Patents

Literature

85 results about "Nepheline syenite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nepheline syenite is a holocrystalline plutonic rock that consists largely of nepheline and alkali feldspar. The rocks are mostly pale colored, grey or pink, and in general appearance they are not unlike granites, but dark green varieties are also known. Phonolite is the fine-grained extrusive equivalent.

Nanoclay modified waterborne compositions for coating plastic and methods for making the same

InactiveUS20050059765A1Improve thermal shock resistanceMaterial nanotechnologySpecial tyresWater dispersibleWater insoluble

The present invention provides aqueous dispersion compositions comprising one or more than one of each of aqueous dispersions of water-dispersible polymers and aqueous nanocomposite dispersions of at least partially exfoliated layered silicates and water-insoluble polymers to enhance the thermal shock resistance of a waterborne coating, film, or article comprising the composition. Only 2 to 10 phr of the layered silicate, e.g. sodium montmorillonite surprisingly enhances thermal shock resistance. Optional fillers, such as nepheline syenite, may be added. Such compositions may be coated on automotive plastic, TPO or resinous substrates, and provide coatings having a 19 or greater thermal shock resistance according to Ford laboratory test method BI 107-05 when coated on TPO and baked for 15 minutes at from 74 to 90° C. Further, the present invention provides methods of making aqueous nanocomposite dispersions comprising mixing unmodified layered silicate and water insoluble neat resin in water to at least partially exfoliate the clay and subjecting the resulting mixture to high shear.

Owner:NIPPON PAINT USA

Heat curable thermosetting luminescent resins

InactiveUS6905634B2Improve luminous performanceImprove propertiesLuminescent paintsElectroluminescent light sourcesSodium BentoniteAlkaline earth metal

Luminescent polymers are prepared from thermosetting unsaturated polyesters, suspending fillers and phosphorescent pigments and utilized to make gel coated articles and molded, cast and fiberglass reinforced plastic (FRP) articles. The luminescent polymers show bright and long-lasting photoluminescent afterglow, strong thermostimulation of afterglow by heat and electroluminescent properties. The preferred thermosetting unsaturated polyester resins are prepared by condensing mixtures of ethylenically unsaturated and aromatic dicarboxylic acids and anhydrides with dihydric alcohols and a polymerizable vinylidene monomer. Preferred suspending fillers and thixotropic modifiers include silica, microspheres, glass fibers and other short fibers, nepheline syenite, feldspar, mica, pumice, magnesium sulfate, calcium carbonate, bentonite and the various clays and thixotropic modifiers and mixtures thereof. Preferred phosphorescent pigments include alkaline earth aluminate phosphors, zinc sulfide phosphors and mixtures of these phosphors.

Owner:BURNELL JONES PETER

Copper-red transmutation glaze, copper-red transmutation glaze ceramic product prepared from same and preparation method

The invention relates to a copper-red transmutation glaze, a copper-red transmutation glaze ceramic product prepared from the same and a preparation method and belongs to the technical field of ceramics. The copper-red transmutation glaze comprises components in parts by weight as follows: a glaze type basic material including 34-35 parts of nepheline syenite, 20-22 parts of calcium carbonate, 3-4 parts of barium carbonate, 2-3 parts of zinc oxide, 1-2 parts of magnesium carbonate, 26-27 parts of kaolin and 9.5-10.5 parts of nano silicon oxide, and a chromogenic reagent including 1.8-2.5 parts of lithium carbonate, 2-4 parts of bone ash and 2-4 parts of copper carbonate. The ceramic product prepared from the copper-red transmutation glaze through firing has brighter red color, the glaze color is uniformly distributed, and the yield is high.

