Multifunctional environment-friendly glazed ceramic tile and preparation method thereof

A multi-functional, glazed technology, applied in the field of ceramic products, can solve problems such as difficulty in popularization and promotion of marketization, and achieve the effects of improving practical value, improving functional effects, and low radioactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

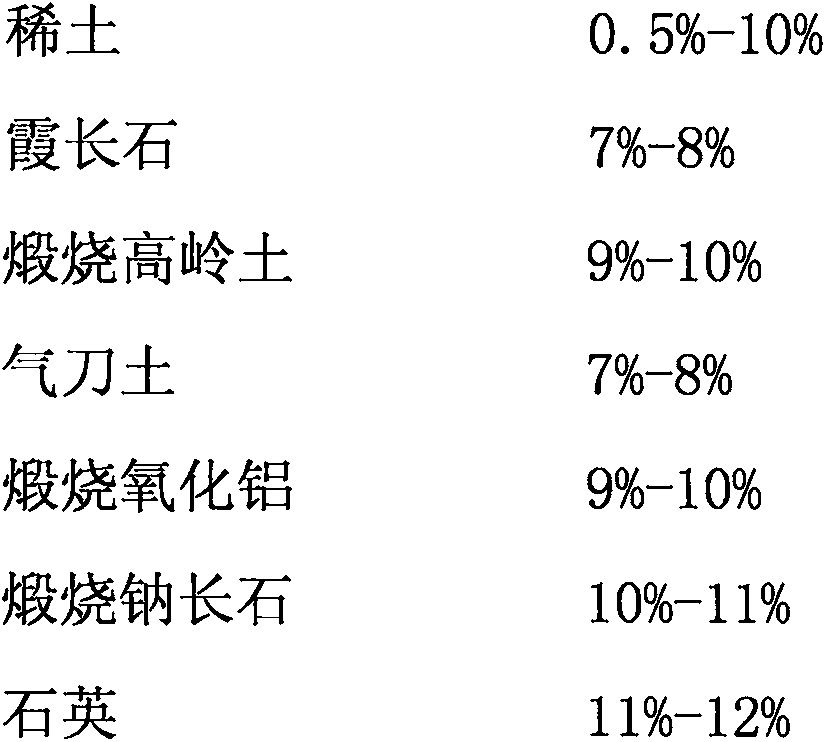

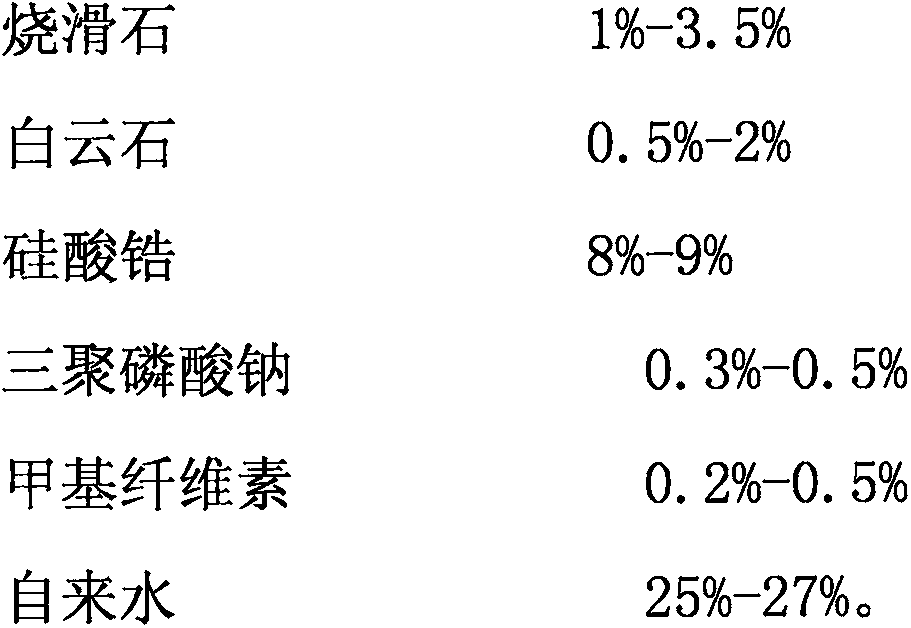

[0033] The formula table of embodiment 1 prepares a kind of preparation method of multifunctional environmental protection glazed ceramic tile, comprises the steps:

[0034] Step 1 Rare earth grinding: put the rare earth in a grinder and grind the fineness to 200nm to obtain nano-rare earth powder for later use;

[0035] Step 2 Raw materials are pulverized, ground, and sieved: after pulverizing nepheline, calcined kaolin, air-knife clay, calcined alumina, albite, quartz, calcined talc, dolomite, and zirconium silicate in a pulverizer, place Grind in a grinder, place them on a vibrating sieve, and the particle size of the sieve is 350 mesh, and the particle size is 350 mesh nepheline powder, calcined kaolin powder, air knife soil powder, calcined alumina powder, albite powder, quartz powder, Burnt talcum powder, dolomite powder, zirconium silicate powder, spare;

[0036] Step 3 slurry preparation: Weigh 260kg of tap water, 30kg of sodium tripolyphosphate, 20kg of methyl cellul...

