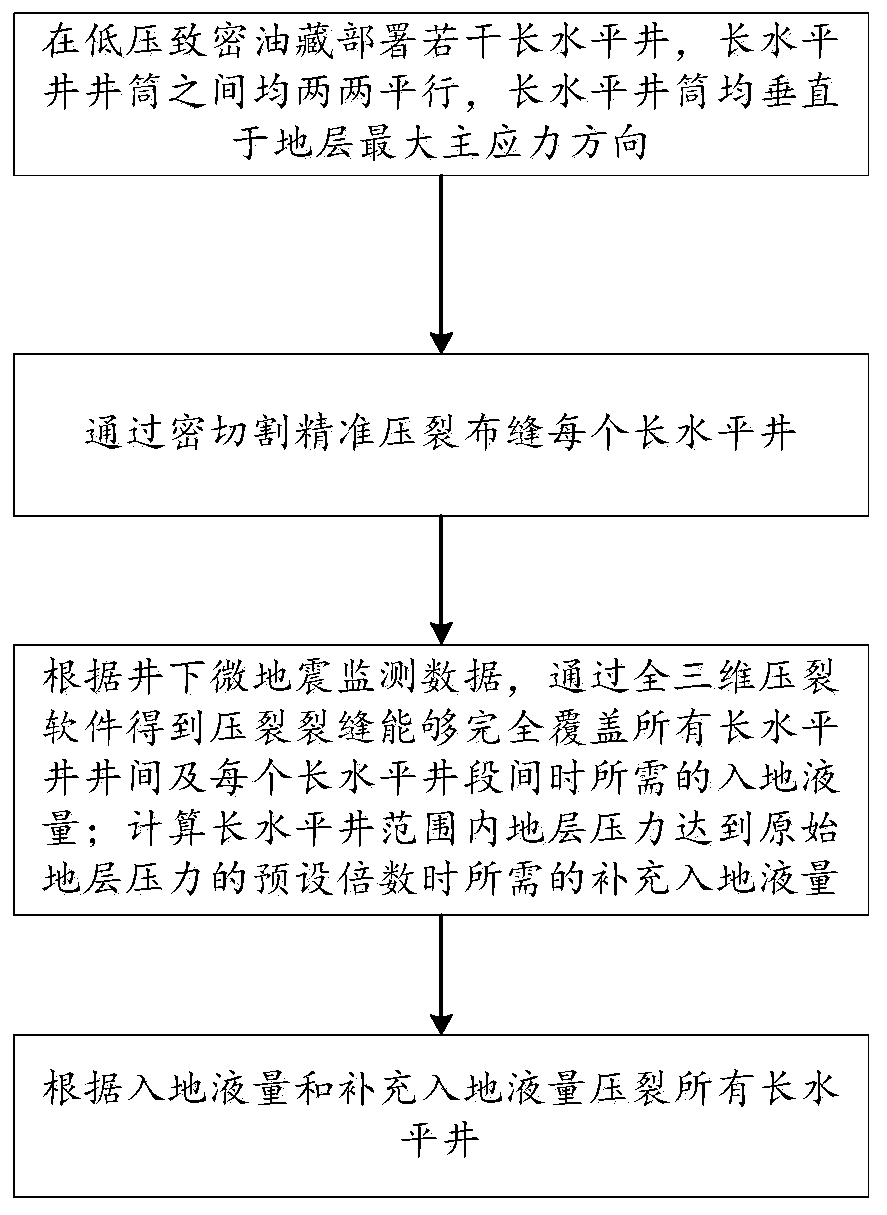

Low pressure dense oil reservoir supplementary energy fracturing method

A technology for tight oil reservoirs and energy supplementation, which is applied in the field of oil and gas field exploration and development, and can solve the problems of large production decline, limited swept area, easy water visibility, etc., so as to improve the cumulative oil production and recovery degree, and prolong the stable production period of oil production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