Owner:FUJIAN DEHUA HUAMAO CERAMICS CO LTD

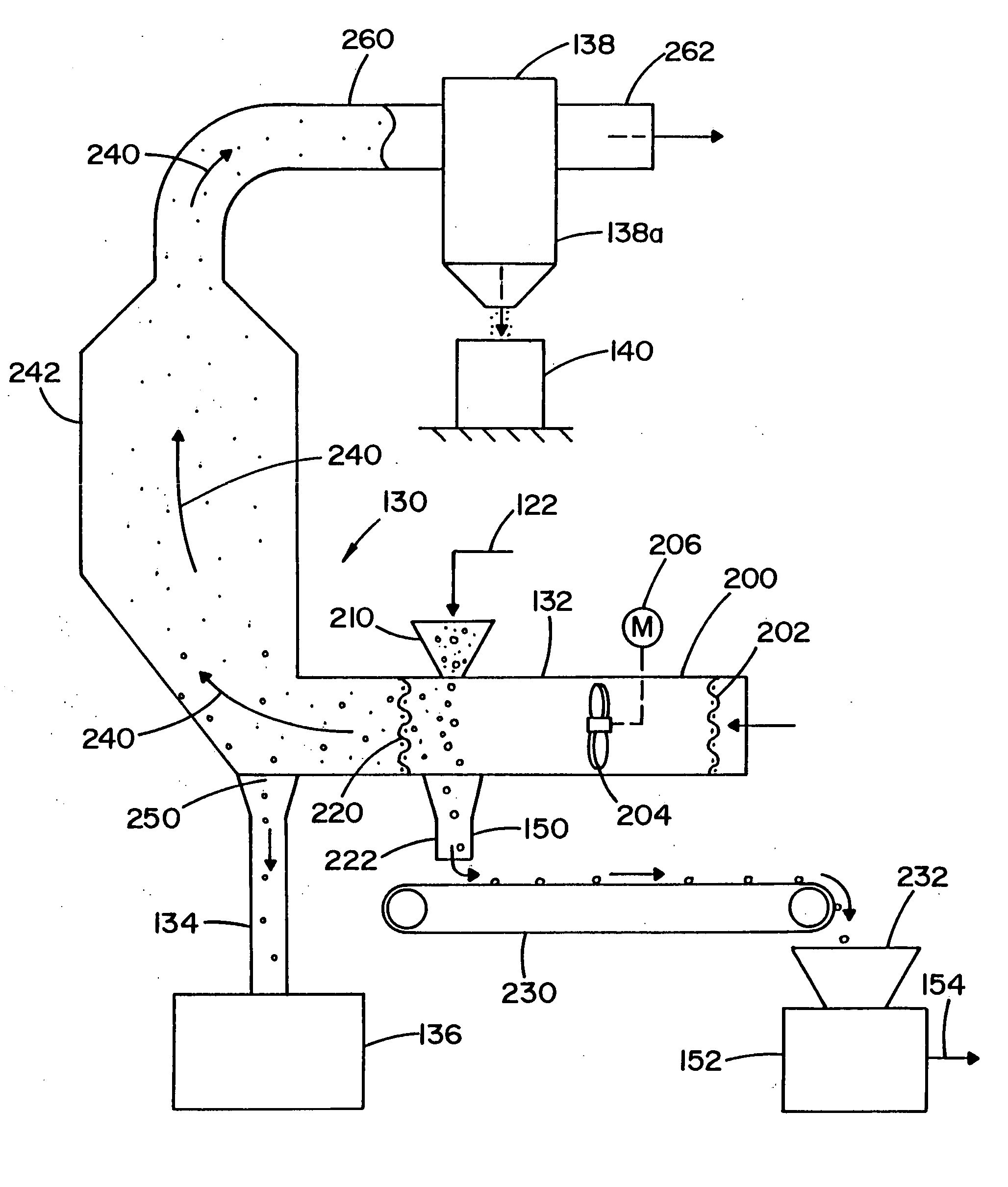

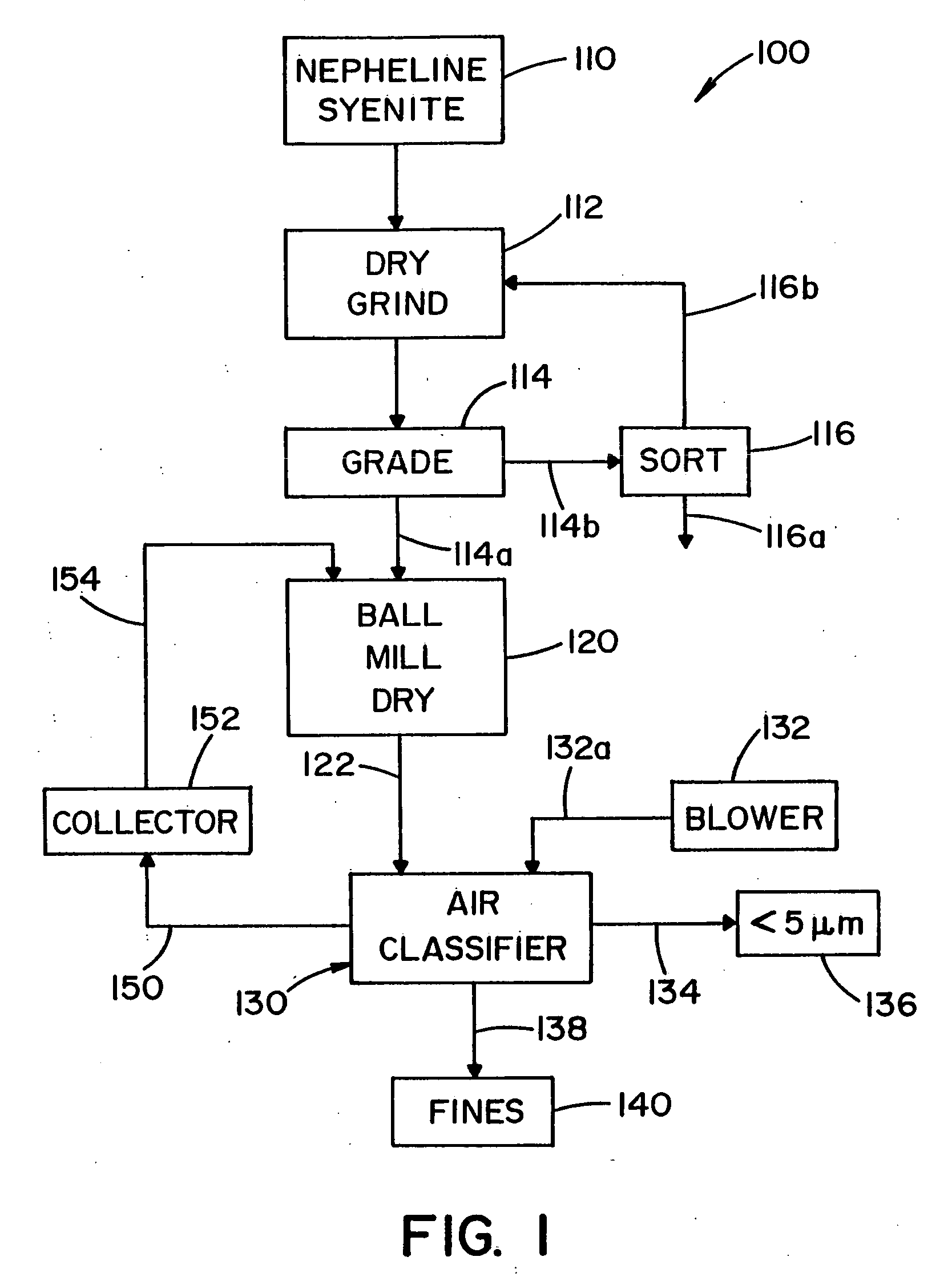

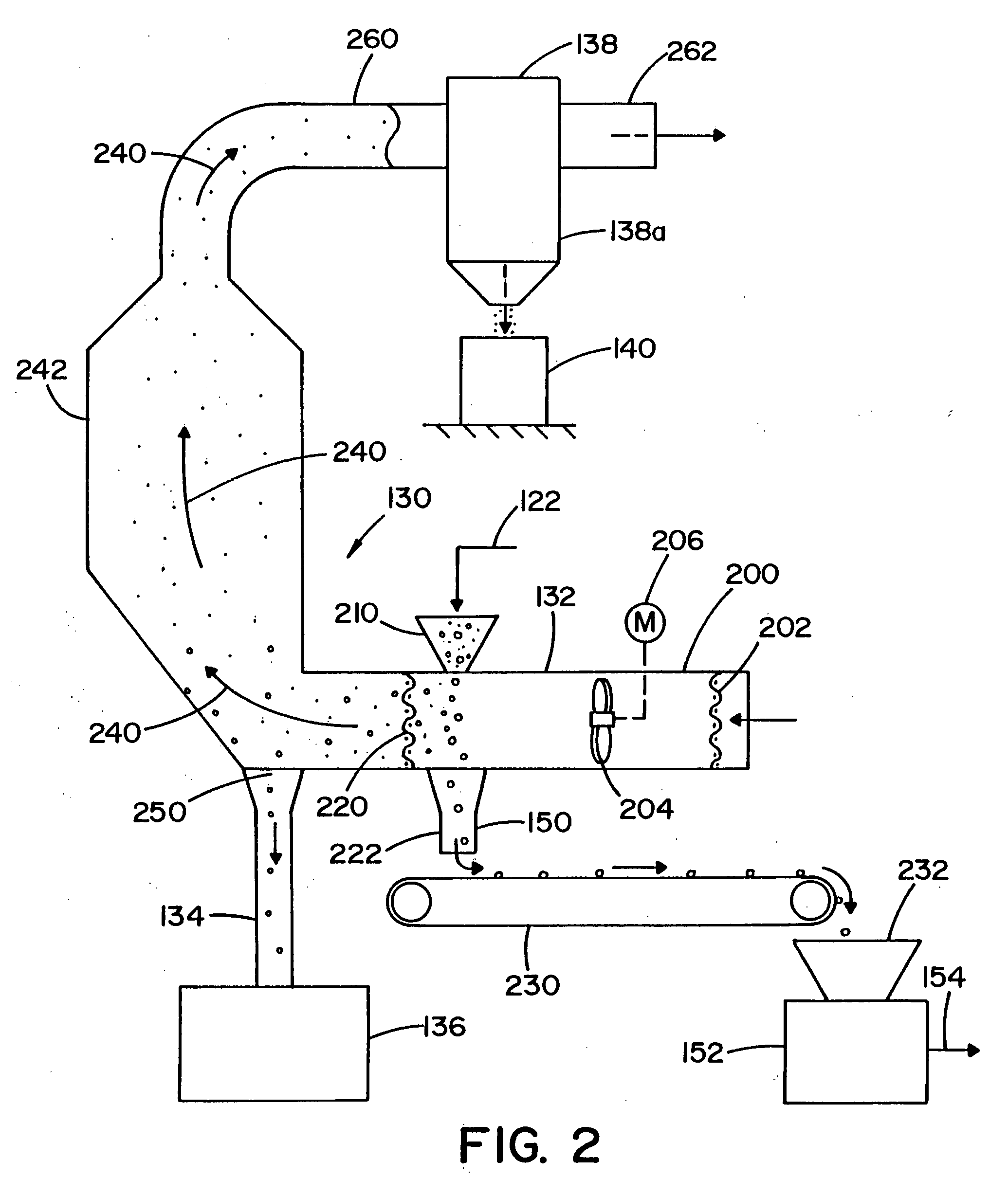

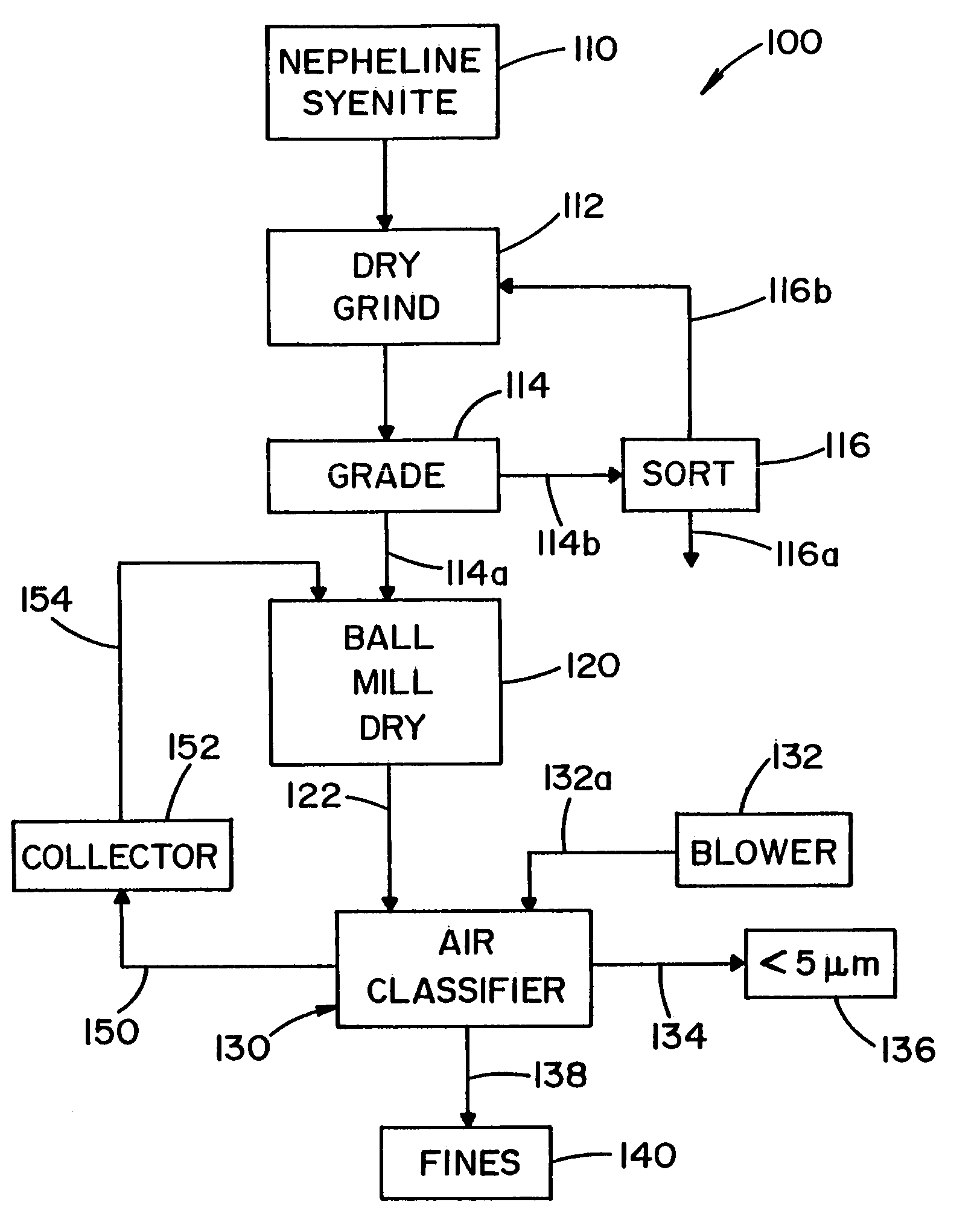

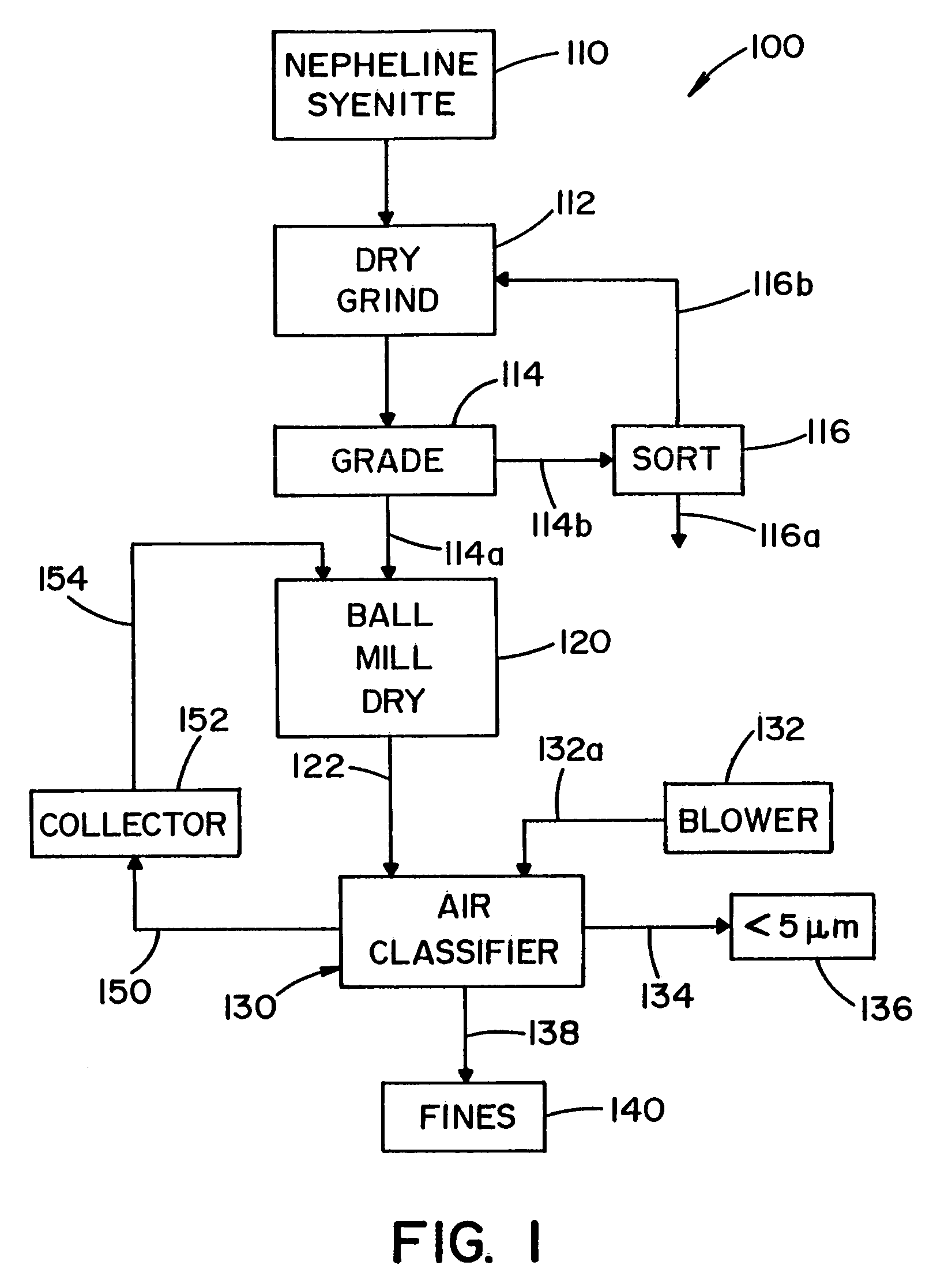

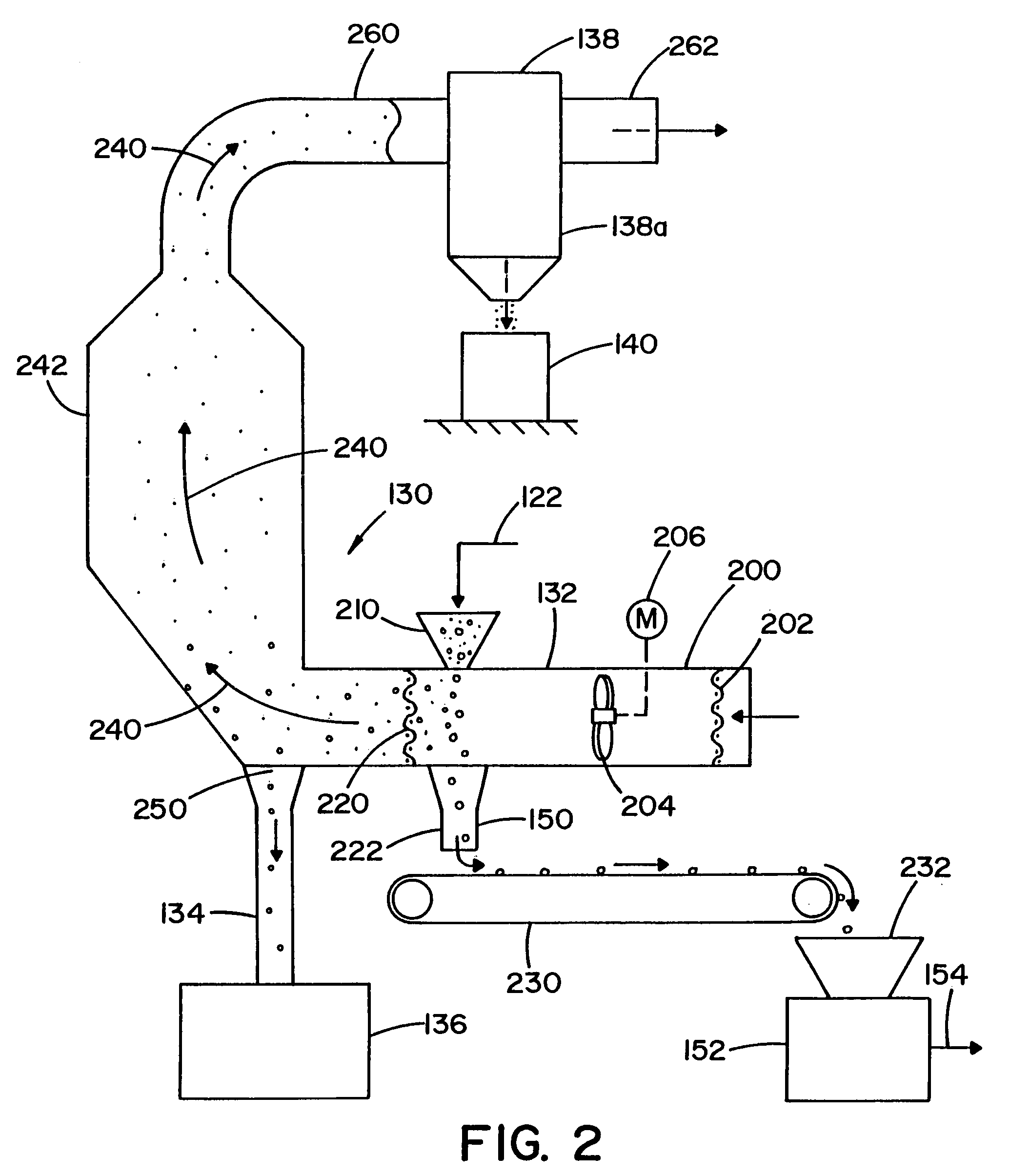

Method of processing nepheline syenite powder to produce an ultra-fine grain size product

The method of converting nepheline syenite particulate feedstock with a grain size profile to an ultra-fine grain finish product for subsequent commercial use, the ultra-fine grain final product has a maximum grain size of less than about 6 microns. The method comprising: providing a dry feedstock with a controlled maximum particle size greater than about 20 microns; grinding the feedstock in a dry state by passing the feedstock vertically downward through a continuous, high-speed stirred ball mill whereby the feedstock is ground into an intermediate powder having a drastically reduced grain size profile than the grain size profile of the feedstock; and passing the intermediate powder from the mill through an air classifier using a rapidly moving high speed air stream moving along a given path to convey the ultra-fine grain product along the path and from the classifier and to allow coarse particulate material including particles larger than the ultra-fine product to be separated and then expelled from the classifier.

Owner:COVIA HLDG CORP

Method of Controlling Organoleptic Odors

InactiveUS20100189595A1Reduce odorMolecular sieve catalystsDeodrantsCalcium silicateSodium Bentonite

A method is taught for capturing organoleptic odor. Where a functional additive has odors from a plurality of organolepic sources, and is blended with an odor control agent and a resin to produce a blend, where the blend exhibits at least a 5% reduction in odor based on a standardized odor test SAE-J1351. The odor control agent is selected from the group but not limited to: nepheline syenite, silica gel, hydrogels, hard and soft clays, bentonite, clinoptilolite, hectorite, cationic exchanged clinoptilolites, cerium, cesium, chabazite, faujasite, gmelinite, brewsterite, calcium silicate, hydrotalcites, zinc or magnesium aluminum hydroxy carbonates, zinc oxide, zinc hydroxide, zinc carbonate, calcium oxide, calcium hydroxide, calcium carbonate, potassium meta phosphate, silver oxide, magnesium hydroxide, magnesium oxide, copper oxide, ferric and ferrous oxides, sorbitol, glucitol, mannitol, glucose, dextrose, dextrin, allophanes, silica, sodalite, silicon oxide, aluminum oxide, natural zeolites, manganese dioxide, nano zinc oxide and nano titanium and combination thereof.

