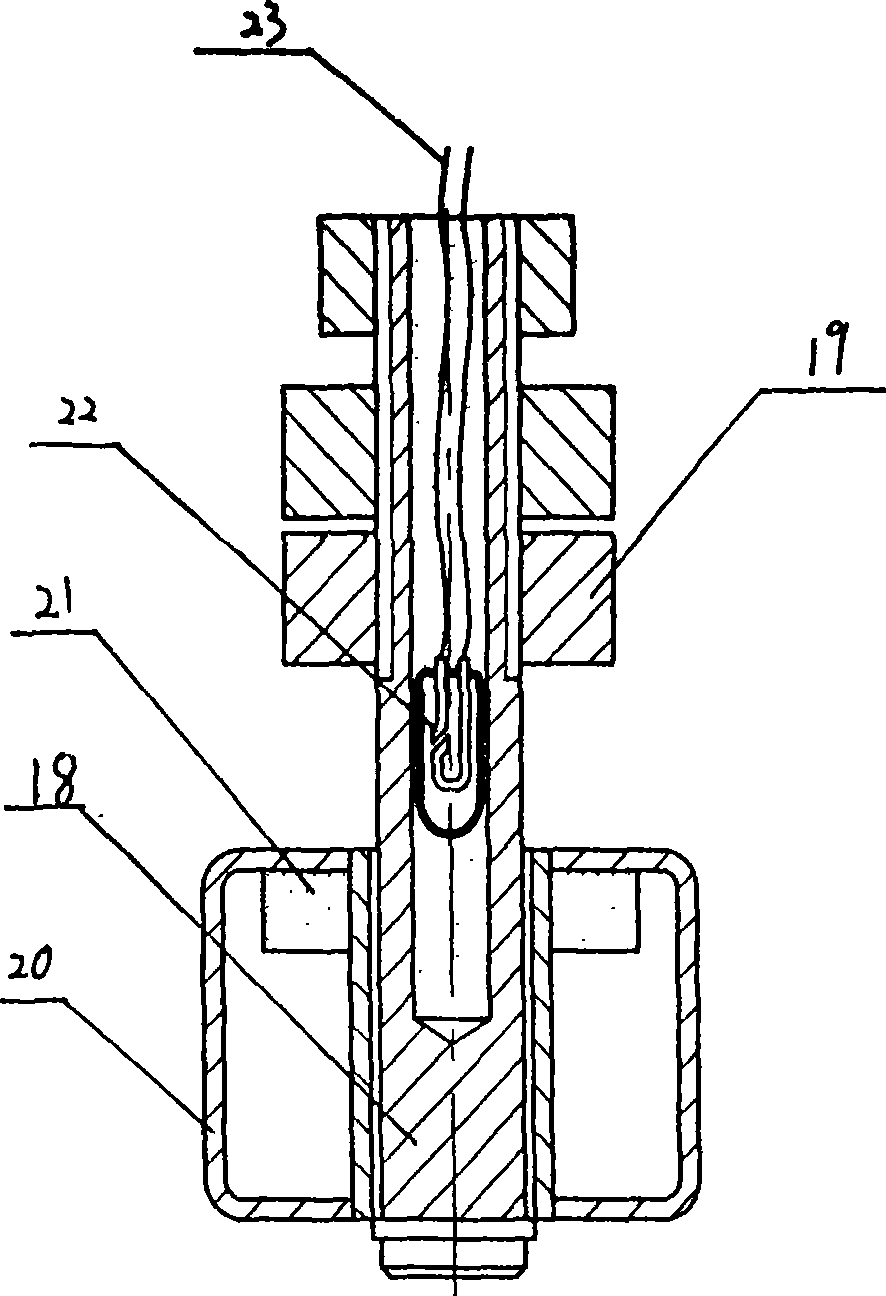

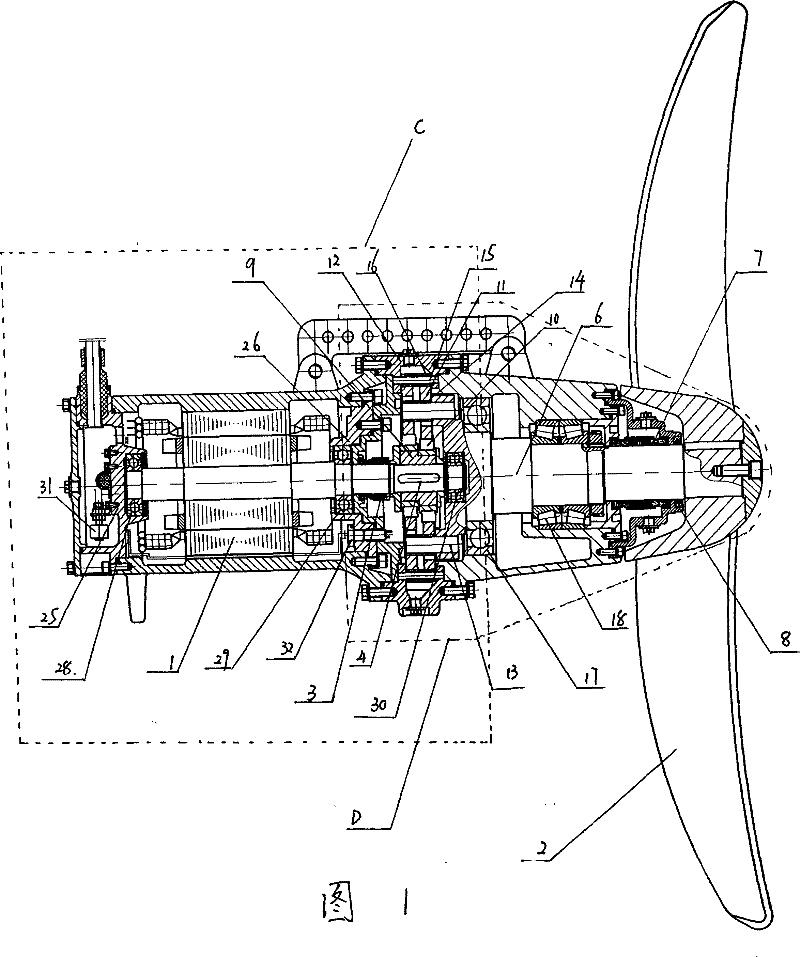

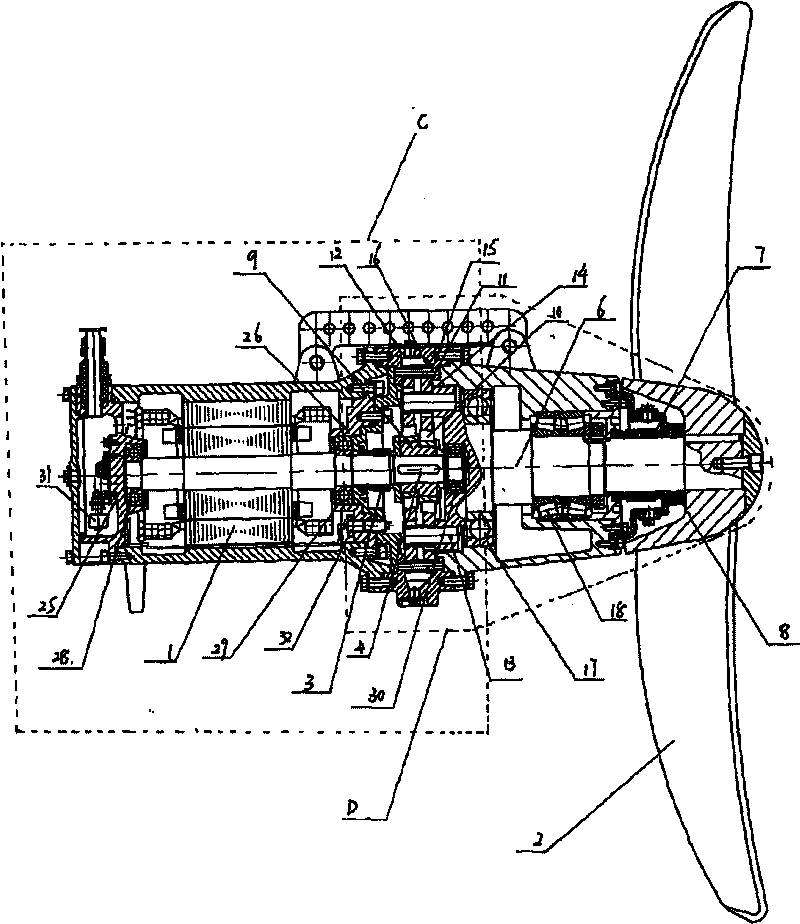

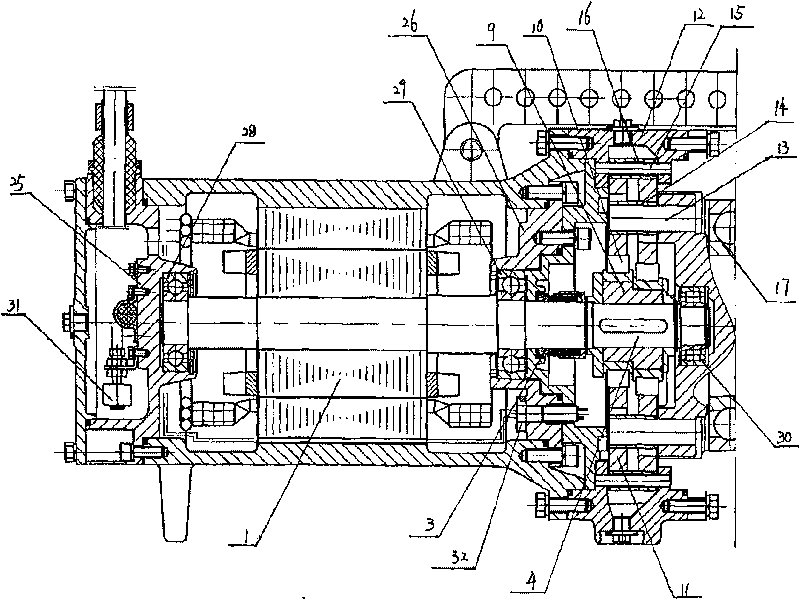

Motor peering type cycloid star wheel diving flow impeller

InactiveCN101456631AExquisite structureReduce volumeWater aerationSustainable biological treatmentImpellerPinion

