Double-shaft stirrer

A dual-shaft stirring and stirring shaft technology, which is applied in the field of stirring machinery, can solve the problems of cyclic movement, inability to unify materials, and not smooth, etc., and achieve the effects of improving stirring speed and efficiency, speeding up mutual mixing, and improving use efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

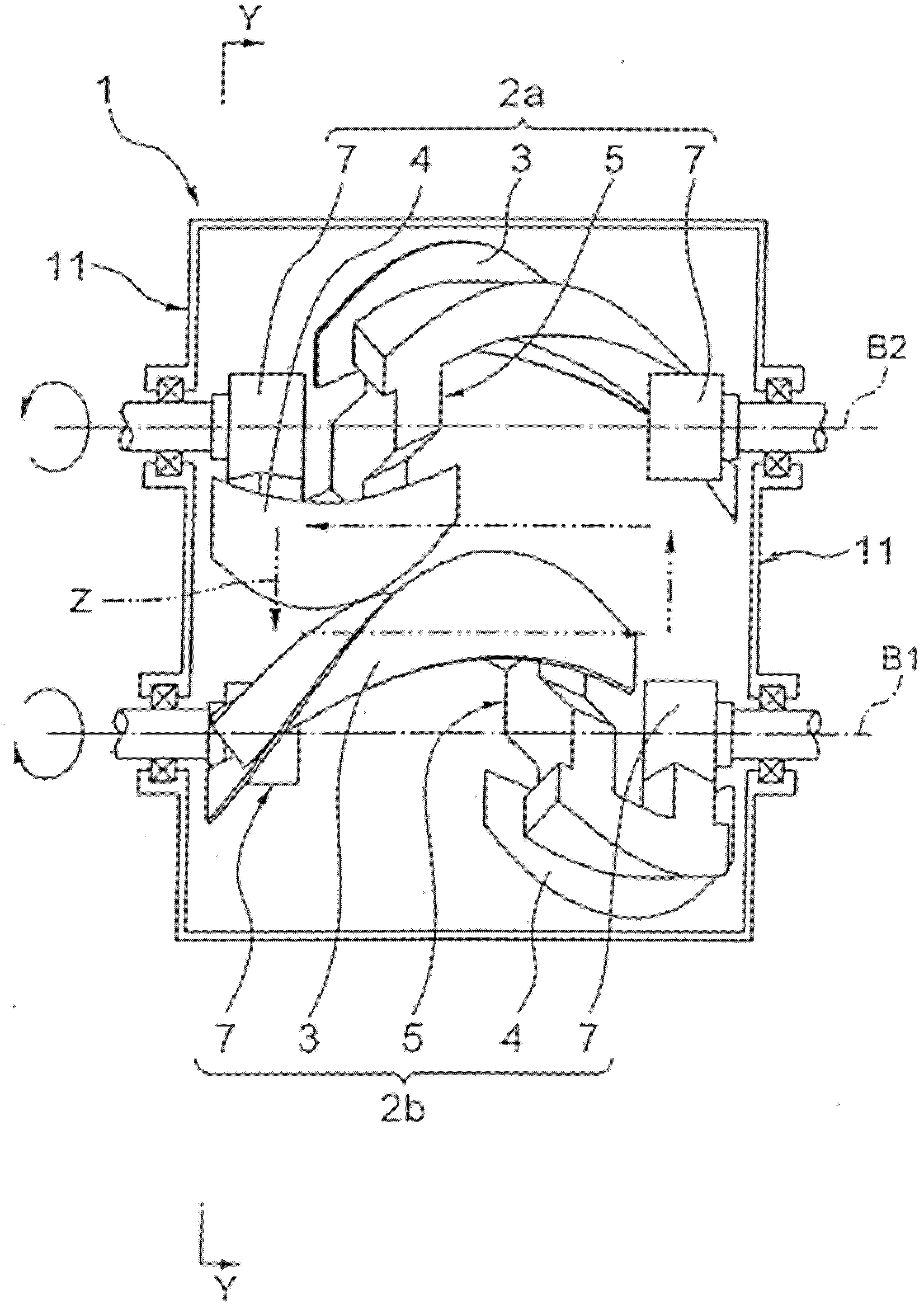

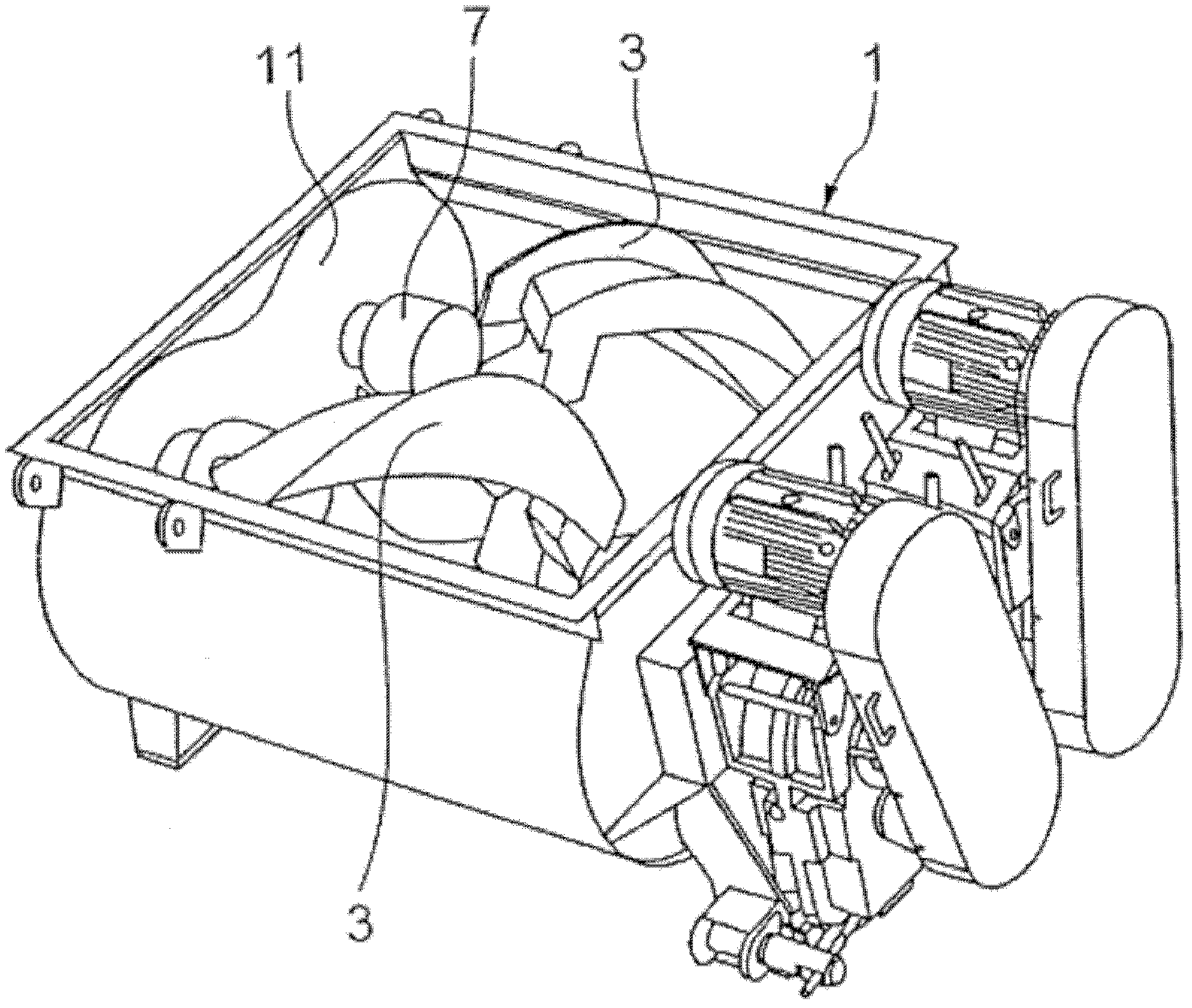

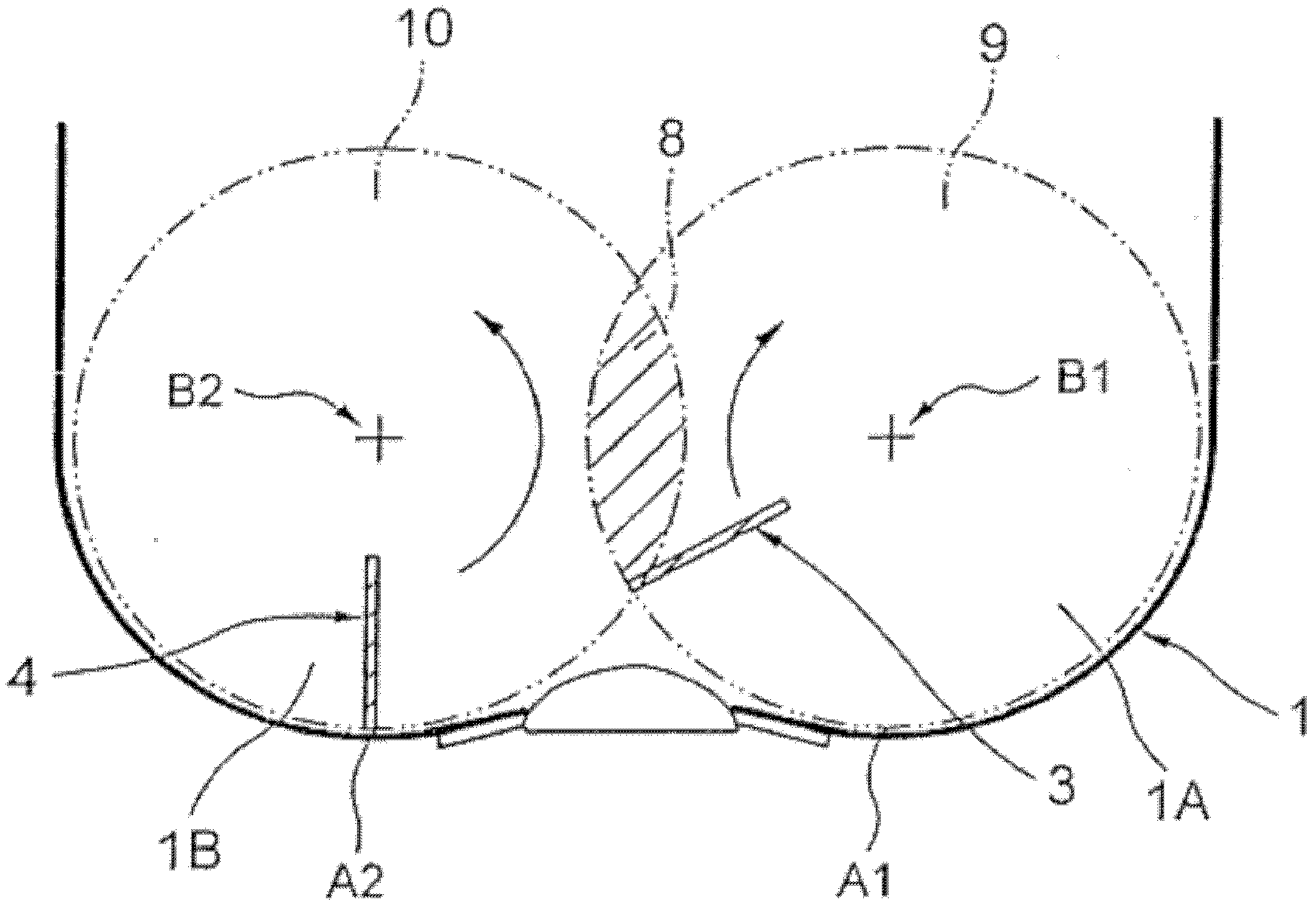

[0021] see figure 1 and figure 2 , shows the schematic diagram of twin-shaft stirrer of the present invention, and this twin-shaft stirrer 1 comprises shell 11, first stirring shaft 2a and the second stirring shaft 2b, is provided with stirring tank in this shell 11, and this first stirring shaft 2a and the second stirring shaft 2b are respectively arranged in parallel in the stirring tank along the first axis B2 and the second axis B1, the stirring tank is provided with a material inlet at the top, and a discharge port with a gate that can be opened and closed is provided at the bottom (not shown) shown), the two ends of the first stirring shaft 2a and the second stirring shaft 2b are supported by bearings on both sides of the housing 11, and can rotate relative to the housing. Both ends of the first stirring shaft 2a and the second stirring shaft 2b are At least one first blade and at least one second blade in opposite directions are provided.

[0022] see figure 2 One ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com