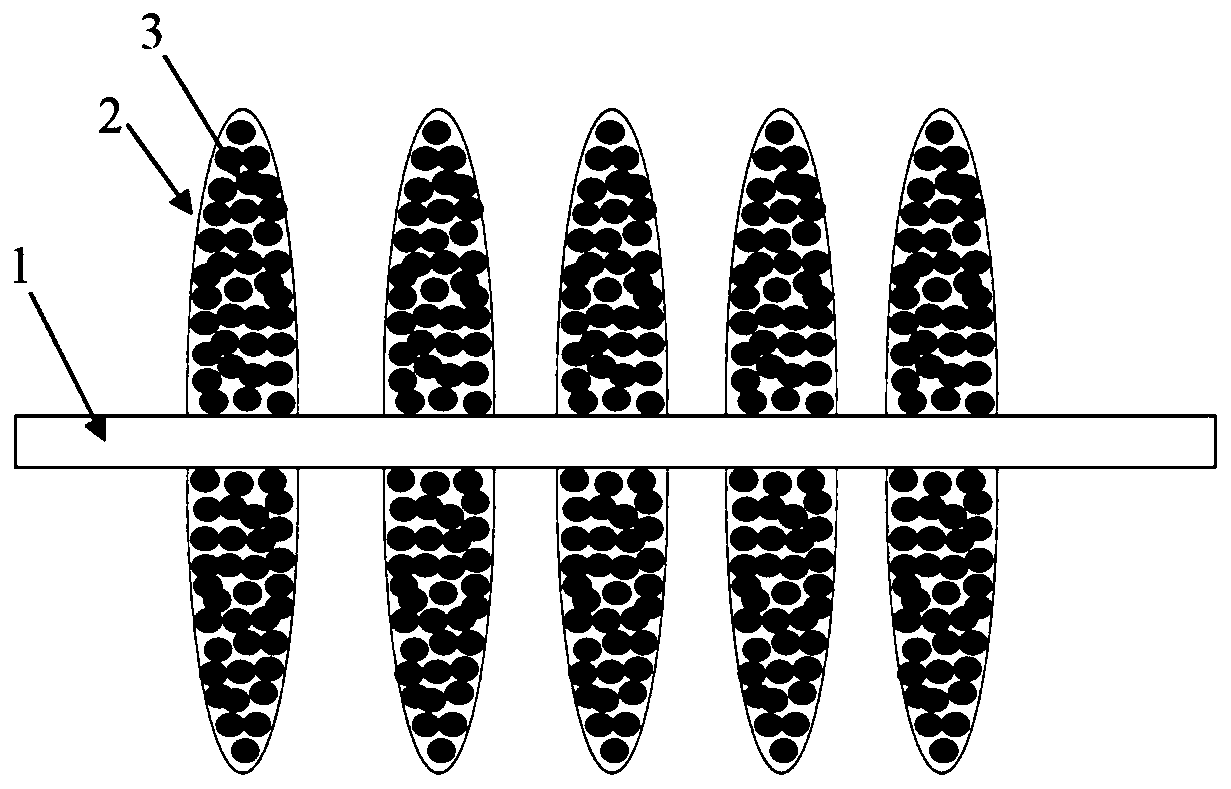

[0046] 20 long horizontal wells were deployed in a low-pressure tight oil reservoir. The horizontal section is 1500m long. The wellbores of the horizontal wells are parallel to each other. The well spacing is 800m. The long horizontal wellbores are all perpendicular to the direction of the maximum principal stress of the formation. The thickness of the oil layer is 15m, the original formation pressure is 15.8MPa, and the comprehensive compressibility coefficient is 0.0005MPa -1 .

[0047] The dense cutting and precision fracturing fracture design is adopted. The average length of a single horizontal well is 55m, and the average single-stage perforation is 5 clusters, with an average cluster spacing of 8.5m.

[0048] The full three-dimensional fracturing software was used to simulate the relationship between the single-stage fluid volume of the long horizontal well and the half-length of the fractured fracture 2, and the model was corrected by combining the previous downhole mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com