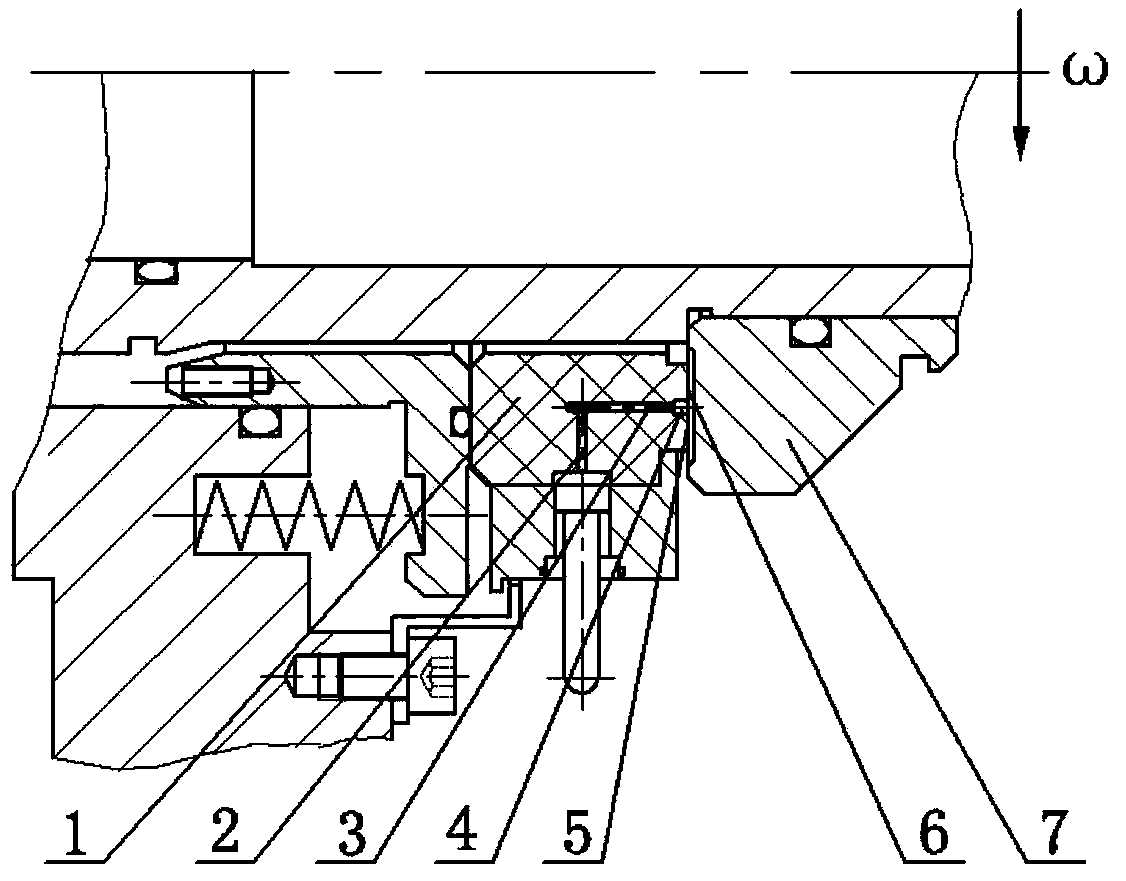

Direct and reverse flow pumping combined radial double-end-surface mechanical sealing device

A mechanical seal device, double-end technology, applied in the direction of engine seals, mechanical equipment, engine components, etc., can solve the problems of lack of leakage, no feasible solution for dynamic pressure effect, neglect of sealing benefits, etc., to reduce leakage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

