Crop straw co-fermentation device

A technology for crop straw and combined fermentation, which is applied in biochemical cleaning devices, enzymology/microbiology devices, bioreactor/fermenter combinations, etc. Fermentation and other problems, to achieve the effect of shortening the fermentation period of the material, improving the gas production potential, and having a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

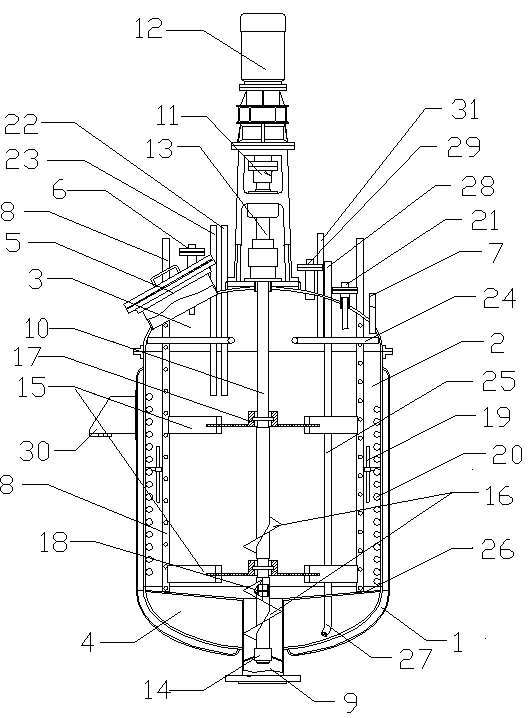

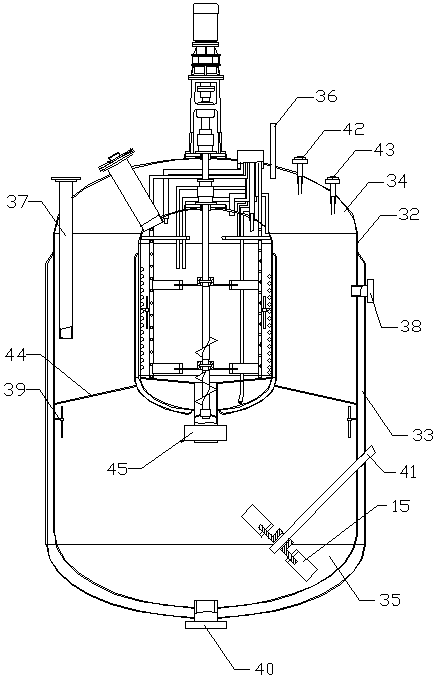

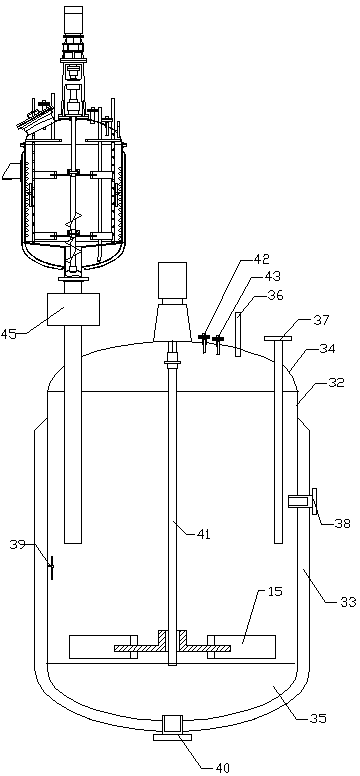

[0021] Such as figure 1 As shown, the present invention includes a connected pretreatment reaction tank and anaerobic fermentation tank, and the materials in the pretreatment reaction tank enter the anaerobic fermentation tank body 32 for fermentation after being pretreated. The pretreatment reaction tank includes a pretreatment reaction tank body 2 arranged in the pretreatment reaction tank jacket 1, and the upper and lower ends of the pretreatment reaction tank body 2 are respectively provided with a pretreatment reaction tank upper head 3 and a pretreatment reaction tank The lower head 4, the upper head 3 of the pretreatment reaction tank are provided with a pretreatment reaction tank material inlet 5, a pretreatment reaction tank material sampling port 6 and a pretreatment reaction tank gas outlet 7, and the pretreatment reaction tank body 2 It is equipped with oxygen pipe 8, pretreatment reaction tank stirring and conveying device, pretreatment reaction tank heating devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com