Liquid self-supporting high-speed channel fracturing fluid and experimental method

A channel fracturing and self-supporting technology, which is applied in the direction of chemical instruments and methods, mining fluids, earth drilling and production, etc., can solve the problems of high cost, low flow conductivity, large amount of phase change fracturing fluid, etc., to avoid sand Blocking risks, saving costs, and reducing the effect of construction techniques

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] A liquid self-supporting high-speed channel fracturing fluid. Mix 40 g of bisphenol A epoxy resin E-51 with 0.04 g of modified polypropylene fiber, and then add 8 g of triethylenetetramine curing agent and mix evenly to obtain A Liquid; mix 500 g of guar gum fracturing fluid, 0.5 g of organic boron crosslinking agent, 20 g of potassium chloride, and 0.5 g of modified polypropylene fiber to obtain liquid B. Take the above liquid A and liquid B according to the mass ratio of 1:10. Spray liquid A into liquid B, and then inject the mixed liquid into fractures in the flat plate, simulating the formation temperature at 60°C, and curing time for 60 minutes.

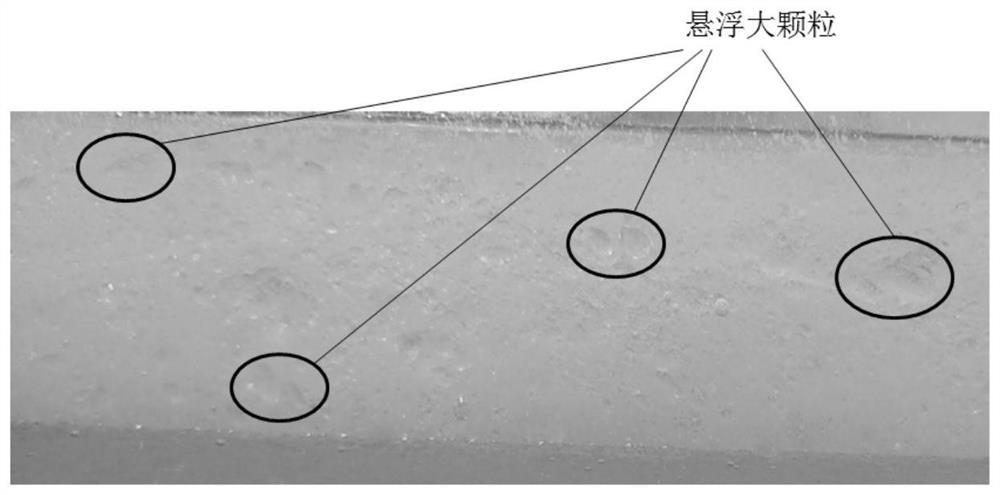

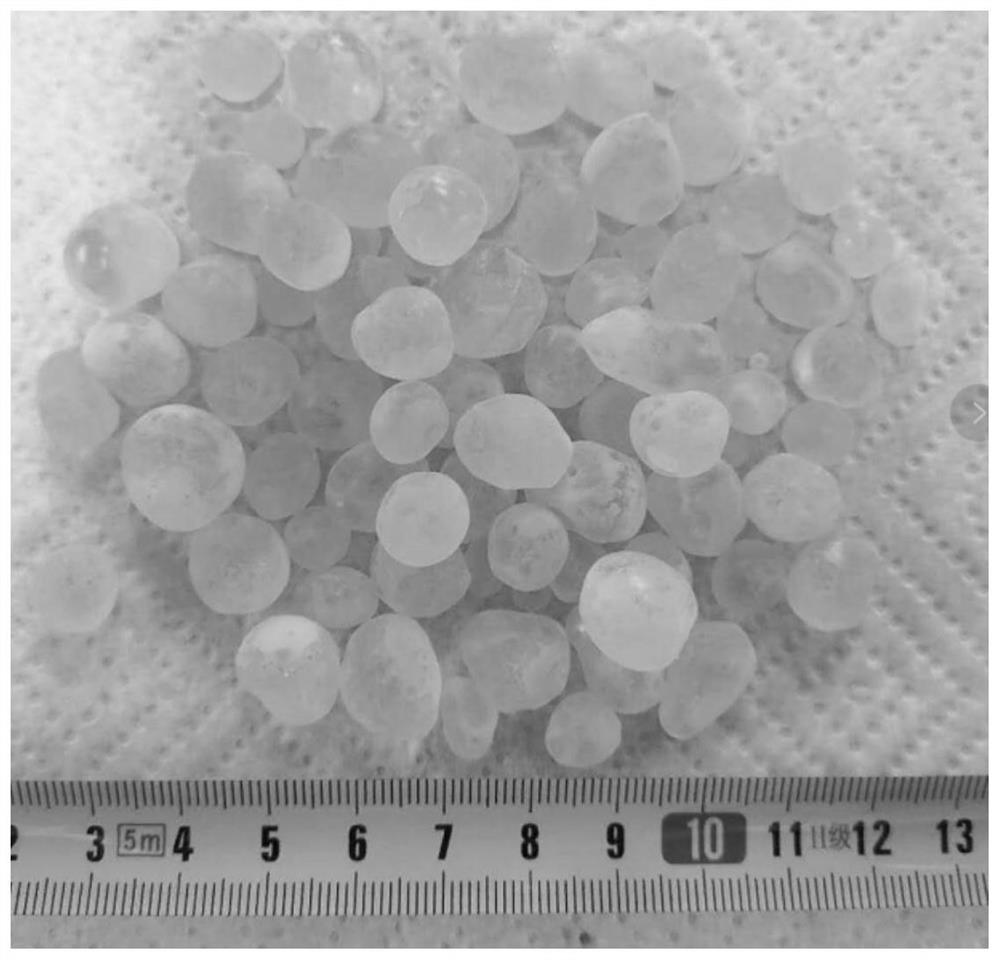

[0068] The schematic diagram of the experiment in the plate seam is as follows: figure 1 shown. After solidification, centimeter-scale particles are formed, and the particles are evenly dispersed in the cracks, and centimeter-scale pores are formed between the particles. The schematic diagram of the experimental result...

Embodiment 2