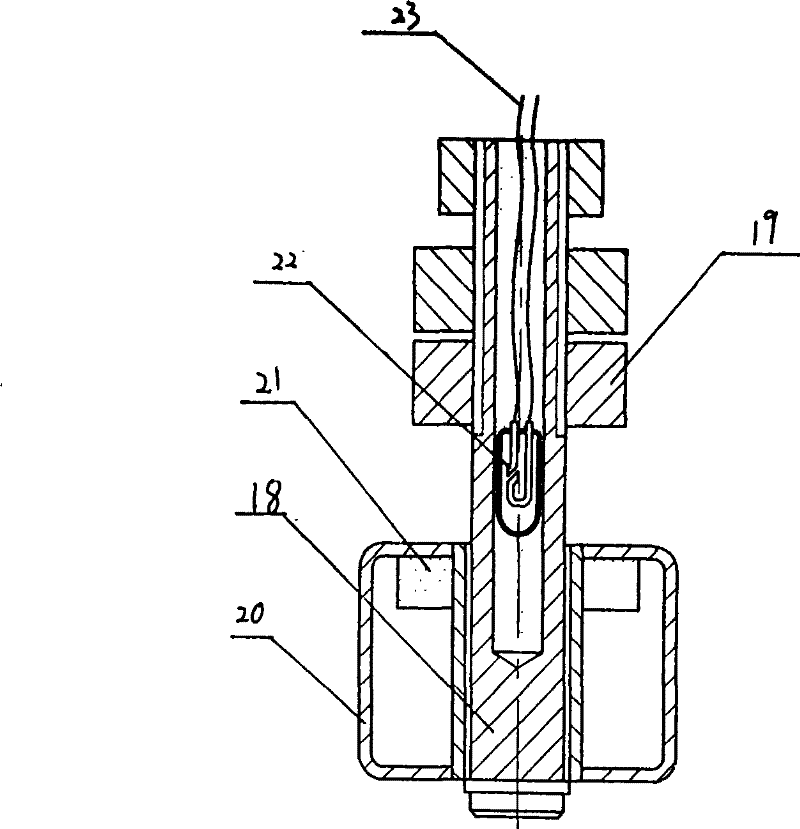

The invention discloses a cycloidal pinion submersible water impeller directly connected with a motor. A leakage alarming protection system comprises a leakage alarm device(31) and an oil-water probe alarm device(32); the oil-water probe alarm device(32) is horizontally arranged at the lower end of a front bearing cap(26) of the motor(1) and passes through the bearing cap; the oil-water probe alarm device(32) and the bearing cap are mutually sealed, one end of a probe body(24) of the oil-water probe alarm device(32) is flat-hexangular, the flat-hexangular end points to the motor(1), and the other end of the probe body(24) is thin column-shaped; and the inside of a through hole of the probe body(24) is fixedly provided with two probe needles(27) and an oil-water probe signal line(28), one part of each probe needle(27) is positioned outside the column-shaped end surface of the probe body(24), the oil-water probe signal line(28) is connected with the probe needles(27), and the probe needles(27) are connected with an oil-water probe control circuit through the oil-water probe signal line(28), and the probe needles(27) extend into an oil chamber of a reducing mechanism.

