Variable distribution porous end face mechanical sealing structure

A mechanical seal, hole end face technology, applied in the direction of engine seal, mechanical equipment, engine components, etc., can solve the problems of weak pressure resistance, poor dynamic pressure effect, easy to seize, etc., to achieve strong dynamic pressure effect, The effect of increasing the withstand voltage and increasing the blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

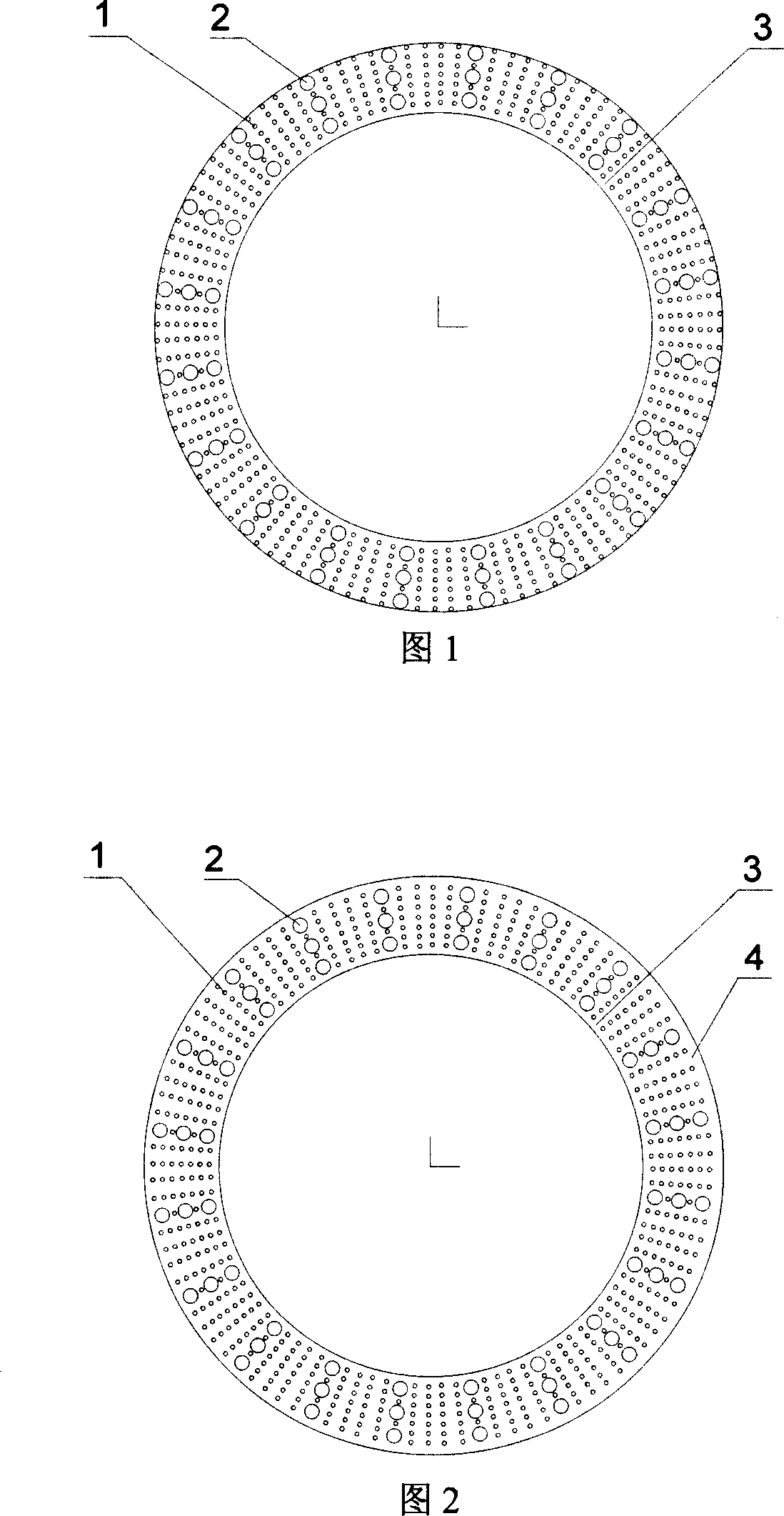

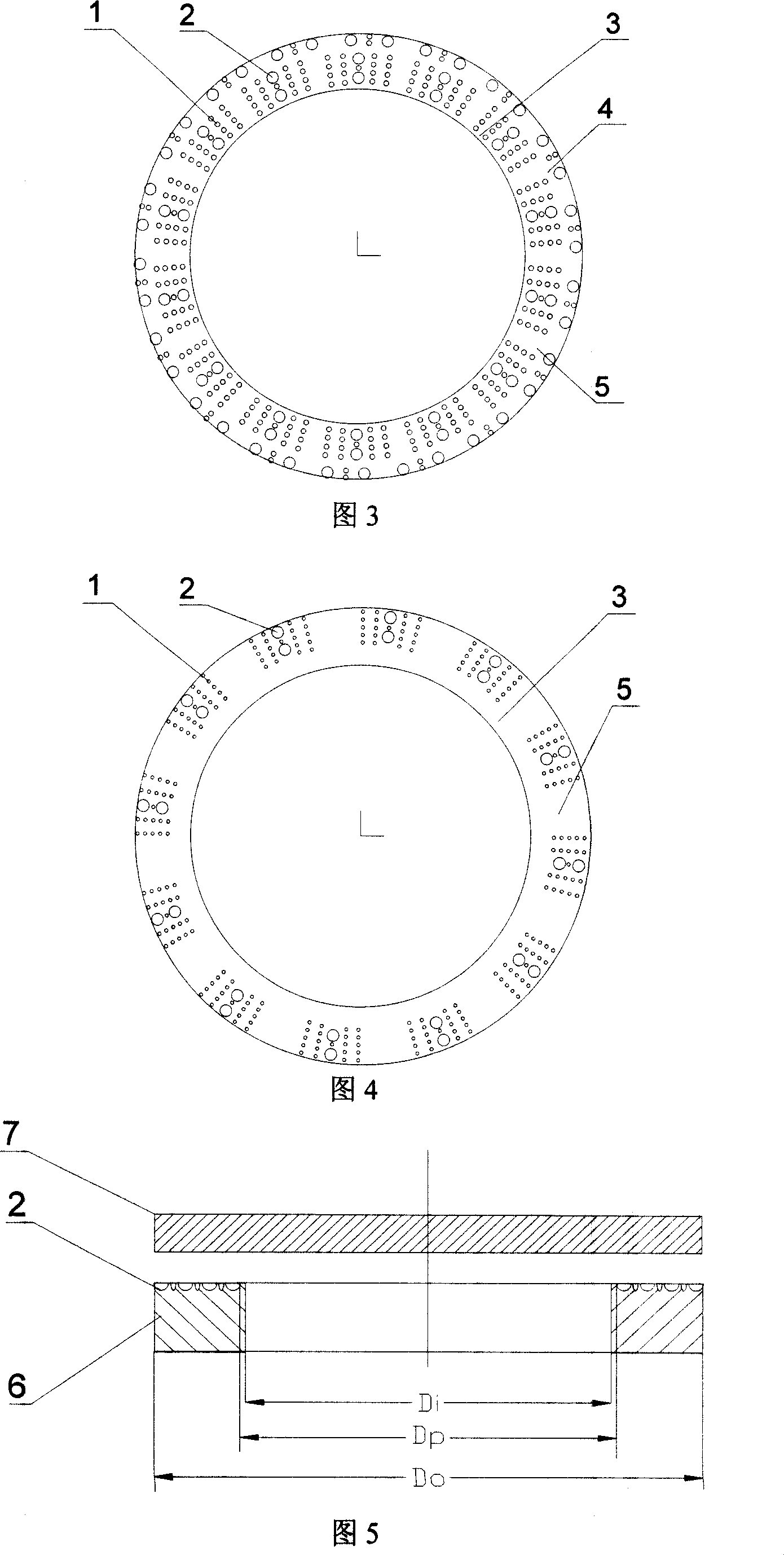

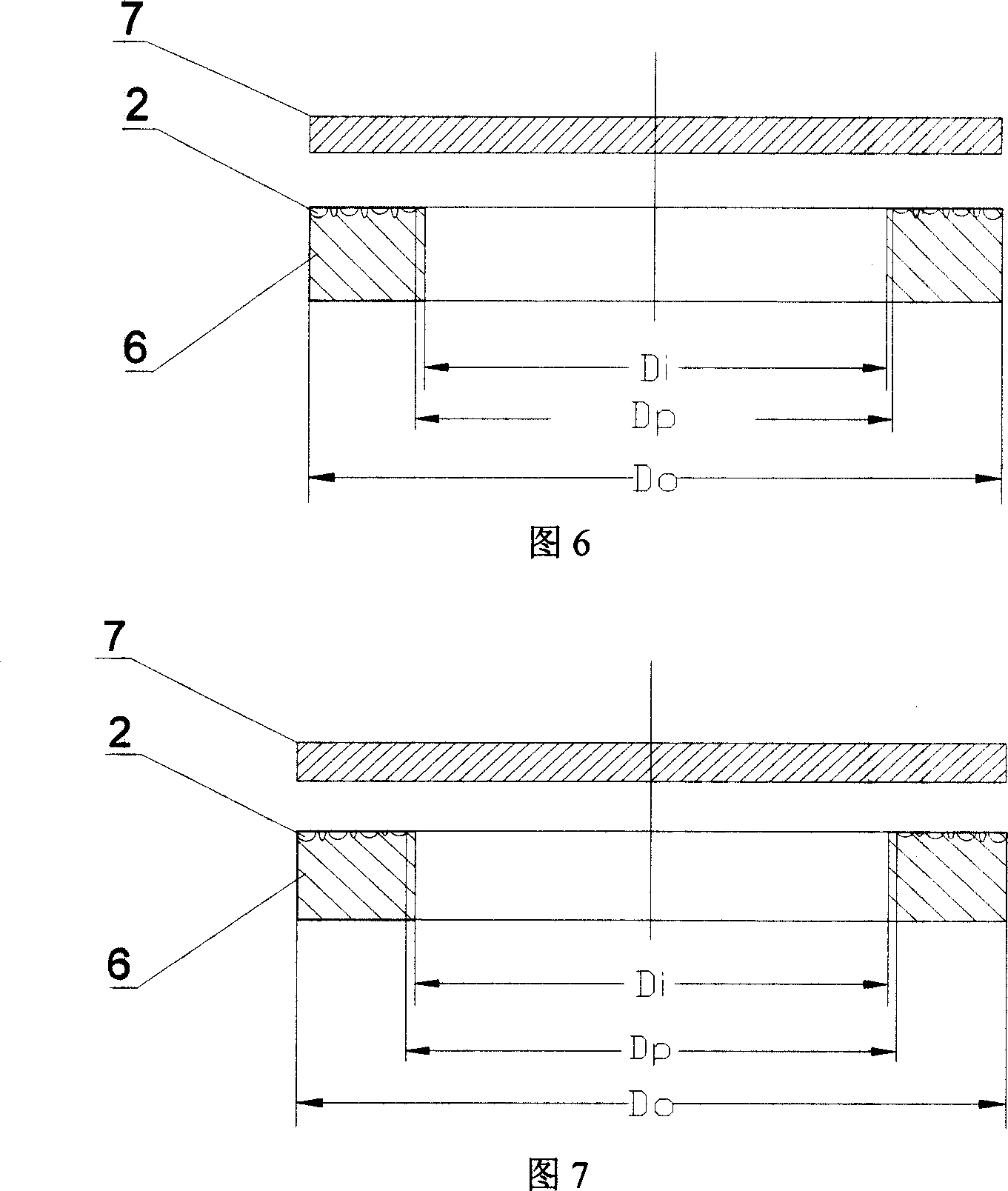

[0040] See Figure 1 and Figure 5: A variable distribution porous end face mechanical seal structure, including the moving ring, static ring and other related parts of the mechanical seal, the sealing end faces of the moving ring and the