Lateral pressure spiral spring and sealing ring with same

A coil spring, side pressure technology, applied in the direction of engine seal, spring, engine components, etc., to achieve the effect of improving dynamic sealing effect and stable preloading force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

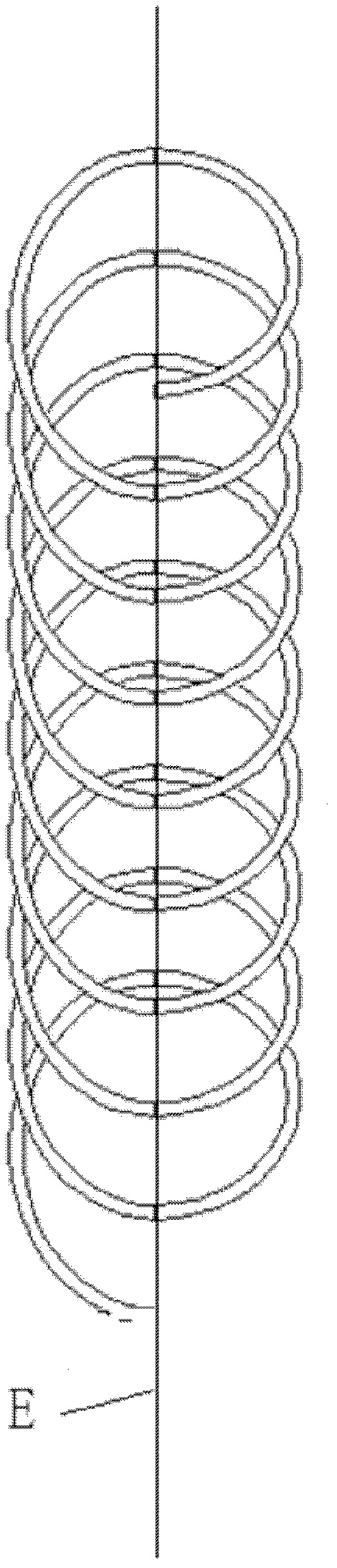

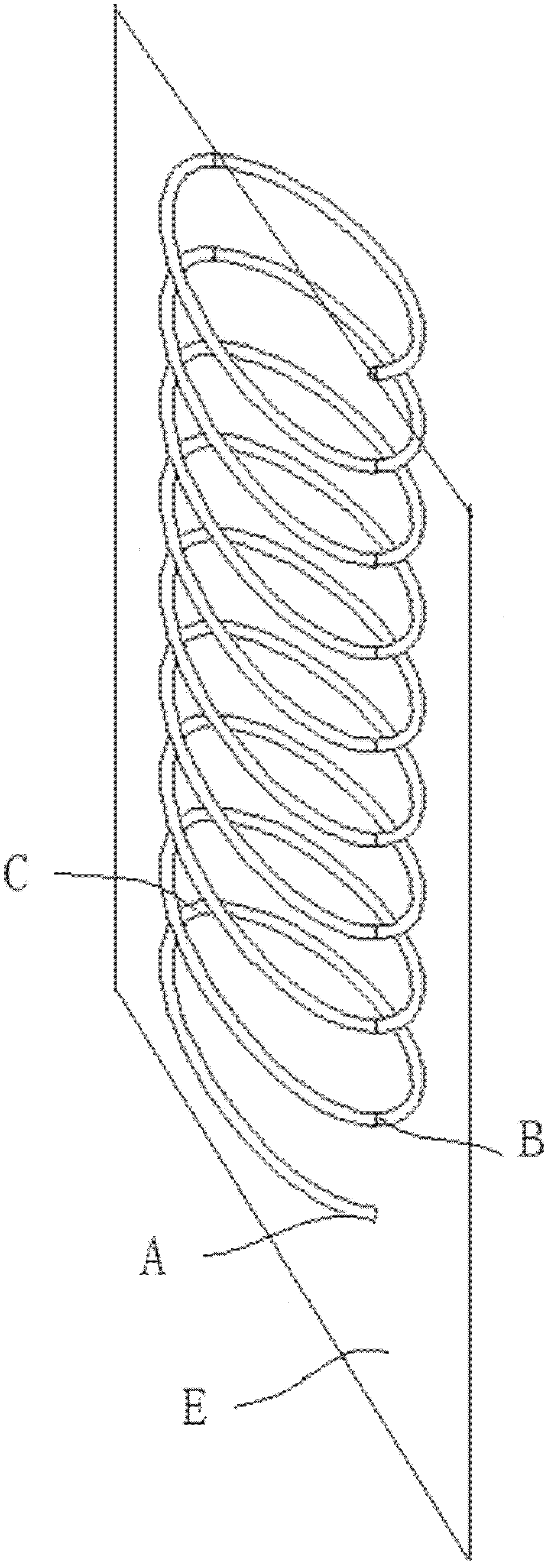

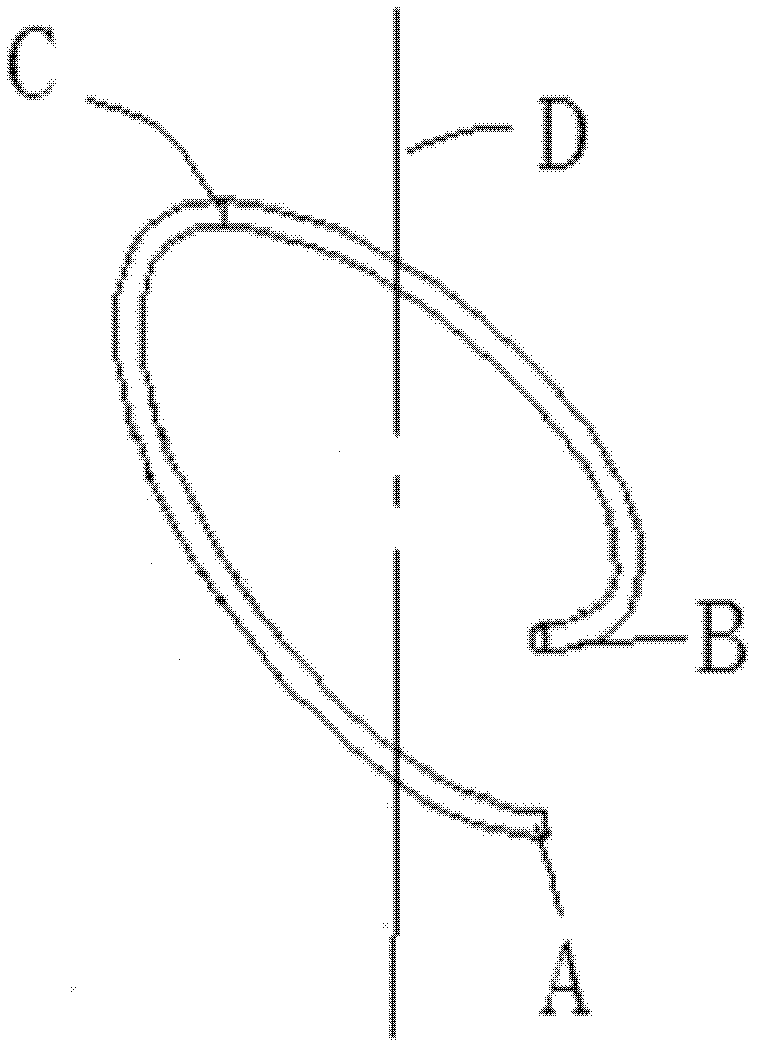

[0030] Such as Figure 1a , 1b , 1c, a side pressure helical spring according to the present invention is formed by winding a central line of linear material and rotating and bending it, and its winding sequence is as follows Figure 1c Shown: Start from the starting point A, rotate around the center line D, gradually rise, after half a circle of inflection point C, change to gradually rotate and descend, and finally reach the end point B, complete a circle; go round and round until the required length. The distance between A and B is the pitch of the spring. Obviously, any point in A, B, and C can be understood as the starting point or inflection point of another circle; thus, a transition surface E of a set of helix angle inflection points is formed between the first half circle and the second half circle, and the transition surface E also Coincides with the centerline D of the spring.

[0031] Such as figure 2 As shown, the unfolded model of a lateral pressure helical s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com