A centripetal turbine device with vibration damping and sealing structure

A technology of turbine device and sealing structure, which is applied to the supporting elements of blades, machines/engines, mechanical equipment, etc., can solve the problems of aerodynamic efficiency, impeller life and safe operation of centripetal turbines, affecting the aerodynamic efficiency of turbines, and easy operation. Problems such as wear and tear occur, and the effect of improving rigidity, improving leakage and improving impeller rigidity can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing.

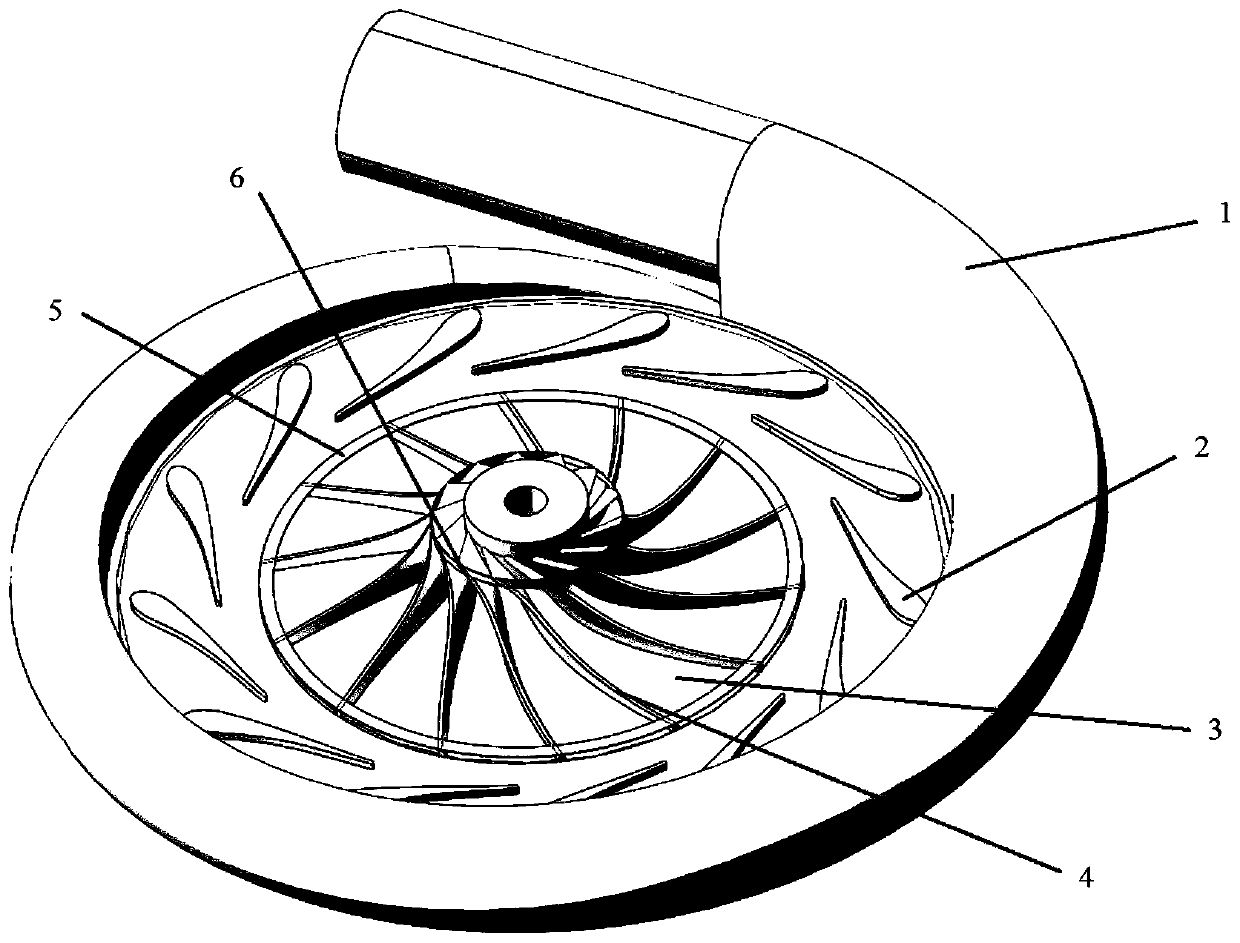

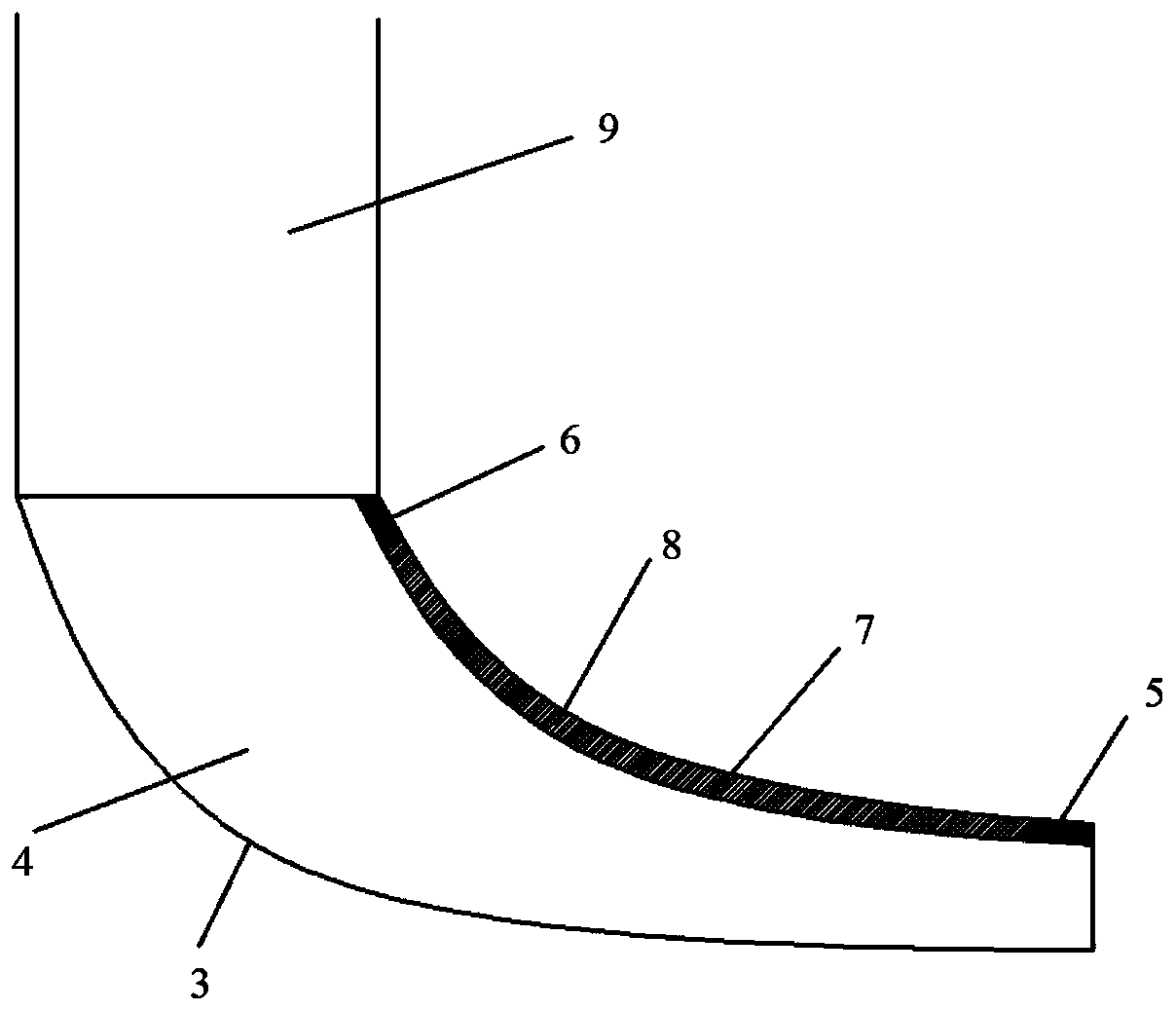

[0023] refer to figure 1 and figure 2 , a centripetal turbine device with a vibration damping and sealing structure provided by the present invention includes a volute 1, a hub 3 and a wheel cover 7 arranged at the center of the volute 1, and several nozzles arranged in the circumferential direction of the hub 3 The centripetal turbine impeller blade 4 at the ring 2 and the center, and the outlet channel 9 connected to the outlet of the centripetal turbine impeller blade 4; Belt 5 and blade outlet shroud 6, and in the impeller flow channel, brush seal 8 is used between the wheel cover 7 and the centripetal turbine blade 4; wherein, the hub 3 and the centripetal turbine blade 4 form the impeller together. The working medium first enters the centripetal turbine device from the volute 1, and then enters the nozzle ring 2, where the pressure of the high-temperature and high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com