static ring are bonded to form a circular sealing end face , one side of the ring-shaped sealing end face is the high-pressure side, that is, the upstream side, and one side of the ring-shaped sealing end face is the low-pressure side, that is, the downstream, and the sealing end face of the moving ring or the static ring is open There are micropores, the micropores are of different sizes, and are arranged symmetrically on the sealing end face. The downstream of the microporous ring is provided with an annular sealing dam (3) according to the center symmetry of the end face. The end face of the sealing dam is smooth. surface.

[0041] The micropores are divided into larger micropores (2) and smaller micropores (1). The smaller micropores and th...

Embodiment 2

[0047] See Fig. 1 and Fig. 6: the hole depth of the larger micropore in the upstream first hole ring zone is equal to the depth of the smaller micropore, and the larger micropore gradually decreases along the medium leakage direction, and it is the last one in the downstream. The depth of the larger micropores in the ring zone is not less than 2 μm.

[0048] The remaining structures and implementation modes of this embodiment are the same as those of Embodiment 1.

Embodiment 3

[0050] See Figure 1 and Figure 7: The pore depths of the larger micropores and smaller micropores decrease slightly along the medium leakage direction, and the minimum pore depth or the pore depth of the last pore ring zone downstream is not less than 2 μm.

[0051] The remaining structures and implementation modes of this embodiment are the same as those of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com