Novel coating with composite structure and preparation method thereof

A composite structure and coating technology, applied in coating, metal material coating process, superimposed layer plating, etc., can solve the problem of lack of high temperature resistance, oxidation resistance and thermal erosion resistance, restriction of engine turbine performance, adhesion Oxidation failure of the layer and other problems, to achieve the effect of improving the thermal cycle resistance and the overall performance of the equipment, improving the industrial production efficiency, and improving the film adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

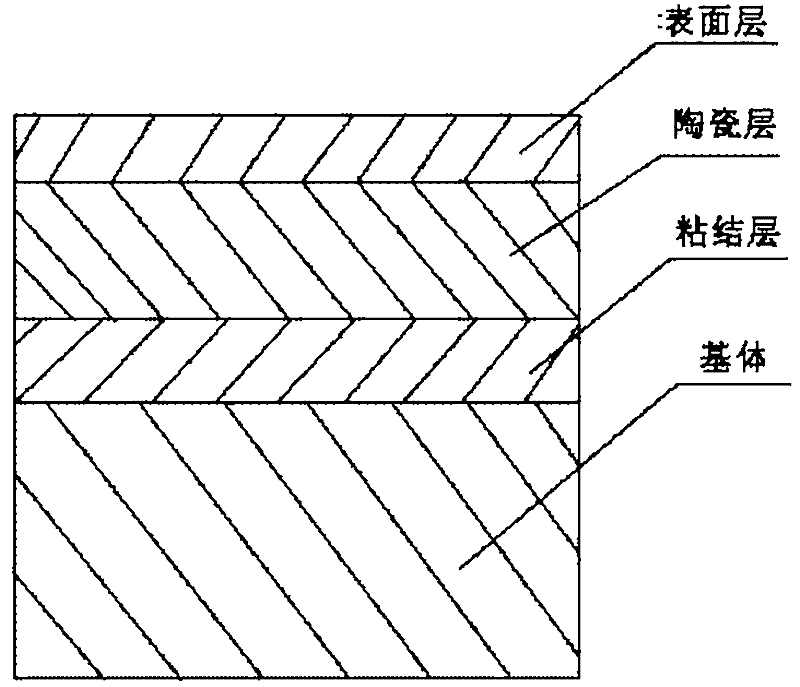

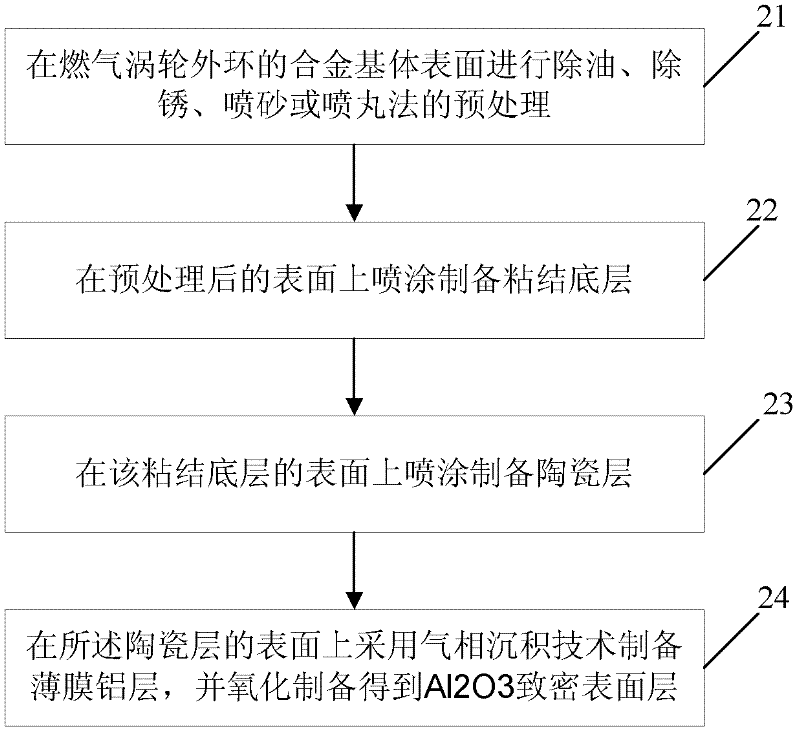

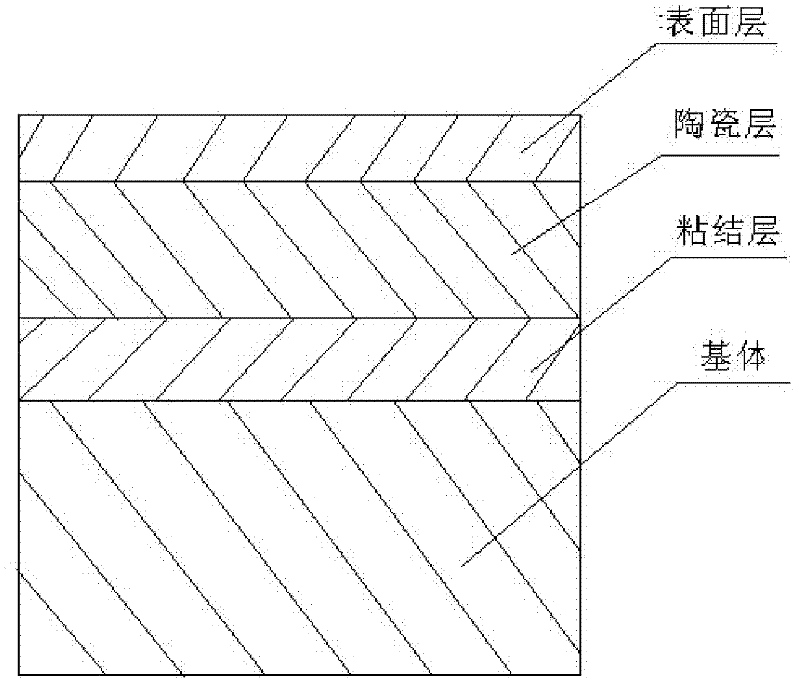

[0033] The embodiment of the present invention also provides a kind of preparation method of novel composite structural coating, such as figure 2 Shown is a schematic flow chart of the preparation method of the novel composite structural coating provided by the embodiment of the present invention, figure 2 Including:

[0034] Step 21: Carry out pretreatment of oil removal, rust removal, sandblasting or shot blasting on the surface of the turbine alloy substrate.

[0035] In this step, the alloy matrix includes iron-based alloys, cobalt-based superalloys, nickel-based superalloys, or cobalt-nickel superalloys with different mass ratios (wherein, Ni: 30-74.5wt%, Co: 25-66.5wt%) %).

[0036] Step 22: Spray on the pre-treated surface to prepare a bonding primer.

[0037] In this step, in the bonding bottom layer (ie MCrAlY layer), M is cobalt Co, nickel Ni or cobalt Co, nickel Ni alloy; Cr is chromium; Al is aluminum; Y is yttrium.