Owner:LEHIGH TECH INC

Modified tourmaline powder for ceramic glaze, anion ceramic glaze and preparation method

The invention relates to modified tourmaline powder for ceramic glaze, anion ceramic glaze and a preparation method, belonging to the technical field of ceramics. The anion ceramic glaze comprises the following raw materials in parts by mass: 20-30 parts of nepheline syenite, 5-8 parts of kaolin, 6.8-9.5 parts of muscovite, 6.2-7.8 parts of modified tourmaline powder, 3-6 parts of zinc oxide, 8-12 parts of light calcium carbonate, 4.6-5.7 parts of aluminum oxide, 1-4 parts of magnesium oxide, 2.5-4.8 parts of potassium oxide and 0.1-0.3 part of rubidium oxide. According to the invention, through the modification of tourmaline powder, the anion release amount of the tourmaline powder is effectively increased, and the surface polarity of the modified tourmaline is relatively low; and due to the stable dispersing performance of the tourmaline powder, the agglomeration phenomenon is avoided in the preparation of glaze slurry, and the ceramic products get a good anion function.

Owner:FUJIAN WILL CERAMIC CO LTD

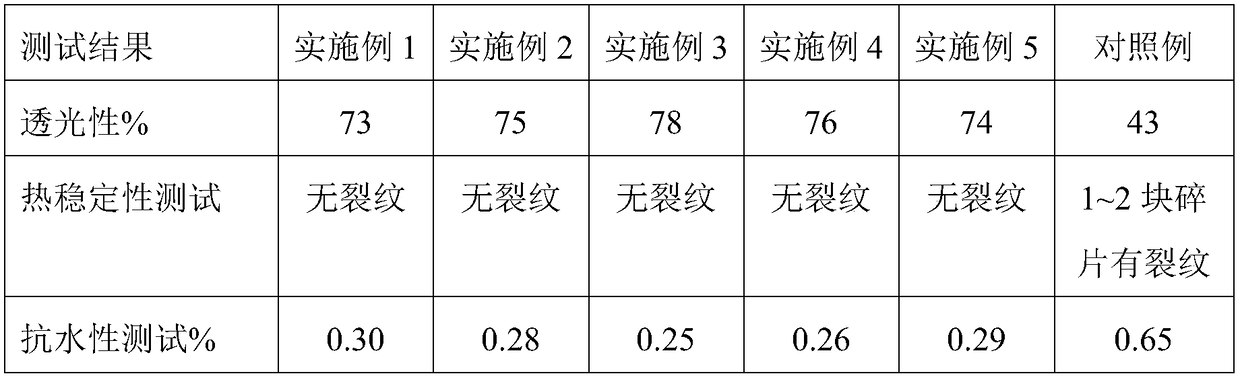

High-transmittance eggshell white ceramic product and making method thereof

The invention provides a high-transmittance eggshell white ceramic product. The high-transmittance eggshell white ceramic product comprises a preform body and glaze, wherein the preform body is prepared from the following raw materials in parts by weight: 45 to 50 parts of kaolin, 18 to 25 parts of potassium feldspar, 15 to 18 parts of montmorillonite, 10 to 15 parts of quartz, 10 to 14 parts of clay and 1 to 5 parts of talc; the glaze is prepared from the following raw materials in parts by weight: 25 to 30 parts of nepheline syenite, 18 to 22 parts of dolomite, 8 to 12 parts of burned talc,4 to 8 parts of kaolin, 3 to 6 parts of calcium carbonate, 3 to 5 parts of sepiolite, 2 to 5 parts of plant ash, 0 to 3 parts of potassium oxide, 0 to 2 parts of sodium oxide and 0.1 to 0.5 part of ferric oxide. The making method provided by the invention comprises the steps of burdening, throwing, fettling, biscuit firing, glazing and firing. The ceramic product prepared from the raw materials bythe process has the characteristics of white glazing color, high transmittance, clear and clean glaze surface, firm and white matrix, warm jade color, no cracks on the whole, and certain water resistance and thermal stability.

