A double-layer high-strength fracturing proppant and its preparation method

A fracturing proppant, high-strength technology, applied in chemical instruments and methods, earthwork drilling, wellbore/well components, etc., can solve the problems of weak corrosion resistance, low compressive strength, high fracture rate, etc., to achieve anti-corrosion Strong corrosion resistance, high compressive strength and low breakage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

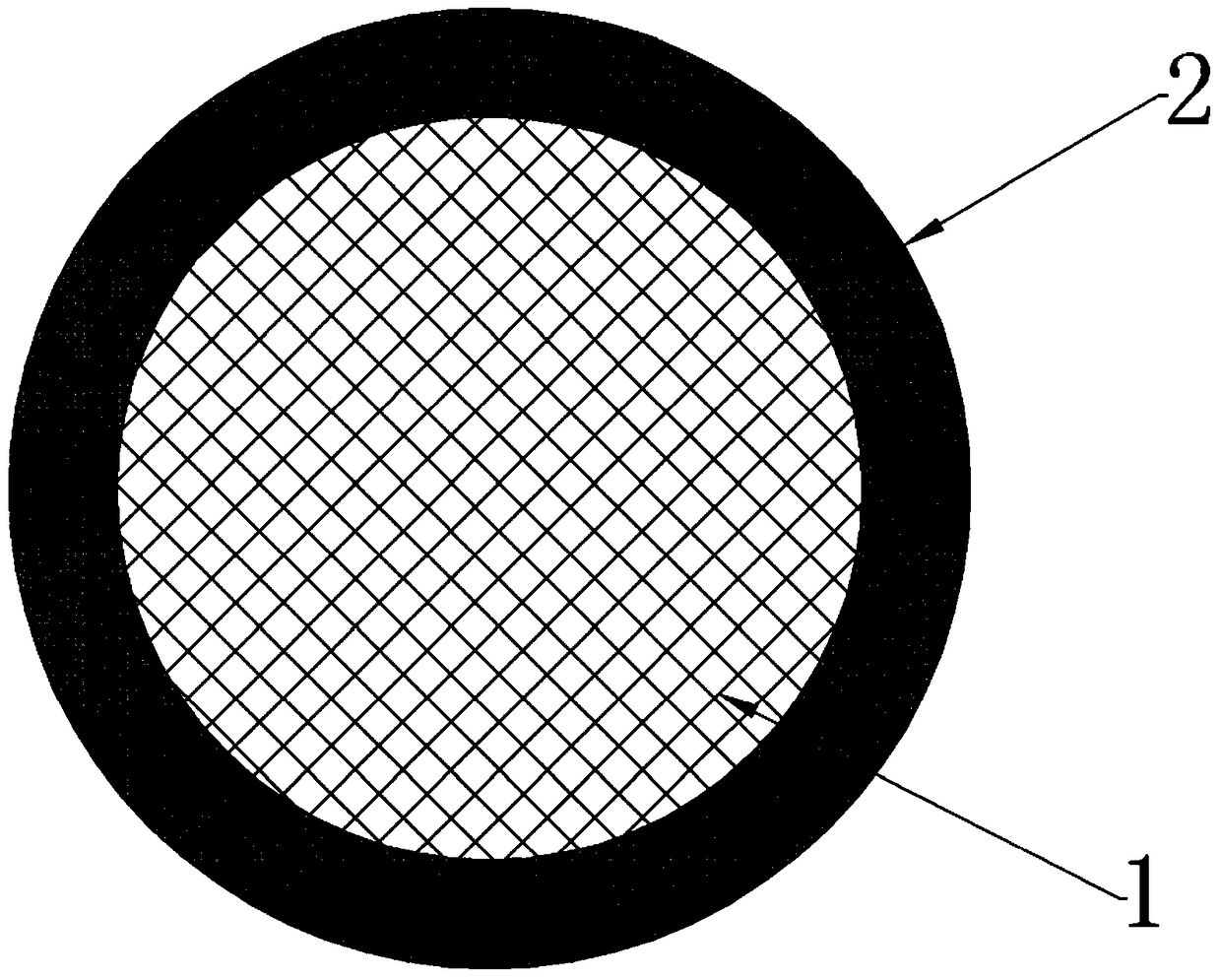

[0045] The double-layer high-strength fracturing proppant of this embodiment, such as figure 1 As shown, it includes a ceramic inner core 1 and a silicon nitride ceramic shell 2 coated on the surface of the ceramic inner core 1, and the ratio of the diameter of the ceramic inner core 1 to the thickness of the silicon nitride ceramic shell 2 is 7:1;

[0046] The ceramic inner core is mainly made of the following core materials by mass percentage: 45% of low-bauxite, 45% of shale, and 10% of coal gangue; the mass content of alumina in the low-bauxite is 50%;

[0047] The silicon nitride ceramic shell is mainly made of the following shell materials in mass percentage: 60% of silicon nitride and 40% of high alumina bauxite. The mass content of alumina in the high alumina bauxite is 70%;

[0048] The preparation method of the double-layer high-strength fracturing proppant of this embodiment comprises the following steps:

[0049] 1) Take low bauxite, shale, and coal gangue and cr...

Embodiment 2

[0056] The double-layer high-strength fracturing proppant of this embodiment has the same structure as that of Embodiment 1, including a ceramic inner core 1 and a silicon nitride ceramic shell 2 coated on the surface of the ceramic inner core 1, and the diameter of the ceramic inner core 1 is the same as The thickness ratio of the silicon nitride ceramic shell 2 is 5:1;

[0057] The ceramic inner core is mainly made of the following core materials by mass percentage: 50% of low-bauxite, 45% of shale, and 5% of coal gangue; the mass content of alumina in the low-bauxite is 40%;

[0058] The silicon nitride ceramic shell is mainly made of the following shell materials in mass percentage: 70% of silicon nitride and 30% of high alumina bauxite. The mass content of alumina in the high alumina bauxite is 80%;

[0059] The preparation method of the double-layer high-strength fracturing proppant of this embodiment comprises the following steps:

[0060] 1) Take low bauxite, shale, ...

Embodiment 3

[0066] The double-layer high-strength fracturing proppant of this embodiment has the same structure as that of Embodiment 1, including a ceramic inner core 1 and a silicon nitride ceramic shell 2 coated on the surface of the ceramic inner core 1, and the diameter of the ceramic inner core 1 is the same as The ratio of the thickness of the silicon nitride ceramic shell 2 is 10:1;

[0067] The ceramic inner core is mainly made of the following core materials by mass percentage: 47% of low-bauxite, 43% of shale, and 10% of coal gangue; the mass content of alumina in the low-bauxite is 45%;

[0068] The silicon nitride ceramic shell is mainly made of the following shell materials in mass percentage: 65% of silicon nitride and 35% of high alumina bauxite. The mass content of alumina in the high alumina bauxite is 75%;

[0069] The preparation method of the double-layer high-strength fracturing proppant of this embodiment comprises the following steps:

[0070] 1) Take low bauxite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com