Owner:亚太泵阀有限公司

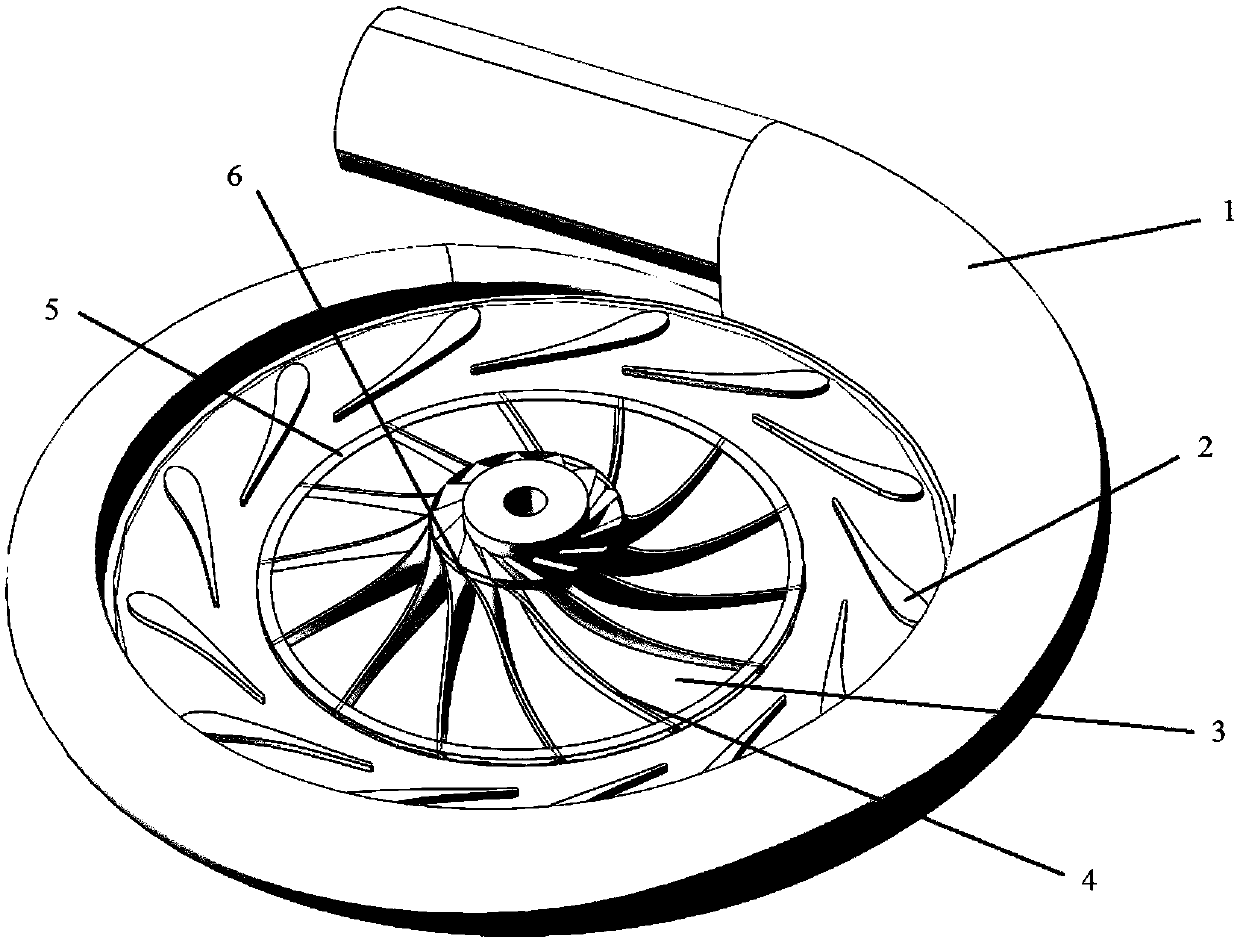

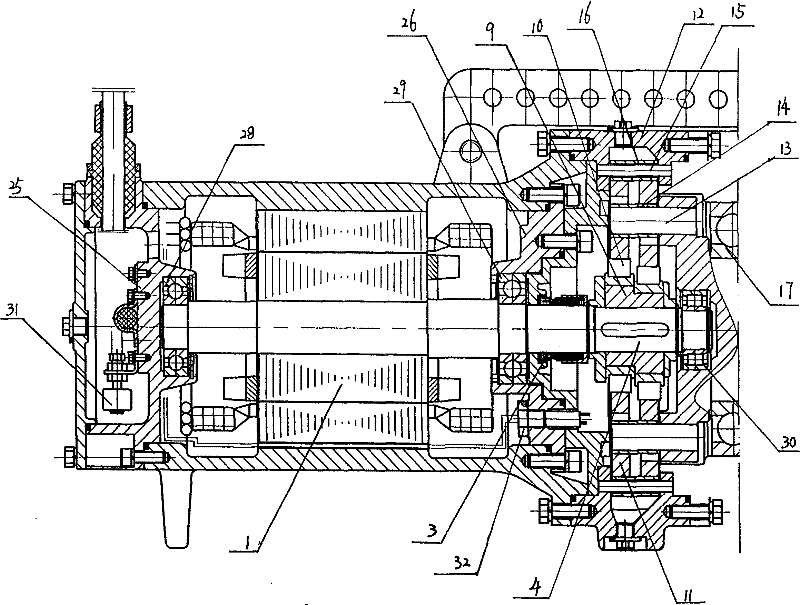

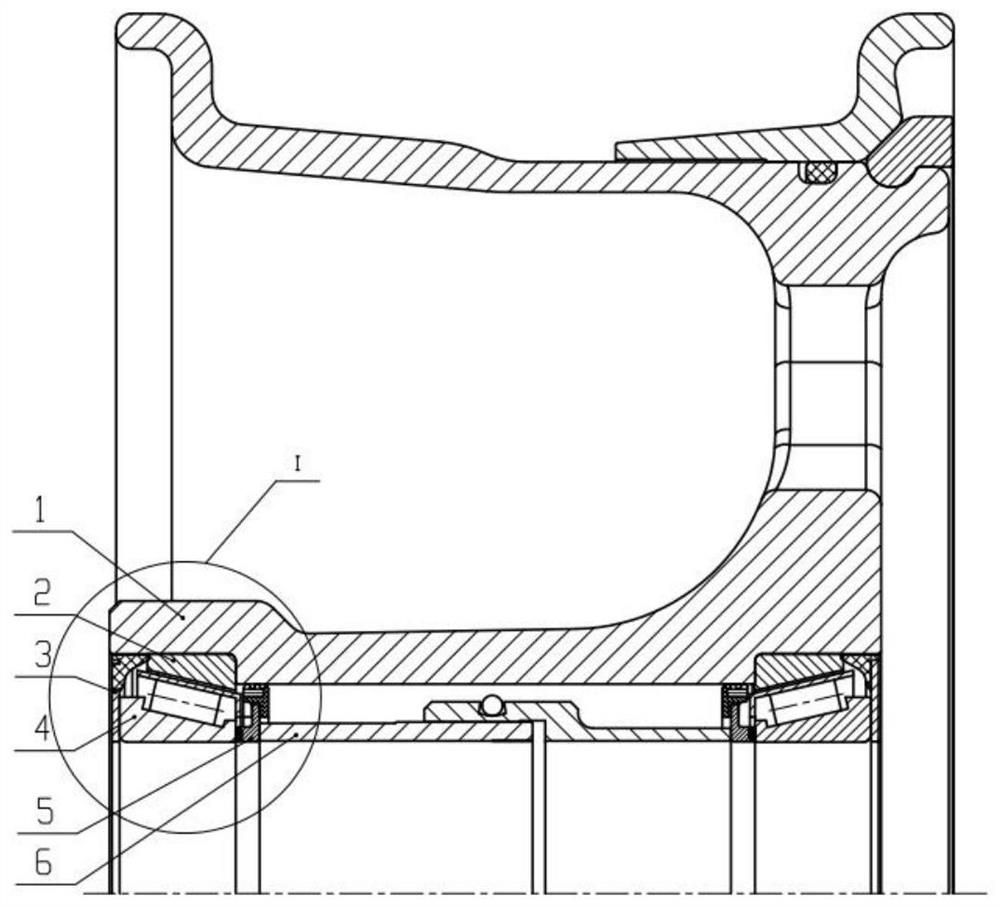

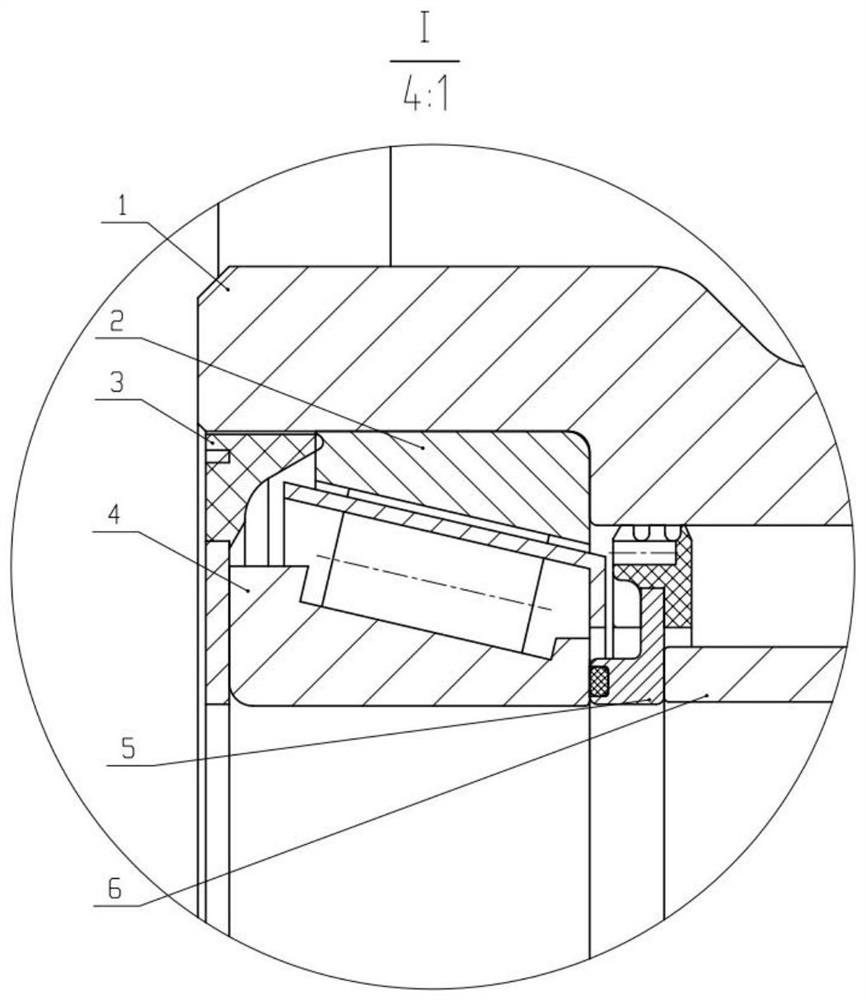

Radial-inward-flow turbine device with shock-absorbing damping function and sealing structure

ActiveCN109519225AImprove rigidityReduce vibration responseBlade accessoriesMachines/enginesImpellerDamping function

The invention provides a radial-inward-flow turbine device with a shock-absorbing damping function and a sealing structure. During work, a working medium enters the radial-inward-flow turbine device through an air inlet volute firstly, and then enters nozzle rings, the pressure of the high-temperature and high-pressure working medium is gradually decreased, the flowing speed is gradually increased, the working medium at outlets of the nozzle rings enters from an inlet of an impeller and does work through expansion in the impeller, and the pressure and the temperature are gradually decreased; and in the impeller, the working medium is subjected to flow guiding by closed flow channels formed by blade inlet shrouds and a hub firstly, then arrives at the middles of impeller blades of a radial-inward-flow turbine to continue doing work through expansion, and finally passes through closed flow channels formed by blade outlet shrouds and the hub, and the low-pressure and low-temperature working medium is discharged from the radial-inward-flow turbine device through an outlet flow channel. The radial-inward-flow turbine device adopts the shroud structures at inlets and outlets of the blades, by matching brush-type sealing between an impeller cover and the impeller blades, the aerodynamic efficiency of the radial-inward-flow turbine device is improved while rigidity is improved significantly, vibration response is lowered and operating safety is ensured, and the radial-inward-flow turbine device has important engineering significance and wide application prospects.

Owner:XI AN JIAOTONG UNIV

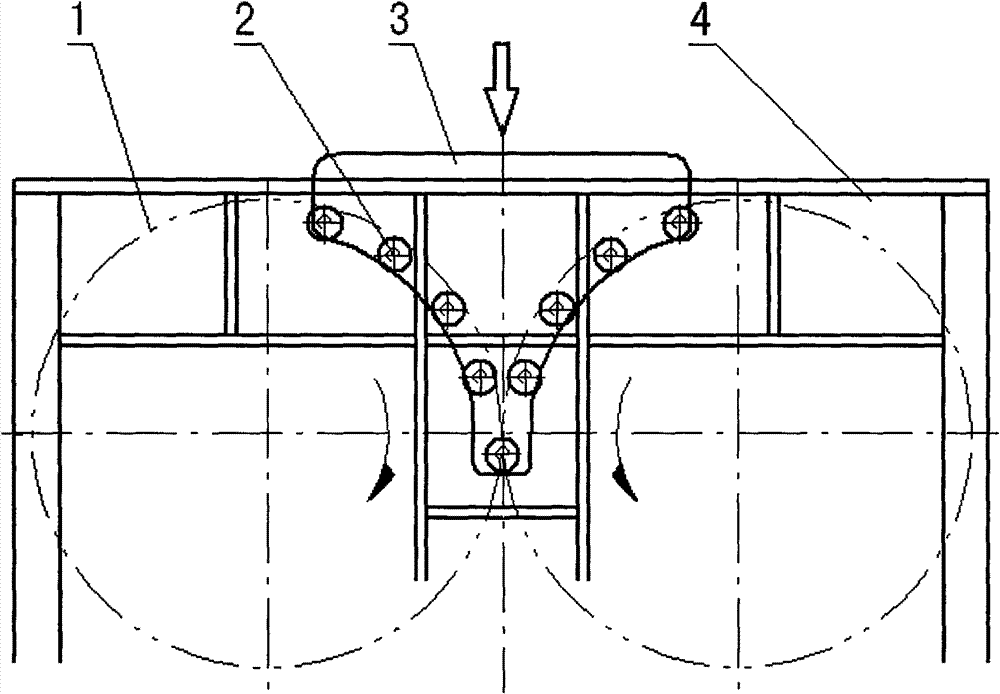

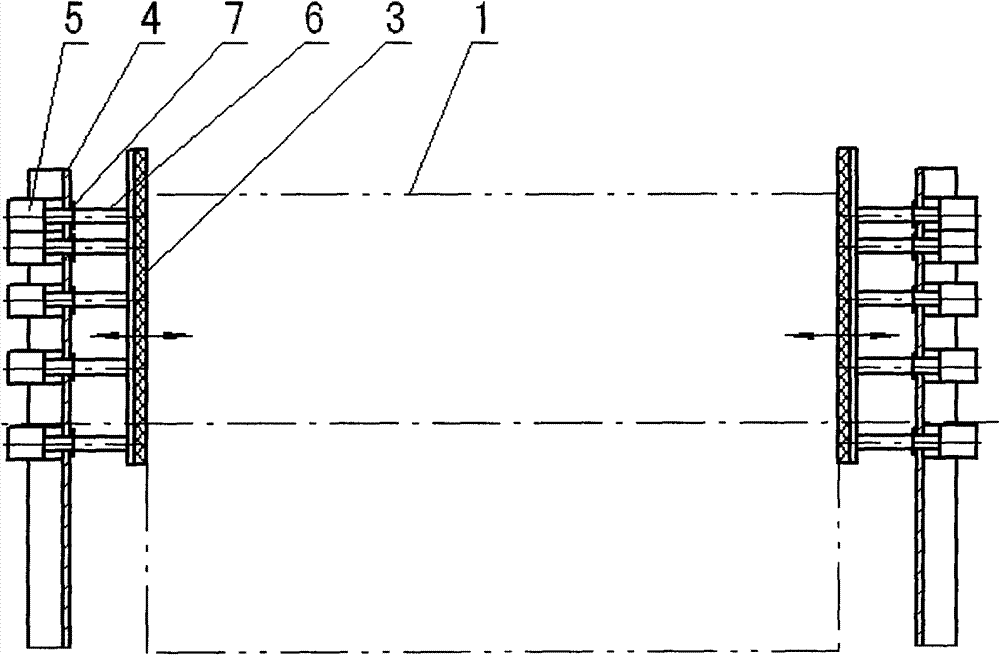

Moveable side striker plate for double-drum drier material pond

InactiveCN102772908APrevent leakage of raw material liquidEasy to checkEvaporator accessoriesEngineeringLinear motion