Owner:福建省德化业美陶瓷有限公司

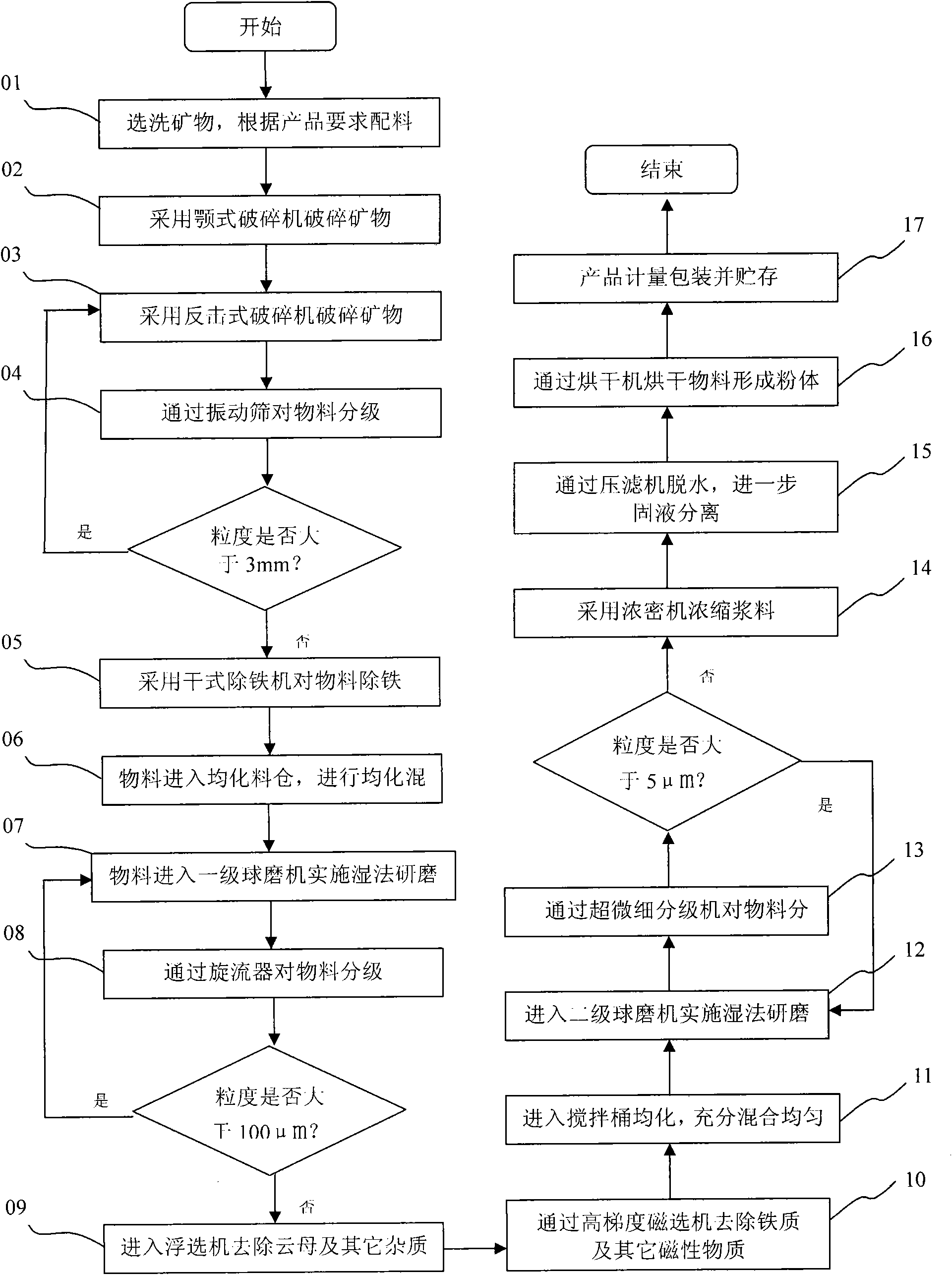

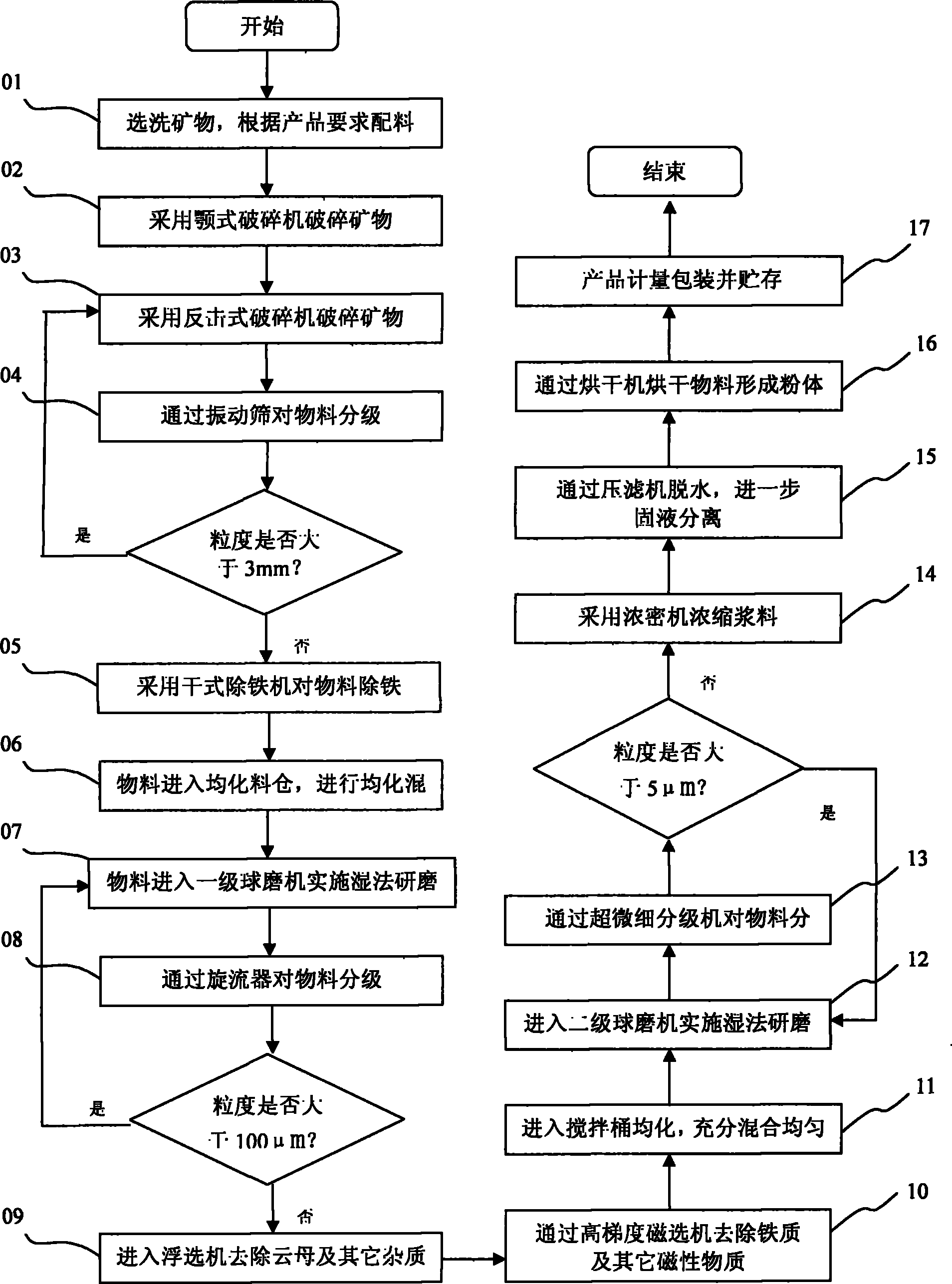

Method for preparing nepheline syenite powder

InactiveCN101912811AMeeting Structural Ceramic RequirementsUniform changeFlotationWet separationClosed loopEngineering

The invention relates to a method for preparing nepheline syenite powder. The method comprises the following steps of: elutriating and washing raw materials; smashing ores; performing graded screening; performing ball milling and fine crushing; removing impurities and filtering; and dewatering and drying, wherein the impurity-removing and filtering step comprises a flotation procedure for removing mica in the nepheline syenite. A two-stage closed-loop wet grinding process, a flotation process and a magnetic separation and impurity removing process are adopted by the method, so that impuritiessuch as the mica and the like can be removed basically and a contradiction between purification and super small product particle size is solved. Material smashing and grinding are performed by using a closed-loop system, so that power consumption is lowered to the maximum extent and the reasonable distribution of the product particle size is ensured simultaneously. A new high-purity nepheline syenite material which hardly contains any mica impurity and is prepared by the method has TiO2 content of lower than 0.01 percent and Fe2O3 content of lower than 0.10 percent and meets the requirements of functional ceramics and structural ceramics.

Owner:广东奥胜新材料有限公司

Method of processing nepheline syenite powder to produce an ultra-fine grain size product

The method of converting nepheline syenite particulate feedstock with a grain size profile to an ultra-fine grain finish product for subsequent commercial use, the ultra-fine grain final product has a maximum grain size of less than about 6 microns. The method comprising: providing a dry feedstock with a controlled maximum particle size greater than about 20 microns; grinding the feedstock in a dry state by passing the feedstock vertically downward through a continuous, high-speed stirred ball mill whereby the feedstock is ground into an intermediate powder having a drastically reduced grain size profile than the grain size profile of the feedstock; and passing the intermediate powder from the mill through an air classifier using a rapidly moving high speed air stream moving along a given path to convey the ultra-fine grain product along the path and from the classifier and to allow coarse particulate material including particles larger than the ultra-fine product to be separated and then expelled from the classifier.

Owner:COVIA HLDG CORP

Low titianium dioxide coatings

Owner:AKZO NOBEL COATINGS INT BV

Binder composition for waste materials

An inorganic binder composition has a first constituent which is a poly(sialate) or a poly(sialate-siloxo) admixed with a second constituent which has one or more of: fly ash F, fly ash C, fumed silica, Al2O3, pozzolan, ground slag, nepheline syenite, anhydrous aluminum silicate, hydrous aluminum silicate, hydrous sodium hydroxide, silicic acid, potassium salt, and sodium salt. The binder is used to recycle and reuse revert materials from metal smelting operations.

Owner:COMRIE DOUGLAS C

Copper red reduction transmutation glaze, copper red reduction transmutation glaze ceramic product and preparation method thereof

The invention relates to copper red reduction transmutation glaze, a copper red reduction transmutation glaze ceramic product and a preparation method thereof, which belong to the technical field of ceramics. The copper red reduction transmutation glaze comprises the following components in parts by weight: 34 to 36 parts of nepheline syenite, 19 to 23 parts of light calcium carbonate, 2 to 5 parts of barium carbonate, 2 to 4 parts of zinc oxide, 1 to 2 parts of magnesium carbonate, 9 to 11 parts of kaolin, 14 to 18 parts of waste ceramic biscuit treatment material, 8.5 to 11 parts of quartz, 2 to 4 parts of bone ash, 1 to 4 parts of lithium carbonate and 2 to 5 parts of copper oxide. The copper red reduction transmutation glaze is uniformly in glaze surface color, has double color generation effect of being green in red and black in red and has strong classical atmosphere; and moreover, when a ceramic product is sintered according to the method, the rate of finished product is relatively high, and the method is suitable for ceramics for daily use and decorative ceramics.

