Static axial double-end-face mechanical sealing structure, stirrer and stirred tank

A mechanical seal and double-end face technology, which is applied to engine seals, mechanical equipment, mixer accessories, etc., can solve problems such as failure to meet the high speed requirements of the agitator, failure of mechanical seals, etc., to ensure the effect of mechanical seals and avoid bending deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

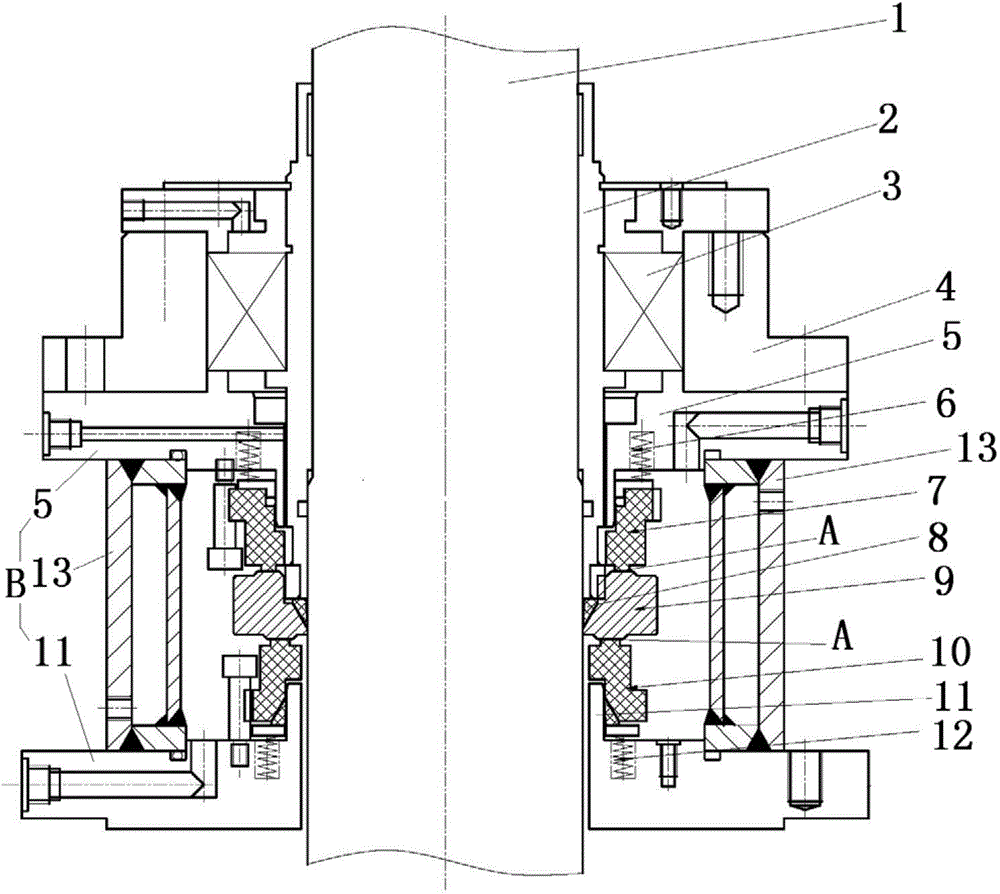

[0041] Such as figure 1 As shown, the present invention provides a static type axial double-end mechanical seal structure, which is installed on the stirring shaft 1 and arranged in the sealing box B, wherein the stirring shaft 1 is covered with a shaft sleeve 2, and the The sealed box B is composed of the first static ring seat 5, the second static ring seat 11 and the cooling water jacket 13, and passes between them (the first static ring seat 5, the second static ring seat 11 and the cooling water jacket 13) Bolt fixed, the first static ring seat 5 is set on the outside of the shaft sleeve 2 and located under the bearing seat 4, and the second static ring seat 11 is set on the outside of the stirring shaft 1 and located on the first Below the static ring seat 5, the cooling water jacket 13 is located between the first static ring seat 5 and the second static ring seat 11, and the stationary axial double-end mechanical seal structure includes the first A spring 6, a first s...

Embodiment 2

[0051] see figure 1 , the present invention provides an agitator, the agitator includes a stirring shaft 1, a shaft sleeve 2, a bearing 3, a bearing seat 4, a sealing box 13 and a static axial double-end mechanical seal structure,

[0052] The static axial double-end mechanical seal structure is installed on the stirring shaft 1 and arranged in the sealing box B, wherein the shaft sleeve 2 is sleeved on the outside of the stirring shaft 1, and the sealing The box B is composed of the first static ring seat 5, the second static ring seat 11 and the cooling water jacket 13, and bolts are used between them (the first static ring seat 5, the second static ring seat 11 and the cooling water jacket 13). fixed, the first static ring seat 5 is set on the outside of the shaft sleeve 2 and located under the bearing seat 4, and the second static ring seat 11 is sleeved on the outside of the stirring shaft 1 and located on the first static ring seat. Below the ring seat 5, the cooling wa...

Embodiment 3

[0062] see figure 1 , The present invention provides a stirred tank, including a tank body, the stirred tank also includes the agitator, and the agitator is arranged on the tank body. The structure of the stirrer in the third embodiment is exactly the same as that in the second embodiment, and the description of the stirrer will not be repeated in this embodiment.

[0063] Since the stirred tank of the present invention includes the stirrer in Embodiment 2, the mechanical seal structure of the present invention is a stationary axial double-end mechanical seal, that is, the first spring 6 is installed under the first static ring 7, and the second spring 12 is installed under the second static ring 10, the first spring 6 and the second spring 12 do not rotate with the stirring shaft 1, avoiding the possibility of bending deformation, ensuring the mechanical sealing effect, and meeting the high requirements of certain chemical reactions on the agitator. RPM requirements. The ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com