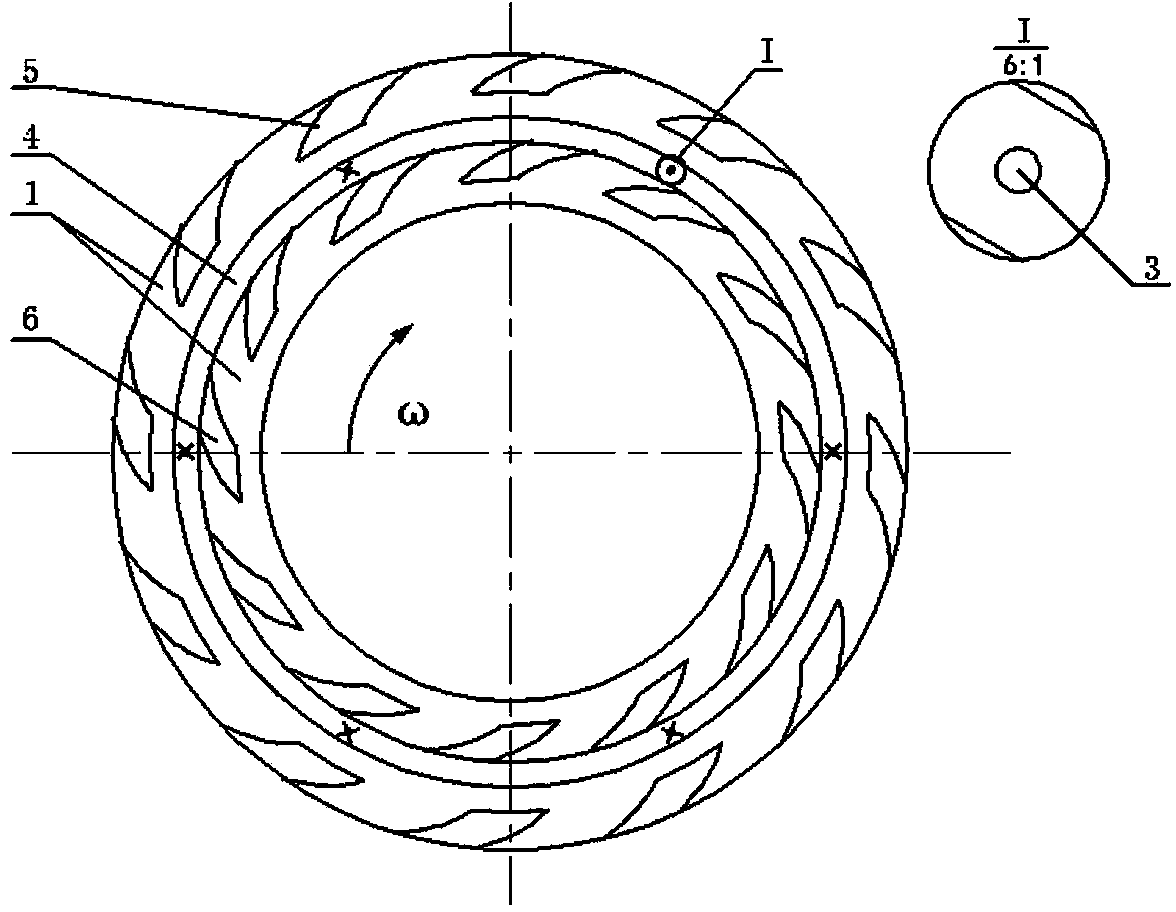

[0027] refer to figure 2 , this embodiment is a common occasion.

[0028] The outer dynamic pressure groove 5 is arranged on the outermost side of the static ring 1, and there is a dam area between it and the annular groove 4; the inner dynamic pressure groove 6 is arranged inside the annular groove 4 and communicates with the annular groove 4; the reverse flow pump on the outer side The dynamic pressure groove 5 can reduce the flow of the externally applied fluid to the outside of the seal, and the downstream pumping dynamic pressure groove 6 on the inside can increase the flow of the externally applied fluid to the inside of the seal. By separately controlling the flow of the externally applied fluid to the inside of the seal The amount of leakage on the outside, and then effectively control the leakage of the actual sealing medium inside the seal to the outside of the seal.