Owner:FUJIAN QUANZHOU DESHENG GROUP

Ceramic bond and preparation method thereof

ActiveCN105150122ALower firing temperatureImprove gripAbrasion apparatusGrinding devicesChromium sesquioxideLithium carbonate

The invention relates to a ceramic bond and a preparation method thereof, and belongs to the technical field of grinding wheel bonds. The ceramic bond is prepared from, by weight, 20%-40% of borosilicate glass, 22%-43% of feldspar, 10%-35% of nepheline syenite, 5%-13% of clay, 2%-5% of lithium carbonate and 3%-13% of chromium sesquioxide. According to the ceramic bond, all the components are subjected to a synergistic effect within a limited dosage range, the firing temperature of the ceramic bond is lowered to be 1000 DEG C, high-temperature burning loss of ceramic microcrystal grinding materials is avoided, the revolving strength of a grinding wheel manufactured through the bond is improved, and the grinding linear velocity reaches 80 m / s maximally. The preparation method is easy and convenient to operate, easy to control and suitable for industrial application and popularization.

Owner:白鸽磨料磨具有限公司

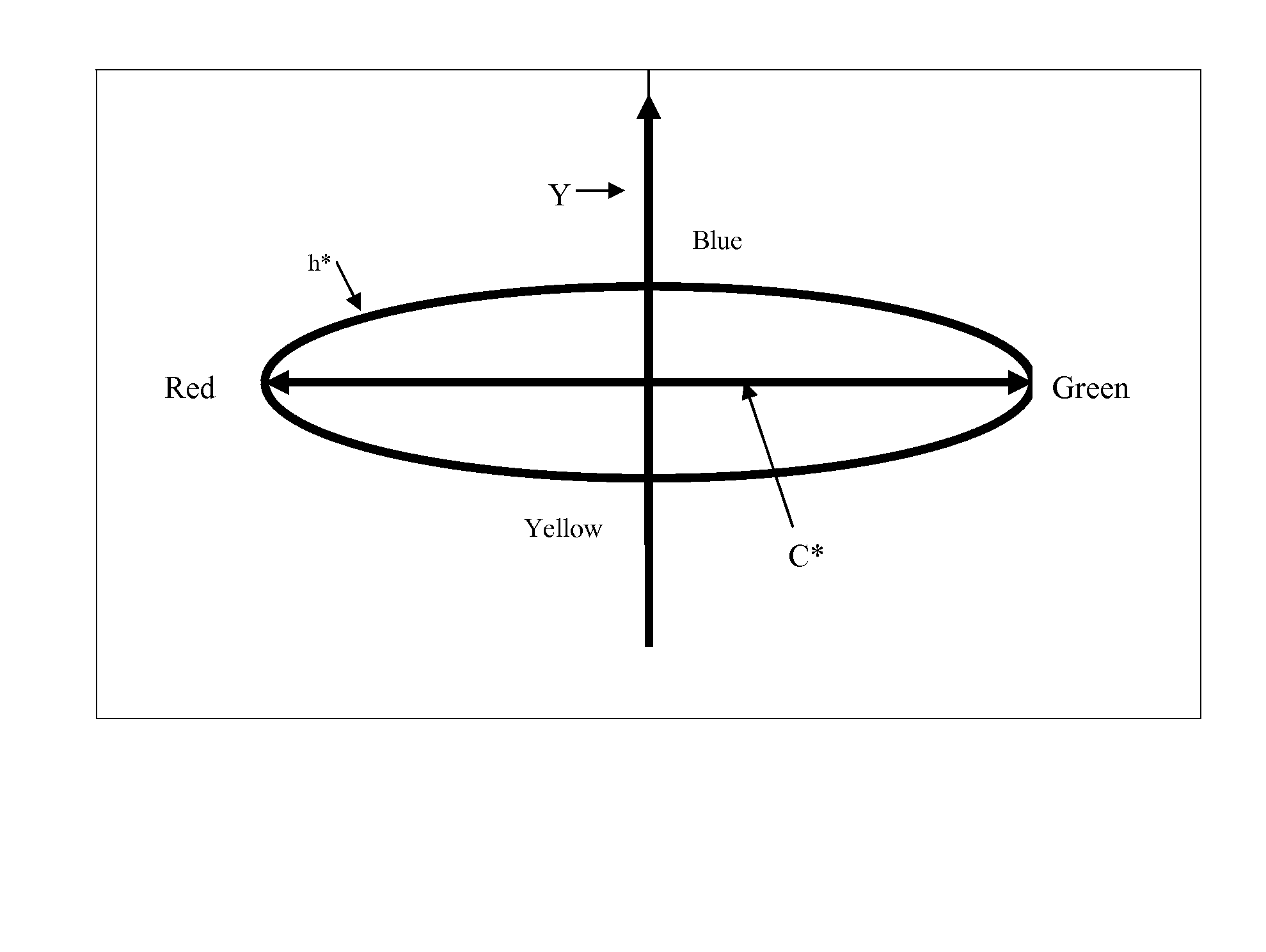

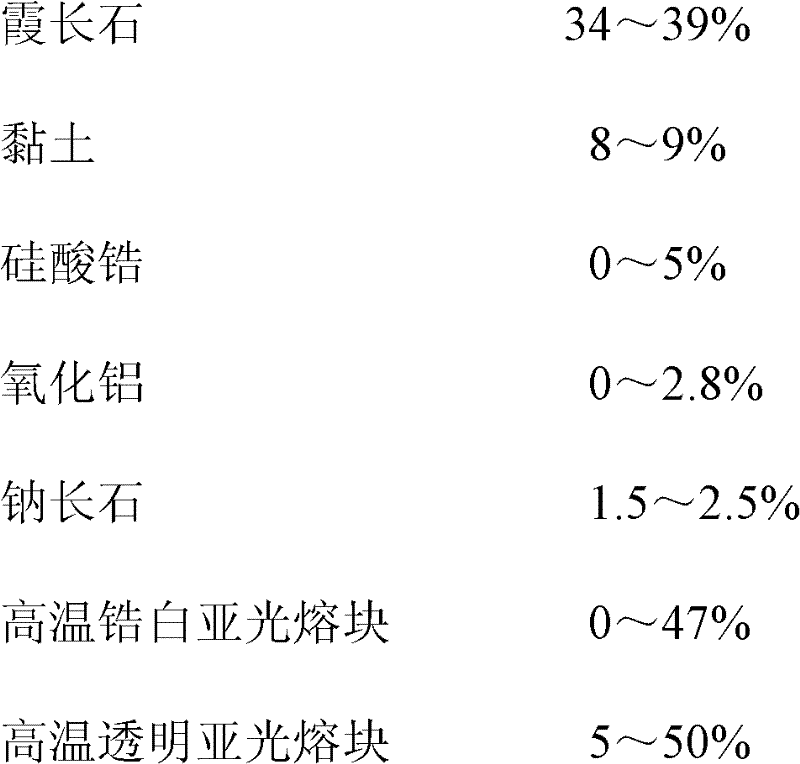

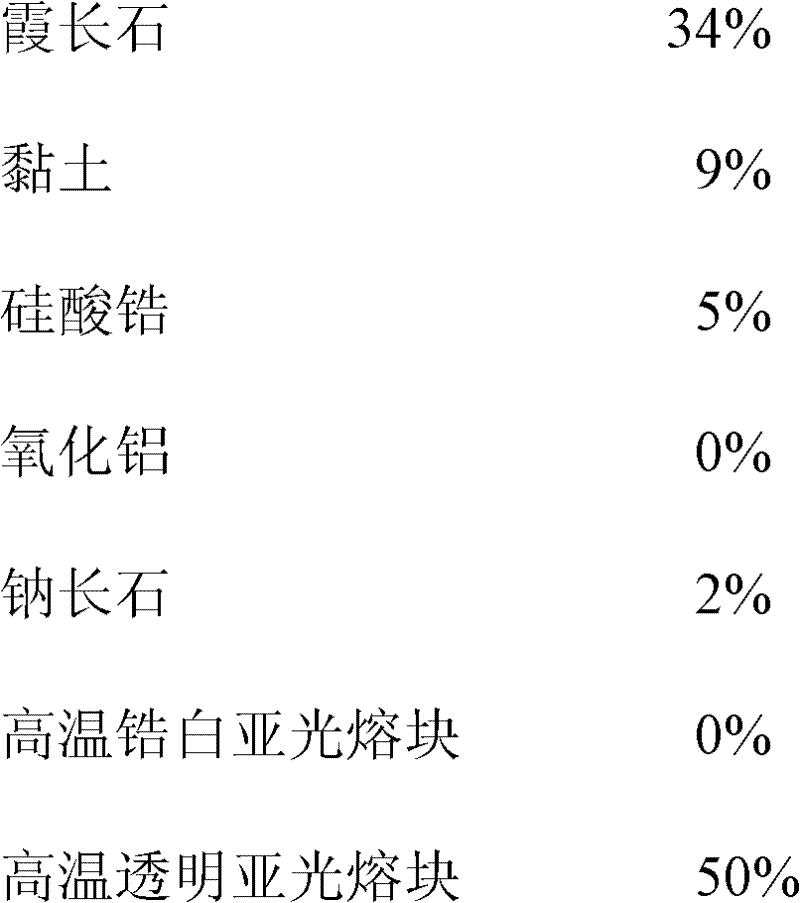

Fast-fired composite-phase microcrystal matt surface glaze slip and application thereof

The invention discloses a fast-fired composite-phase microcrystal matt surface glaze slip and an application thereof. The matt surface glaze slip comprises material mixture, sodium methyl cellulose, sodium tripolyphosphate and water, wherein the material mixture comprises the following components in percentage by weight: 34-39% of nepheline syenite, 8- 9% of clay, 0-5% of zirconium silicate, 0- 2.8% of aluminium oxide, 1.5-2.5% of soda feldspar, 0-47% of high-temperature zirconium white matte fused block, and 5-50% of high-temperature transparent matte fused block. An electron microscope for a polarized light research is adopted to analyze and detect the composite-phase matt glaze, and the crystal phase volume distribution reaches more than 95%. The product which is prepared from the fast-fired composite-phase microcrystal matt surface glaze slip, has weak glaze light refraction, low and fine glossiness (glossiness smaller than 10), and is unglazed.

