Novel foam metal sand-prevention pipe

A technology of metal foam and sand control pipe, which is applied in the direction of production fluid, wellbore/well parts, earthwork drilling and production, etc. It can solve the problems of low permeability, poor flow conductivity, increase oil production, etc., and meet the requirements of sand control, Improve the sand control ability and the effect of strong diversion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

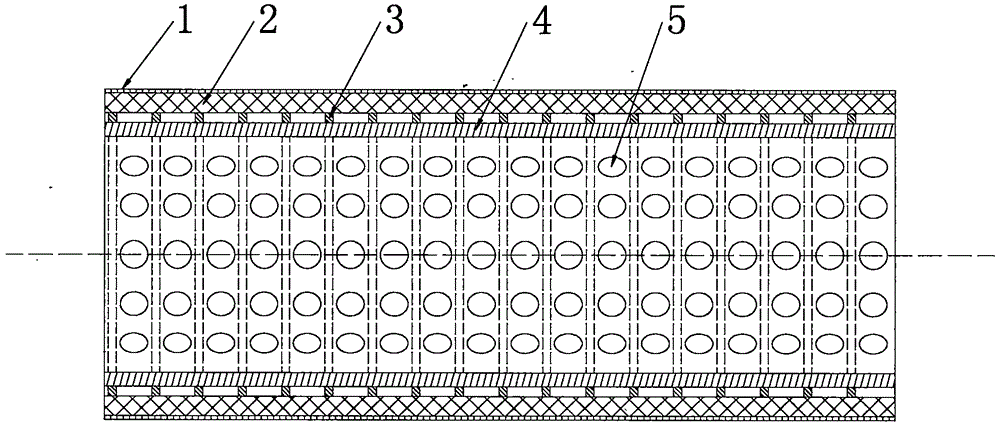

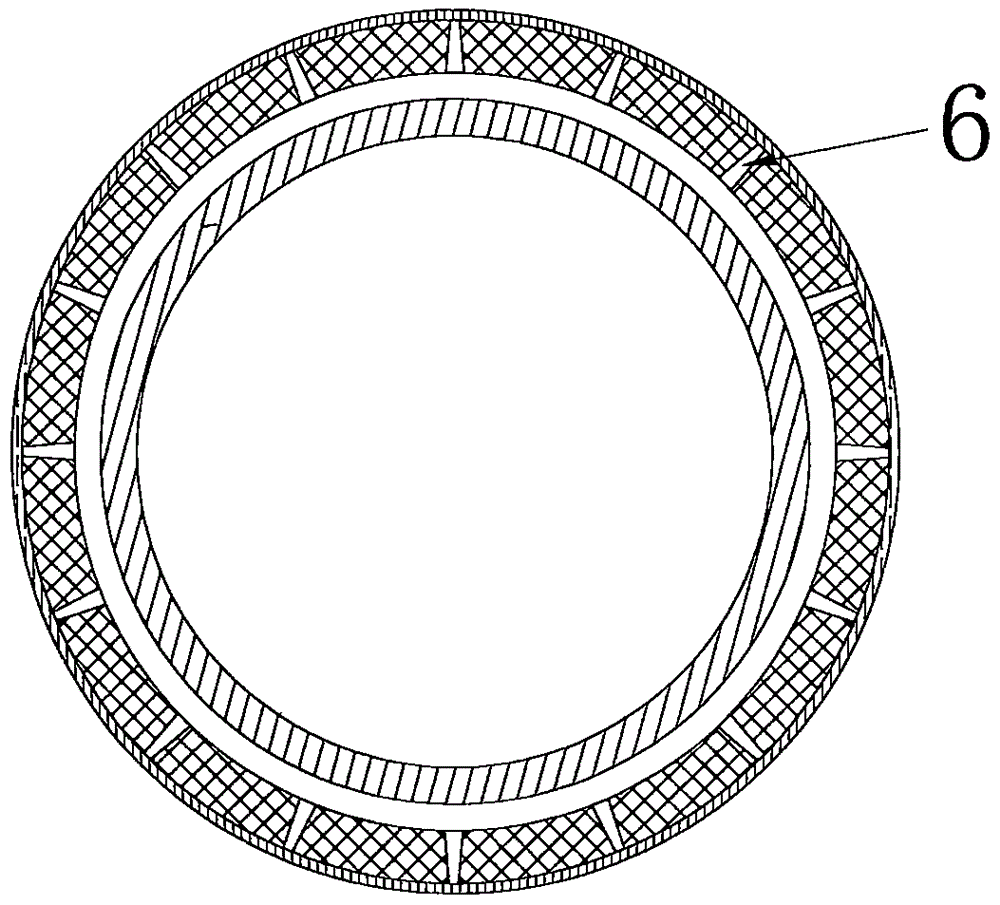

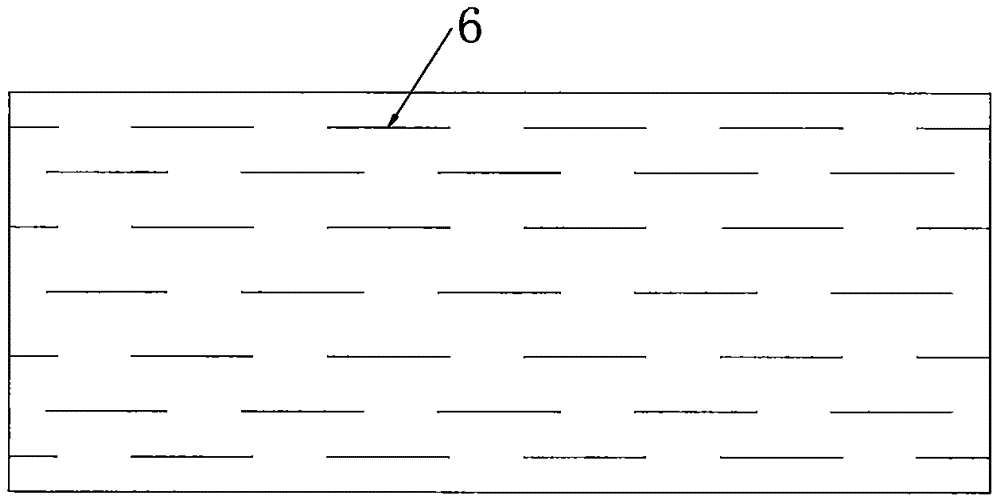

[0014] Such as figure 1 , figure 2 and image 3 As shown, it is the front sectional view, the side view sectional view and the front view of the metal foam sand control layer in the patent of the present invention, which includes the outer tube protective sleeve 1, the metal foam sand control layer 2, the wire-wrapped support strip 3, and the base pipe 4. Diversion holes 5 and diversion seams 6. The feature of the patent of the present invention is that its structure includes from the outside to the inside: the outer tube protective sleeve, the metal foam sand control layer, the wire wrapping support strip, and the base pipe. The diversion seam is a trapezoidal seam with a narrow outside and a wide inside. The wire-wound support strips are welded outside the base pipe, and the base pipe contains parallel diversion holes, each of which is located between two winding holes. In the middle of the wire support bar.

[0015] The unexplained parts involved in the patent of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com