The invention discloses a moveable side striker plate for a double-drum drier material pond, comprising a side striker plate, an end wallboard, a sealing unit and a plurality of push rod assemblies with same structure, wherein the side striker plate is produced by compounding two kinds of materials with different properties; the end wallboard is fixedly arranged at the outer side of the end surfaces of two drums of the double-drum drier; each set of the push rod assembly comprises a push rod drive unit and a push rod, wherein the push rod drive unit is fixedly arranged on the outer side plate surface of the end wallboard, one end of the push rod is fixedly connected with the side striker plate, and the other end of the push rod is movably connected with the matched push rod drive unit through the through holes of the sealing unit and the end wallboard. According to the invention, the moveable side striker plate disclosed in the invention can make a bidirectional horizontal linear motion under control, can timely adjust the clearance between the moveable side striker plate and the end surfaces of two drums and effectively prevent the leakage of raw material fluids, is convenient for checking and changing easily damaged parts, and is beneficial for thoroughly cleaning the device.

Owner:无锡捷尔机械有限公司

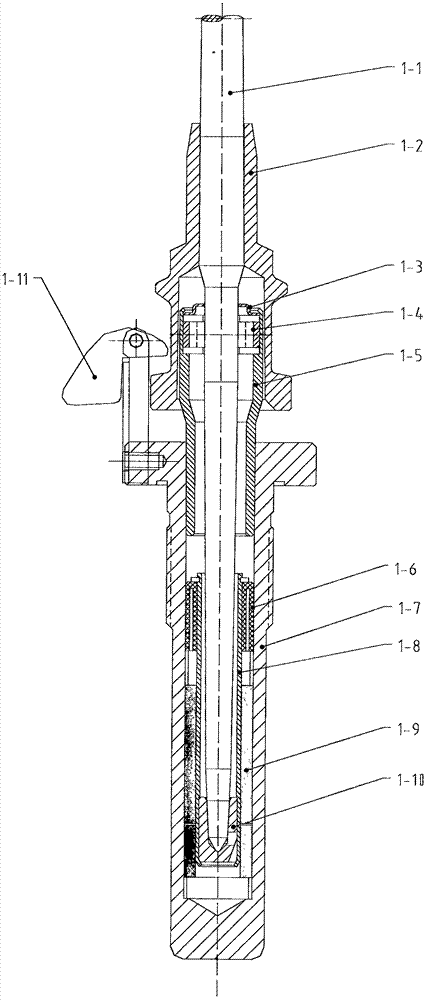

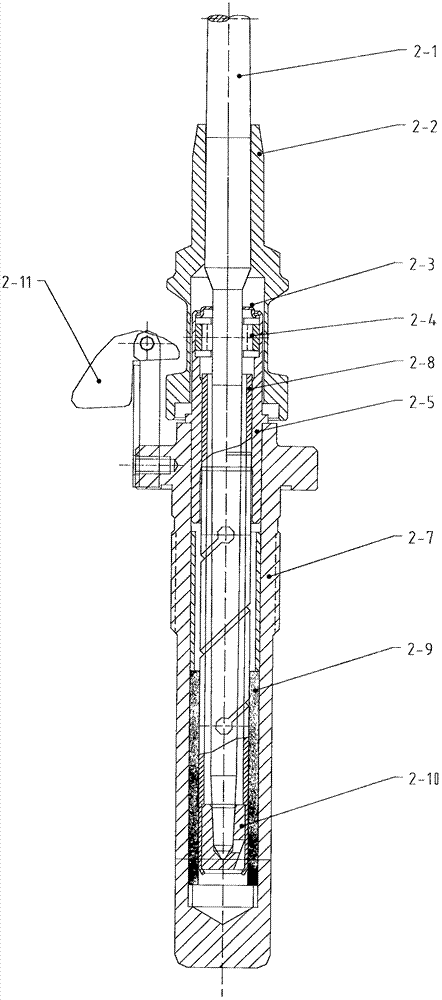

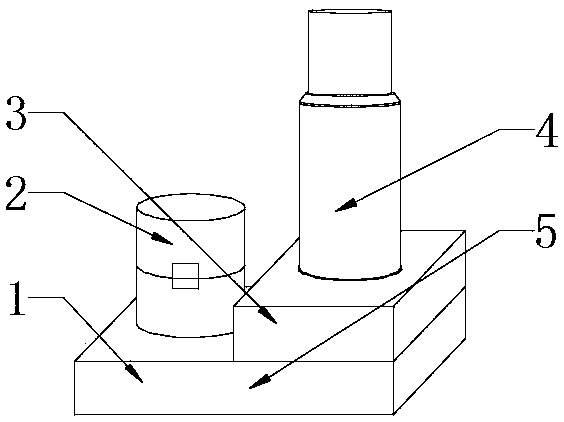

Novel oil-saving spindle with dynamic self-rotating airflow gap sealing

The invention discloses a novel oil-saving spindle with dynamic self-rotating airflow gap sealing, and belongs to the textile machinery industry. Lubricating oil is sealed into an inner cavity of a spindle by dynamic self-rotating airflow gap sealing technology. The novel oil-saving spindle is composed of a spindle rod, a spindle disk, an air gap sealing groove, a rotary airflow bearing sealing cover, a polymer sealing ring, a sealing groove, an upper bearing, an upper bearing seat, a gasket, a spindle foot, an elastic tube, a vibration absorbing coil spring, a spindle bottom, a spindle hook joint part and an axial spring. Spindle oil non-normal loss results from the spindle structure design. In the prior art, the upper bearing of the spindle is open type oil mist thin film lubricating, and the spindle oil evaporates into the atmosphere in an oil mist mode to cause loss. The unique dynamic self-rotating airflow gap sealing technology is used to solve the existing technical shortcomings, and the novel oil-saving spindle is applicable to the transformation of current different spindle oil-saving technologies. The spindle oil filling cycle extends from 3 months to 12-24 months. The operation cost of equipment is reduced; the labor intensity is reduced; the employment of enterprises is reduced; the workload of a spindle oil filling machine is reduced; the needs of spindle oil saving and the like are met.

Owner:HENAN NO 2 TEXTILE MACHINERY

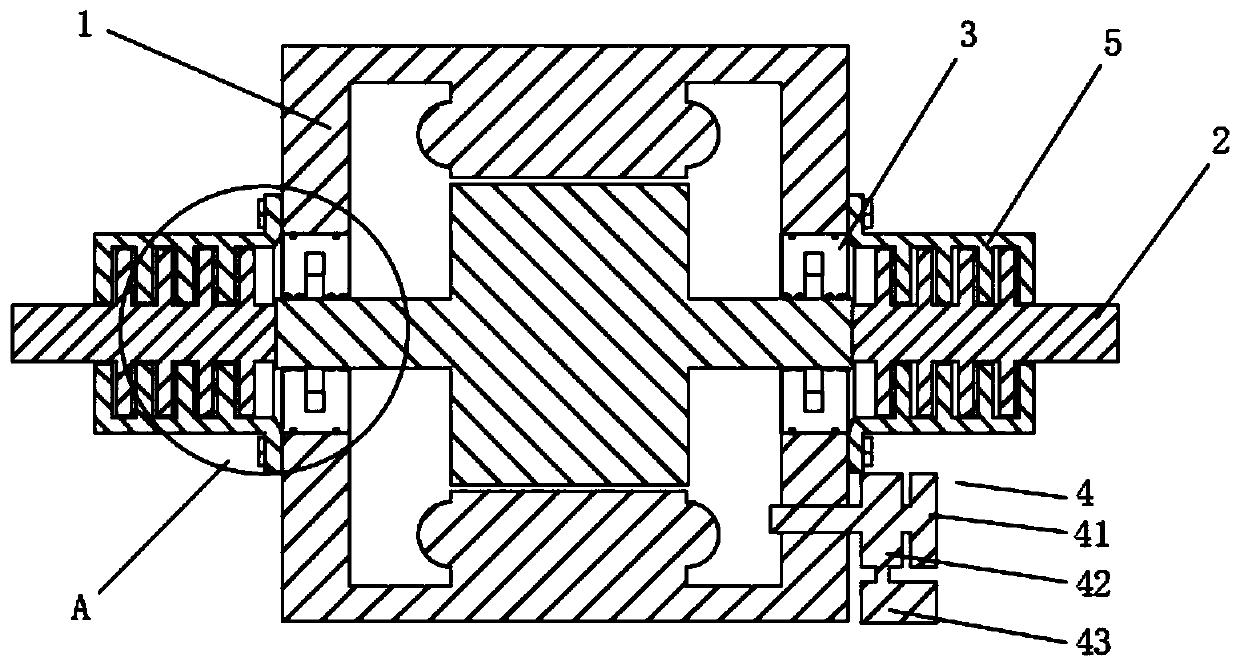

Flow control device

ActiveCN109210236AReduce Internal LeakageImprove internal sealing performanceSpindle sealingsMultiple way valvesValve openingEngineering

