Method for preparing nepheline syenite powder

A technology for nepheline syenite and powder, which is applied in the field of preparing nepheline syenite ultra-fine-grained powder, can solve problems such as hole plugging, affecting product densification, etc., and achieve pressure reduction, uniform change, and relative speed. slow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

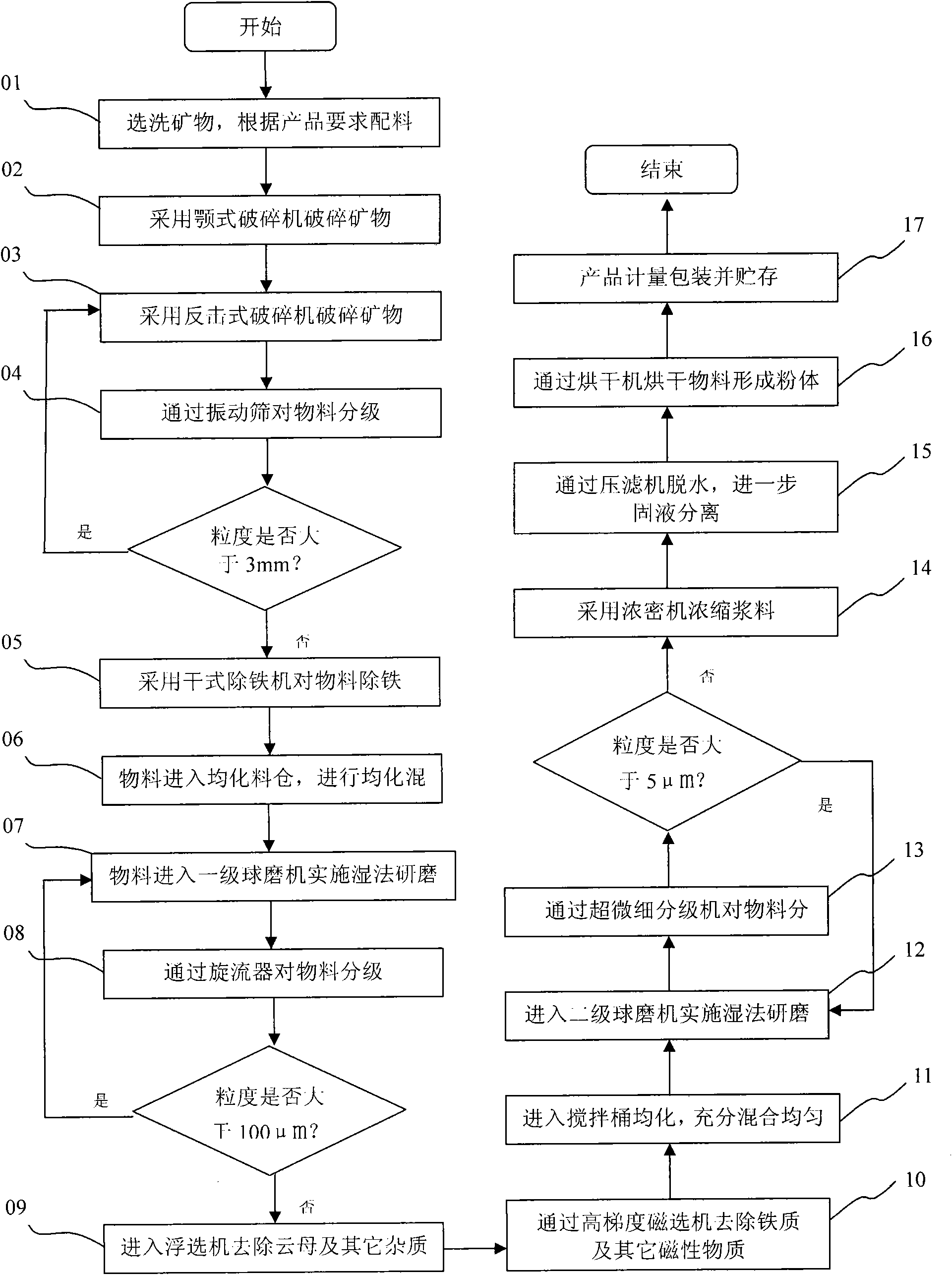

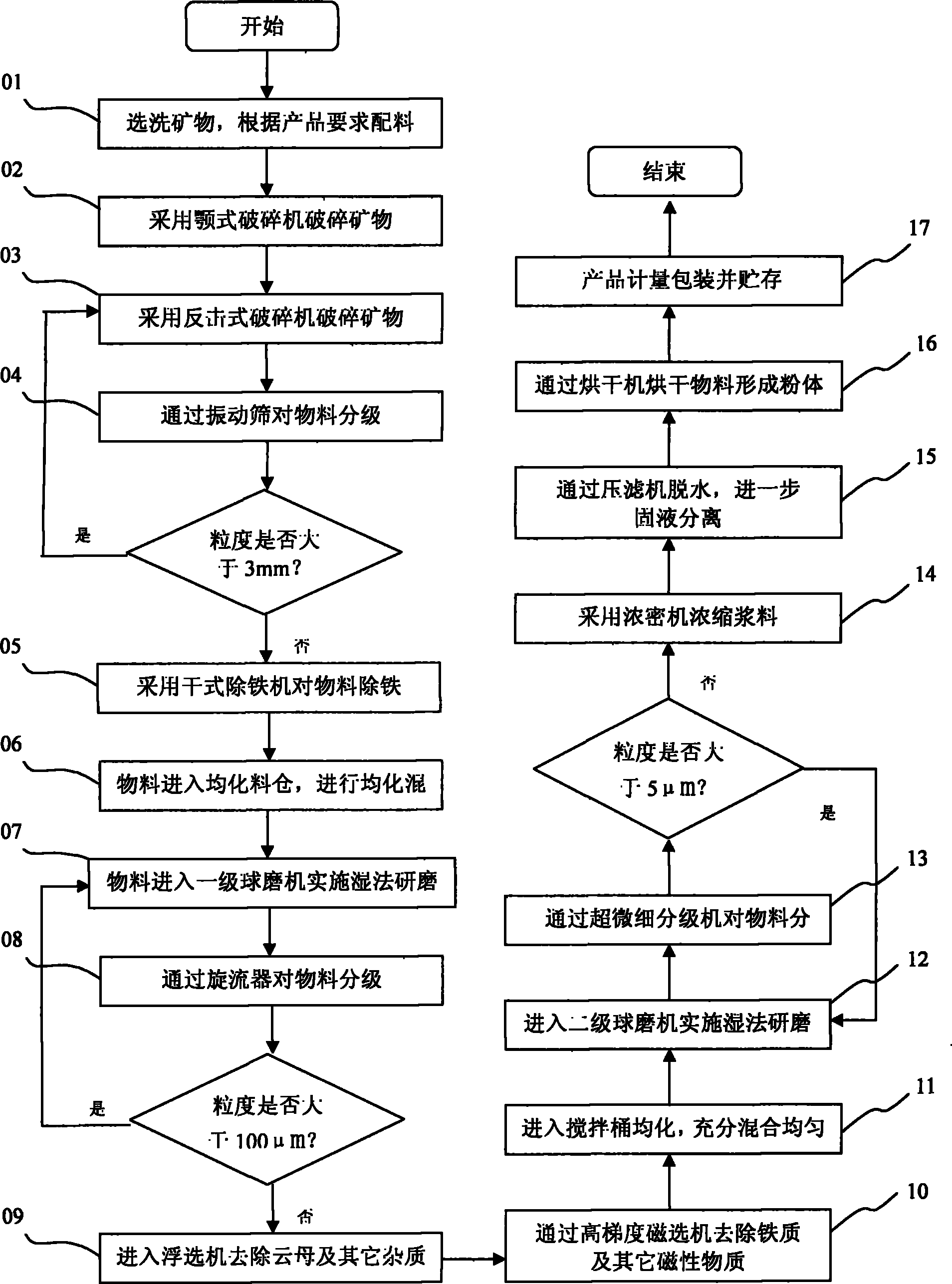

[0016] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the accompanying drawings.

[0017] A method for preparing nepheline syenite powder. The process of the method includes elutriation of raw materials, crushing ore, classification and screening, ball milling, impurity removal and filtration, and dehydration and drying. The procedure of impurity removal and filtration includes floating Selective process to remove mica from nepheline syenite. The flotation process adopts three kinds of medicaments of primary amine salt, sodium silicate and sodium carbonate, and the weight ratio of the three kinds of medicaments is (2.5-3.5): 1: 1 successively, and the consumption sum of the three kinds of medicaments is the flotation material 0.3%-0.8% by weight. According to the actual situation, the dosage of the flotation agent can be adjusted appropriately. In order to ensure the flotation ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com