Low-density laminating propping agent and preparation method thereof

A proppant, low-density technology, used in chemical instruments and methods, earthwork drilling, and fluid production, can solve the problems of low proppant placement concentration, general application effect, and low input-output ratio, and achieve a spherical good chemical inertness, improve concentration and conductivity, and improve the effect of working sand ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Accurately weigh raw materials: 12-20 mesh low-density proppant 200kg, thermoplastic phenolic resin 6kg, organic amine curing agent 1kg, water 3kg, dispersant 0.2kg, plasticized drag reducer 0.2kg.

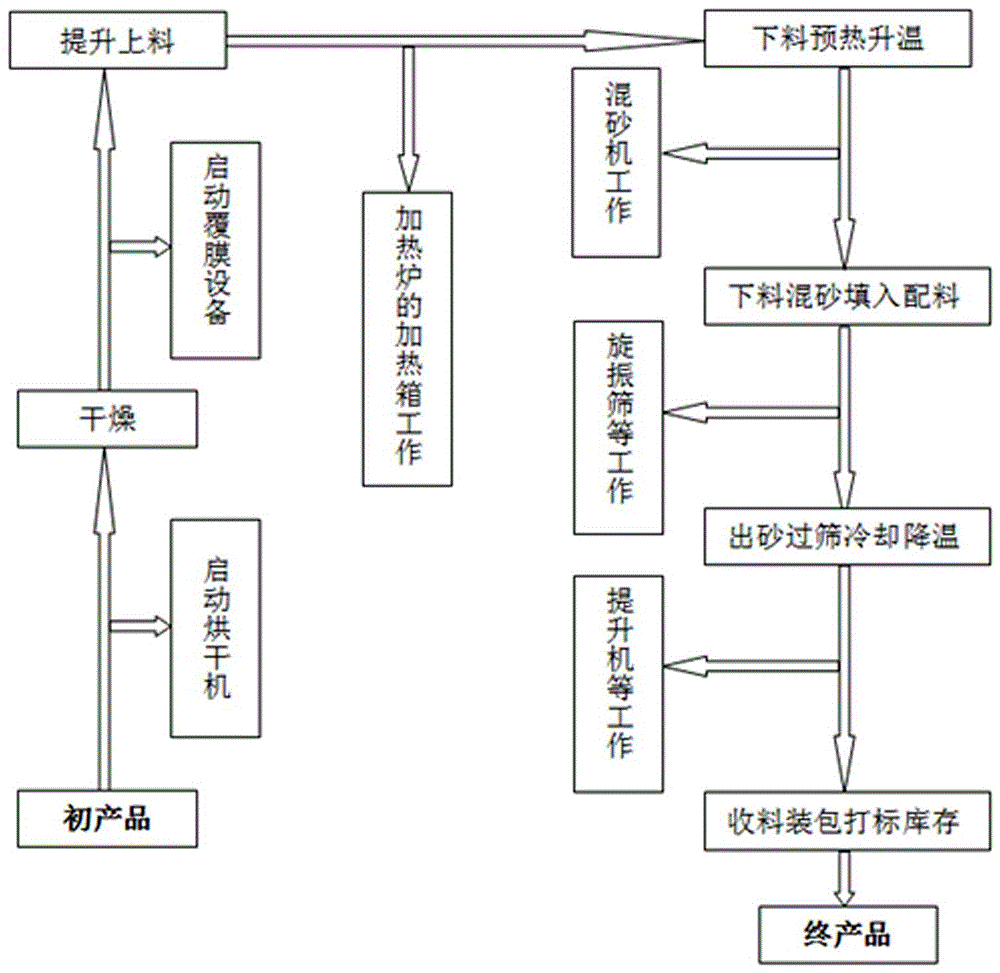

[0020] Such as figure 1 As shown, the preparation method of the low-density film-coated proppant comprises the following steps:

[0021] (a) Crush the wild jujube core into 12-20 mesh spherical particles; and put it into a dryer to dry;

[0022] (b) After drying, start the laminating equipment, lift the material, put the wild jujube core in the heating box of the heating furnace to preheat, and put it into the sand mixer after preheating to rotate and heat to 140°C;

[0023] (c) Put the coated resin into the sand mixer for 90-120s, dissolve the curing agent, dispersant, and drag reducing agent in a solvent, and then add them in sequence, and stir evenly after fully curing;

[0024] (d) Put the processed product into a rotary vibrating sieve to vibrate and sieve, and pack ...

Embodiment 2

[0026] Accurately weigh raw materials: 200kg of 20-40 mesh low-density proppant, 6kg of thermoplastic phenolic resin, 1kg of organic amine curing agent, 3kg of water, 0.2kg of dispersant and 0.2kg of plasticized drag reducer.

[0027] Such as figure 1 As shown, the preparation method of the low-density film-coated proppant comprises the following steps:

[0028] (a) Crushing the wild jujube core into 20-40 mesh spherical particles;

[0029] (b) Put the wild jujube core into the pan for preheating, and put it into the sand mixer after preheating to rotate and heat to 140°C;

[0030] (c) Put the coated resin into the sand mixer for 90-120s, dissolve the curing agent, dispersant, and drag reducing agent in a solvent, and then add them in sequence, and stir evenly after fully curing;

[0031] (d) Put the processed product into a rotary vibrating sieve to vibrate and sieve, and pack it after cooling and drying in a condensing bed.

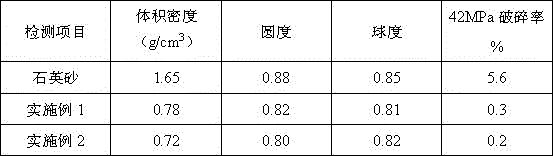

[0032] As shown in Table 1, the performance co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com