A gyro motor bearing unit

A gyro motor and bearing technology, applied in bearing components, ball bearings, electrical components, etc., can solve the problems of low installation qualification rate, low rotation accuracy, low reliability, etc., to improve the installation qualification rate, prolong bearing life, installation Simple and fast effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with specific examples, so that those skilled in the art can further understand the present invention, but the following examples are not intended to limit the protection scope of the present invention.

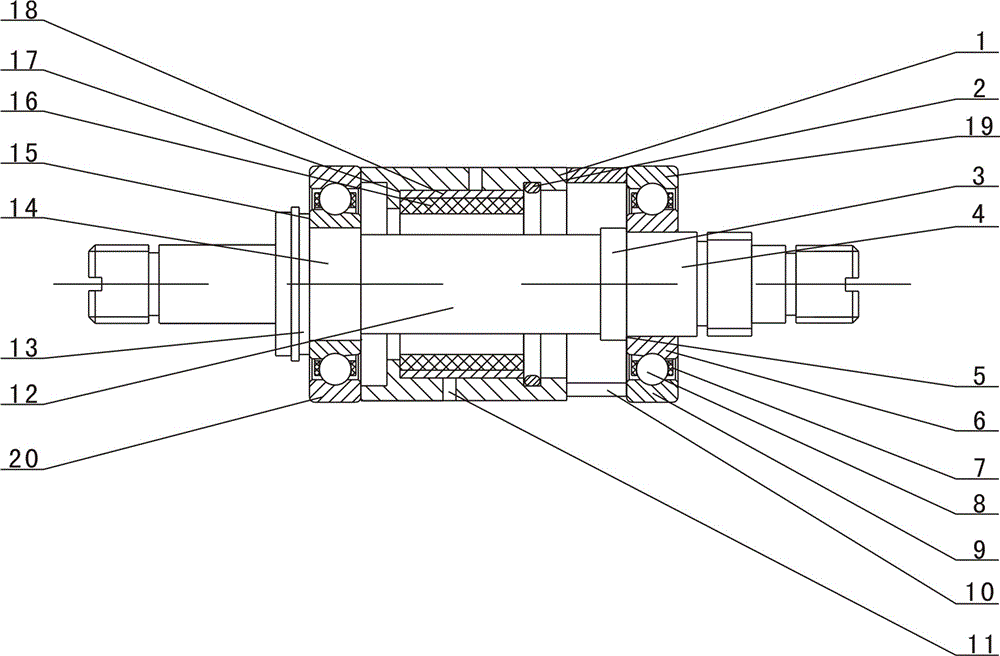

[0025] combined with figure 1 The gyro motor bearing unit includes a stepped shaft 12, a bearing A19, a bearing B20, an oil storage ring 16, an oil storage ring bush 18, an elastic bush 1 and a U-shaped collar 10, on both sides of the middle of the stepped shaft 12 A bearing A19 and a bearing B20 are respectively provided, and the bearing A19 and the bearing B20 are angular contact ball bearings, and the angular contact ball bearings are installed in a back-to-back manner; the bearing A19 and the bearing B20 respectively include inner rings 6, The outer ring 9, the rolling elements 8 and the cage 7 are provided with the outer ring 9 on the outside of the inner ring 6, and the rolling elements 8 are ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com