Micro-bulge double-layer composite groove deep end surface mechanical seal structure

An end-face mechanical seal and double-layer composite technology, which is applied in the direction of engine seals, mechanical equipment, engine components, etc., can solve problems such as seal failure, achieve the effects of avoiding failure, preventing function failure, and enhancing the dynamic pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

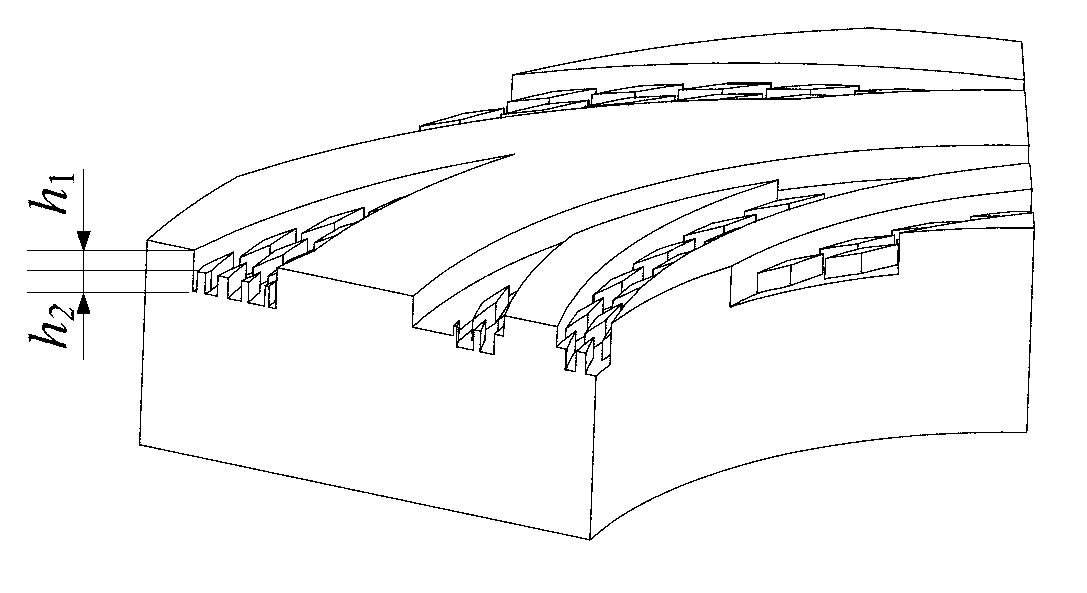

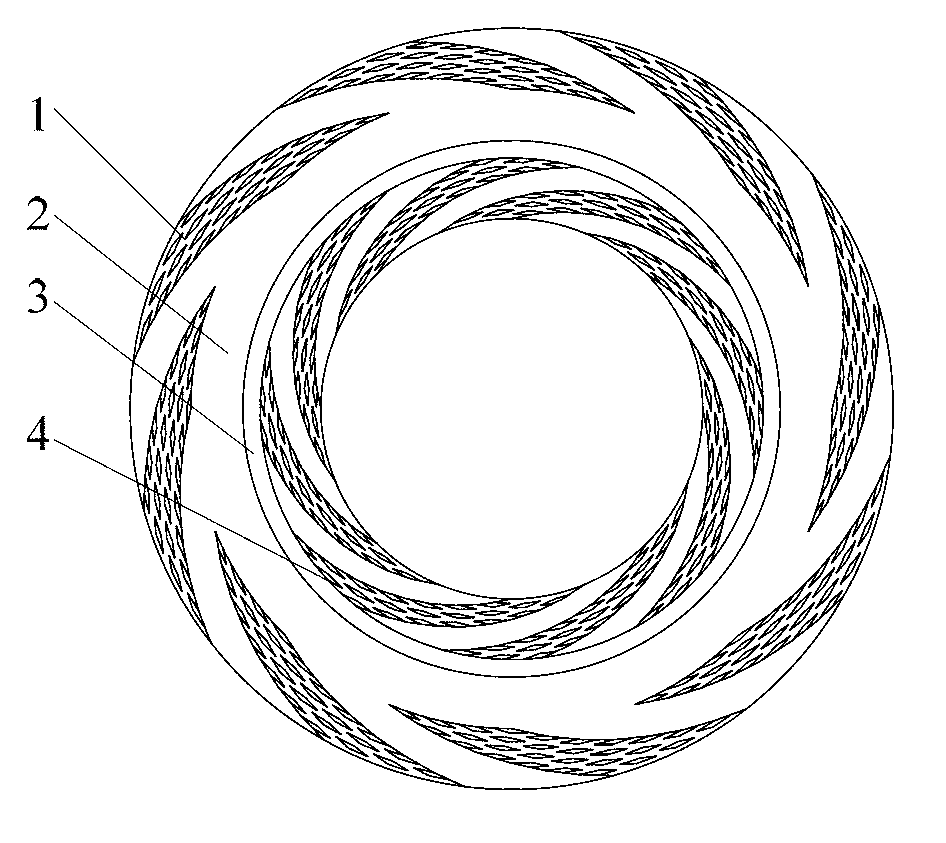

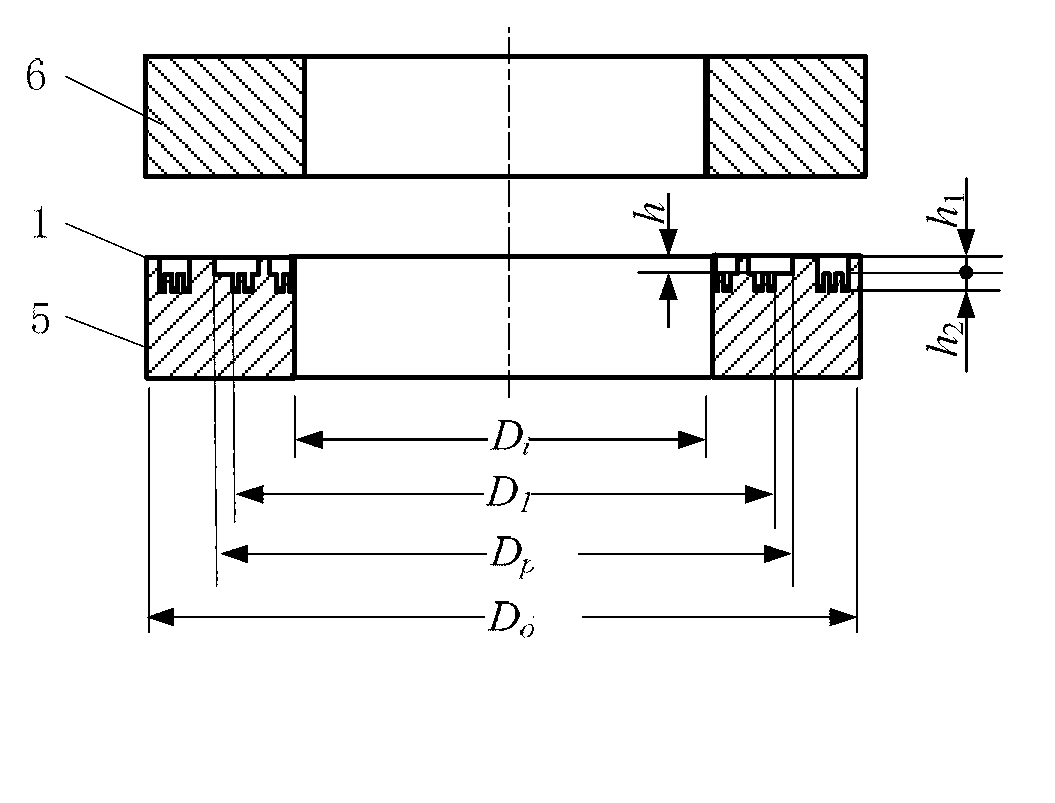

[0021] see Figure 1-3 : Micro-convex body double-layer composite groove deep end face mechanical seal structure, including mechanical seal dynamic ring 5, static ring 6, the mutual contact surface of the dynamic ring and the static ring is the end face, one of the end faces of the dynamic ring or the static ring is controlled by high pressure On the lateral low-pressure side, the asperity double-layer composite groove deep dynamic pressure groove 1, the sealing dam 2, the annular groove 3, the asperity double-layer composite groove deep pumping groove 4, and the dynamic pressure groove 1 arranged symmetrically according to the rotation center are arranged in sequence. It is connected with the ring groove 3 by the seal dam 2, and the seal dam 2 and the pumping groove 4 are connected by the ring groove 3;

[0022] Slightly convex double-layer composite groove Deep dynamic pressure groove 1 is set on the upstream side of the end face (high pressure side). The upper layer of the ...

Embodiment 2

[0031] see Figure 5 , 6 : Asperity double-layer composite groove deep end face mechanical seal structure, including mechanical seal dynamic ring 5, static ring 6, one of the end faces of the dynamic ring or static ring, from the high pressure side to the low pressure side are arranged in sequence according to the rotation center Symmetrical distribution Dynamic pressure groove 1, sealing dam 2, ring groove 3 and deep pumping groove 4 of micro-convex double-layer composite groove, dynamic pressure groove 1 and ring groove 3 are connected by sealing dam 2, sealing dam 2 and pumping groove 4 They are connected by ring groove 3;

[0032] The dynamic pressure groove 1 is set on the upstream side of the end surface (high pressure side). The dynamic pressure groove can be a spiral groove, T-shaped groove, circular micro-hole or inclined elliptical micro-hole and other end-face groove structures. The optimal value range of the groove depth is 2~ 10μm;

[0033] The remaining struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com