A flow control device used for a heat exchange system comprises a shell body, a transmission piece and a first valve piece. The first valve piece comprises a valve main body; a first contact part anda first communicating channel are formed in the valve main body; an opening of the first communicating channel penetrates through one side of the valve main body and faces the side where the first valve piece is located; the first contact part surrounds the radial circumferential side of the opening of the first communicating channel; and a second contact part is further formed on the flow controldevice and located on the radial circumferential side of a circulating valve opening, and the first contact part and the second contact part are arranged in a movable seal mode. The transmission piece can drive the first valve piece through a second transmission part to rotate stably, the movable sealing property of the movable valve piece and the matched part can be improved, inner leakage of aworking medium is relatively reduced, and the inner sealing property of the flow control device can be improved.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

Tumbler switch for tanks and armored vehicles

InactiveCN101635220AImprove dynamic sealing performanceTumbler/rocker switch detailsElectronic switchEngineering

The invention discloses a tumbler switch for tanks and armored vehicles, and relates to the technical field of structures of electronic switches. The tumbler switch comprises an upper shell and a lower shell which are fixedly connected; a sealing washer is arranged between the upper shell and the lower shell; the inside of a cavity formed by the upper shell and the lower shell is provided with a shifting fork and four movable contact arms respectively; the bottom of the lower shell is fixed with four contact columns matched with the four movable contact arms; the upper part of the shifting fork is connected with a ball handle of which the upper part is arranged in a middle hole of the upper shell; and the tumbler switch is characterized in that: the upper end of the upper shell is fixedly connected with a cover plate; the center of the cover plate is provided with a through hole adapted to the ball handle; a sealing gasket is arranged between the cover plate and the upper shell; a copper gasket is arranged between the sealing gasket and the upper shell; and an epoxy resin sealing layer is arranged between the contact columns and the lower shell. The product has good leakproofness, particularly can be used for circuit connection / disconnection or change on surface equipment matched with the tanks and the armored vehicles, and the like, and can keep for 96 hours in a constant temperature and humidity resistant test.

Owner:潘振富

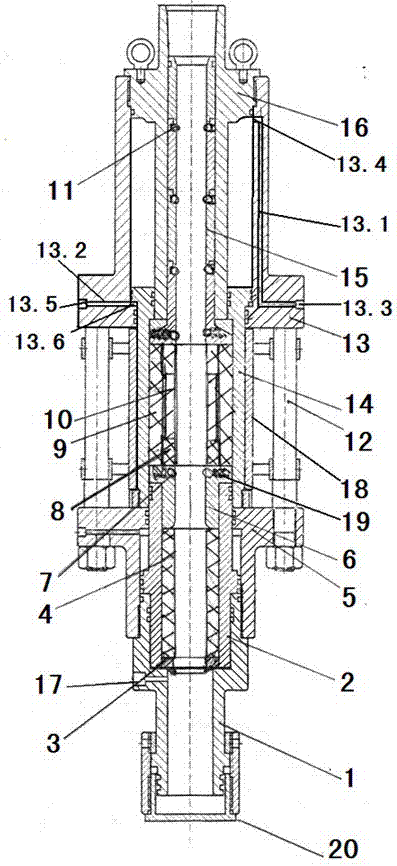

Novel lifting cylinder

InactiveCN105065366AIncrease lift heightIncrease lift rateFluid-pressure actuatorsImpact testMechanical engineering

The invention discloses a novel lifting cylinder. The novel lifting cylinder comprises a cylinder body (2) with a first inner cavity (1), a piston (4) which is arranged inside the cylinder body (2) and can slide along the inner wall of the cylinder body (2), and a base (6) which is connected to the first end of the cylinder body (2) and can input gas to the cylinder body (2). The piston (4) is further fixedly connected with a piston rod (8) which penetrates through the second end of the cylinder body (2). The piston rod (8) is connected with the second end of the cylinder body (2) in a dynamic sealing mode. The novel lifting cylinder achieves fast gas advance and retreat, and can provide larger energy, hoist the height and increase the frequency for an impact test stand when being applied to the field of impact and collision tests.

Owner:SUZHOU FNS VIBRATION SYST

Waterproof electric push rod

InactiveCN108832765AImprove practical performanceImprove transmission stabilityMechanical energy handlingElectricityEngineering

The invention provides a waterproof electric push rod comprising a base, a conduit, an electric motor, a storage battery, a double-pole double-throw switch, a push rod and a dynamic seal ring. The conduit is installed at the upper side inside the base; the motor is installed at the lower side inside a motor box; the storage battery is installed at the upper side inside the motor box; the double-pole double-throw switch is arranged at the front side of the annular side of the motor box; the push rod is installed inside the conduit; and the dynamic seal ring is installed at the upper side insidethe conduit. Therefore, problems of unstable transmission and poor reciprocating effect controlling of the original waterproof electric push rod are solved. The waterproof electric push rod has advantages of reasonable structure, good waterproof sealing performance, good transmission effect and stable working performance.

Owner:董道明

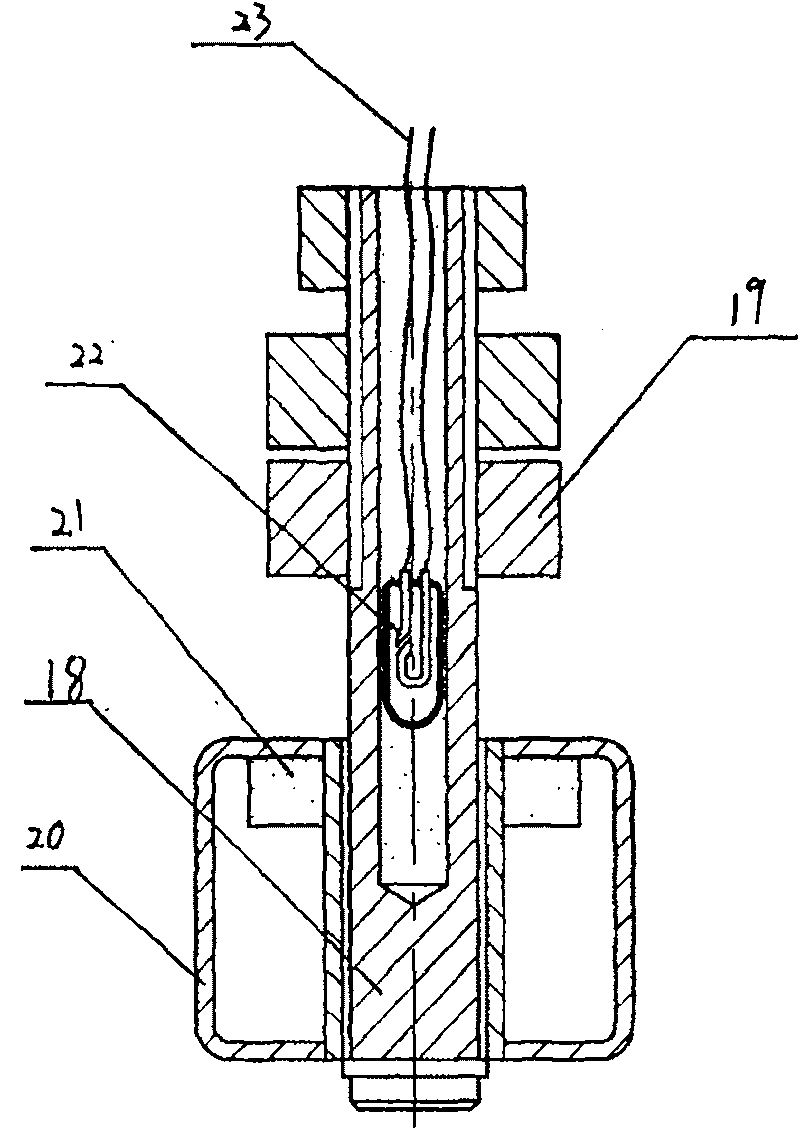

Motor peering type cycloid star wheel diving flow impeller

The invention discloses a cycloidal pinion submersible water impeller directly connected with a motor. The cycloidal pinion submersible water impeller comprises a motor directly-connected type cycloidal pinion transmission system; the motor(1) is provided with a leakage alarming protection system comprising a leakage alarm device(31) and an oil-water probe alarm device(32); the leakage alarm device(31) is provided with a vertical slide rod(18) provided with a nut(19) and a sliding type buoy(20) arranged from top to bottom, and the upper wall of an inner chamber of the sliding type buoy(20) isfixedly provided with a magnetic coil(21) which can up and down slide on the vertical slide rod(18) along the sliding type buoy(20); and the inside of the vertical slide rod(18) is provided with a blind hole, the inside of the blind hole is fixedly provided with a dry reed tube(22) and a leakage alarm signal line(23), and the dry reed tube(22) is connected with a leakage alarm control circuit through the leakage alarm signal line(23).