[0078] A liquid self-supporting high-speed channel fracturing fluid, take 40g of bisphenol A epoxy resin E-51, dilute with 8g of ethanol diluent, then add 0.2g of polyvinyl alcohol fiber and mix evenly, add triethylenetetramine 16g of curing agent, mixed well to obtain liquid A; 500g of guar gum fracturing fluid, 5g of borax crosslinking agent, 100g of potassium chloride, 100g of calcium bromide, 2.5g of modified polypropylene fiber, and surfactant dodecylbenzene Sodium sulfonate 20g was mixed uniformly to obtain liquid B. Take the above liquid A and liquid B according to the mass ratio of 1:3, spray liquid A into liquid B, and then inject the mixed liquid into the cracks of the flat plate, simulate the formation temperature at 80°C, and cure for 40 minutes.

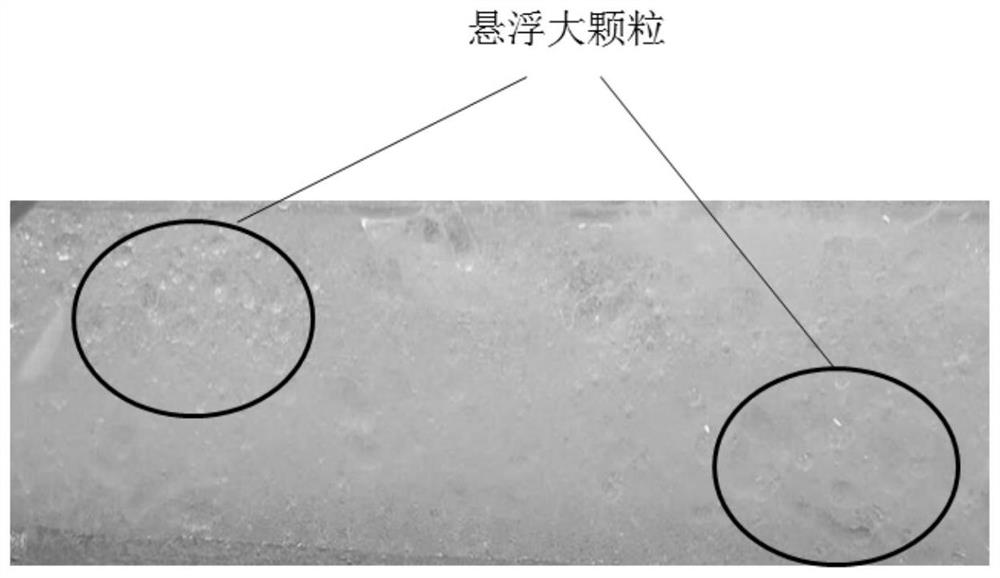

[0079] The schematic diagram of the experiment in the plate seam is as follows: image 3 shown. After solidification, centimeter-scale particles are formed, and the particles are evenly dispersed in the cracks, and cen...

Embodiment 3

[0087]A liquid self-supporting high-speed channel fracturing fluid, take bisphenol A type epoxy resin E-51 and bisphenol F type epoxy resin according to the mass ratio of 3:1 and mix evenly, a total of 60g, add acetone diluent 7g after mixing evenly Add 0.2 g of polyvinyl alcohol fibers and mix evenly, then add 15 g of phthalic anhydride to obtain liquid A; take 750 g of emulsion fracturing fluid, 40 g of potassium chloride, and 1.2 g of polyvinyl alcohol fibers and mix evenly to obtain liquid B. Take the above liquid A and liquid B according to the mass ratio of 1:19, spray liquid A into liquid B, and then inject the mixed liquid into the cracks of the flat plate, simulate the formation temperature at 90°C, and cure for 30 minutes. After solidification, centimeter-scale particles are formed, and the particles are evenly dispersed in the cracks, and centimeter-scale pores are formed between the particles. The schematic diagram of the experimental results is as Figure 4 shown...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com