[0038] The specific spraying method is: u...

specific Embodiment approach 1

[0047]In this embodiment, first, pretreatment is carried out on the surface of the cobalt superalloy substrate by degreasing and derusting shot blasting methods; secondly, supersonic flame spraying is used on the pretreated surface to prepare a NiCrAlY bonding bottom layer with a thickness of 160 μm; and then on the NiCrAlY A zirconia ceramic layer was prepared by low-pressure plasma spraying on the surface of the bonded bottom layer, with a thickness of 800 μm; finally, a thin-film aluminum layer was prepared on the surface of the zirconia ceramic layer by chemical vapor deposition technology, and oxidized to obtain Al 2 o 3 For a dense surface layer, the oxidation temperature is 200°C, the oxygen pressure is 1.0MPa, and the thickness is 5μm.

specific Embodiment approach 2

[0049] In this embodiment, first, pretreatment is carried out on the surface of cobalt and nickel superalloy substrates by degreasing and derusting shot blasting methods, wherein Ni: 50wt%, Co: 50wt%; secondly, explosive spraying is used on the pretreated surface to prepare The NiCoCrAlY bonded bottom layer has a thickness of 250 μm; then supersonic plasma spraying is used on the surface of the NiCrAlY bonded bottom layer to prepare a zirconia ceramic layer with a thickness of 700 μm; finally, a thin film aluminum layer is prepared on the surface of the zirconia ceramic layer by chemical vapor deposition technology, And oxidized to prepare Al 2 o 3 For a dense surface layer, the oxidation temperature is 220°C, the oxygen pressure is 1.0MPa, and the thickness is 4μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com