Owner:ASIA PACIFIC WATER TREATMENT TIANCHANG

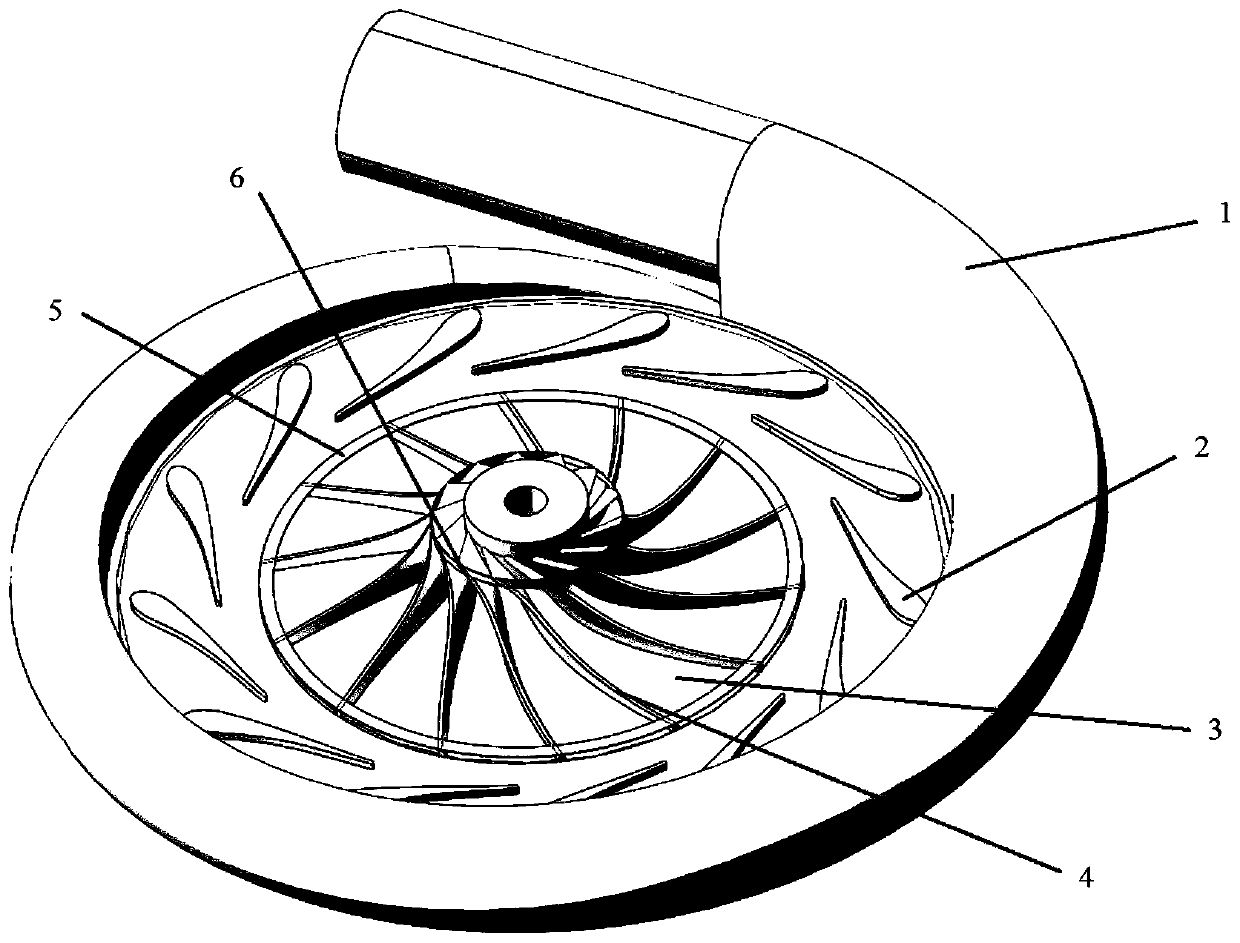

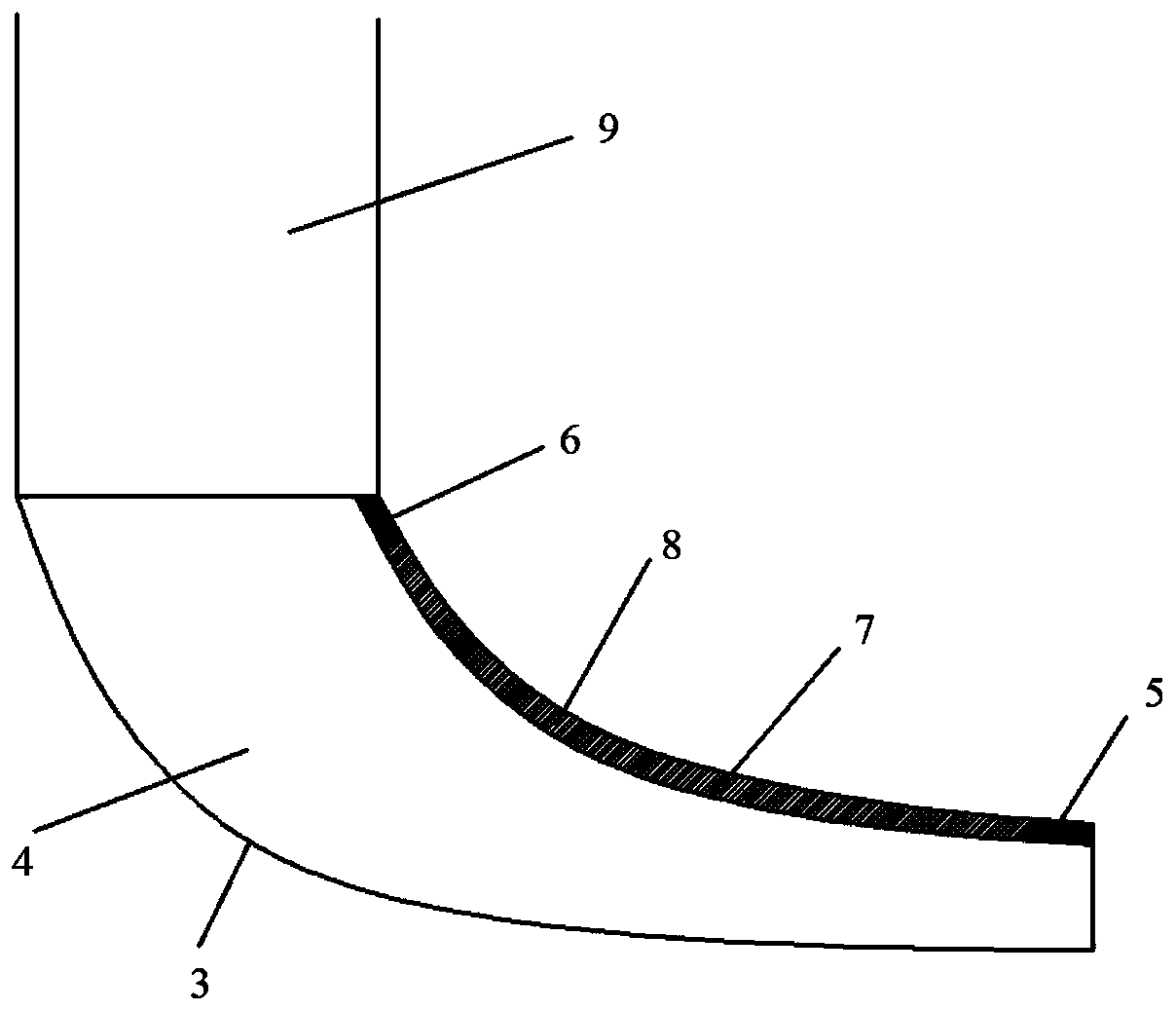

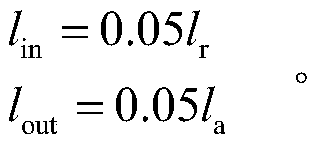

A centripetal turbine device with vibration damping and sealing structure

ActiveCN109519225BImprove rigidityReduce vibration responseBlade accessoriesMachines/enginesEngineeringTurbine

A centripetal turbine device with vibration damping and sealing structure. When working, the working fluid first enters the centripetal turbine device from the intake volute, and then enters the nozzle ring. The pressure of the high-temperature and high-pressure working fluid gradually decreases. The flow rate gradually increases, and the working fluid at the nozzle ring outlet enters from the impeller inlet, expands and performs work in the impeller, and the pressure and temperature gradually decrease. The working fluid in the impeller first passes through the closed flow channel formed by the blade inlet shroud and the hub. Then it reaches the middle part of the centripetal turbine impeller blade and continues to expand and perform work. Finally, it passes through the closed flow channel formed by the blade outlet shroud and the hub. The low-pressure and low-temperature working fluid is discharged from the centripetal turbine device through the outlet flow channel. By adopting the shroud structure at the blade inlet and outlet and cooperating with the brush seal between the wheel cover and the impeller blade, the present invention greatly improves the rigidity, reduces the vibration response and ensures the operation safety, and at the same time improves the efficiency of the centripetal turbine device. Pneumatic efficiency has important engineering significance and broad application prospects.