Owner:GEAREX TECHN CERAMIC KUSN

Pigment composition for paint

ActiveUS20070295247A1Low costReduce the amount requiredPigmenting treatmentSynthetic resin layered productsFluorideSilicon dioxide

A pigment extender that can be used in a covering agent such as paint to improve the properties of the paint. The pigment extender can improve the hiding power of many types of paint formulations. The pigment extender is particularly useful in flat paints that require relatively low sheen values. A pigment extender that includes microcrystalline silica, nepheline syenite and / or metal fluoride. The metal fluoride typically includes a silica coated metal fluoride.

Owner:COVIA HLDG CORP

Low-temperature cracked glaze, ceramic product prepared from same and preparation method of ceramic product

The invention relates to a low-temperature cracked glaze, a ceramic product prepared from the same and a preparation method of the ceramic product, belonging to the technical field of ceramics. The low-temperature cracked glaze comprises the following components in parts by mass: 390-410 parts of nepheline syenite, 48-52 parts of quartz, 48-52 parts of heavy calcium carbonate, 780-820 parts of first glaze frits, 19-21 parts of light calcium carbonate, 19-21 parts of second glaze frits and 76-84 parts of copper carbonate. The cracked glaze can be sintered at relatively low temperature through meticulously blending a glaze material of the low-temperature cracked glaze, so that energy sources are effectively saved; the ceramic product prepared from the low-temperature cracked glaze by using the method disclosed by the invention is not only high in finished product rate up to higher than 95, but also integrated and attractive in glaze surface and remarkable in crack effect; the ceramic product sintered by using the glaze material disclosed by the invention is deep green in glaze surface and uniform and meticulous in crack so as to have favorable application and market prospects.

Owner:FUJIAN PROVINCE DEHUA ZHENNAN CERAMIC CO LTD

Black silver drop reduced transmutation glaze, black silver drop reduced transmutation glaze ceramic product prepared using same and preparation method

The invention relates to black silver drop reduced transmutation glaze, a black silver drop reduced transmutation glaze ceramic product prepared using the same and a preparation method and belongs to the technical field of ceramic. The black silver drop reduced transmutation glaze comprises, by mass, 33-36 parts of nepheline syenite, 18-22 parts of light calcium carbonate, 4-6 parts of barium carbonate, 2-4 parts of zinc oxide, 1-3 parts of magnesium carbonate, 9-12 pats of kaolin, 14-18 parts of waste ceramic biscuit treating material, 8-12 parts of quartz, 2-6 parts of bone ash, 2-8 parts of manganese oxide and 2-7 parts of copper oxide. The black silver drop reduced transmutation glaze is simple and easy in implementing of glazing mode, and production efficiency can be improved effectively; the black silver drop reduced transmutation glaze ceramic product prepared has pitch-black glaze surface and is modest luxury, and silver drops are adopted for decorating, so that the product is more noble and elegant; the product is calcined according to the method, finished product rate of the ceramic product can be up to higher than 92%, and the black silver drop reduced transmutation glaze is suitable for being used to produce ceramic for daily use and decorating ceramic.

Owner:FUJIAN QUANZHOU DESHENG GROUP

Exterior wall coating

The invention provides an exterior wall coating. The coating is prepared from deionized water, propylene glycol, hydroxyethylcellulose, silica sand powder, dispersant, nonionic surfactant, defoamer, lignin, kieselguhr, potassium tripolyphosphate, titanium white, zinc oxide, nepheline syenite powder, coalescent solvent, preservative and acrylic copolymerizing emulsion. The exterior wall coating has the characteristics of high durability, high toughness, high alkali resistance and the like.

Owner:戚冬梅

Patina glaze as well as patina glaze ceramic product prepared by patina glaze and preparation method

The invention relates to patina glaze as well as a patina glaze ceramic product prepared by patina glaze and a preparation method, and belongs to the technical field of ceramics. The patina glaze is prepared from the following raw materials in parts by mass: 36 parts to 42 parts of nepheline syenite, 10 parts to 13 parts of calcium carbonate, 4 parts to 5 parts of zinc oxide, 0.8 part to 1.5 parts of magnesium carbonate, 1.2 parts to 1.6 parts of kaolin, 40 parts to 45 parts of quartz, and 11 parts to 14 parts of colour former; the colour former is prepared from the following raw materials in parts by mass: 2 parts to 3 parts of tin oxide, 3 parts to 4 parts of lithium carbonate, 4 parts to 6 parts of bone ash, and 1.5 parts to 2 parts of copper oxide. The raw materials are mixed and subjected to ball milling according to a formula, are mixed into glaze paste with required concentration, and are subjected to glaze dipping and sintering to obtain the patina glaze ceramic product. Through the reasonable formula and the simple preparation method, the patina glaze ceramic product has an attractive glaze surface, and the color of the glaze is changed along with the change of a texture; meanwhile, energy conservation and emission reduction as well as environmental protection are achieved.

Owner:福建省德化县瓷国文化有限公司

Easy-to-clean ceramic product and preparation method thereof

The invention discloses an easy-to-clean ceramic product which comprises a green body and a glaze layer applied to the surface of the green body. The green body is prepared from the following raw materials in parts by weight: 30-40 parts of argil, 8-13 parts of bentonite and 10-17 parts of quartz. The glaze is prepared from the following raw materials in parts by weight: 40-50 parts of nepheline syenite, 1-5 parts of magnesia, 10-18 parts of flint, 4-8 parts of talc, 4-10 parts of barium carbonate, 10-18 parts of dolomite, 1-5 parts of spodumene and 1-5 parts of red butterfly strontium carbonate. Part of components of the glaze are subjected to anaerobic calcination, then the glaze is prepared through a wet grinding method, and the obtained glaze is fine and smooth and good in stability. The ceramic product is prepared by combining slow temperature control and high-temperature calcination, and the obtained ceramic product has the characteristics of stable performance and high yield.

Owner:德化县德鸿陶瓷有限公司

Low titianium dioxide coatings

Aqueous coating composition having a PVC from 78 to 85% and free of non-fugitive coalescing solvent, comprising, based on the total volume solids of the dry coating unless otherwise stated,a) opacifying pigment particles comprising from 3 to 10% titanium dioxide and from 0 to 20% of hollow polymeric particles;b) non-opacifying extender particles comprising calcium magnesium carbonate and / or calcium carbonate and / or nepheline syenite and / or kaolin;c) polymer binder particles of calculated Fox Tg of from 5 to 25° C. having an acid value of from 15 to 65 mg KOH / g of polymer;d) dispersant having weight average molecular weight of at least 3500 Daltons, and wherein the dispersant demand of a mixture of the opacifying pigment particles, other than the hollow polymeric particles, of a) and the extender particles of b) is greater than 0.35 wt %, calculated on the weight of the titanium dioxide and extender particles;e) fugitive coalescing solvent.

