Thermal exhaust air treatment plant

A waste gas purification and thermal technology, applied in lighting and heating equipment, incinerators, combustion types, etc., can solve problems such as reducing the residence time of split flow, and achieve the effect of improving flow resistance and good distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

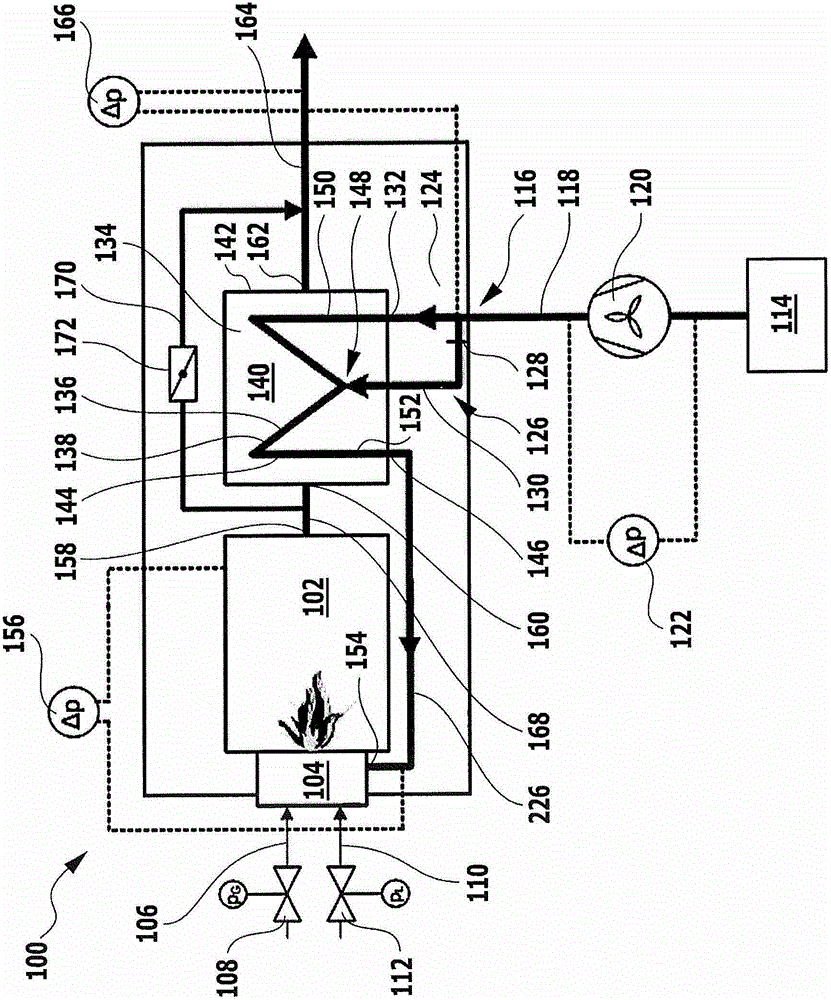

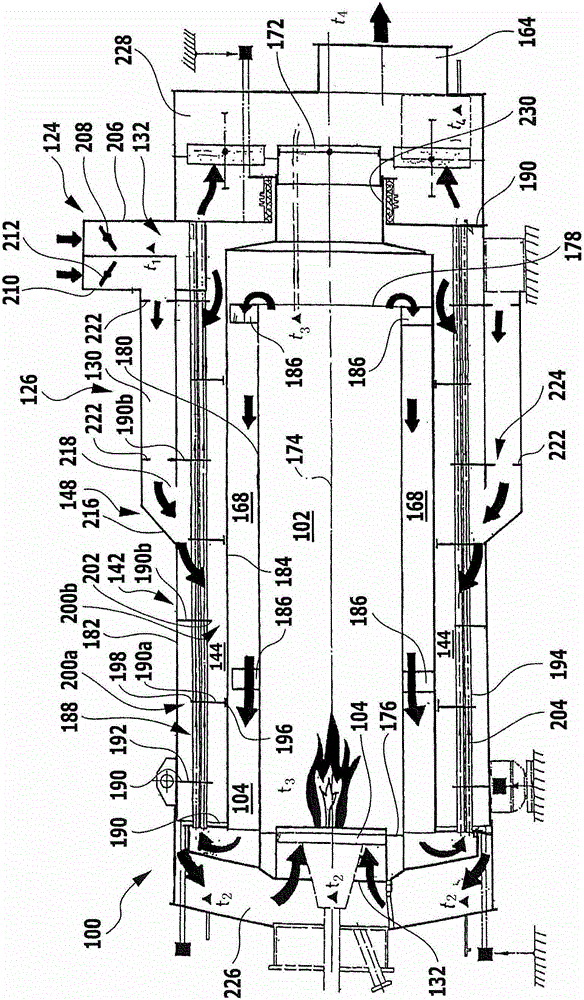

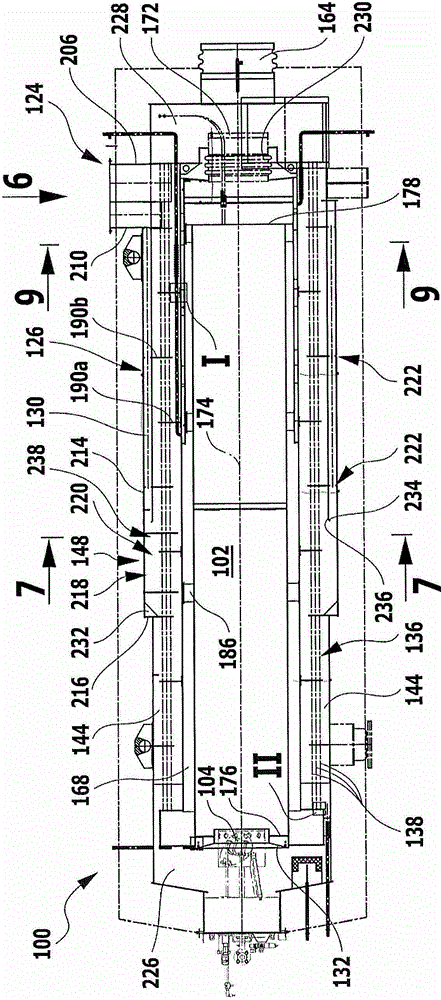

[0087] exist figure 1 with figure 2 The thermal exhaust gas purification plant shown in , denoted as a whole by the reference number 100 , as shown by figure 1 As can be seen from the schematic schematic diagram of the combustion chamber, it includes a combustion chamber 102, a burner 104 is arranged on the combustion chamber inlet of the combustion chamber, and suitable fuel, such as natural gas, can be delivered to the burner through a fuel pipeline 106 with a fuel valve 108, As well as cooling air for the ignition electrode, sight glass and flame monitoring can then be supplied to the burner via a cooling air line 110 with a cooling air valve 112 .

[0088] The exhaust gas to be cleaned is a gas mixture which contains oxidizable components such as volatile organic compounds.

[0089] The oxidizable components of the exhaust gas are oxidized in the combustion chamber 102 together with the added fuel and rendered harmless.

[0090] The mixed gas containing combustible com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com