Owner:XI AN JIAOTONG UNIV

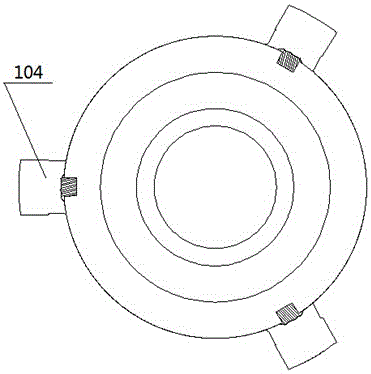

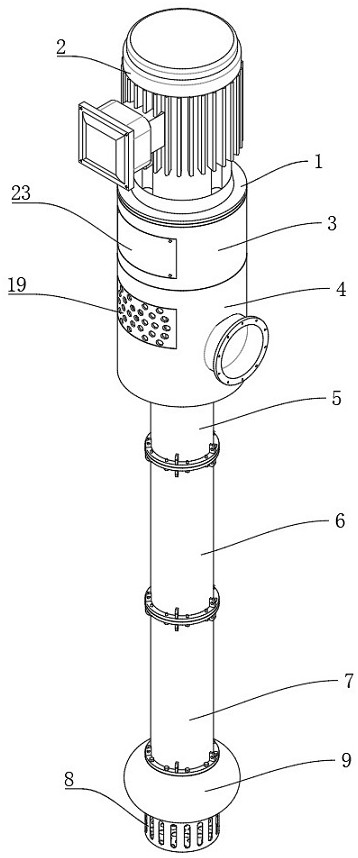

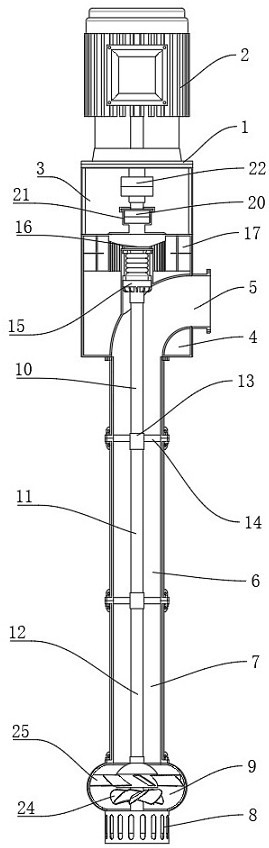

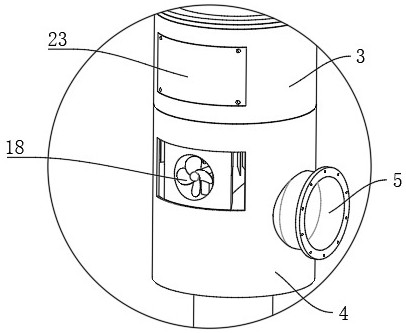

Power sealing type vertical long shaft pump

PendingCN112524040AReduce work stressExtended service lifePump componentsPump installationsImpellerCooling chamber

The invention discloses a power sealing type vertical long shaft pump. The power sealing type vertical long shaft pump comprises a motor base, wherein a motor is fixedly arranged on the upper side ofthe motor base; an observation chamber is fixedly arranged on the lower side of the motor base in a matched mode; a cooling chamber is fixedly arranged on the lower side of the observation chamber ina matched mode; a pump base is fixedly arranged in the cooling chamber in a matched mode; a first external connection pipe is fixedly arranged at the lower end of the pump base in a matched mode; a second external connection pipe is fixedly arranged at the lower end of the first external connection pipe in a matched mode; a backflow body is fixedly arranged at the lower end of the second externalconnection pipe in a matched mode; a filter screen is fixedly arranged on the lower side of the backflow body in a matched mode; a shaft body assembly is arranged in the first external connection pipeand the second external connection pipe; an auxiliary impeller assembly matched with the shaft body assembly is arranged in the cooling chamber; a cooling assembly matched with the auxiliary impellerassembly is arranged in the cooling chamber; a bearing part matched with the shaft body assembly is arranged in the observation chamber; and an impeller assembly is arranged in the backflow body in amatched mode. According to the power sealing type vertical long shaft pump, the working temperature of a sealing ring in the device can be reduced, the service life of the sealing ring is prolonged,the sealing effect is effectively improved, and the high reliability is achieved.

Owner:利欧集团湖南泵业有限公司

An underwater electric actuator

ActiveCN109089397BImprove dynamic sealing performanceImprove liquidityHermetically-sealed casingsEngineeringActuator

The invention discloses an underwater electric actuator, which comprises an electric actuator, a protective barrel body, a first pressure cap, a sealed cabin and a second pressure cap. The electric actuator comprises an electric actuator body and a telescopic rod connected with the electric actuator body; the protective barrel body is arranged on the electric actuator body. The front end of the protective barrel body is hermetically and fixedly connected with the first pressure cap, the rear end of the protective barrel body is hermetically and fixedly connected with the second pressure cap, the sealed cabin is fixedly connected with the second pressure cap, the telescopic rod passes through the second pressure cap and the sealed cabin, and the telescopic rod and the second pressure cap and the telescopic rod and the protective barrel body are sealed and connected; a sponge thin insulating oil filling area, a rubber sleeve and a viscous insulating grease asbestos ring are arranged coaxially from the outside to the inside of the sealed warehouse; the side wall of the sealed cabin is provided with an opening on the side of the sealed cabin, and a third pressure cap is installed at the opening of the sealed cabin. The underwater electric actuator can improve the dynamic sealing performance of the underwater actuator and overcome the defect that the underwater electric actuator iseasy to leak.

Owner:江苏海博流体控制有限公司

Lateral pressure spiral spring and sealing ring with same

InactiveCN102494067BStable preloadEffective stress compensationEngine sealsSpringsEngineeringBreaking point

The invention provides a lateral pressure spiral spring which is formed by rotating and bending a cylindrical body wound by using linear materials, wherein the axis of the cylindrical body is a central line of the spring, and basic parameters include a material linear diameter, an external diameter of the spring and a spiral angle; and the cylindrical body can be wounded into a cylinder or a ring shape connected end to end. The lateral pressure spiral spring is characterized in that the spiral angle is a variable. The front half circle of the spiral angle is a positive spiral angle, and the rear half circle of the spiral angle is a negative spiral angle; a transitional surface of break points of the spiral angle is formed between the front half circle and the rear half circle, and the absolute value of the positive spiral angle is larger than that of the negative spiral angle; and the spring is in a spiral raising structure as a whole. The spring can be applied to various mechanical application fields and particularly to the sealing field, is wide in stress range and can provide multidirectional stress compensation for elements, the stress compensation direction can be adjusted at any time along with the change of an external acting direction, and the spring can still provide enough stress compensation when pressure stress is not on the same horizontal surface but forms a certain angle with the horizontal surface.

Owner:上海大亚密封技术有限公司

Direct-connected swing spider immersible impeller of motor

InactiveCN101028581BExquisite structureReduce volumeRotary stirring mixersToothed gearingsImpellerPropeller

A submerged propeller has a directly coupled motor-cycloidal spider driver system consisting of a motor with single-end mechanical seal on its mainshaft, a cycloidal spider type speed reducer with dual-end mechanical seal and multi-lip seal on its output axle, a propeller, and a leakage alarm protecting system for the front and back bearing covers of said motor.

Owner:ASIA PACIFIC WATER TREATMENT TIANCHANG

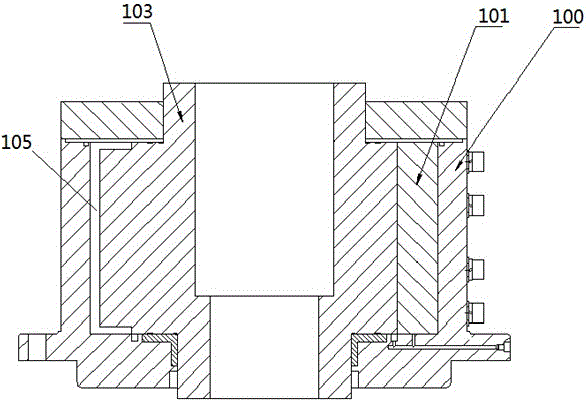

Dynamic sealing device

Owner:大连杜尔环保科技有限公司

A Finned Low Hysteresis Contact Fingertip Seal

ActiveCN106567747BImprove dynamic sealing performanceEliminate contact frictionLeakage preventionMachines/enginesHysteresisDifferential pressure

A low-hysteresis contact type fingertip seal with a fin comprises a contact type fingertip sealing device matched with a rotor. The contact type fingertip sealing device is formed by connecting a front baffle, a high-pressure fingertip sheet and a low-pressure fingertip sheet. The low-pressure fingertip sheet is provided with a fin structure, and the fin structure and the surface of the low-pressure side of a fingertip beam are arranged in a T-shaped mode. The fin structure has a certain width in the axial direction and accordingly can provide supporting force for resisting the front-back differential pressure for the fingertip sheet, so that the fingertip sheet is protected against axial deformation under the action of fluid pressure, and the fin structure plays a role in axially supporting a rear baffle in a conventional contact type fingertip seal. The rear baffle structure is omitted. The hysteresis effect caused by friction force between a low-pressure fingertip sheet and the rear baffle of the conventional contact type fingertip seal is reduced. The dynamic sealing performance of the contact type fingertip seal is improved.

Owner:TSINGHUA UNIV

A ribbed non-contact fingertip seal

ActiveCN106246242BImprove dynamic sealing performanceGood ability to withstand high pressure differenceLeakage preventionMachines/enginesHydrostatic pressureContact type

A kind of non-contact type finger seal rib comprising a non-contact type finger cooperating sealing means and the rotor, the non-contact finger by a longitudinal baffle seal means, and a sheet having a high pressure fingertip fingertip shoe structures low pressure pieces are connected to each finger, with a low-voltage side surface of the fingertip and finger beams shoe structures were "T" shaped ribs disposed on the low voltage fingertip sheet; together with the ribs by the fluid and a low pressure shoe fingertip hydrostatic pressure and dynamic pressure effect, the lifting force generated at the differential pressure and effect rotation of the rotor, the finger lifted off the surface of the rotor plate, in order to achieve non-contact seal with the rotor; radial displacement occurs in the rotor, the structure It can be automatically adjusted more effectively fingertip sheet posture, so that movement of the finger plate adapted radial runout of the rotor, maintaining non-contact state, while ensuring the sealing effect, serves to reduce or even eliminate the conventional non-contact seal finger "hysteresis effect" role in enhancing the sealing properties of the non-contact dynamic sealing finger.

