Blockage-removing method for polymer flooding blocking wells

A polymer and mortar technology, which is applied in drilling compositions, chemical instruments and methods, and earth-moving drilling and mining, etc., can solve the problem of short plugging validity period, decreased production, and no consideration of the plugging characteristics of polymer injection wells near the wellbore, etc. problem, to achieve the effect of improving oil recovery, reducing impact, and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The plugging removal method of the polymer flooding plugged well of the present embodiment may further comprise the steps:

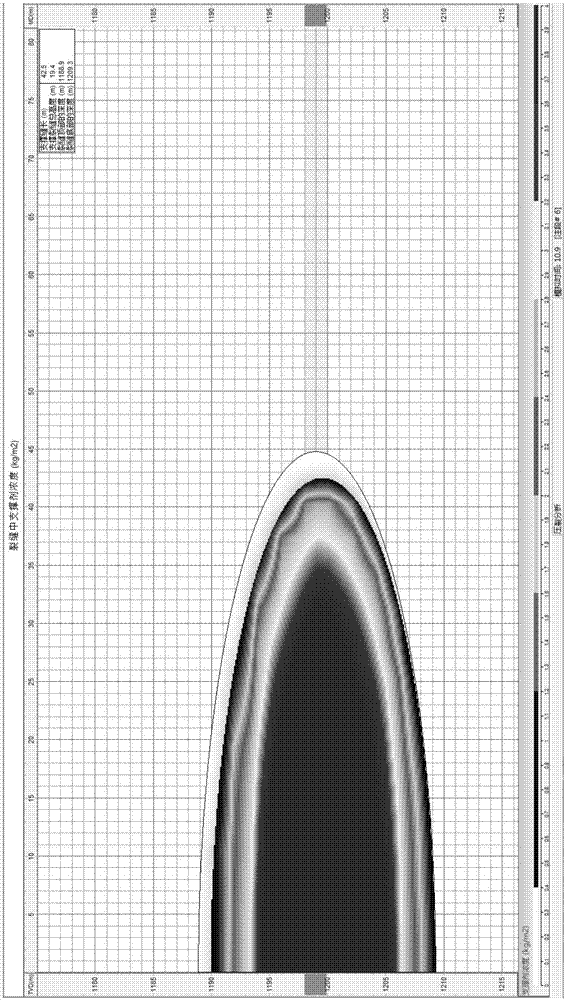

[0055] 1) The cumulative injection volume of polymer in Well T4-212 is 2.1×10 4 m 3 , the formation temperature is 50°C, and the PV number is 0.2; the depth of the oil layer is 1200m, and the oil production drops to 1.8 tons / day; the cementing quality of the production well is qualified and the upper and lower adjacent layers of the oil layer are all dry layers;

[0056] 2) Carry out fracturing construction on the oil layer blocked by polymer injection, and control the length of the artificial fracture to be 40m-60m, and the height to be below 20m; the fracturing construction includes the following steps:

[0057] a) Adjust a 700-type pump truck to the second gear, with a distance of 1.2m 3 / min displacement will be 10m 3 The formation treatment fluid is injected into the formation to pretreat the formation under the condition of lower than the...

