Planetary differential radial dual-end-face mechanical seal

A mechanical seal and double-end technology, which is applied in mechanical equipment, differential transmissions, transmissions, etc., can solve problems such as unsatisfactory sealing effects, improve sealing reliability and service life, and avoid excessive specific pressure or failure. The effect of pressure and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is analyzed below in conjunction with accompanying drawing.

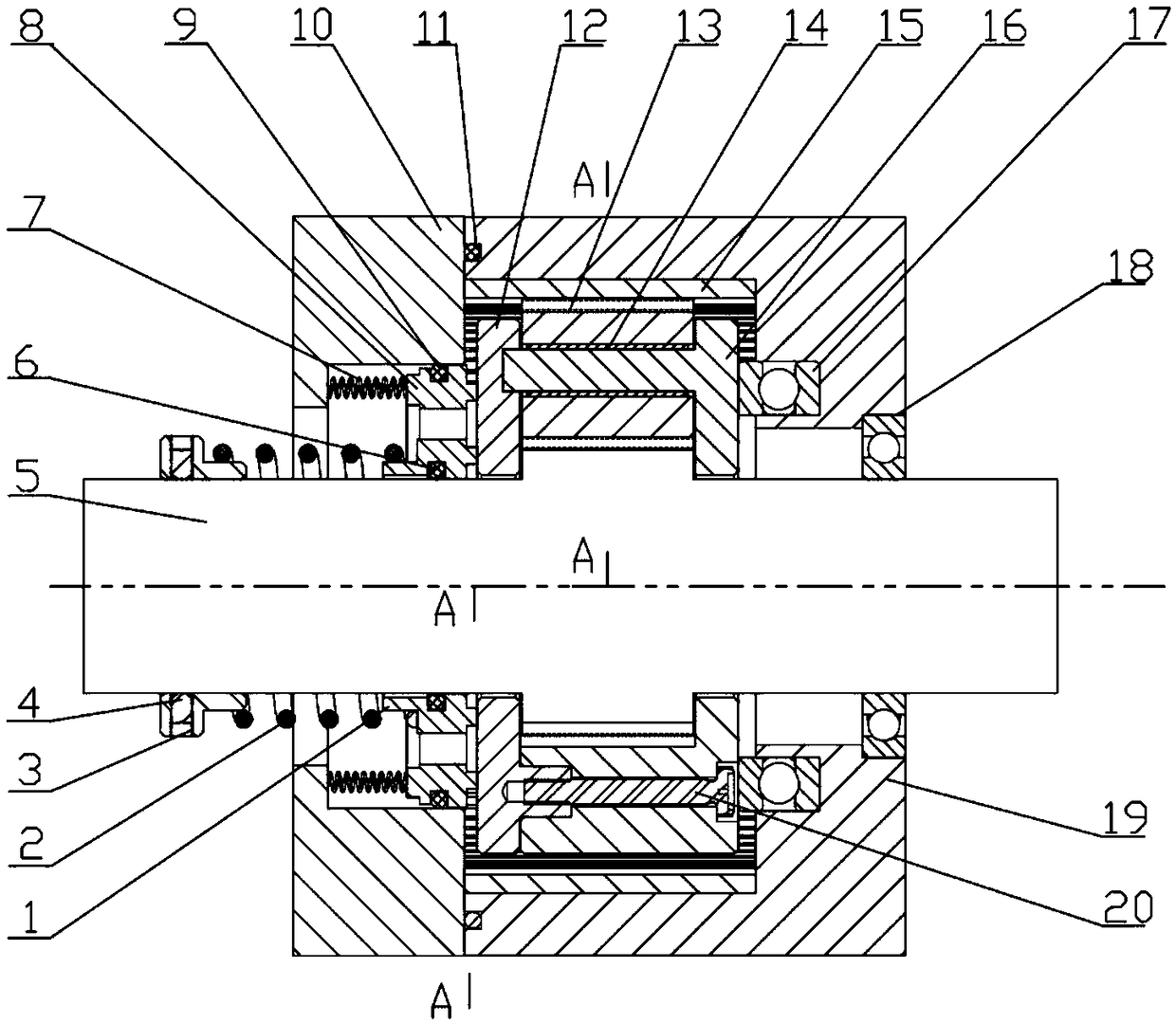

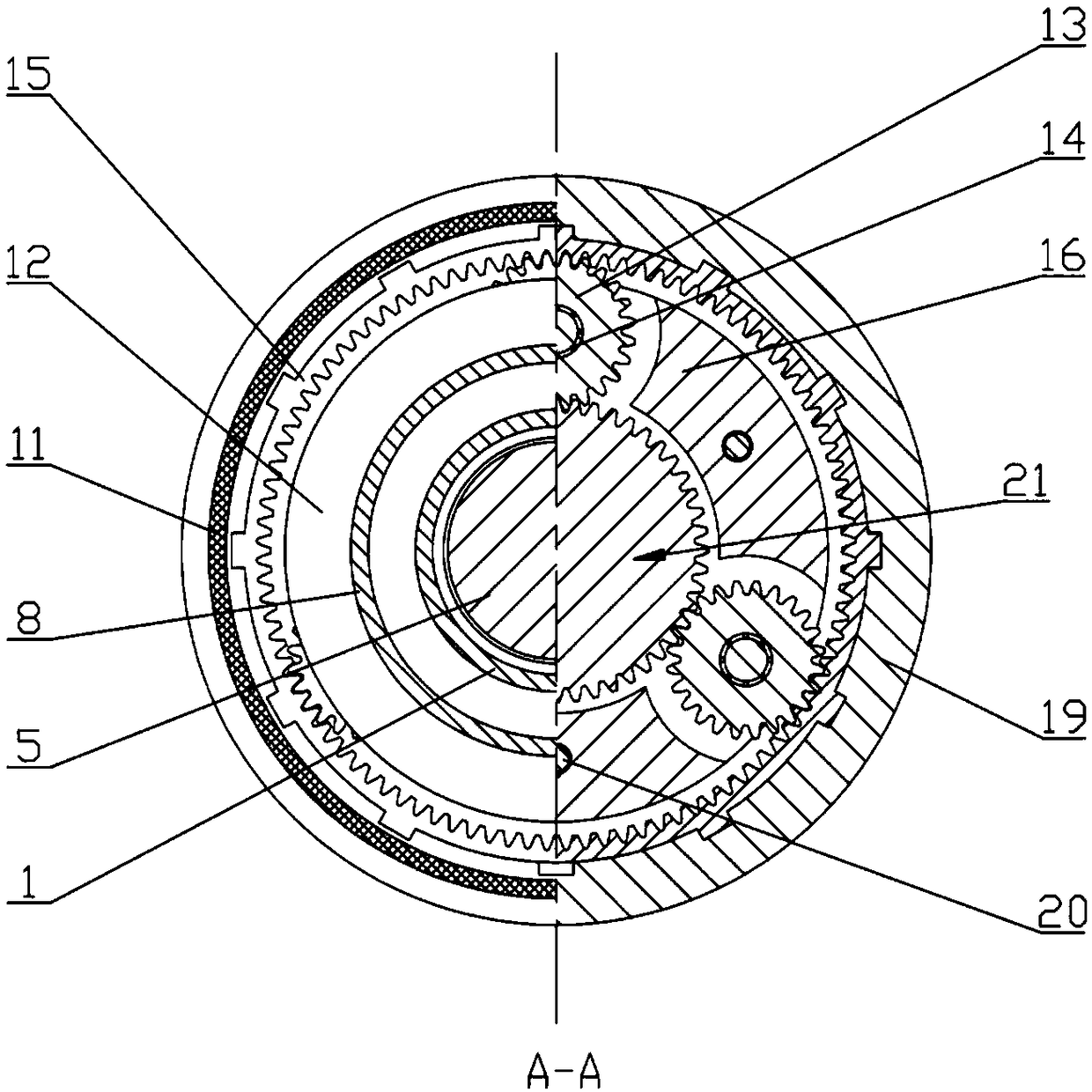

[0019] Refer to attached figure 1 :

[0020] 1—rotating sealing ring; 2—rotating spring; 3—rotating spring seat; 4—fastening screw; 5—rotating shaft; 6—auxiliary sealing ring; 7—spring; 8—stationary sealing ring; 9—auxiliary sealing ring; 10 —Static ring seat; 11—Seal; 12—Medium side differential wheel; 13—Planetary gear; 14—Needle bearing; 15—Inner ring gear; 16—Air side differential wheel; 17—Thrust bearing; 18 —rolling bearing; 19—stationary shell; 20—bolt; 21—central sun gear.

[0021] figure 1It is a structural schematic diagram of Embodiment 1 of the present invention: a planetary differential radial double-end mechanical seal, which is characterized in that: the left end of the planetary differential radial double-end mechanical seal is the medium side, and the right end is the air side. For friction pairs and bearings, the two pairs of friction pairs include a seal pair consi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com