Owner:TSINGHUA UNIV

Processing Technology of Rotary Vane Hydraulic Steering Gear

ActiveCN105666070BQuality improvementImprove running stabilitySteering ruddersNumerical controlAgeing

The invention discloses a machining process for a rotating vane type hydraulic steering engine. The machining process comprises the following machining procedures: machining a rotor, a cylinder and a fixed blade, assembling the cylinder and the fixed blade, machining the rotor body of the rotating vane type hydraulic steering engine and machining a sealing groove of the fixed blade, wherein in the rotor body machining procedure, a moveable blade and a substrate are separately machined; in the cylinder machining procedure, the casted and molded blank is subjected to coarse turning, precise turning, pneumatic grinding, polishing with sand bags, round angle trimming and oil hole machining on a numerical control vertical lathe; in the machining procedure of the fixed blade of the rotating vane type hydraulic steering engine and the assembling procedure of the fixed blade and the cylinder, the casted and molded blank is subjected to coarse turning, ageing, semi-precise turning, linear cutting, cover plate mounting hole boring, clamping, boring first mounting threaded holes of the cylinder, fixing cylinder and the fixed blade, machining pin holes and threaded holes for assembling the cylinder and the fixed blade, clamping, hydraulic valve mounting hole drilling, sealing groove boring and milling, fixing the cylinder and the fixed blade, precise turning of inner holes of the assembled fixed blade, threaded holes and sealing groove machining, and facing-up with the cylinder cover, so as to finish machining.

Owner:CHONGQING HUAYU HEAVY IND ELECTROMECHANICAL CO LTD

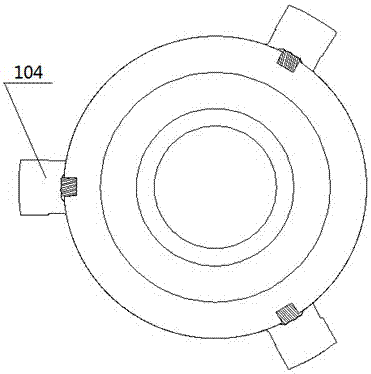

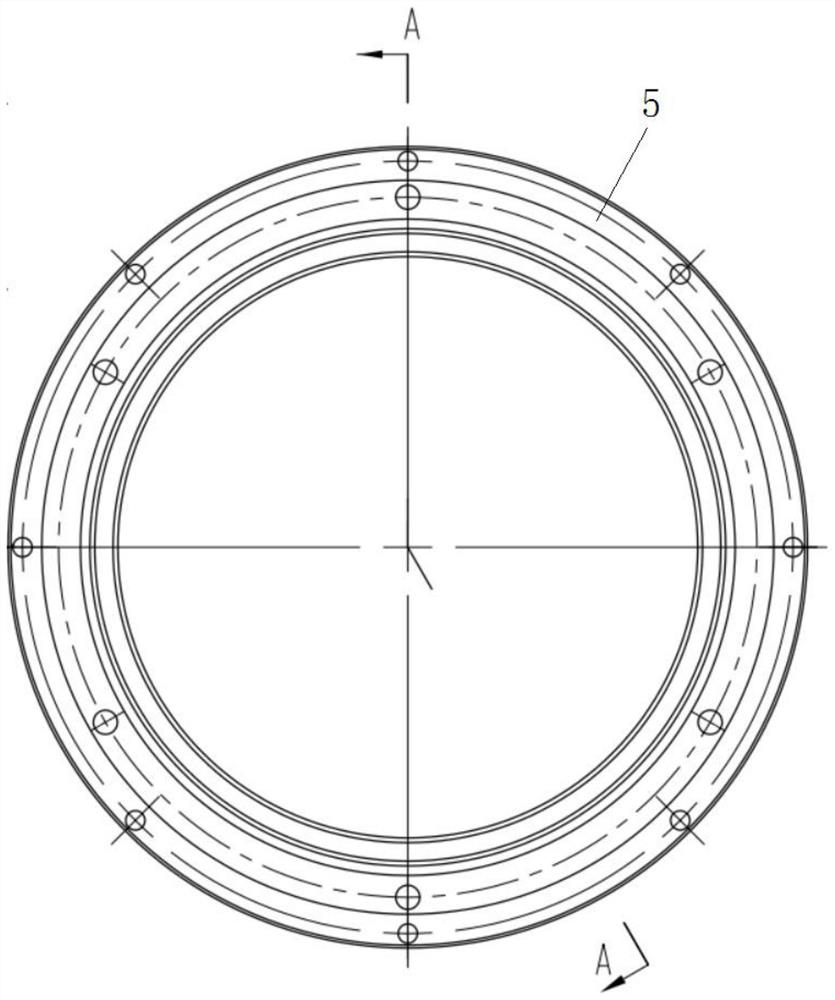

A kind of aircraft wheel inner oil deflecting ring and its oil deflecting ring assembly

ActiveCN112797079BImprove sealingImprove fitPiston ringsBearing componentsAirplaneTapered roller bearing

The invention discloses an aircraft wheel inner oil deflector ring and an oil deflector ring assembly thereof. The inner oil deflector ring includes a metal frame ring, a dynamic seal ring and a static seal ring, and the dynamic seal ring is detachably arranged on the metal frame ring. On the outer diameter side of the wheel, the static sealing ring is detachably arranged on the outer end surface of the metal skeleton ring; the dynamic sealing ring is dynamically sealed with the inner diameter side of the wheel, and the static sealing ring is connected with the inner ring static seal; the oil deflector ring assembly includes an inner oil deflector ring and an outer oil deflector ring, and the inner oil deflector ring and the outer oil deflector ring are respectively arranged on the inner side and the outer side of the tapered roller bearing; The skeleton ring is detachably provided with a dynamic seal ring and a static seal ring, the dynamic seal with the inner diameter side of the wheel is realized through the dynamic seal ring, the static seal with the inner ring of the tapered roller bearing is realized through the static seal ring, the static seal ring and the The dynamic sealing ring can adopt different structures or materials to achieve better sealing effect.

Owner:长沙鑫航机轮刹车有限公司

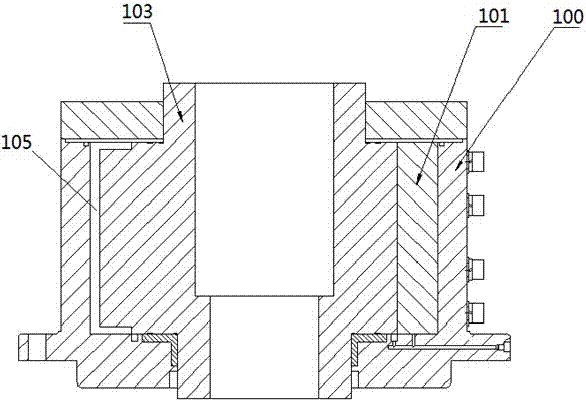

Dynamic sealing device

The invention discloses a dynamic sealing device which is used for achieving sealing between relatively moving equipment. The dynamic sealing device comprises a flexible sealing pipe, a first connecting part, a second connecting part and a compensating arm, wherein the first connecting part and the second connecting part are arranged at the two ends of the flexible sealing pipe respectively, and the compensating arm is connected between the first connecting part and the second connecting part. The first connecting part is fixed to the first equipment, the second equipment is inserted into the flexible sealing pipe inwards from the second connecting part, and the compensating arm allows the first equipment and the second equipment to conduct relative displacement in the axial direction, the radial direction and the angle direction of the first equipment and the second equipment. The dynamic sealing device used for achieving sealing between the two sets of relatively moving equipment comprises the flexible sealing pipe which can be bent to deform, the first connecting part arranged at one end of the flexible sealing pipe and the second connecting part arranged at the other end of the flexible sealing pipe; because the first connecting part and the second connecting part can perform relative deviation in the axial direction, the radial direction and the angle direction, relative deviation, in the axial direction, the radial direction and the angle direction, of the two sets of relatively moving equipment can be effectively compensated for, and the dynamic sealing performance of the dynamic sealing device can be improved.

Owner:大连杜尔环保科技有限公司

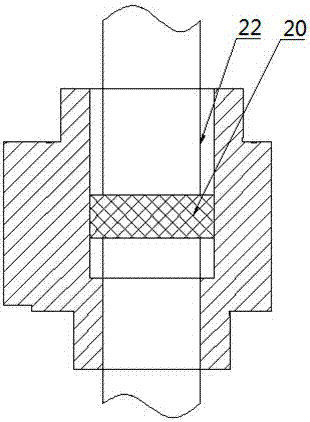

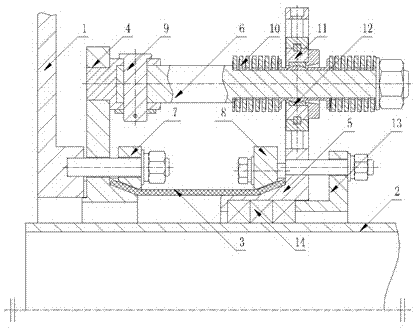

Polyimide composite material-fluororubber material combined seal

PendingCN114719020AIncrease the sealing areaImprove dynamic sealing performanceEngine sealsMetal frameworkMachining process

The invention discloses a polyimide composite material-fluororubber material combined seal which is composed of a metal outer framework (1), a metal inner framework (2), a metal framework pressing ring (3), a fluororubber sealing ring (4), a carbon steel spring (5), a polyimide sealing ring (6) and a spring piece (7). The sealing device is mainly characterized in that the fluororubber sealing ring (4) and the carbon steel spring (5) are combined to seal oil, the carbon steel spring (5) provides corresponding holding force for the fluororubber sealing ring (4), the polyimide sealing ring (6) is made through a machining process and combined with the spring piece (7) to seal gas, and the spring piece (7) improves the following performance of the polyimide sealing ring (6). Through the combination of different materials and different structure seals, a sealing product can seal grease and high-pressure air at the same time, and the sealing performance is maintained at a reasonable level for a long time. The sealing device is stable in working condition, reliable in sealing performance, long in service life, convenient to install, good in universality and interchangeability, capable of adapting to working conditions of high temperature, high speed, dry grinding and the like, and particularly suitable for the severe environment where a sealing shaft jumps randomly and other conditions with the harsh sealing requirement.

Owner:BEIJING RES & DESIGN INST OF RUBBER IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com