Embodiment 2

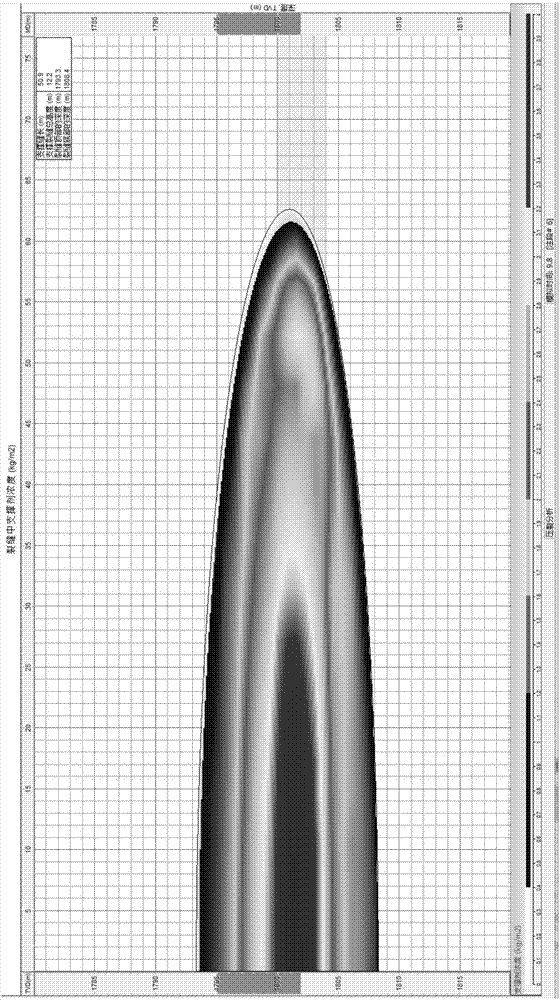

[0075] The plugging removal method of the polymer flooding plugged well of the present embodiment may further comprise the steps:

[0076] 1) There are two oil layers in Well T470, and the cumulative polymer injection in the first oil layer A is 2.9×10 4 m 3 , the formation temperature of the first layer is 79°C, the PV number is 0.35, and the cumulative polymer injection volume in the second oil layer B is 3.0×10 4 m 3 , the formation temperature of the second layer is 80°C, and the PV number is 0.4; the depths of the first and second oil layers are 1800m and 1821m respectively, and the oil production of this well drops to 1.0 tons / day; the cementing quality of this oil production well Qualified, 1791m above the first oil layer is a water layer, and the adjacent layer at 1832m below the second oil layer is a water layer;

[0077] 2) Carry out fracturing construction on the oil layer blocked by polymer injection, and control the length of the artificial fracture to be 40m t...

Embodiment 3

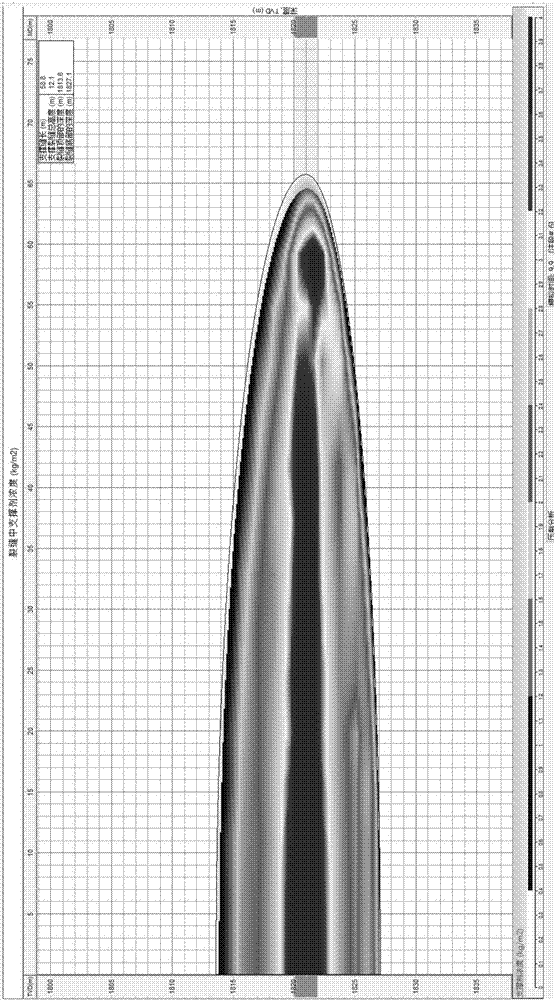

[0086] The plugging removal method of the polymer flooding plugged well of the present embodiment may further comprise the steps:

[0087] 1) The cumulative injection volume of polymer in the first oil layer of Well T478 is 6.1×10 4 m 3 , the formation temperature is 110°C, and the PV number is 0.46; the cumulative injection volume of polymer in the second oil layer is 8.1×10 4 m 3 , the formation temperature is 120°C, the PV number is 0.58; the depths of the first and second oil layers are 2300m and 2400m respectively, and the oil production drops to 0.5 tons / day; the cementing quality of the production well is qualified and the upper, The lower adjacent layers are all dry layers;

[0088] 2) Carry out fracturing construction on the oil layer blocked by polymer injection, and control the length of the artificial fracture to 40m-60m, and the height to be below 20m; the fracturing construction parameters are shown in Table 2, and other uninvolved processes are the same as in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com