Embodiment 4

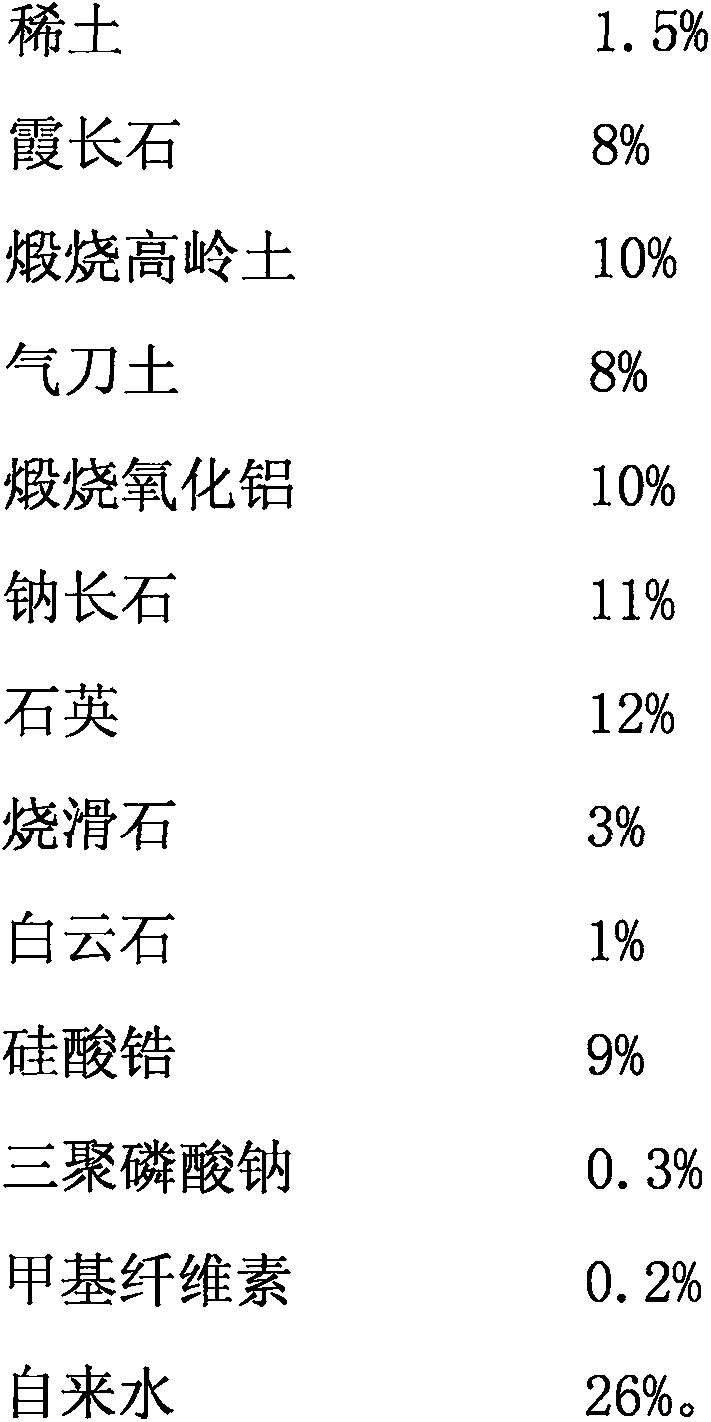

[0041] The recipe table of embodiment 4 prepares the preparation method of multifunctional environmental protection glazed ceramic tile, comprises the steps:

[0042] Step 1 Raw material crushing, grinding, and sieving: crush nepheline, calcined kaolin, air knife soil, calcined alumina, albite, quartz, calcined talc, dolomite, and zirconium silicate in a pulverizer, respectively, and place Grind in a grinder, place them on a vibrating sieve, and the particle size of the sieve is 350 mesh, and the particle size is 350 mesh nepheline powder, calcined kaolin powder, air knife soil powder, calcined alumina powder, albite powder, quartz powder, Burnt talcum powder, dolomite powder, zirconium silicate powder, spare;

[0043] Step 2 slurry preparation: Weigh 260kg of tap water, 30kg of sodium tripolyphosphate, and 20kg of methyl cellulose according to weight percentage and place them in a blender and stir for 30 minutes to obtain a mixed slurry for subsequent use;

[0044] Preparati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emissivity | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com