Large-spacing pillarless mining method

A mining method and technology without bottom pillars, which can be used in surface mining, underground mining, special mining, etc., can solve problems such as relatively few studies, methods of increasing stope structure parameters, etc., to achieve convenient on-site control and improve mining. Ore quality, increase the effect of controlling the amount of ore

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

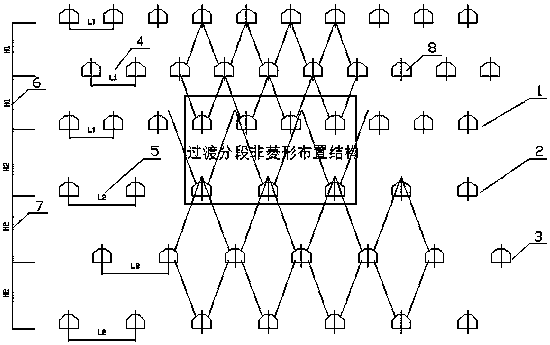

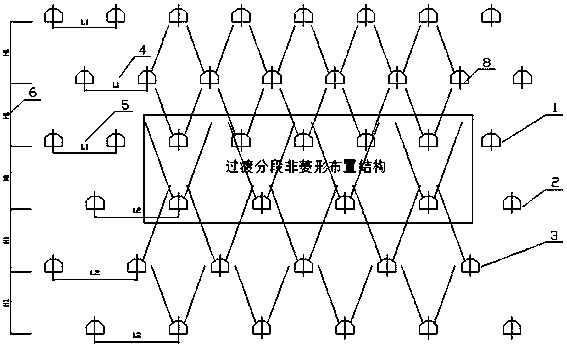

[0032] In an underground mine, the ore body occurs between -36m and -524m. It adopts the plan of phased construction and phased mining, adopts shaft development, and mining by segmental caving method without pillars. The stage height of the first phase of the mining project of the mine is 120m, divided into two middle sections of -78~-138m and -138~-198m, and -198m is the stage transportation level. The original stope structural parameters are: the height of the first segment 6 × the first approach distance 4 = 12m × 10m, the plane size of the ore block is 60m × 50m, when the mining work is carried out to -138m, according to the present invention, one is to adopt The least common multiple method changes the route from 3 to 2 within 30m in the plane direction, and changes the segments from 5 to 4 in the height direction to form a large-space stope structure; the second is to adopt the least common multiple method in the plane In the 20m range in the direction, the route will be...

Embodiment 2

[0034]In a certain production mine, the method of combined development of ramps and shafts, and the sub-level caving method without pillars are used for mining. The stage height of the first stage mining project of the mine is 120m, divided into two middle sections of 0~-60m and -60~-120m, and -120m is the stage transportation level. The original stope structure parameters are: the height of the first section 6×the spacing of the first approach 4=15m×18m, and the plane size of the ore block is 90m×75m. When the mining work reaches -60m, according to the present invention, the least common multiple method is used to change the routes from 4 to 3 within the range of 72m in the plane direction, and change the segments from 4 to 3 in the height direction, forming For the large-space stope structure, the new parameters at this time are: the height of the second section 7×the spacing of the second approach 5=20m×24m, so the area controlled by a single approach changes from 270m² to ...

Embodiment 3

[0036] In an underground iron mine, the ore body is buried between +45m ~ -360m, the ore body strike length is 1200m, the average thickness is 35m, and the dip angle is 75°~85°. 80m, -200m, -320m three stages of transportation levels, each stage is divided into two middle sections. The stope structure parameters originally adopted by the mine are: the height of the first subsection 6×the first approach distance 4=12m×15m, when the mining work reaches -200m, according to the present invention, the least common multiple method is adopted in the range of 90m in the plane direction Change the routes from 6 to 5, and change the segments from 5 to 4 in the height direction to form a stope structure with large spacing. At this time, the new parameters are: second segment height 7 × second approach Road spacing 5 = 15m×18m, so the area controlled by a single access road changes from 180m² to 270m². Since increasing the route spacing will inevitably change the corresponding relationsh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com