Owner:AKZO NOBEL COATINGS INT BV

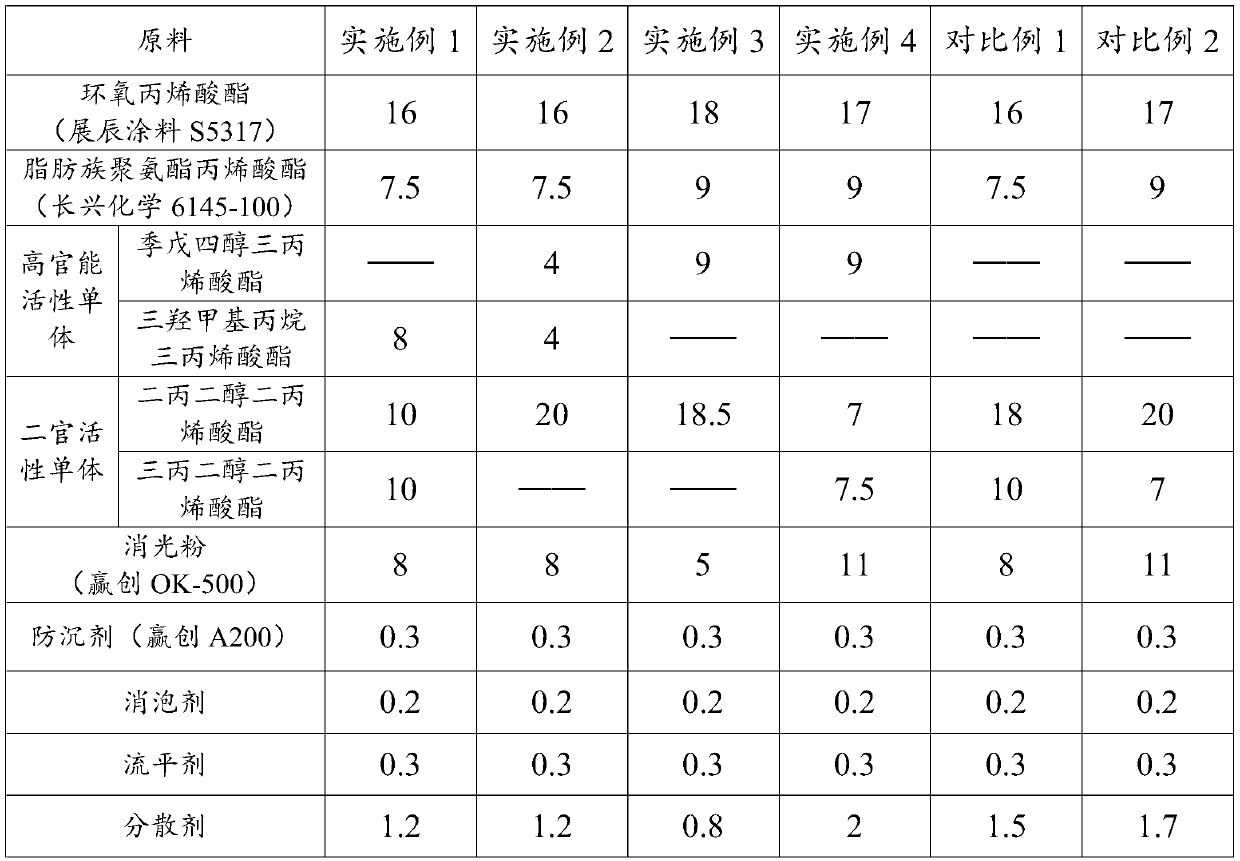

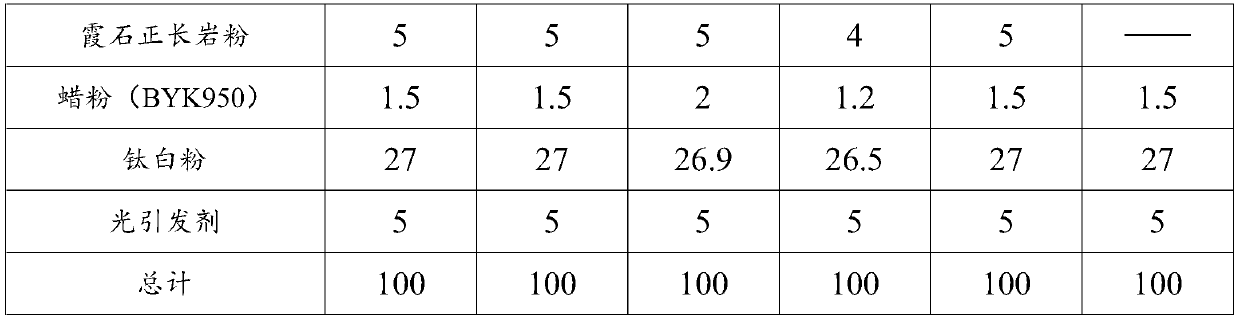

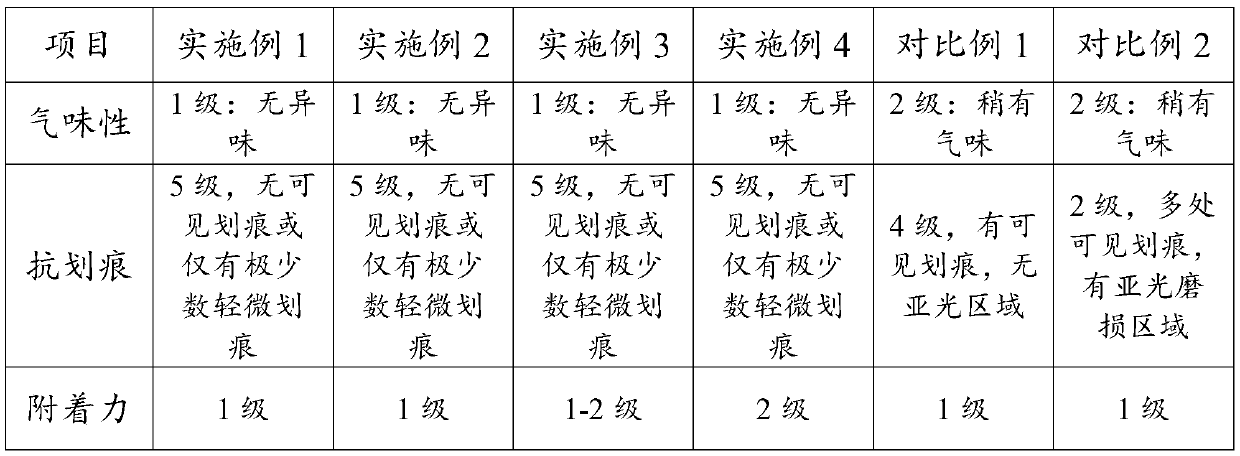

Scratch-resistant photocuring odorless matte white finish paint

ActiveCN111471375ASolve the smellSolve the problem of poor scratch resistancePolyurea/polyurethane coatingsEpoxy resin coatingsPolymer scienceColored white

The invention relates to anti-scratch UV photocuring odorless matte white finish paint. The white finish paint is characterized in that the white finish paint comprises following raw materials by mass: 15-20 parts of epoxy acrylate, 5-10 parts of aliphatic urethane acrylate, 7-15 parts of a high-functional active monomer, 15-25 parts of a bifunctional active monomer, 4-12 parts of extinction powder, 0.3-0.5 part of an anti-settling agent, 0.1-0.3 part of an antifoaming agent, 0.2-0.4 part of a leveling agent, 1-2 parts of a dispersing agent, 3-5 parts of nepheline syenite powder, 0.5-2 parts of wax powder, 20-30 parts of titanium dioxide and 4-6 parts of a photoinitiator. The product provided by the invention has the advantages of quick drying, high hardness, wear resistance, excellent scratch resistance, easy curing and no residual smell, and is applied to coating of white cupboards, wooden doors and handicrafts, and the production efficiency can be greatly improved.

Owner:上海展辰涂料有限公司 +1

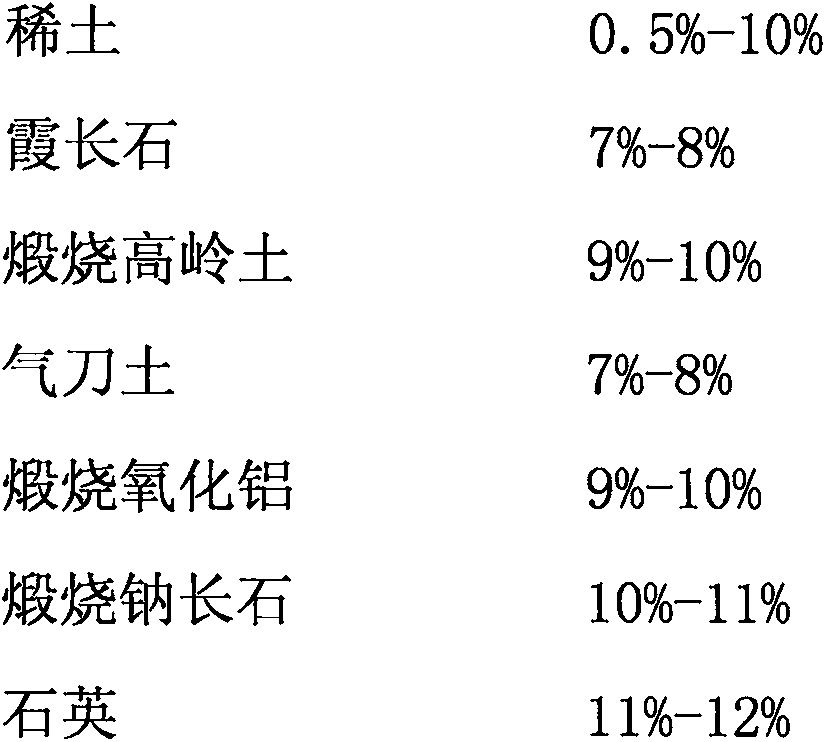

Multifunctional environment-friendly glazed ceramic tile and preparation method thereof

