Wear-resistant domestic ceramic and preparation method thereof

A wear-resistant, daily-use technology, applied in applications, household appliances, clay products, etc., can solve the problems of difficult to clean, easy to wear surface, poor wear resistance of glaze, save labor and equipment costs, high hardness and flexural strength, the effect of improving the toughness of the glaze layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

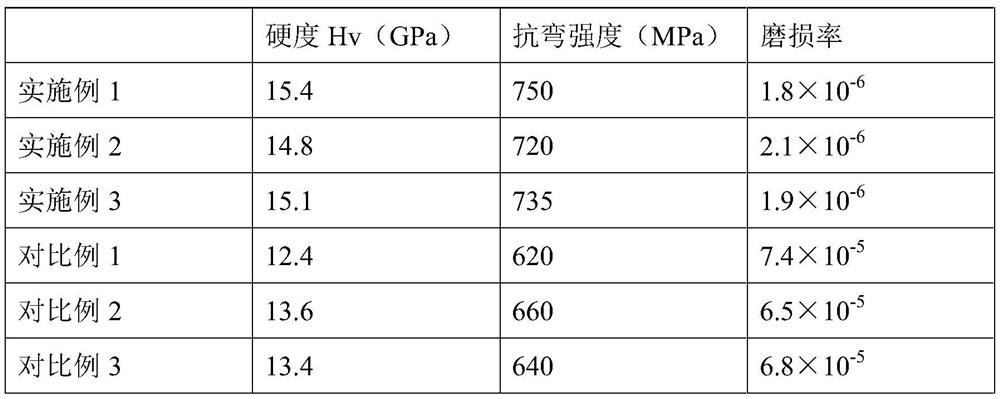

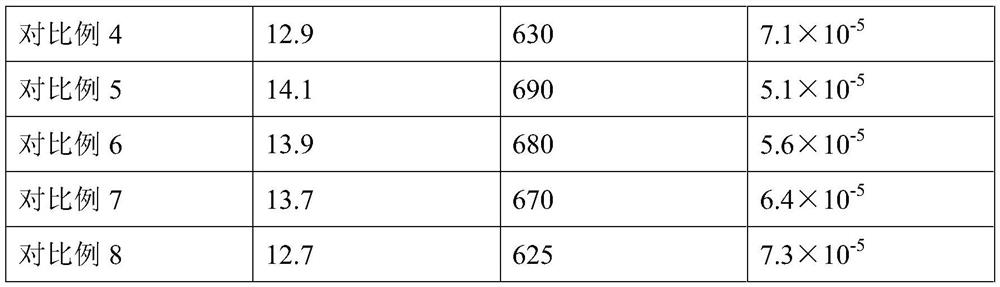

Examples

Embodiment 1

[0038] A wear-resistant ceramic for daily use, comprising a ceramic body for daily use and a glazed layer, the glazed layer is made of the following raw materials in parts by weight:

[0039] 35 parts of zircon sand, 14 parts of baddeleyite, 8 parts of nepheline syenite, 5 parts of titanium carbide powder, 4 parts of titanium dioxide, 5 parts of lutetium oxide, 3 parts of tungsten powder, 5 wt% polyvinyl alcohol 3 parts, 3 parts of glycerin, 25 parts of water.

[0040] The particle size of the zircon sand is 5 μm, the particle size of the baddeleyite is 6 μm, and the particle size of the nepheline syenite is 10 μm.

[0041] The particle size of the titanium carbide powder is 30nm, the particle size of the titanium dioxide is 20nm, the particle size of the lutetium oxide is 15nm, and the particle size of the tungsten powder is 8nm.

[0042] A kind of preparation method of above-mentioned wear-resistant ceramics for daily use is characterized in that:

[0043] 1) Preparation o...

Embodiment 2

[0049] A wear-resistant ceramic for daily use, comprising a ceramic body for daily use and a glazed layer, the glazed layer is made of the following raw materials in parts by weight:

[0050] 40 parts of zircon sand, 10 parts of baddeleyite, 5 parts of nepheline syenite, 6 parts of titanium carbide powder, 3 parts of titanium dioxide, 6 parts of lutetium oxide, 2 parts of tungsten powder, polyvinyl alcohol with a mass fraction of 5wt% 4 parts, 2 parts glycerin, 30 parts water.

[0051] The particle size of the zircon sand is 6 μm, the particle size of the baddeleyite is 4 μm, and the particle size of the nepheline syenite is 12 μm.

[0052] The particle size of the titanium carbide powder is 20nm, the particle size of the titanium dioxide is 25nm, the particle size of the lutetium oxide is 10nm, and the particle size of the tungsten powder is 10nm.

[0053] A kind of preparation method of above-mentioned wear-resistant ceramics for daily use is characterized in that:

[0054...

Embodiment 3

[0060] A wear-resistant ceramic for daily use, comprising a ceramic body for daily use and a glazed layer, the glazed layer is made of the following raw materials in parts by weight:

[0061] 30 parts of zircon sand, 10 parts of baddeleyite, 5 parts of nepheline syenite, 6 parts of titanium carbide powder, 6 parts of titanium dioxide, 4 parts of lutetium oxide, 4 parts of tungsten powder, polyvinyl alcohol with a mass fraction of 5wt% 2 parts, 4 parts of glycerin, 20-30 parts of water.

[0062] The particle size of the zircon sand is 3 μm, the particle size of the baddeleyite is 8 μm, and the particle size of the nepheline syenite is 8 μm.

[0063] The particle size of the titanium carbide powder is 40nm, the particle size of the titanium dioxide is 15nm, the particle size of the lutetium oxide is 20nm, and the particle size of the tungsten powder is 5nm.

[0064] A kind of preparation method of above-mentioned wear-resistant ceramics for daily use is characterized in that: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com