Secondary anaerobic fermentation and power generation system for large-middle scale biogas engineering

A two-stage anaerobic fermentation and power generation system technology, applied in the field of biogas production systems, can solve the problems of low gas production rate, wide distribution, small scale, etc., and achieve the effect of improving gas production efficiency and reducing production and management costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

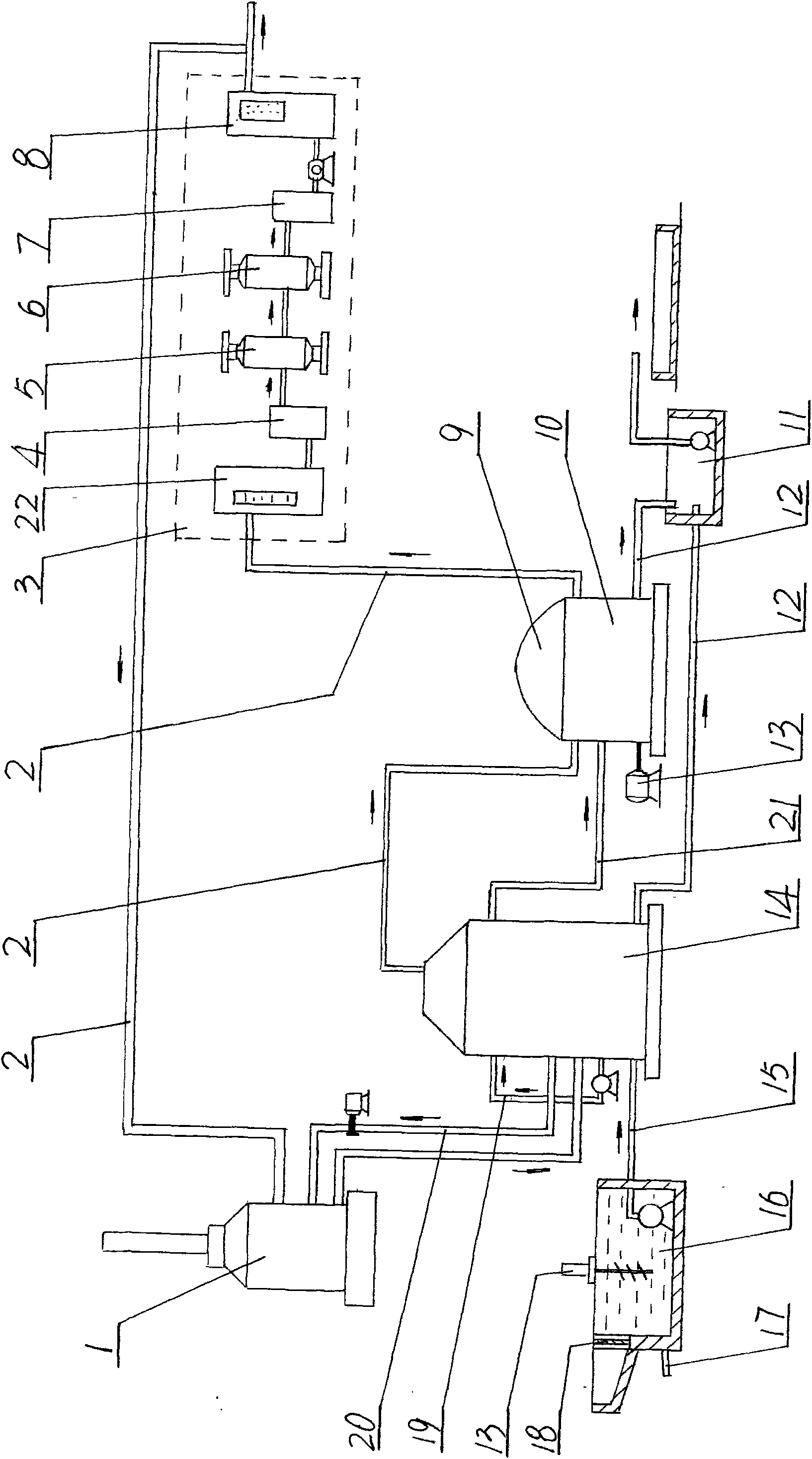

[0010] Such as figure 1 Shown: pretreatment pool 16 communicates with the bottom of USR reactor 14 through feed pipe 15, is provided with the overflow pipe 21 that is communicated with secondary fermentation tank 10 in the upper part of this USR reactor, in USR reactor 14 and the bottom of the secondary fermentation tank 10 are respectively provided with a slag discharge pipe 12 communicated with the digester 11, and the top of the USR reactor 14 is provided with an air duct 2 communicated with the secondary fermentation tank 10, and the top of the secondary fermentation tank 10 The gas storage membrane 9 supplies biogas to the generator through the biogas purification device 3; The cabinet consists of 8.

[0011] In the above technical scheme, the USR reactor 14 is an upflow anaerobic solid reactor, which is a new type of reactor dedicated to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com