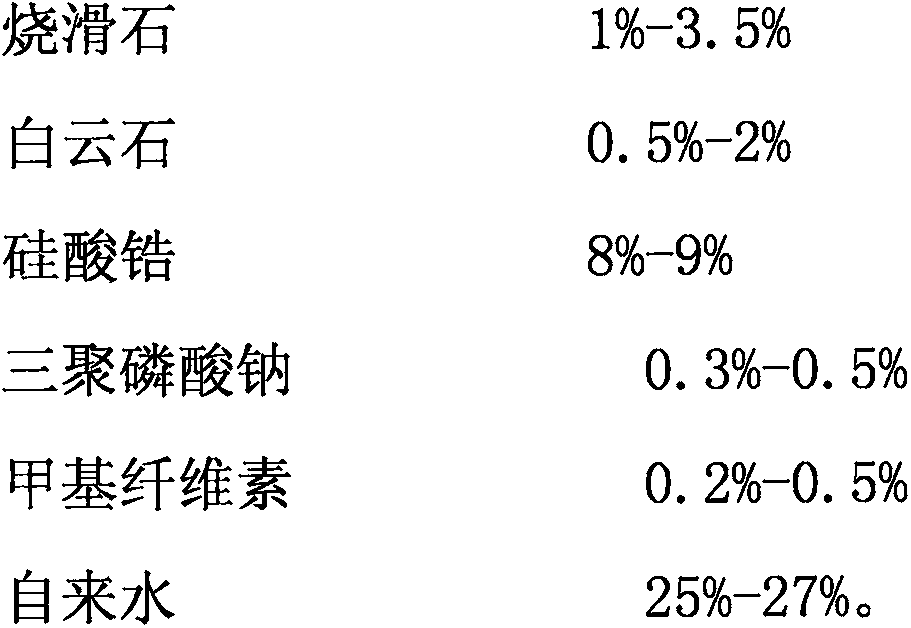

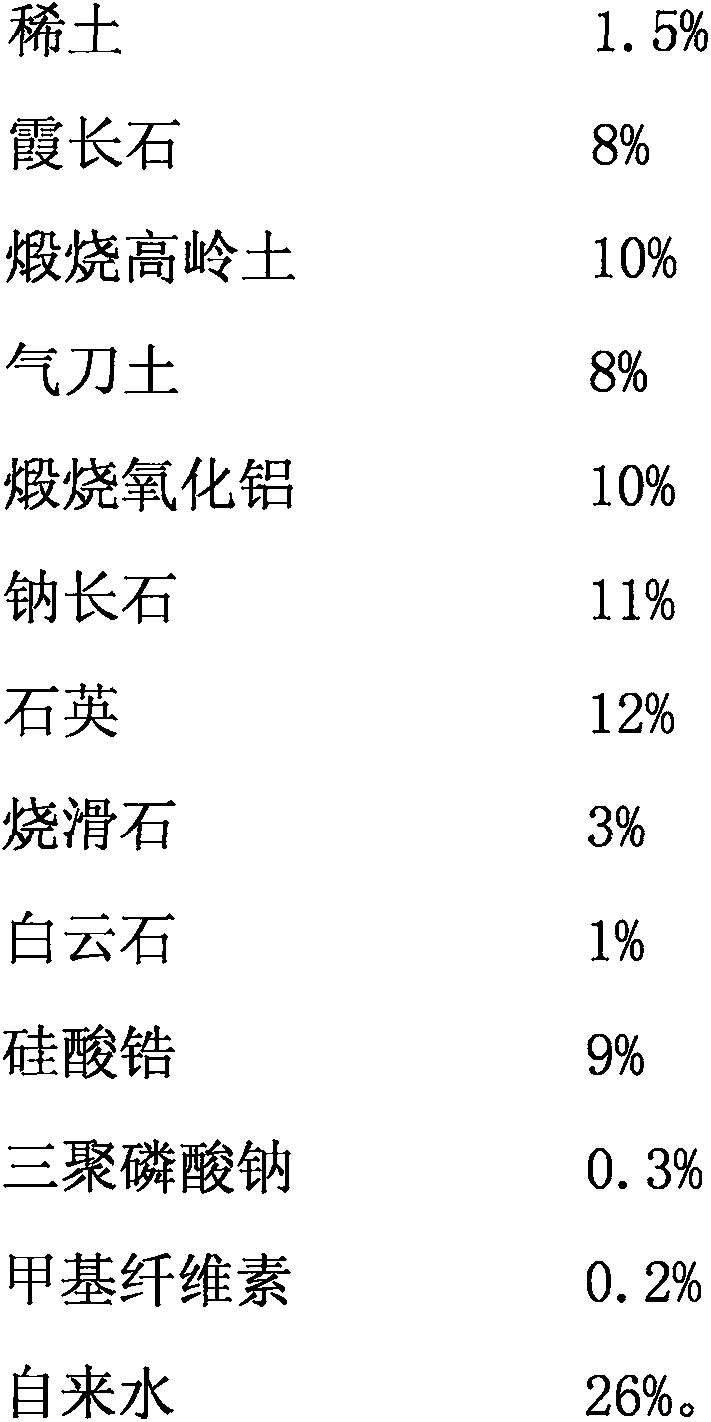

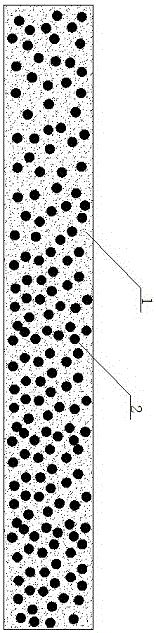

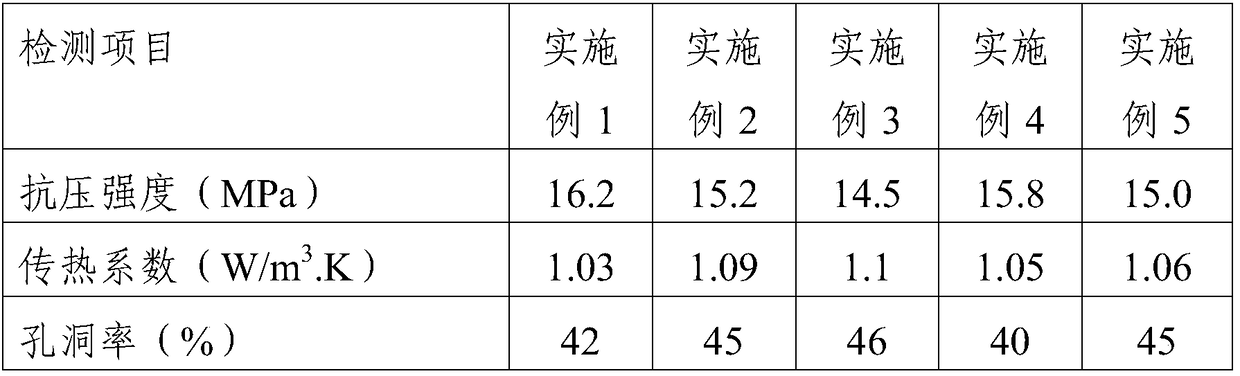

The invention relates to a multifunctional environment-friendly glazed ceramic tile and a preparation method thereof. The multifunctional environment-friendly glazed ceramic tile comprises a ceramic green body and a glazed surface attached on the outer surface of the ceramic green body; the glazed surface on the outer surface of the ceramic green body is prepared from the following raw materials and components by weight percent: 0.5-10% of rare earth, 7-8% of nepheline syenite, 9-10% of calcined kaolin, 7-8% of Qidao clay, 9-10% of calcined alumina, 10-11% of calcined albite, 11-12% of quartz,1-3.5% of burnt talc, 0.5-2% of dolomite, 8-9% of zirconium silicate, 0.3-0.5% of sodium tripolyphosphate, 0.2-0.5% of methyl cellulose and 25-27% of tap water. The multifunctional environment-friendly glazed ceramic tile has the beneficial effects that the glazed surface layer of the multifunctional environment-friendly ceramic tile is prepared from nano-rare earth elements, and is subjected tohigh temperature sintering; the product has the functions of removing formaldehyde, benzene, bacteria and unpleasant odor, resisting radiation, generating far infrared rays, and the like, and has no side effects on the human health; furthermore, the far infrared rays produced by the ceramic tile is beneficial to the human health.

Owner:广东唐色新材料科技有限公司

High-water-absorption ceramic brick

InactiveCN104891974AImprove water absorptionGood water permeabilityCeramic materials productionClaywaresBrickSilicic acid

A high-water-absorption ceramic brick is composed of the following raw materials in parts by weight: 15-30 parts of ceramic waste, 4-9 parts of aluminum oxide, 3-8 parts of a waste glass powder, 5-9 parts of quartz sand, 3-6 parts of nepheline syenite, 1-3 parts of calcium oxide, 7-10 parts of white feldspar, 9-14 parts of zirconium silicate, 2-5 parts of barium carbonate, 1-4 parts of raw kaolin, 3-10 parts of nickel oxide, 4-8 parts of rosin, 8-14 parts of shale, 1-3 parts of silicon carbide, 6-11 parts of glass micro-beads, and 3-8 parts of silicon dioxide. The high-water-absorption ceramic brick has the beneficial effects that the ceramic brick has good water absorption and water permeability, besides, has quite good strength and hardness, and is not easy to crack.

Owner:青岛百千川海洋生态科技有限公司

Fiber-reinforced ceramic tile with high impact resistance

The invention discloses a carbon fiber reinforced ceramic tile with high impact resistance, belongs to the field of domestic building materials and aims at solving the problems that an existing ceramic tile is insufficient in toughness and easy to crack. The carbon fiber reinforced ceramic tile comprises a ceramic matrix and reinforced carbon fibers. The preparation method of the carbon fiber reinforced ceramic tile comprises the following steps: firstly, mixing and preparing the following raw materials in parts by weight and fully mixing in a mixer: 20 parts of quartz, 10 parts of nepheline syenite, 40 parts of albite, 5 parts of stannic oxide, 20 parts of pyrophyllite, 5 parts of barium titanate and 5 parts of magnesium carbonate, so as to form a mixture; secondly, carrying out surface coating treatment on the reinforced carbon fibers by adopting a chemical vapour deposition method, wherein feed gas is mixed gas of fuel gas, boron chloride and hydrogen with the volume ratio of 2:1:1, the total flow velocity of the gas is 100-200ml / min, and deposition temperature is 900-1200 DEG C; thirdly, adding the reinforced carbon fibers obtained in the step two into the mixture obtained in the step one, and mixing by adopting a physical method; and fourthly, preparing the ceramic tile.

Owner:CHENGDU 90 DEGREE IND PROD DESIGN CO LTD

Mineral based fillers used as a substitute for wood fillers in simulated wood products and simulated wood products containing the same

ActiveUS9085671B2Reduce moisture contentReduce processing costsOther chemical processesNephelineWood flour

A simulated wood product such as decking, fencing and architectural trim of the type heretofore made from a plastic with a natural wood powder as filler, wherein at least most, if not all, of the wood powder is replaced by a powder formed from a hard naturally occurring mineral, such as nepheline syenite or feldspar.

Owner:COVIA HLDG CORP

Light porcelain low-temperature furnace transmutation red spot glaze formula, preparation and using method

The invention belongs to the field of manufacturing of ceramics, and particularly relates to a furnace transmutation glaze formula for light porcelain firing, a preparation method and a using method. The light porcelain low-temperature furnace transmutation red spot glaze formula comprises glass powder, transparent fritted glaze, red ceramic pigment, nepheline syenite, boronic acid, kaolin and zinc oxide. The furnace transmutation red spot glaze formula is low in cost, convenient to use and low in firing temperature, and has unique art sense. The ground color of a glaze surface fired by furnace transmutation red spot glaze is red or copper red, irregular black spots are distributed on the ground color of the glaze surface uniformly, sizes and densities of the black spots are respectively changed according to ceramic shapes and glazing thicknesses, and an artistic effect is unique. Grades and sale prices of porcelains manufactured by the glaze are increased, and economic value is high. In addition, the glaze can be industrially produced in batches, can be popularized quickly, is easy to use, and has high competitiveness in markets.

Owner:FUJIAN PROVINCE DEHUA COUNTY GRANGTOP CERAMICS CO LTD

High zinc-boron fritted glaze

The invention relates to high zinc-boron fritted glaze. The high zinc-boron fritted glaze is prepared from the following raw materials in parts by weight: 82 to 91 parts of frit, 9 to 12 parts of nepheline syenite, 2 to 4 parts of wollastonite, 3 to 6 parts of lithium cornish stone, 0 to 5 parts of quartz, 0 to 7 parts of periclase, 0 to 5 parts of cryolite, 0 to 9 parts of kaolin and 0 to 5 parts of aluminium oxide; the frit is prepared from the following components in parts by weight: 45 to 51 parts of willemite, 38 to 43 parts of borax, 12 to 15 parts of calcium borate, 13 to 16 parts of vesuvianite, 4 to 8 parts of scapolite, 3 to 7 parts of potassium feldspar and 1 to 4 parts of talc. A high zinc-boron fritted glaze product prepared from the raw materials disclosed by the invention has the advantages of good whiteness and attractiveness, smooth glaze, high hardness and good acid-alkali resistance; the rate of a finished product reaches 98 percent; the cost of the raw materials is greatly reduced while the mass of the high zinc-boron fritted glaze is comparable to that of high-aluminum durable porcelain, so that the high zinc-boron fritted glaze has powerful market competitiveness.

Owner:GUANGDONG SHUNXIANG PORCELAIN

Golden yellow black drop reducing transmutation glaze and golden yellow black drop reducing transmutation glaze ceramics by using same as well as preparation method thereof

The invention relates to a golden yellow black drop reducing transmutation glaze and a golden yellow black drop reducing transmutation glaze ceramic product by using same as well as a preparation method thereof, belonging to the technical field of ceramics. The golden yellow black drop reducing transmutation glaze is prepared from the following components in parts by mass: 27 to 28 parts of nepheline syenite, 16 to 18 parts of light calcium carbonate, 1 to 3 parts of barium carbonate, 1 to 3 parts of zinc oxide, 1 to 3 parts of magnesium carbonate, 8 to 12 parts of kaolin, 9 to 11 parts of waste ceramic biscuit processing materials, 22 to 24 parts of quartz and 2 to 6 parts of rutile. According to the invention, the waste ceramic biscuit processing materials are recycled, glazing is performed through a glaze soaking mode, then golden yellow transmutation glaze ceramic product with black spots are obtained by sintering, the golden yellow black drop reducing transmutation glaze is unique and exquisite, safe and wearproof, sintering is performed according to the method provided by the invention, the yield rate of the ceramic product is high, and can reach 90 percent or more, and the ceramic product is applied to domestic ceramic and decorative ceramic.

Owner:FUJIAN DEHUA YOUSHENG CERAMICS

Manufacturing technique of high-adding-quantity fly ash sintered hollow brick

InactiveCN108285325AHigh plasticity indexHigh strengthCeramic materials productionCeramicwareBrickFree cooling

The invention provides a manufacturing technique of a high-adding-quantity fly ash sintered hollow brick. The manufacturing technique comprises the steps of 1, using a 150-180 mesh sieve to conduct sieving; 2, weighing 52-57 parts of fly ash, 12-20 parts of kaolin powder, 13-16 parts of high-viscosity attapulgite clay powder, 5-9 parts of nepheline syenite powder and 2-5 parts of mica powder whichare obtained through sieving, adding weighed substances into a stirrer, adding 8-13 parts of canal mud and 14-18 parts of water after stirring, continuing to conduct mixing to obtain a mixture, and conducting aging; 3, conveying the aged mixture into a double-shaft stirrer to be stirred and kneaded, and conveying the mixture to a twin-stage vacuum brick extruder to be shaped; 4, conducting drying; 5, firing hollow dry brick bodies in a furnace; 6, conducting natural cooling.

Owner:HEXIAN MINGSHENG ENVIRONMENTAL PROTECTION MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com