A ribbed non-contact fingertip seal

A fingertip sealing, non-contact technology, applied in the direction of leakage prevention, engine components, machines/engines, etc., can solve the problems that the fingertip sheet is difficult to return to the original position, increase the sealing gap, and reduce the sealing performance, etc., to improve The effect of dynamic response ability, elimination of frictional resistance, and ability to withstand high pressure difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings.

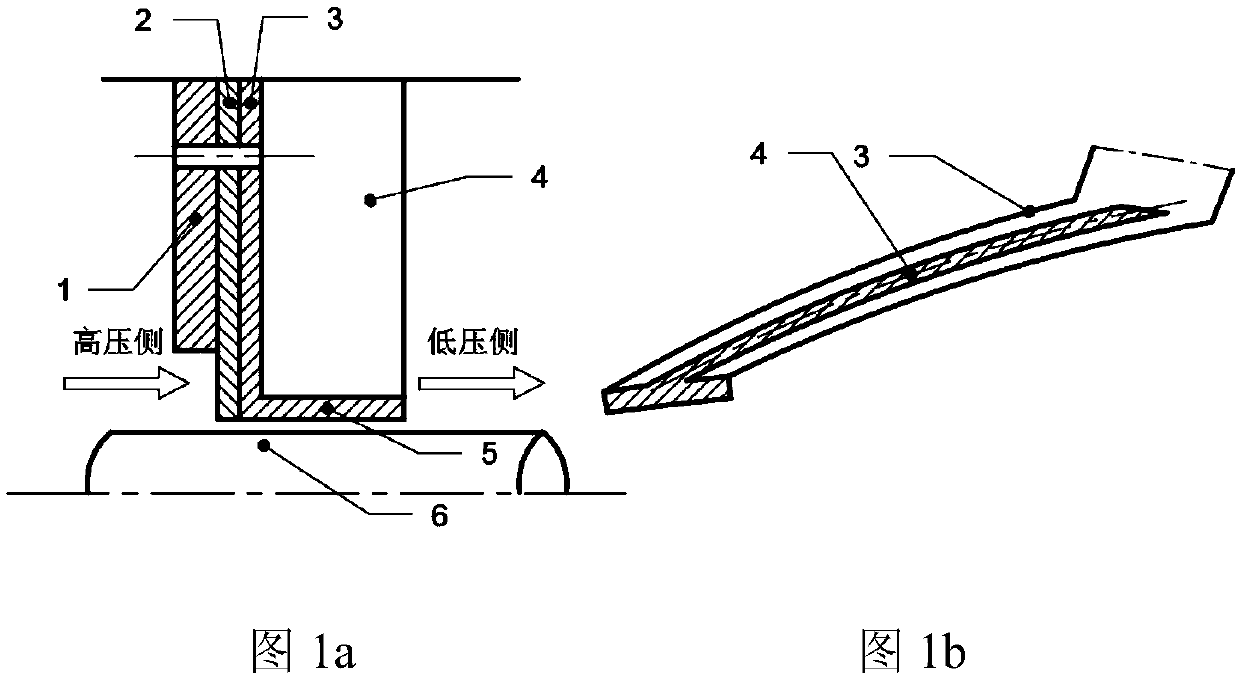

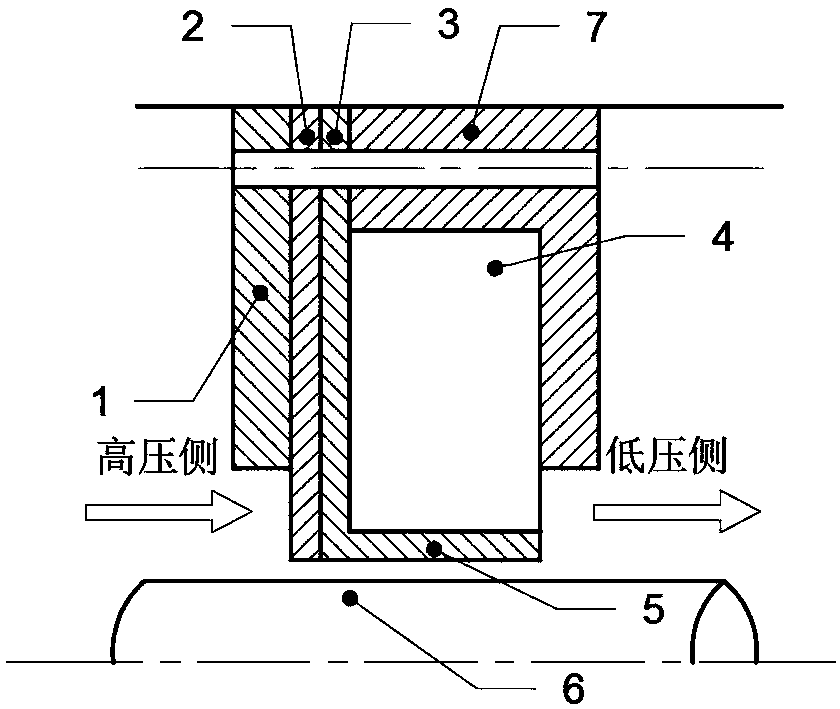

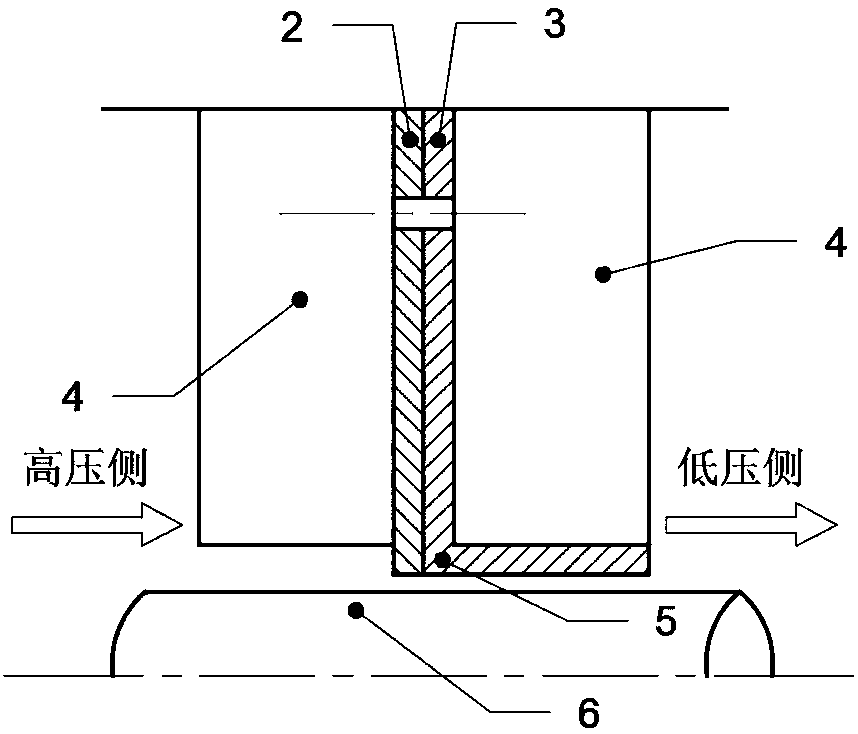

[0015] refer to figure 1 , a ribbed non-contact fingertip seal, including a non-contact fingertip seal matched with the rotor 6, the non-contact fingertip seal consists of a front baffle 1, a high-voltage fingertip sheet 2 and a The low-voltage fingertip pieces 3 of the fingertip shoe structure 5 are connected in sequence, and there is a rib structure 4 on the low-pressure fingertip piece 3 .

[0016] The ribs 4 and the low-voltage side surface of the fingertip beam of the low-voltage fingertip sheet 3 and the fingertip shoe structure 5 are arranged in a "T" shape, and the low-voltage fingertip sheet 3, the fingertip shoe structure 5 and the ribs 4 are One structure. The ribs 4 are strip-shaped thin leaf structures with a certain width, and the profile in the length direction is the same as the profile of the fingertip beam of the low-voltage fingertip sheet 3, suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com