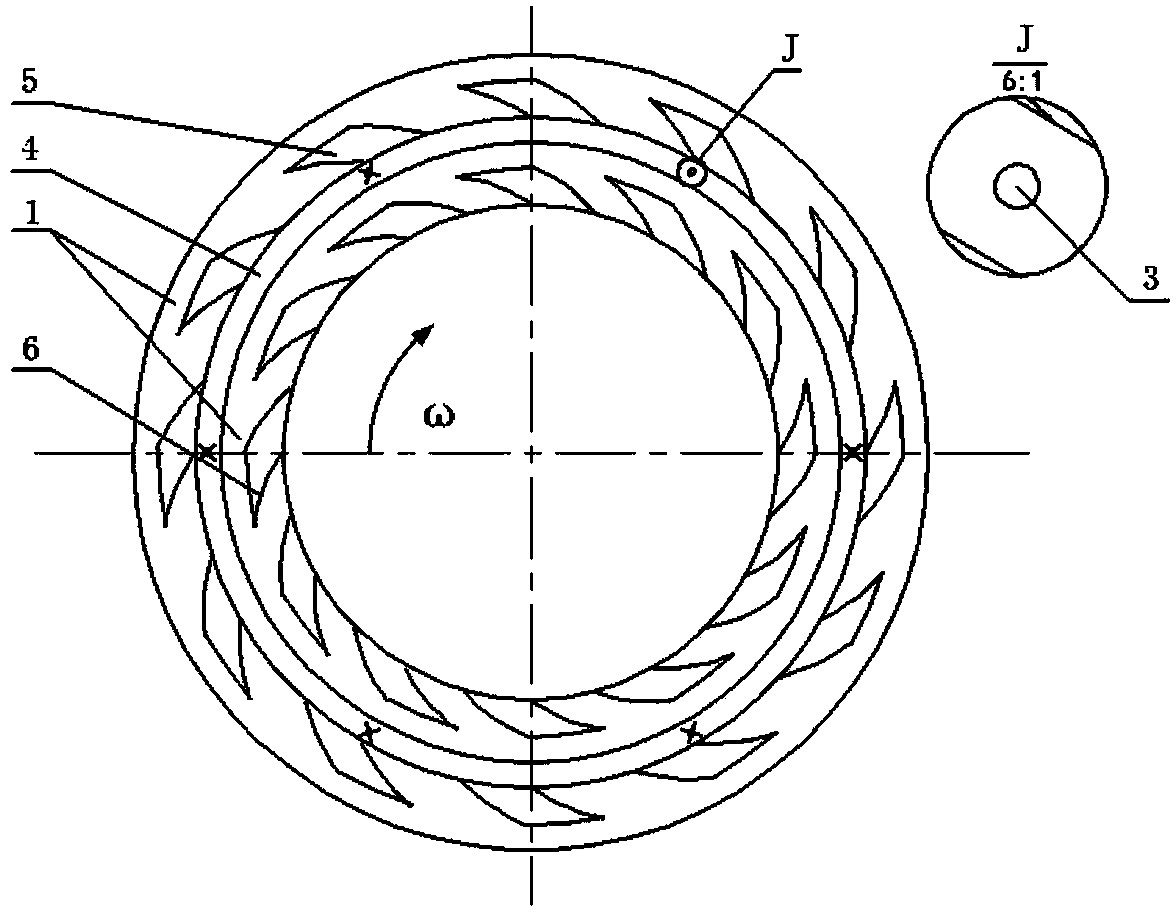

Embodiment 2

[0030] refer to image 3 The difference between this embodiment and Embodiment 1 is that the outer dynamic pressure groove 5 is distributed on the outside of the annular groove 4 and communicates with the annular groove 4, and the inner dynamic pressure groove 6 is distributed on the inner diameter side of the static ring 1 and connected with the annular groove 4. There is a dam area between the grooves 4; the outer downstream pumping dynamic pressure groove 6 can increase the flow of the externally applied fluid to the outer side of the seal, and the inner countercurrent pumping dynamic pressure groove 5 can reduce the flow of the externally applied fluid to the outside of the seal. The role of the flow inside the seal is to control the leakage of the externally applied fluid to the inside and outside of the seal respectively, thereby effectively controlling the leakage of the actual sealing medium on the outside of the seal to the inside of the seal. The rest of the structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com